This type of foundation is considered easy to construct and quite reliable. On certain soil compositions, it has proven itself well for light structures, which include bathhouses built from any material except brick stone. The pile foundation for a bathhouse is popular; construction requires a minimum amount of materials, labor costs and time, which allows you to save money. This type of foundation can be erected independently, without special construction skills.

When to use a pile foundation

In most cases, a pile foundation for a bathhouse is built on a soil composition that is not capable of providing the necessary stability to the building. Such places include:

- quicksand;

- sandy soils;

- peat bogs;

- loams excessively saturated with water.

In such areas, the piles must be lowered to the level of the dense soil layer so that all the load forces created by the structure are transferred to it.

It is recommended to use a pile foundation on soils that freeze below the one and a half meter mark in winter. To fill a strip base, large volumes of excavation work will be required, while installing piles will cost much less.

The next option when it is necessary to arrange just such a foundation is if the site allocated for construction has complex terrain. To level it, you have to incur unplanned and very significant costs, and it is better to build the foundation on pile supports.

Pile foundations are also used on dense and difficult-to-cultivate soils, when digging a foundation pit is difficult and quite expensive.

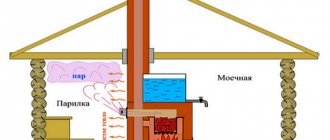

Drain in a bathhouse on screw piles

The floor of the bathhouse, raised on screw supports, can be insulated from the outside by backfilling with perlite or ordinary polystyrene foam. The outlet from the washing compartment and steam room must be connected through a bellows and elbow to a plastic sewer pipe. The sump must have drain and flush taps, otherwise it will be difficult to clean it and drain the water if the bathhouse on stilts spends the winter without load.

If you plan to use the steam room all year round, then the drain ladder or corrugation is installed without a bellows, and the inlet opening must be closed with a removable lid. For winter baths on stilts, the use of a ladder is not recommended, since the water seal inside the body can freeze and break the mounting flange.

Design

Near reservoirs and in areas with frequent flooding, they tried to raise objects above the soil surface, for which purpose they drove logs into the ground, placing them in the corner sections of the structure, under walls and partitions. For such piles, hard wood was used, which could resist moisture for a long time.

Larch was considered the best option, as it gained additional strength from water.

Nowadays, pile supports made of wood are used quite rarely, but the foundation of such supports turns out to be the most profitable and quite reliable.

In modern construction, twelve options for pile supports are known, but for low-rise buildings they use one of three:

- driven reinforced concrete;

- screw metal;

- bored.

Foundations on reinforced concrete piles are very rare, because to install such supports you will have to hire special equipment. But with such pillars the foundation is the strongest.

The screw version is good for screwing in - this work can be done manually. The disadvantage lies in the material of manufacture - metal is capable of conducting heat. You will have to install additional insulation to make walking on the floor comfortable.

When constructing a pile foundation on your own, in most cases, preference is given to the third type. Bored piles, although they are considered the most labor-intensive option for installation, provide an opportunity for good savings.

Construction site preparation

In order to properly equip the foundation for a 4x6 m bathhouse, strip or any other, and then build the building itself, it is necessary to draw up a large-scale plan for the future bathhouse. Then you need to prepare the site for construction work. To do this, the selected area must be cleared of plantings, small outbuildings, unnecessary objects and debris. Then the site must be leveled and marked strictly according to plan.

To mark and make the foundation you will need:

- roulette;

- building level;

- square;

- cord or rope;

- hammer or mallet;

- construction knife;

- pegs;

- shovels and bayonets;

- stretcher;

- buckets;

- trough;

- Master OK;

- construction mixer;

- hacksaw.

First, the corners of the planned building are marked. Here you need to install pegs made of wood, fittings or, for example, a thin pipe. A cord or rope is stretched between them. Smooth corners are formed using a square. To ensure that the cord is tensioned evenly, additional marks must be driven in between the corner pegs. It should be remembered that when marking the foundation, it is necessary to add approximately 10 cm (depending on the selected type of foundation) on each side.

Errors made when pulling the cord will help identify control cords stretched diagonally between opposite corners. If the length of the diagonals differs by 3 cm or more, it means that the marking was done incorrectly.

Types for building a foundation for a bathhouse

As a rule, a bathhouse is not a large object, and this is the main condition when choosing a foundation. Driving posts will require special construction equipment, the rental of which is expensive. In addition, each driven reinforced concrete pile will have to be capped. It turns out that this type of foundation is suitable for the construction of a mago bath, so many people prefer screw and bored options.

Bored

This option is used for almost any small object, which includes a bathhouse. There is only one difficulty here - drilling wells.

The bearing capacity of a bored pile column is formed as a result of work in two planes - from the support located on the underlying soil layer and from the interaction of the side surfaces of the column with the soil in contact with them.

Distribution of load-bearing capacity: from 50 to 75% - supporting, 50 - 25% - lateral.

Differing in similar features, the bored column may not reach a durable soil layer located at great depths, but fulfill its functional purpose thanks to the work of the side parts. In this case, the piles are called “hanging” and it is not recommended to use formwork structures for their installation.

You can construct formwork from steel, asbestos-cement or plastic pipes, use box-section structures for this, but in this case the cost of constructing the foundation will approximately double, because in addition to the formwork you will need piles that maintain load-bearing capacity. The concrete solution is poured directly into a well drilled in the ground.

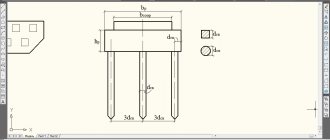

Taking into account the fact that the bathhouse is not capable of creating a significant load, calculations for installing bored pile supports will not be needed. But there is a simple technique that you still have to use:

- the diameter of the wells should be twenty to thirty centimeters, the drilling depth should be from two to two and a half meters. If this condition is not met, this means that the pile has reached a dense soil layer, and it can be left at that depth;

- pile supports are installed at corners, external walls and internal partitions;

- installation step - no more than three meters (for a bathhouse 6 x 4 m, if there is only one load-bearing internal wall - 9 supports).

If wells of the specified diameter cannot be constructed, it is allowed to reduce their diameter to ten centimeters by installing small supports in triangles in increments of 30 - 40 cm.

Small piles are united by a common concrete cap.

Screw

Such supports are suitable for any small structure. Their load-bearing capacity depends on support on dense soil.

Among the main advantages are:

- maintaining the integrity of the surface layer;

- speed of foundation construction;

- reasonable installation costs.

The pile, which is a steel pipe with blades, is screwed into the soil composition. On the upper sections of the pipes, supporting metal frames (grillages) are installed, on which the structure rests. It turns out that the bathhouse seems to “hang” in the air. Screw supports are positioned every two and a half to three meters, without fail - at corners and load-bearing walls. Pile diameter – from 108 mm.

Technologically, the process does not cause difficulties, but there are certain features:

- the pile should be buried at least 1.6 m, for which it will be necessary to conduct a study of the soil composition;

- during the screwing process, abrasions will inevitably appear on the walls of the pile, which will lead to corrosion of the metal;

- installation of piles must be carried out strictly vertically, the heads are aligned along a single horizontal line. This entails additional measures to trim or build up installed supports;

- since the bathhouse on a pile-screw foundation is raised above the ground, the water supply and drainage for the bathhouse will have to be carefully insulated;

- for greater stability, builders recommend reinforcing the piles before concreting them;

- When performing work in the winter season, preliminary drilling should be carried out, reaching the freezing point of the soil.

Brick pillars

Piles/pillars for the foundation of a bathhouse can also be made of bricks or rubble stone, which are connected to each other using concrete mortar. Then the foundation is called columnar. The choice of location and distance between supports are similar. The manufacturing technique changes - bricks are placed on mortar.

The columnar foundation is made using the same technology. There will be more excavation work: you will have to dig a hole for each pillar

In the corners they are placed with a square section (at least 38*38 cm), the intermediate ones are made rectangular 38*25 cm. To save on bricks (rubble stone), half the depth of the pit can be filled with coarse sand. Sand is poured into layers of 10-15 centimeters, each layer is filled with water and compacted thoroughly.

Brick piles/pillars are made 30-40 cm above the ground level. The space between them is then filled with brick (thickness - brick or half a brick). These brick walls need to be buried 25-30 cm into the ground. The piles and walls are leveled using mortar and covered with a layer of roofing felt to ensure waterproofing.

Stages of work execution

To install a screw foundation for a bathhouse, you need to perform the following algorithm of actions.

Determining the depth of immersion

This value depends on the level of dense soil layers. The fact is that the construction of a “hanging” version of the foundation ultimately ends in subsidence or deformation of the grillage part, which entails the destruction of the outer walls.

Conventional calculations to determine the bearing capacity of the soil allow one to establish reliable data that shows only the current situation at the construction site. If the groundwater level changes, seasonal movements, or frost heaving, all your calculations will lose their relevance.

There is only one, but the most correct way - test drilling or complete installation of one pile support. The desired value will be the depth at which the pile begins to contact the dense soil layer.

Determination of height above the soil surface

The height of the upper parts of pile supports is influenced by the following factors:

- snow level in the winter season;

- water flooding during floods and rains;

- location of groundwater.

You can find certain data in the current SNiPs, others will have to be clarified at geological exploration or meteorological stations.

The main goal is to raise the bathhouse on a pile foundation to such a height as to eliminate or reduce the degree of negative impacts. As a rule, the bathhouse is raised above ground level by forty to sixty centimeters, which is quite enough to prevent the walls from coming into contact with snow and water.

This condition does not apply when building a bathhouse on a site with a slope or uneven terrain. In this case, the height is determined by the smallest indicator.

Principles of installation of screw piles

To install the supports, you can use a specialized machine, a portable power tool, or wrap the pipes manually. The larger the diameter and the number of screw piles, the more arguments in favor of the mechanized method.

To wrap the support you will need:

- Construction plumb line;

- Gate pipe with a shoulder length of at least two meters;

- Ballast weight;

- Several tens of liters of clay solution in water.

Each pile is installed on the ground at the point of rotation, loaded with ballast and leveled plumb in a strictly vertical position. While one worker holds the screw support vertically, two assistants use a steel lever to screw the pipe into the ground, adding clay solution.

After installing all screw piles on the foundation field, marking cords are pulled and the pipe heads are cut so that the cutting line of all supports is in one strictly horizontal plane. Support platforms made of steel plates or strips of metal are welded onto the cut racks.

Making a frame

Before assembling the walls of the bathhouse from profiled timber, screw piles must be laid on the frame. The base frame is sewn from solid oak timber 150-200 mm or polished sleepers 220-250 cm long.

The strapping material is attached to screw piles using anchor bolts with an undercut head to hide the nut in the thickness of the wood. Before fixing it on screw piles, each section of the strapping is checked with a building level and, if necessary, leveled with washers or thin metal. One of the options for tying the foundation of a bathhouse on screw piles is shown in the video

Assembling the log house

The installation of bathhouse walls on screw piles is practically no different from the process of laying profiled timber. The first beam is mounted on an adhesive or mastic base, the steel crowns of the bath are laid out “dry”, with a lining of jute or synthetic fiber.

If the bathhouse box is assembled from profiled timber, then the remaining cracks between the crowns are caulked with linen putten with the addition of wood glue. After assembling the strapping frame, subfloor logs are laid on screw piles on the timber using metal corners and “moths”. You can use a board with a cross-section of 150x40 mm or even an inch board, since the rough base does not experience any special load.

Installation work

When building a bathhouse with a pile foundation, certain work steps must be completed.

Preparatory activities

The area allocated for construction is cleared of debris and vegetation. You should arrange access roads for equipment if you plan to install pile supports mechanically.

According to the calculations performed, we purchase and transport to the site the required number of pile supports of a certain size. In addition, you will have to prepare some tools and materials:

- shovel;

- roulette;

- scrap and metal pipes one and a half to two meters long;

- grinder and metal circle;

- welding unit and electrodes;

- pile heads;

- sand and cement material;

- wooden pegs for markings;

- level;

- special coatings for metal and welds;

- channel, I-beam or rail for tying.

Carrying out markings

Pegs mark the points for screwing in pile supports according to the design solution. The marking is carried out from the corner area, while the compliance of the diagonals is monitored. For ease of construction, experienced developers recommend installing a 6 x 6 m foundation for the bathhouse.

Having marked the corners, places for the installation of intermediate supports are outlined, after which a pit is prepared at each peg with a depth of up to thirty centimeters and a diameter corresponding to the size of the helical blades. This measure will facilitate the process of screwing in the pile and ensure its vertical installation.

Installation of piles

There is a specific scheme for driving piles. It should be observed so that the installed supports do not interfere with the immersion of other pillars. This is especially important if the piles are installed by machine, because the equipment needs to come close to the drilling point.

Work on installing supports begins from the central part, gradually moving to the edges in a snake or spiral. Each immersed support is controlled for compliance with the vertical level, which is especially important at the initial stage, when misalignment is possible. Corrections are allowed at the beginning of the dive, since it is prohibited to level the pile by twisting it, and no one performs the installation at the same point a second time.

We cut, tie, concrete

The installation of pile supports is completed by cutting them to the same height. To do this, install a laser level, mark a horizontal line at the required height, and mark the cutting lines of the piles with chalk.

Excess pipes are cut off with a grinder, after which the piping is done - the piles are connected in the longitudinal and transverse directions with rolled metal, which requires a welding machine.

Once a single structure has been created, the welds are coated with special compounds to protect these areas from corrosion. After this, concrete mortar is allowed to be poured into the pile supports in order to increase their rigidity and provide additional resistance to loads from heaving. Concreting is carried out with a dense grade of mortar from M200 and above. Heads for installing a grillage are mounted on concrete supports.

Construction of the grillage part

Anyone who builds a bathhouse with their own hands on a pile foundation is recommended to use a beam with a cross-section of 15 by 20 or 20 by 20 cm to construct this element. The installation of the beams is carried out on the heads; before this, a double layer of roofing material should be placed to install a waterproofing layer.

The connection at the corners is made in half the tree, the diagonals are measured, the axes are aligned and the beams are attached to the heads through specially prepared holes. Wood material should be immediately treated with antiseptic agents to protect it from the negative effects of moisture.

Flooring

The usual poured floor laid in a Russian bathhouse is not suitable for us in this case. The fact is that water flowing between the boards gets into the soil and has a negative effect on the metal piles, weakening the adhesion of the soil and the pillars. In addition, certain difficulties arise in maintaining a comfortable temperature regime, because the bathhouse is located at a certain height relative to the soil surface.

If you do not insulate, you will have to consume additional fuel or electrical energy. The best option in this case, as follows from numerous reviews from developers, is floor insulation and high-quality waterproofing. To do this, the surface is filled with a thin layer of solution, but funnels are first installed in the floor, through which water will be drained into the sewer network. Ceramic tiles are laid along the screed, on top of which wooden gratings with wide slats and small gaps are placed for unhindered drainage of liquid.

Comparison of support parameters

Screw piles have insufficient load-bearing capacity to withstand heavy loads of heavy structures, so in most cases they are used for the construction of lightweight and low-rise structures. At the same time, metal supports are economical and relatively simple to install.

A detailed comparison of pile and driven supports is shown in the table:

| Options | Screw supports | Driven rods |

| Scope of application | private housing construction, construction of low-rise residential buildings, agricultural buildings, garages, warehouses, fences and other lightweight structures, strengthening of existing foundations and slopes | civil and industrial construction, construction of transport structures, as well as engineering and hydraulic structures |

| Soil types | various soils, except rocks, as well as difficult areas prone to landslides and subsidence | |

| Difficulty of terrain | landscape with any elevation changes | |

| Maximum service life | 70–100 years | 100–150 years |

| Load-bearing capacity of one product | up to 7 tons | up to 10 tons |

| Susceptibility to corrosive processes | highly susceptible | not susceptible |

| Waterproofing method | cold or hot galvanizing, polyurethane coating, alkyd paint or primer application | adding hydrophobic compounds to concrete |

| Burying method | screwing method | using impact force |

| Impact of installation method on the ground base | the blades break up the soil masses, the soil takes time to shrink | reinforced concrete support pushes the soil, compacting it underneath |

| Installation speed | high, from one day | |

| Installation equipment | electric screwing machines, devices for manual installation (rods) | piling units |

| Possibility of DIY construction | installation requires the collaboration of at least three builders | impossible |

Average price:

| Construction type | Wooden house | Foam block building | Brick building |

| Screw piles | 120 thousand rubles. | 460 thousand rubles. | Not recommended |

| Driven piles | 200 thousand rubles. | 475 thousand rubles. | 525 thousand rubles. |

A lot of useful information about pile-driven foundations is presented in this section of the site.

Marking of reinforced concrete piles in accordance with GOST

- “C” - pillars with transverse reinforcement.

- "SK" - round piles with a cavity.

- “SP” - pillars of a square configuration, have a round cavity, due to which their weight is reduced. Reinforced using both prestressed and conventional methods.

- “SG” - rectangular piles made of heavy concrete. Due to the increase in cross-sectional area, they have a greater load-bearing capacity than square ones.

- “SC” - piles with a square cross-section without transverse reinforcement.

- “1SD” - columnar piles.

- “2SD” - columnar piles designed for installation along the middle axes.

- “SSN”, “SSV” - composite pile pillars.

Depending on the position, piles are reinforced in two ways:

- Longitudinal reinforcement (represents the main working reinforcement).

- Transverse reinforcement (its purpose is to combine the longitudinal reinforcement and take the impact load during the process of driving the pile).

Prices

You can build a foundation on bored pillars with your own hands, which allows you to save a lot of money. However, errors in the implementation of the technology will certainly affect the reliability of the power structure and the durability of the structure itself. Having no experience in foundation work, as well as in the design of such structures, you should entrust the work to professionals.

It is also necessary to take into account that it is convenient to lay supporting elements with a diameter of up to 300 mm and a depth of up to 1.5–2 m with your own hands, which is due to the capabilities of a hand drill and the simplest installations for constructing pits.

Average market prices for contractor work are presented in the table below:

| Pile diameter, mm | Cost of work, rub./m |

| 150 | 1980 |

| 180 | 2150 |

| 200 | 2230 |

| 220 | 2400 |

| 250 | 2450 |

| 300 | 2300 |

| 320 | 3220 |

| 350 | 3450 |

| 400 | 3700 |

| 426 | 3900 |

| 450 | 3950 |

| 500 | 4210 |

| 530 | 4375 |

| 550 | 4450 |

| 600 | 5280 |

| 620 | 5450 |

| 800 | 6435 |

| 1000 | 7410 |

| 1200 | 9550 |

The cost of laying bored piles will be determined by the volume and complexity of the work, as well as the features of the technological processes (embedded or removed casing pipes, extended heel or the same cross-section along the entire length of the pile, etc.).

Additional information on the construction of foundations on bored piles