Need for additional heating

The classic option for heating a steam room for bathing procedures is a brick or metal heater.

In this case, additional equipment is used to maintain a given air heating temperature both in the steam room and in other rooms. It is impossible to ensure fast and uniform heating of the dressing room and rest room from a sauna stove.

And if in summer this does not cause problems, then in winter such a situation can lead to a decrease in comfort when organizing a bathing holiday. In this case, all the heat produced will be accumulated in the steam room, and the dressing room and other rooms of the bath will remain unheated.

Installation of additional heating equipment will ensure the maintenance of a comfortable temperature necessary for a long stay in the dressing room.

Integrating a water container into the oven

In this case, the water heating tank can be combined with the stove base in the following ways:

- if you want to make a hinged structure, the container is attached from the outside to the side wall of the furnace or installed on its body (if the latter is positioned horizontally);

- The heating tank is built into the stove structure directly above the firebox (stove).

As a variation of the second option, installing a remote tank in the washing room can be considered. In this situation, heating is carried out indirectly, for which a water circuit built into the firebox is used.

Features of the heating system

A very important question for water supply is how to heat water in a bathhouse. Heating must be provided directly in the sauna area so as not to encounter the problem of heat retention. In principle, hot water can be provided in the following ways:

- installation of a solid fuel heating column, usually with a wood firebox;

- installation of a standard geyser, which can be powered from a centralized mains or gas cylinder;

- use of electric heating elements of the required power;

- heating water in a sauna stove.

Electric heating is popular in modern baths. Since ancient times, heating water in a sauna stove was considered a traditional method.

In this case, you can use 2 options: a tank installed on the stove, or a pipe system passing through the stove, in which the water is heated according to the “pass-through” principle. Another method sometimes used is a heating tank on the chimney, which uses the heat of the smoke removed from the stove. Electric heating is popular in modern baths. Its main advantage: the ability to control the heating temperature and warm up the water in winter when the system freezes. The design of electric heaters can be of two types: capacitive and flow-through. Heating water in a container seems preferable, because... requires turning on the heating elements only for the period of heating to the desired temperature, and then only periodically maintaining it is required.

The main advantage of electric heating is the ability to control the heating temperature and warm up the water in winter when the system freezes

Geyser

Modern types of furnace devices are assessed by experts according to their level of efficiency, that is, according to their operational efficiency. In accordance with this factor, geysers that are powered from the local gas distribution line or connected to a replaceable cylinder have optimal performance.

Other advantages of this heating method (when compared with a wood boiler, in particular) include:

- ease of operation, which eliminates the need for constant loading of solid fuel;

- fairly fast heating;

- compact size of the gas unit.

Dispensers operating on gas contain a conventional burner and a coil installed above it, made in the form of a radiator.

As cold water passes through the coil, the useful area of which is noticeably larger than that for a straight pipe, it heats up evenly. Its temperature can be adjusted using a special valve that increases or decreases the combustion rate of gas fuel.

Installation principles

It's easier to use a mounted tank. To assemble and install it you need:

- Make a box from metal sheets 2–3 mm thick. Weld individual parts.

- Cut a hole in the top of the box for pouring liquid. Make a hole in the bottom and install a tap. This is necessary to use the liquid or drain it from the tank.

- Attach metal hooks to the side of the stove.

- Weld two tags to the tank, by which it will be hung on hooks.

The optimal amount of liquid for one person is 15 liters.

Even after connecting the water supply system to the bathhouse, questions will arise about how to heat the water. There are several methods for this, each of which has certain features and is suitable for different types of baths.

Bath boiler with tank

It is also a fairly simple, yet reliable option for heating water. Structurally, it is made of two parts:

- The lower one is intended for burning wood and other solid fuels (but not coal);

- The upper part is the reservoir. which heats the contents due to the heat of the chimney pipe passing inside the container.

It can be connected to a cold water supply system or equipped with a separate tank installed on the roof of the bathhouse. Under the influence of physical forces, hot liquid is displaced by heavy cold liquid during the washing process. The water heating tank must always be filled during use.

A wood-burning boiler for a bath with a container is equipped with a shower head and a special tap, which the manufacturer prohibits from replacing with ordinary faucets.

Advantages of a wood boiler: compactness, efficiency, ease of use, requires a small amount of solid fuel.

Electric heater

Special electric heaters for bath needs are traditionally divided into two classes: storage-type boilers and units with flow-through action. When choosing a type suitable for given conditions, it is recommended to proceed from the following considerations.

In areas where there are frequent power outages, a storage tank is more suitable for installation in a bathhouse; in the simplest case, it is a container with a useful volume of 30 to 200 liters. A heating element and a special heat-sensitive sensor are installed in its internal space, which is responsible for maintaining the water temperature at a given level.

Among the advantages of such heaters it should be noted:

- increased level of electrical protection;

- the ability to use heated water for some time even in the absence of electricity;

- availability of several designs (vertical and horizontal);

- efficiency.

For areas with a reliable power supply, less common flow-through heaters that operate on approximately the same principle as a gas water heater may also be suitable.

The disadvantages of units of this type include significant energy consumption and the need for equipment in a bath with powerful electrical wiring. In addition, in order to maintain a fixed level of water heating in this case, it will be necessary to ensure the stability of its supply.

How to make a heat exchanger yourself?

It is not advisable to buy expensive stainless steel products for use in a bathhouse. You can easily make a heat exchanger for a sauna stove yourself. How to make a heat exchanger for a sauna stove with your own hands? Step-by-step instructions will be below.

Materials and tools

What materials are of primary importance for the heat exchanger of a sauna stove? Depends on how much water needs to be heated. Here is a sample list of what you will need:

- metal sheet, thickness 2-3 mm - S=2*(0.40*0.80+0.40*0.20)+0.80*0.20 = 2*(0.32+0.08) +0.16 = 0.96 m2

- tap Ø32 mm – 2 pcs.

- check valve Ø32 mm - 1 pc.

- fittings Ø32 mm—6 sets.

- pipes Ø32 mm - 6 pcs.

- valve Ø32 mm (for drainage) - 1 pc.

- metal pipe, corrugated Ø32 mm - 3 m.

- pipe Ø32 mm (cold water supply) - as needed.

- sealing cord for sealing connections - 1 pack.

- electrodes - 1 pack.

What tool is used? Here is the list:

- welding inverter;

- "Bulgarian"

- other tools.

Size calculation

The power of the heater must correspond to the power of the furnace itself. It is recommended to make a heat exchanger based on the following:

- The heat exchanger should not consume more than 10% of the power of the furnace itself. In this case, the power of the stove will be enough to heat the room. Fuel will be used as efficiently as possible. The heating time will not increase.

- The total length of the pipes should not exceed 3 meters. It is necessary to make the necessary slope, which is 2500 on the direct feed, and on the return one - more than 300 towards the stove. This way the coolant will be effectively supplied by gravity. Otherwise, you cannot do without a pump.

- There should be enough water. It should heat up for no more than two hours, but not boil. If you make the tank too small, the coolant will boil very quickly. If the boiler is located directly in the steam room, it will be very difficult to wash there. Heavy steam will fill the room and it will become impossible to breathe normally. If the volume of the metal tank is too large, the coolant may not heat up at all.

- Don't forget that when the stove burns out, the water should still remain hot for some time. Therefore, you need to provide the necessary power reserve.

Considering all of the above, let's try to choose the optimal metal heat exchanger. We assume that to warm up the air in the bathhouse you need 5 kW. Then the power of the metal heat exchanger will be 10 kW, and its area will be 1 m2. We will assign 3 kW to possible heat loss. Then installing 1 m2 of heat exchanger will give us 7 kW of energy. Water heating time is 2 hours. Then we determine the required heat exchanger area using the formula: S = 1/7*W, where

W = 0.00117*V*(tk-tн) /T= 0.00117*65*(70-10) /2= 2.3 kW, hence S = 1/7*W=1/7*2.3 = 0.33 m2, where S is the required heat exchanger area, m2;

W is the required power of the heat exchanger, kW (it is important to determine it correctly); V is the volume of water that needs to be heated, we take 65 liters (enough for 4 people); tk is the required water temperature, we take 700C (optimal hot water temperature); tn is the initial water temperature, we take 100C. The required furnace power is 5+2.3 = 7 kW. 0.3 kW can be ignored, because

10% of the initial furnace power is an acceptable loss (0.3 kW

0.3 kW can be ignored, since 10% of the initial furnace power is an acceptable loss (0.3 kW

Manufacturing instructions

- Let's make 2 water tanks correctly: one is best made in the shape of a cylinder (for the heat exchanger), the second is rectangular (remote). We calculate the sizes individually; it is better to proceed from the calculation above and your own needs.

Design options

- We make a coil and install it in the tank.

Coil design example 1

Example 2

Example 3

Example 4

- Fill with water and test for 6 hours. All seams must be sealed, there should be no stains or leaks. Keeping water in the tank at sub-zero temperatures is prohibited.

- We weld 2 pipes for forward and reverse (bottom) supply to organize circulation.

Heat exchangers near the chimney

The simplest, but very effective heat exchanger made of copper tube.

Copper tube heat exchanger

Depending on the diameter of the chimney, you need to purchase 1.5÷2.0 meters of copper pipe with a diameter of approximately 10 millimeters. The smaller the diameter of the tube, the larger the surface of its direct contact with the pipe, the faster the water heats up. But, on the other hand, the small diameter of the tube significantly reduces the speed of water flow, and this can cause it to boil. Taking into account both factors, we recommend taking a tube with a diameter of 10 mm.

Copper tube

Adapters should be put on the ends of the tube and flared. There are special devices for flaring.

Do the flaring carefully; the plane of the flared end must be even and smooth, otherwise there will be leaks at the junctions of the pipelines.

Source of water supply

A water source is rarely constructed exclusively for a bathhouse. In the absence of a centralized water supply system, a water supply system is needed primarily for residential buildings and household needs. Therefore, as a rule, a bath water supply system is built into an existing private water supply system. For this purpose, a collector distribution line is installed, where the pipe is routed to the bathhouse building.

The most common source of water is a well. It most often reaches the second aquifer, and its depth is 10-30 m, depending on the depth of the groundwater. If the task is specifically to make water in a bathhouse of a wooden or other structure, then the potable degree of purification is not necessary, which means that it is enough to open the uppermost water carrier at a depth of 5-10 m. Such water should not be used for cooking, but for It's quite suitable for swimming.

Water supply diagram from a well

The depth of the well shaft is important for choosing the type of pumping equipment. The fact is that when lifting from depths of up to 12-15 m, you can safely use conventional centrifugal, surface pumps. With a deeper fence, you will have to lower the deep, submersible installation, which is somewhat more expensive and more difficult to operate.

Another option for a water source is a well. Its depth is 30-50 m, which makes it possible to reach the lower artesian layers, which provide especially pure water, and most importantly, a large and stable volume of liquid for a long time. It is the inextricability of the well source that is considered its main advantage, because wells tend to dry up periodically. The lifting of water from the well is ensured only by deep pumps.

In principle, a third option is also possible - pumping water from a natural reservoir. However, such a system is used quite rarely, and most often unofficially, because requires approval from the relevant authorities. The most important thing is that in this case you will have to solve the problem of installing a rather complex treatment plant.

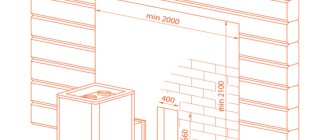

Heating a bathhouse from the home heating system

If the central heating system of the house has sufficient power, the auxiliary rooms of the bathhouse can be heated using it.

To do this, heat-insulated pipes are laid from the home heating system to the bathhouse, to which heating radiators for the auxiliary rooms of the bathhouse are connected. In this case, the stove-heater can only be used to heat the steam or washing section of the bath, if necessary. If the distance from the water heating boiler of a residential building to the bathhouse is small, then heat loss with such a heating system can be minimal. In addition, the presence of an independent external heating system will allow you to maintain the optimal temperature in the bathhouse during the winter. This is required to prevent freezing of water supply and sewerage pipes, as well as the bathhouse itself. The combination of heating systems of a residential building and a bathhouse in this case can be of an auxiliary, backup nature.

Boiler in a bathhouse in winter

The boiler in the bathhouse in winter is exposed to low temperatures, which can damage it. We list the basic rules for handling a boiler (electric) in winter, which will help maintain its performance:

- It is recommended to purchase models equipped with an additional option for heating the tank: the water inside will not freeze, it will not have to be drained after the procedure;

- The large volume of the device requires early activation, so you should calculate whether it is really necessary. A boiler in a bathhouse in winter uses less hot water than a similar one at home;

- It is recommended to purchase a device with a lower power to comply with the electricity use limit (for example, in a summer cottage);

- The system for draining liquid from the water heater should be convenient, going directly into the sewer;

- The design of the connection of the system with the boiler must be made so that the safety valve does not freeze with the remaining unfused liquid;

- Install water supply pipes on the wall surface. Inside, hidden by panels and thermal insulation, the pipes will become covered with condensation, which will cause the appearance of mold and mildew;

- It should be remembered that constant draining of liquid from the water heater leads to accelerated wear of the device. The magnesium anode protects the inner surface of the tank, the heating element only while in the water. An empty container with liquid residue on the walls is not protected, over time it corrodes and fails.

Drying the bath

There are two components to quickly drying wet rooms: heating and ventilation. They should not be considered separately, because together they work most effectively. You just need to combine them in a specific case.

How to dry: ventilation methods

The ventilation system is laid at the stage of construction of the bathhouse (see here about the diagrams and design of the bathhouse ventilation). Therefore, if something is forgotten, it may be too late to redo everything.

For example, vents are usually made in the foundation - these are through holes lined with sewer (most often) pipes that lead to the underground space. They have plugs on the outside that allow you to open and close them at the right time.

For more details about the scheme, see

Such vents are opened only after procedures. And they serve for better ventilation and drying of the bath.

Also, another through hole is usually made in the wall of the steam room under the shelves, leading to the street. On the inside it has an adjustable plug. This hole is also used to speed up the drying of the steam room.

You can dry the bathhouse in winter with the help of ventilation by opening the windows and doors wide - after all, the air inside is much more saturated with water vapor. But you shouldn’t think that all the moisture will leave the bathhouse only thanks to open doors and windows.

In addition to ways to create a draft simply by opening holes, there is also a method where ventilation actively cooperates with heating and works when the stove is on - this is bastu, which you can read about.

Well, don’t forget that even if natural ventilation is not installed correctly or its power is not enough to ventilate the bathhouse, you can always install fans in the air ducts. Forced ventilation, although noisy, is still effective.

BY THE WAY! Heat guns can help here too.

For those who believe that heating alone is enough, and ventilation becomes optional, we recommend watching the video by Konstantin Bely:

After washing: methods of heating

Heating is just as necessary for drying as ventilation. You understand the mechanism: by heating water molecules, you make them more mobile, transform the water into a gaseous state (steam), and it is easily carried away by the breeze. What will the breeze do if the water is cold? Nothing. And if there is no breeze, the steam will cool over time and calmly settle as condensation.

So, the easiest way to dry a bathhouse after washing in winter is to put one or two logs in the firebox and let them burn out. All ventilation openings must be open.

This is for an iron stove. A brick stove is a heat-storage stove, so its heat is enough to dry the bathhouse after the procedures (together with open ventilation).

***

Well, as you can see, you have to invest some money and make an effort in order to use a large bathhouse in the winter. The smaller it is, the easier it is to warm it up even in cold weather. The power of the sauna stove is calculated for the steam room; it is difficult to fit other things into its responsibilities, because there is summer when all this is not needed. So it is better to use autonomous heaters.

Installation of a water floor from a sauna stove

Initially, water heated floors were not intended for installation in a bathhouse. Therefore, when laying such a “pie” in a bathhouse, it is required to equip it with additional elements.

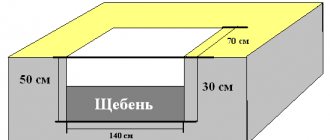

The installation of a water heated floor from a sauna stove includes several components:

The heated floor contour is the main working element, which is laid evenly across the entire floor of the room with a certain pitch, filled with a concrete-cement mixture screed. You should choose the right pipe model; in this situation, not every one will be suitable. It is best to use copper, metal-plastic or stainless steel corrugations. However, many people prefer cross-linked polyethylene pipes with increased heat resistance, with a service life of at least 30 years, or polypropylene pipes, with a warranty period of at least 50 years.

The mixing unit is an important part of the system, since the stove is not capable of heating the coolant to the required level. It heats the water almost to the boiling stage; in this state it cannot be supplied to the circuit. Therefore, a mixing unit is needed, in which boiling water will be mixed with the waste coolant to the required 40 degrees, and in this form it will be sent into the pipeline. It is used to regulate, configure and automatically maintain the temperature level of the heated floor in the desired mode.

Heat exchanger - a container, coil or register located above the firebox, where the liquid from the furnace is heated. When using antifreeze as a coolant, you will need to equip a separate heat exchanger, then the antifreeze will not be able to get into the washing water.

A circulation pump is necessary to ensure that the coolant is evenly distributed and moves through the pipeline. Without it, a warm water floor cannot function, as it provides the circuit with additional pressure for fluid circulation. When selecting the pump power yourself, you need to take into account the area of the heated room; the larger it is, the higher its performance should be.

To reduce the load on the pump, it is recommended to divide the pipeline into several parts of equal length.

Drainage is necessary to remove excess liquid from the steam room and washing room of the bathhouse. You can equip it with your own hands, taking into account the following two points: by constructing a water outlet - a drainage hole, through which the water will flow into the pipe and be discharged into the sewer pit; fill the screed with a slope in the direction of the drain hole - then all the water will flow towards the slope.

What makes this type of floor heating system unique?

Thermal energy tends to the top, so in the bathhouse the air is distributed in layers - cold at the bottom, hot at the ceiling, most comfortable in the center. Therefore, the floor in the bathhouse is always cold, which cannot but cause discomfort. This problem is especially relevant for baths with ceramic tiles on the floor. This finishing material is beautiful, but has a cold surface. But there is a way out - to mount the system in the floor, the coolant in which will be heated by the stove.

Instead of a boiler, the heating unit will be a furnace, so a heat exchanger is installed above the firebox - a tank made of stainless steel or other metal that is not subject to corrosion. The pipeline from the heat exchanger is carried out to the premises where the “warm floor” will be installed.

Sauna stove with heat exchanger

To return cooled water back to the tank, you need to install a circulation pump. It is impossible to refuse it, since the stove is not installed below floor level. It is recommended to choose a pipe diameter of 24, while for installation of “warm floors” in residential premises, contours of 16 diameter are chosen. The main feature of a water system powered by a furnace is that the temperature of the coolant inside cannot be adjusted.

For a “warm floor” system, a comfortable coolant temperature is 40 degrees. Very hot water, almost boiling water, will be supplied to the system from the stove, which is unacceptable. Therefore, it will be necessary to install a mixing unit, where the cooled coolant will flow into the hot water. It is advisable to install a “warm floor” from the stove in all rooms of the bathhouse.

Cake of water “warm floor”

Indirect heating boiler in the bath

When it is not possible to install the tank directly next to the stove, the boiler is placed in a convenient location, and the device heats the contents indirectly.

Structurally, the water distribution is done so that part of the pipes passes through the furnace. Cold liquid from the reservoir passes through pipes, is supplied to the coil inside the furnace, is heated there and flows back into the container from above. The physical law of displacement of hot liquid by cold is also used here.

As a rule, the capacitive volume of the structure is 60-80 liters, the contents warm up in 1.6-2.2 hours. Advantages of this scheme:

- Separate placement from the stove;

- Can be used for a sauna;

- Ease of operation;

- Minimum resource costs.

The complicated design is a disadvantage that is compensated by ease of placement and functionality.

DIY making

Despite the availability of different options for sale, you can try your hand at making a heat exchanger yourself. It's not that difficult if you have welding experience. In any case, it’s easier than making a stove from scratch.

But before you get started, you need to do a little calculation.

Calculation of heat exchanger power and area

It was already mentioned above that heat exchangers connected to the body take away part of the furnace power. Therefore, the first rule will be the following:

IMPORTANT! The heat exchanger power should not be more than 1/10 of the furnace power. The second rule is related to the length of the pipes: if the system is gravity-fed, then you should not extend the pipes further than three meters

The pump in the system eliminates such restrictions. But the pump is installed more often when the coolant is used to heat rooms. However, if the storage tank is not located too high, you can only wash with a hose. If this is inconvenient, then you need to either take the tank into the attic and insulate it, or install the same pump

The second rule is related to the length of the pipes: if the system is gravity-fed, then you should not extend the pipes further than three meters. The pump in the system eliminates such restrictions. But the pump is installed more often when the coolant is used to heat rooms. However, if the storage tank is not located too high, you can only wash with a hose. If this is inconvenient, then you need to either take the tank into the attic and insulate it, or install the same pump.

The third rule concerns the volume of the heat exchanger (if it is a small flow-through tank and not a coil). The water in it should heat up within a couple of hours. If it’s longer, then the volume is too big. If it is faster, then it is better only at first glance - the water should not boil, this will cause scale, steam, testing the expansion tank, and other problems.

Now, actually, the calculation itself:

The power of the heat exchanger depends on its area: 9 kW for each square meter of the exchanger. The area is quite simple to calculate: if it is a coil, then multiply the circumference (3.14 * diameter) by the length of the pipe. If this is a “samovar” heat exchanger, then take the diameter of the inner pipe, multiply it by the number Pi, and multiply it again by the height of the “samovar”.

If the exchanger hangs on the chimney, you can ignore the rule of deducting its power from the power of the stove. Only if he is on or in her body.

You can calculate the power required to heat a room using the same principle as for a steam room, that is, based on the volume of the room. In the steam room, a kilowatt per cubic meter is taken, but the adjacent ones do not need high temperature, so focus on half the value.

Knowing how many kilowatts are needed to heat a washing room, you get the area of the heat exchanger, and from it the length of the pipe for the “samovar” or coil.

Let's consider a couple of options for self-manufacturing heat exchangers.

Let's assume that you decide to increase the efficiency of the stove by installing a heat exchanger on the chimney.

- The thickness of the steel required for this is 2.5 mm.

- In addition to the sheet material, you will need two pipes with different diameters.

- The smaller one should be adjacent to the chimney pipe, the larger one should be 5-10 cm wider than the first one.

- Two circles are cut out of sheet metal to fit the diameter of the larger pipe, then a hole is cut in the center to fit the diameter of the smaller one and everything is carefully welded.

- You also need to make holes for the pipes through which water will come and go.

- The pipes are threaded and must match the diameter of the connecting pipes.

ADVICE! After checking the tightness of the seams, installation on the chimney and routing of pipes, it is recommended to insulate the heat exchanger using mineral wool and foil - this will dramatically increase the rate of water heating.

Another option for a heat exchanger for a chimney is a coil made of a copper tube with a diameter of 10 mm, which is made to tightly wrap around the chimney pipe. 1.5-2 meters of pipe is enough. The ends of the coil are inserted into the nuts, flared under the fittings, and then the fittings are screwed to the nuts.

Note! The copper tube must be flared exactly under the cone of the fitting so that they eventually fit tightly against each other. Be careful because this is where future leaks can occur if you flare with an uneven thickness.

Here are a couple of videos on the topic:

Video

How to bend a copper tube yourself with a pipe bender.

Without pipe bender.

We heat for heating

Frost creates additional requirements for how we heat a bathhouse in winter.

How to drown

The rooms become cold, approaching the temperature of the environment. In this case, heating immediately causes the appearance of condensation - water vapor from the air strives to instantly settle on something colder than the air itself.

The process of kindling in such conditions becomes an art. Of course, what type and fuel you use is also of great importance. It is difficult to cope with a brick stove; an iron stove is simpler in this regard.

There was a video on the Internet, the author of which shares his experience of lighting a Feringer stove at sub-zero temperatures:

But this is not so much about art, but about whether a small stove can bring a steam room out of the red in an hour. The author clearly shows that he can.

We want to say that you can’t break time records with a brick, but if it happens in winter, and the bathhouse has cooled down to sub-zero temperatures, then you need to be more careful with the stove.

After a cold period, the brick oven is first slowly heated and the moisture is allowed to evaporate.

The video below shows the process of heating a brick stove in a house, and this is somewhat different, because in the house the stove is not overcooled, it does not need to be gradually turned into positive mode, besides, it has a different operating mode - it is heated only in cold weather and constantly, and the bathhouse is heated for procedures at any time of the year. But so far no one has made a video about how you can heat a bathhouse in winter with a brick stove.

How can I heat it?

The question “how to heat a bathhouse in winter” can be answered in two ways - talk about what kind of firewood is best suited for winter heating. Or how to achieve a comfortable temperature for a person in rooms other than a steam room. Above, we have already talked about alternative methods for heating a bath without heating in winter.

Therefore, here we will only say that the only fuel whose quality depends on us is firewood. And you should know that this quality determines how well your stove will work. Specifically, how long will your chimney last without cleaning?

This is influenced by the presence of resin in the firewood - firewood made from coniferous wood is, of course, the cheapest, but it also creates the most problems. Because during combustion, more soot is formed, which settles in the chimney pipe.

Hardwood is much better in the firebox. But they also differ in the heat of combustion. Unfortunately, valuable hardwood species have the highest combustion heat - oak, hornbeam, and ash are good for burning. But, on the other hand, not all of their wood is suitable for processing and turning into building materials, furniture or something else.

Fruit trees (cherry, apple, etc.) are suitable for heating; they are only slightly inferior in heat of combustion to the species mentioned above.

Next come deciduous trees, but not so rare - birch, alder, etc. It is better to use them than conifers.

Another important characteristic of firewood is its moisture content. The damper the wood, the worse it burns, everyone knows this. Therefore, the woodpile should be located in a dry place, protected from precipitation, and you can also dry the wood next to the stove, using its heat to drive out excess moisture from the wood, which will then go into the firebox.

How to choose the optimal water tank?

To ensure yourself a pleasant holiday, during which you don’t have to think about the technical features of the water heating process, we recommend that you pay attention to them at the bathhouse design stage. The choice of a water tank of optimal volume and configuration is influenced by several factors:

- Steam room type. A classic samovar tank is suitable for a Russian bath, while a Finnish sauna will require moving the water container to a separate room.

- The area of the entire bathhouse and steam room. The built-in small-volume water tank will save the most space. A remote tank is also convenient.

- Duration of stay of visitors in the bathhouse. Those who like to steam and wash themselves in a couple of hours install samovar tanks in their baths, while fans of long steaming sessions (more than 4 hours) are more suitable for remote tanks. This is due to their ability to maintain a constant water temperature.

- Location of the washing compartment. A samovar-type tank is installed in a bathhouse when the washing room and steam room are the same room. If guests of the bath do not wash in the steam room, the best solution would be to choose a remote tank.

- Features of the premises. The steam room can be so cramped that access to the lid of the samovar tank will be difficult.

- The material from which the tank is made. Many manufacturers offer cast iron and enameled products. The former retain heat for a long time, but also take a long time to heat up, and their heavy weight creates difficulties during transportation and installation. The latter are democratic and simple, but short-lived, and constant contact with water leads to corrosion even on an enamel-protected coating. offers water tanks made from stainless steel, the most practical and popular material for this application.

Experts advise choosing a water tank volume with a small reserve so that your guests can also enjoy a real hot bath. The optimal capacity parameters are 55-80 liters, although it can also offer miniature boilers of 40 liters for a small family. If the volume of the tank is determined correctly, then you will wait for the water to heat up to 70-75 degrees in 30-50 minutes. At this time, the temperature in the steam room will reach 90 degrees, and you can start steaming.

We invite you to familiarize yourself with Hot water at the dacha from a well

It is attention to the technical characteristics and their scrupulous study that guarantees you the choice of a suitable water tank for your bathhouse. carefully preserves the traditions of the Russian bathhouse, successfully combining them with the latest technological developments

We offer you functional, easy to install and use, high-quality and efficient sauna stoves with a water tank. Contact our managers for advice and receive comprehensive information about products

carefully preserves the traditions of the Russian bathhouse, successfully combining them with the latest technological developments. We offer you functional, easy to install and use, high-quality and efficient sauna stoves with a water tank. Contact our managers for advice and receive comprehensive information about the products.

Traditional water heating

Usually a brick or metal stove is installed in the bathhouse, where combustion of wood is used as fuel. The advantage of the method is the possibility of periodic heating, only before taking procedures, the disadvantage is a long heating time.

Options for location of the water tank when using a brick oven

The easiest way is to install a cast iron stove over the firebox, on which to place a metal tank with a lid. Such a removable container is easy to descale, but there is a risk of getting burned on its walls. To avoid the need to pour boiling water during a long fire to reduce humidity from steam in the room, a drain valve is installed in the tank. Otherwise, installation of external additional capacity is required, which reduces the mobility of the device.

The tank may be built into the furnace, which makes repair work difficult when detecting damage to its body. It is more rational at the masonry stage to provide a special recess in the structure, inside which to install a water container. The tank can be located on the wall near the stove, provided it is heated sufficiently - otherwise the process will be too long.

Advice! When using brick stoves, to prevent carbon monoxide from entering the room, you must wait until the firewood is completely burned.

The best option is considered to be the option of installing a heat exchanger, which can have a very different design. The simplest device is a U-shaped piece of pipe or a section of a cast iron battery. A heat exchanger located in the firebox connects the stove to the tank. The dimensions depend on the volume of water, its initial temperature, the power of the oven and the desired heating time.

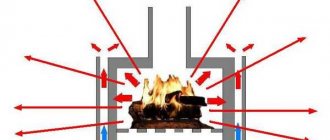

Use of metal furnaces

This type of water heating equipment has gained great popularity due to a number of its advantages:

- Compact dimensions;

- High speed of water heating;

- Significant fuel savings;

- Possibility of adjusting air and water temperature;

- Large volume of heated space.

The disadvantage of metal stoves is their rapid cooling.

Important! Due to the protection against depressurization of the chimney and combustion duct, carbon monoxide cannot leak into the room, so it is possible to continue heating during bathing procedures. The stove is installed between the steam room and the washing room, as if mounted into the wall between them

The water heating tank is made of 2 mm thick stainless steel sheet. It is installed on the washing room wall. Additional heating of the container is provided by the brick lining of the wall around the stove. Communication between the elements of the system is arranged using a heat exchanger. The tank to ensure the circulation of boiling water should be located above it. The container has a tap at the bottom, and a hole in the lid for drawing and adding water.

The stove is installed between the steam room and the washing room, as if mounted into the wall between them. The water heating tank is made of 2 mm thick stainless steel sheet. It is installed on the washing room wall. Additional heating of the container is provided by the brick lining of the wall around the stove. Communication between the elements of the system is arranged using a heat exchanger. The tank to ensure the circulation of boiling water should be located above it. The container has a tap at the bottom, and a hole in the lid for drawing and adding water.

The system allows you to obtain 100 liters of boiling water year-round. The temperature is controlled by changing the draft in the firebox. The position of the firewood in the stove makes it possible to regulate the direction of heating. Placing fuel near the wall heats the air in the steam room, and placing water closer to the door. Before firing, the container is filled to a certain level, and the circulation of boiling water begins when the furnace heats up.

Storage boilers

A storage type heater consists of a thermally insulated tank, a heating element, an automation unit and a safety group. In modern boilers, some manufacturers install a magnesium electrode, which prevents the formation of scale on the heating element and corrosion of the inner surface of the metal container. Installations of this type are available in both horizontal and vertical versions.

The principle of operation of the boiler is as follows: the tank of the device is filled with water, which is heated by a heating element to a temperature set by the owner in the range from 35 to 85 ° C. Once the temperature is reached, heating stops. When the liquid temperature drops by 0.5°C, the heating element automatically turns on and heats the water in the tank to the set temperature.

Advantages of using storage boilers in a bathhouse:

- Low power consumption compared to flow-through analogues.

- Does not require additional costs for increasing the wiring cross-section.

- With the correct selection of container, it provides a sufficient amount of hot water.

- Maintains liquid temperature for a long time even during a power outage.

- Less demanding on liquid quality.

In addition, storage electric boilers are reliable, durable, fire and electrical safe.

The disadvantage is the large weight and dimensions.

Flow type heater

An electric instantaneous water heater for a bath is a device in which water passes through a heated heating element.

The heating element is switched on and off automatically when the point of consumption is opened. Installations of this type have many advantages:

- Full hot water bath (no volume limitation).

- Quick receipt of heated water.

- No maintenance required.

- No need to drain liquid after use.

Flow-through water heaters have another undeniable advantage - small dimensions. Now a few words about the shortcomings.

- To heat a sufficient amount of running water, a large heating element power is required. (from 8 to 27 kW), and this entails problems with wiring.

- In simple (by design) devices, the degree of heating is determined by the power of the heating element and the liquid flow rate.

More complex devices are equipped with automation that is capable of maintaining the required temperature in the hot water system, but this entails a significant increase in cost.

Indirect heating boiler in the bath

When it is not possible to install the tank directly next to the stove, the boiler is placed in a convenient location, and the device heats the contents indirectly.

Structurally, the water distribution is done so that part of the pipes passes through the furnace. Cold liquid from the reservoir passes through pipes, is supplied to the coil inside the furnace, is heated there and flows back into the container from above. The physical law of displacement of hot liquid by cold is also used here.

As a rule, the capacitive volume of the structure is 60-80 liters, the contents warm up in 1.6-2.2 hours. Advantages of this scheme:

- Separate placement from the stove;

- Can be used for a sauna;

- Ease of operation;

- Minimum resource costs.

The complicated design is a disadvantage that is compensated by ease of placement and functionality.

The easiest way

Manufacturers make sauna stoves with ready-made water tanks. This option is the simplest for installation and further operation. Relevant for buildings that do not have gas and water supply communications; a limit on the use of electricity has been determined.

Hot water tanks can be installed in two ways:

- The tank is placed directly on the chimney pipe of the stove, the liquid is heated by the heat of the smoke coming out. At the same time, the pipe can heat up to very high temperatures (500⁰ C), quickly warming up the contents of the tank. The bottom of the container is equipped with an opening equal to the cross-section of the chimney pipe. It is necessary to ensure the tightness of the joints of the pipe and the tank at the inlet so that water does not leak out. The joint can be treated with a heat-resistant sealant, clay-lime-sand mortar. Cement mortar becomes cracked when exposed to heat. At the same time, such placement allows you to heat the water with heat, which is usually removed outside. And it is easier to install a chimney pipe inside the attic space, since excess heat is transferred to water.

- Mounted tank. It is placed wall-mounted on one side of the stove, most often inside the steam room (capacity 40-70 l). A wood stove heats the water in the tank in 1.2-1.6 hours. To speed up the process, you can thermally insulate the tank. It is also a simple, low-cost method that does not require significant material costs and is easy to maintain.

Placing such a tank inside the steam room is considered a disadvantage due to the large release of water vapor. For bathhouses located in the country, this is one of the few available ways to heat water that does not require any effort in winter arrangement. A current option for a classic Russian bath. It is not recommended to equip a sauna with such a tank.

Air type register

There are special designs of furnaces with air-type heat exchangers, which are used to heat not only garages, but also large greenhouses or other buildings.

Corrugated heat exchanger

Corrugated sewer pipes can be successfully used to organize a heat exchanger. They are wound around an uninsulated section of the chimney so that the air inside them heats up faster and spreads into neighboring rooms. And if you wrap such a pipe and chimney with foil material, then heating will occur faster.

Bell-type heat exchanger

If you need to organize heating of the second floor and attic of the house, then it is convenient to use a heat exchanger in the form of a hood. It allows you to trap warm air that accumulates near the ceiling inside the room. Gradually cooling, the air will sink down and warm the room with residual heat.

Such a cap can be made from fireproof plasterboard, galvanized sheet or other material, and then lead the air ducts to their destination. For beauty, the cap can be lined with artificial stones, which will heat up and gradually release heat.