The fittings that are used in the bathhouse are practically no different from those that we could use in any other room, but still they have their own specifics. Because the bathhouse is characterized by high humidity and temperature. Both impose restrictions on the materials used. In particular, metals should be stainless, and objects with which a person comes into contact should not heat up too much. But first things first.

Hinges for heavy bath doors

You have two options: either look for especially strong hinges for heavy bath doors, or simply increase the number of regular hinges, which also increases the strength and durability of the fastening.

In general, when purchasing, you should ask what maximum weight this or that model is designed for. Because there are also plastic fittings on sale that are suitable only for the lightest door panels.

On the other hand, there are companies that produce models specifically designed for heavy or frequently used doors. Let's take ASSA ABLOY Group Company as an example.

You should also know the principle of calculating the number of fittings:

| Door weight (kg) | Number of hinges or canopies |

| up to 25 | 2 |

| 25-40 | 2-3 |

| 40-60 | 3 |

| >60 | 4 |

ADVICE! When installing 3 loops, the middle one should not be located exactly in the middle, its place is 20-30 cm from the top one, and the top one should be installed 20 cm from the top edge of the fabric.

Where can I buy

Companies offering doors for baths and saunas also have various types of fittings in their assortment.

Share on social networks

Sana, we need to take stainless hinges. Brass, stainless steel, or at least coated (chrome plating, galvanized) And in your case, the advice is to replace

I can only say from my own experience: I changed the hinges on the front door, but it was not very heavy, the position of the hinges had to be changed, but several months have passed - the flight is normal. It seems to me that the heavier the door, the more correct it is to put the hinges not in the same place, but in the nearest undamaged one. But a light door doesn’t matter.

Anton, it’s hard to tell from the photo how heavy the door is. As Anna wrote above, the weight of the door affects the decision. I would advise gluing, maybe not with epoxy, but just plain PVA. And if you twist it in the same place, then for reliability you can tighten it with several screws in a place perpendicular to the crack. Or, it’s better to twist it nearby, your second option is more reliable.

By sending a message, you consent to the collection and processing of personal data. Privacy Policy.

Source

Installing a door in a bathhouse

Difficulties may arise when installing doors in a log house - made of logs or timber. The technology here is different.

First of all, doors and windows are not installed in a new log house. It must stand and shrink for at least a year. At this time, the crowns are periodically caulked, which constantly lowers and raises the logs, changing the geometry of the walls. How to install doors/windows here? They will not withstand such loads. You need to wait until the main shrinkage has passed.

To prevent the door frame from getting jammed or crushed during shrinkage, a casing is made

In an established log house, holes are made for windows and doors. Most often, they are cut out with a chainsaw. Marking is done only using a laser level or plumb line. Building-grade precision is not enough here.

In the resulting hole, logs can walk freely, which is unacceptable. In addition, a wooden house, even after many years, can rise a little - during caulking, and settle - after. All the same, you will periodically have to plug the gaps that form.

In such conditions, even the thickest door frame is unlikely to be able to withstand the load. That’s why they came up with the idea of making a frame or casing in the windows/doors. This is a doorway frame made of thick boards that compensates for changes in height and holds the free ends of the logs. They are made in several ways.

Method one

Such an installation is only possible on an established log house. The procedure is as follows:

- The logs are hemmed, leveling the surface around the perimeter so that platbands can later be installed.

- Nail two side posts, securing them into each crown with several long and thick nails. The length of the nail is at least three times the thickness of the board.

- The horizontal stand is nailed 6-8 centimeters below the height of the opening. This gap will serve to compensate for the shrinkage of the building. Later this hole is filled with insulation.

- The door frame is nailed to the finished frame, then the door leaf is hung.

- The last stage is the installation of platbands. First, they are nailed on one side, the cracks are foamed with polyurethane foam or lined with flax tow. The gap at the top is filled with insulation tightly folded in several layers. Then everything is closed with platbands on the other side.

Method two

This option for installing a door in a log house is more labor-intensive, but also more reliable. It also involves installation in a not fully established log house.

Casing box for door with groove and block

- At the end of the opening, a groove is selected in the logs. Its width is 50 mm, depth - 48-50 mm. This can be done with a chain saw or circular saw, but best of all, with a router. Everything is finished and leveled with a chisel and chisels (especially in the corners).

- A 50*50 mm block is hammered into the groove made. Its length with a settled log house is 2 cm less than the height of the opening, with a fresh one - 5 cm.

- The top bar is still fixed lower than the height of the doorway and also by 5 cm.

- The door frame is nailed to a block.

With this method of installing a door in a wooden bathhouse, it turns out that the entire load during shrinkage falls on the timber, and the door frame remains intact.

Method three: timber casing

This type of installation can also be used on an unsettled log house. There is more work to be done here: both the tongue and groove will need to be molded. It is more convenient to make a tenon with a circular saw and a little chisel and chisels. The groove depends on who you want, but the most convenient device for this is a router.

- A tenon 50 mm thick and slightly less than 40 mm deep is cut out on the vertical parts of the opening.

- In bars measuring 100*100 mm or 100*200 mm and a length slightly less than the height of the doorway (2 cm shorter for an established log house and 5 cm for a new one), a groove of 40*40 mm is cut in the middle of the width.

- At the bottom of the doorway we work on a threshold equal to the width of the casing beam - for its reliable fixation. It should be slightly recessed, about 5 mm.

- After installing the sidewalls, a transverse board is attached to the top. It turns out to be 5.5 cm (or 2.5 cm) below the doorway.

- With this method, you don’t have to install the bath door frame, but hang the doors. directly to the casing. When choosing this installation method, you need to cut out holes for the hinges in the sidewall, and then hang the door leaf.

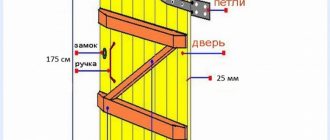

Approximate dimensions and design of a casing box with a spike

Watch the video on the topic.

In this video, select a recess for installing racks.

Choose any bath door installation. All of them have been tested, but the best, according to experts, is the second. Even with a small amount of work, it guarantees that the frame will not be flattened and the doors will not jam.

Read more about making casings and sockets here.

How to Install Butterfly Hinges

Fittings are an integral part of the door. Without it, normal functioning, opening and closing of the door leaf is impossible. Technical advances make it possible to produce hinges of different designs, including butterfly hinges.

Features of hinges

Butterfly loops consist of two parts. During their folding, the smaller part is inserted into the larger one. Therefore, the installation of butterfly hinges on interior doors does not require a groove. The canopies are attached using hardware and this does not require the use of any professional tools.

Advantages of hinged hinges

Typically, butterfly hinges are used as fittings for the first attempt at installing an interior door. They are characterized by the following advantages:

- Relative strength and wear resistance. Typically, this fittings are made of stainless steel or brass and coated with a galvanic layer, which provides additional resistance to mechanical wear.

- Easy installation. The hinges do not require insertion, so inserting them does not require the help of a specialist.

- Comfort of use. The design of the fittings includes bearings that ensure smooth operation and no squeaking.

- Versatility. Suitable for left and right door mounting.

- Aesthetic appearance. The stylish and modern shape of the hinges goes well with many interior styles. A wide range of colors allows you to choose fittings in accordance with the shade of the door.

To hang a standard size canvas, it is enough to purchase two loops designed for loads from 40 to 100 kg.

Disadvantages of butterfly loops

The disadvantages of card loops include:

- Their lack of reliability. Due to the fact that the fittings are located on the outside of the canvas, it is easy to dismantle for the purpose of hacking.

- Inability to screw door hinges onto a door equipped with a hinged strip around the entire perimeter.

- Not suitable for hanging techno-style doors with the illusion of no fastening.

Experts identify several features of butterfly awnings that must be taken into account before installing hinges on an interior door:

- the need to accurately screw the hinges to perfectly fold the sides of the canopy to avoid unevenness of the door and problems during operation;

- frequent appearance of a small gap, which is a side effect of loop cards;

- impossibility of removing the door leaf without unscrewing the hardware.

Butterfly hinges are best suited for lightweight interior doors. To hang heavy interior or entrance structures, it is better to give preference to other more reliable fittings.

When analyzing the advantages and disadvantages of these products, you need to decide whether you will install a butterfly hinge or give preference to other, more suitable fittings.

How to install butterfly hinges on doors yourself

For those who do not know how to embed hinges into an interior door, let us explain that this process consists of the following steps:

- applying special markings for hinges to the surface of the door leaf, as well as to the surface of the door frame;

- using a drill to drill holes for hinges in pre-marked places;

- checking the tightness of the door connection;

- checking the functionality of the door.

How to secure the door frame and install butterfly hinges on the interior door will directly determine their service life. The color range is not that wide. Most often there are imitations of various metals. In particular, copper, gold, bronze, or nickel. Butterfly door hinges can be either matte or glossy.

For those who do not know how to install hinges on an interior door, we provide detailed instructions.

Apply markings to the surface of the door leaf and the surface of the door frame;

- Install the rotary axis, which is the main structural element and which ensures the functioning of the entire mechanism.

- Measure 20 cm from the top and bottom edges of the door.

- Place the loop at the mark.

- Attach the plates using self-tapping screws.

We attach the hinge to the box:

- insert the canvas into the box, in the same way mark with a marker the location of the other part of the loop on the outer border;

- place one part of the butterfly in place, circle the points for the holes with a marker;

- carefully drill holes, place the product in place and fasten it with screws;

- unscrew the loop from the end, then attach it to the outer area, use an awl to mark the locations for the holes;

- make holes and secure the hinges with self-tapping screws, first attaching the inner part of the hinge, and then attaching the outer side to the box.

This design is suitable for almost any type of door leaf, with the possible exception of heavy solid oak doors. Hinges for heavy doors are slightly different from ordinary ones; they have a thicker flange and have built-in bronze bushings.

For greater clarity, we recommend watching a selection of videos on installing butterfly hinges.

Solving possible installation problems

Since the ideal installation of this type of fastener is possible only with a perfectly flat door leaf (which is rare), some shortcomings may arise during the work: non-critical, but nevertheless requiring correction. We'll tell you how you can correct possible defects that appeared during the installation process.

The most common problem when installing butterfly hinges is the gap between the hinge plate and the door frame. If there is such a defect, this means that the door will not be able to close tightly, which over time will lead to loosening of the structure and rubbing of the threshold. A small spacer made of cardboard, wood chips, or rubber band (even a match can do) solves this problem. The presence of such a gasket will slightly worsen the quality of installation, however, it will successfully solve the gap problem. If you are not satisfied with the fact that the butterfly hinge plates close too tightly, you can “drown” one part of the hinge a little into the thickness of the door frame.

Common Mistakes

The most harmless thing is that it may be an incorrect indentation from the edge of the canvas. If the hinges are installed correctly, but too close to the edges, then you will simply ruin the appearance.

The next and most common mistake is when people confuse the installation locations: the small inner part of the hinge is attached to the box, and the large outer part is attached to the canvas. This setup is dangerous for several reasons.

If the outer part of the loop runs along the edge of the canvas, then the holes will be at a distance of a couple of millimeters from the edge, respectively, if you slightly skew the screw and it will come out from the side, or you may get caught in a knot and then the outer edge will break off altogether.

If installed correctly, the holes in the small part of the butterfly will be located almost in the center of the door leaf, which means there is no need to worry about any cracks or distortions.

Things are no better with the box. The photo shows that the holes are too close, and the thickness of the lightweight box is small, so it can burst under load.

In addition, the box is usually attached to the wall with anchors in 3 places - these are two points under the hinges and one in the lock area. If we do everything as expected, then we will have 2 places left where we can drive the anchor and cover it with a loop, otherwise the anchor will be visible, which is also not very good.

There is one more nuance: during installation, all hinges must be strictly parallel to each other. The slightest distortion vertically or horizontally will lead to the door starting to “play” and eventually the hinge will burst or the screws will break out.

Video description

This video shows how to properly install butterfly hinges

To install hinges on interior doors, you do not need to make cutouts in the panels and doors, which greatly simplifies the task and saves time:

- The first step is to attach a loop to the side of the canvas at a distance of 200-250 mm from the edge to mark the holes for fastening.

- Afterwards, indentations are made on the marks with a drill. If you start screwing in the screws right away, the material may crack. This will also create the correct direction for screwing. The inner part is attached to the canvas, because it is problematic to mark the location of the inner side on the box.

- Next, the distance is measured with a ruler and marks are placed for the screws.

Since the hinges have a non-separable design, you must first drill holes everywhere, and then immediately install the entire finished structure. It is advisable to install the mechanism first on the door, and then on the frame.

During the installation process, sometimes there is a snag: the strip does not fully contact the door. If the situation is not changed, the hinges will not fully connect when the door is closed or will “play.” You can eliminate this problem by placing a strip of paper or elastic under the bar, on the side where it fits tightly.

How to lubricate butterfly hinges

There is no need to lubricate anything right away, since they already have factory lubricant. But with daily use it becomes less and an unpleasant sound appears. To get rid of it, you need to pour a little lubricant into the moving mechanism.

There are four options for lubricating the butterfly hinges of interior doors:

- The easiest and most effective method is the use of sewing machine oil. But not everyone has such liquid.

- The modern way is to use WD-40, but not everyone has lubricant either. It is without a greasy base and one or two injections are enough for the loop to stop being smeared.

- The third method is vegetable oil, but this method does not last long.

- And the last option, which also won’t last long, is a pencil. It is inserted into the mechanism and needs to be moved. The stylus will crumble and treat the inner surface.

Material

Having understood what dimensions of the entrance door to the bathhouse are suitable, you need to choose the material from which they will be made. For this, the following can be used: wood, durable glass, plastic.

Solid wood

Our ancestors used wood for this purpose. And today, despite the development of technologies for the production of various materials, wood remains quite in demand.

One of the most popular types of wood is linden. It is affordable, durable, and has good aesthetic characteristics. Products made from ash are often found. Manufacturers of wooden structures value this wood for its excellent performance qualities.

Wooden door to the steam roomSource remont.castorama.ru

Some manufacturers offer bath doors made of oak in different sizes. This option is considered one of the most durable and reliable, but at the same time expensive. In addition, a feature of oak is its significant weight, which also scares off potential buyers.

Glass

For the production of doors for baths and steam rooms, special heavy-duty tempered glass is used.

When choosing a product from this material, you need to pay attention not only to the size of the bath doors, but also to the thickness of the glass itself, the degree of its heat resistance, the model and the absence of any mechanical damage on the surface.. Usually the height of such a door is 1.6-1.7 meters

Width - within 60-80 cm. The thickness of the glass should be no less than 8 cm. If it is thinner, it may deform or burst over time.

Typically the height of such a door is 1.6-1.7 meters. Width - within 60-80 cm. The thickness of the glass should be no less than 8 cm. If it is thinner, it may deform or burst over time.

The following types of glass doors are usually offered for steam rooms:

- completely transparent or slightly tinted designs;

- frosted glass products;

- options with a thematic image or engraved design.

Door to the steam room made of tempered glassSource derdomus.ru

In order for the material to withstand mechanical loads and overheating up to 300 degrees, it is subjected to a fire polishing process.

The advantages of a glass door include:

- ease of care;

- ease of opening;

- resistance to high temperature and high humidity;

- safety in use;

- large selection (shape, shade, texture);

- the ability to apply a drawing;

- ability to retain heat due to high-quality joining and the use of silicone seal;

- the ability to choose the optimal size of the door for the bathhouse;

- affordable price.

When choosing a glass door, you need to consider some points:

- In the sauna, a tempered glass door is attached to a frame made of wood (aspen, linden). To protect the wood surface, veneering or lamination can be additionally used.

- For a Turkish steam room, you can choose a door made of frosted glass mounted on an aluminum frame. This metal is not afraid of interaction with water and condensate.

Hinged glass door to the steam roomSource podmoskovie.info

Plastic

This material is not very common in baths. Based on the characteristics of plastic, it can be used in some bathhouses:

- Tambour. This room is not heated, so the temperature inside is practically no different from the temperature outside. At the same time, a plastic door can become a good barrier to the penetration of wind and frost. Therefore, a door made of this material is well suited for an entrance vestibule.

- Waiting room. Even if the bathhouse is heated, the air temperature in the dressing room is usually 25-30 degrees. Plastic will easily withstand such values. It also responds well to high humidity. If a room is not heated for a long time in winter, the air temperature in it can drop significantly. Due to such changes, natural wood can become unusable over time, which cannot be said about plastic. Such a door can serve in the dressing room for a very long time, performing its functions efficiently. The only thing a plastic door needs is periodic lubrication of the seal and adjustment of the fittings.

- Shower or washroom. There will always be high humidity in this room. And water negatively affects the condition of the wood. But plastic will feel great in such conditions.

- Steam room. This room is characterized by high air temperature and humidity. From such exposure, a PVC door will quickly become unusable. Therefore, here you need to choose a door made of glass or wood.

PVC bath doorSource birzhaplus.ru

We solve the problem comprehensively

Proper layout of the premises is also important.

Many people, having spent good money on complete insulation of their bathhouse, suddenly discover that for some reason the desired insulation does not occur. Yes, it’s warmer, but where is the promised bliss, and why are there drafts across the floor?

The answer usually lies on the surface and whistles with pleasure - the door, the ordinary door to the bathhouse becomes the cause of this final inconvenience.

The solution to this problem can be very simple, or it can be a little more complicated, namely:

- Insulation of the door leaf itself;

- Insulation and sealing of joints where the door meets the jamb;

- Installation of thermal curtain;

- Installation of a second door.

Today we will go through all the points and be sure to solve two basic questions: how to insulate the door to the bathhouse and how to insulate the door to the bathhouse.

Let's get busy with the canvas

Photo of foamed polyethylene foil.

Any carpenter will tell you that it is not advisable to make the door structure heavier; moreover, this is fraught with distortions, and considering where the door is located (meaning in a bathhouse), then making it heavier is a completely unnecessary undertaking.

Therefore, in this section we solve the problems:

- Which insulation to choose so that it does not absorb moisture, can withstand low temperatures and is not very heavy;

- How to layer this insulation onto the door leaf.

We will not transmit the entire flow of information that the Internet is replete with about insulating fabric; we present a very simple method and its rationale:

As door leaf insulation, we offer you polyethylene foam with a foil layer. The material itself is quite resistant to cold weather, has the invaluable advantage of being wind and moisture impermeable, in addition, the foil layer will return heat flows back to the bathhouse. And the weight of the material will be slightly more than the total mass of the paint and varnish impregnation layers. The hinges will not experience a large load and the canvas will not move.

Regular door covering with this material.

From canvas to jamb

After insulating the door leaf, let's work on the jamb

The simplest thing is to trim the inner perimeter of the jamb with the door tightly closed (and note, already insulated)

In the old days, the most popular insulation for the front door was felt, but now you can use any other method. Basic requirements for the material: it must be soft enough, and at the same time fit tightly to the door leaf, thus preventing the access of air, and also not lose its qualities when in contact with water, not cake or tear.

The technology has not changed:

- The insulation is cut into thin narrow strips at least 5 cm wide;

- A 20x20 mm strip is marked and sawed off in such a way as to completely and tightly cover the internal perimeter of the jamb (taking into account the thickness of the insulation itself);

- The insulation is folded in half and installed with a fold to the door leaf as close to it as possible, pressed and fixed with a strip to the jamb;

- Thus, the entire perimeter of the doorway is covered.

Full guarantee

If you already want to get a full guarantee of protection from the cold, then you can finish insulating the door to the bathhouse by using a curtain made of dense material. You don't need instructions to cut and make the curtain. We chose the material, cut it, cut it, stitched the edges, thought out the fastening system and hung it. In this case, the fastening system can be under the rings on the pipe, simply overlapping the valve and stitching the valve under the pipe, or you can even make a cloth for clothespins (clothespin fastenings). There is also a simple way to attach between two planks. Therefore, we do not limit you in fastening and choice of material.

A few words about the second door

That's the point.

The second door is a method that has been tested and proven to be positive. Place your bet. To implement this, it is necessary to either install a jamb in which it will be technically possible to install two doors, while the adjustment of the two panels must be carried out before installation in the opening, which sometimes requires financial costs, time, and the warm season.

You can install an additional jamb and canvas to the existing ones, but you need to think about fixing the new structure to the existing one. A positive quality of the second door is the layer of air, which plays a buffer role and prevents the cold from quietly passing into the dressing room.

Types of doors to the bathhouse

If you look at the photo of the entrance doors to the bathhouse, you can see that they are made of different materials. There are several options for doors that are suitable for a bath: wooden, plastic and metal.

Wooden entrance door to the bathhouse

Most baths are built of wood. Our ancestors also used this material for construction, so those who want to create a rustic atmosphere in a bathhouse and feel unity with nature give preference to this material.

A wooden entrance door is perfect for a log bathhouse. Its main advantage is its naturalness. Wood is an environmentally friendly material that does not contain chemical impurities or toxic additives; it is absolutely safe for use.

A wooden door looks beautiful and cozy, and when exposed to heat, it emits a pleasant and relaxing woody aroma. By the way, you can additionally decorate the door using carvings; it will help complement the interior and make it more comfortable.

An important advantage is that a wooden door has low thermal conductivity, which helps retain heat in the bathhouse.

A wooden door will cost less than a plastic or metal one, so this option is the most budget-friendly.

Despite the variety of advantages, wood, like any other material, has its disadvantages. The main one is low resistance to moisture. In a humid environment, wood can become deformed, causing cracks and, consequently, drafts.

Wood cannot be called a hygienic material; it is an excellent breeding ground for insects and mold. This can be corrected if you first carefully treat the door with a special compound.

Caring for wooden doors is more difficult than, for example, plastic ones. Not all products are suitable for cleaning wooden surfaces.

Different types of wood can be used to make an entrance door.

A popular option is linden. It has high performance properties, in particular, it tolerates temperature changes and high humidity well. At the same time, its price is low.

Larch is distinguished by its strength and reliability. It also tolerates temperature fluctuations and moisture well.

An oak door is strength and durability. It has an original appearance due to its unique structure. The disadvantage of an oak door is its high price.

Other wood species are also used to make doors: aspen, alder, cedar, etc.

Plastic entrance door for a bathhouse

Plastic doors cannot be called a popular option for baths. Many people do not like not only the fact that the material is artificial, but also the feeling that breaking such a door will not be difficult.

In fact, it is easy to break down an interior plastic door, but an entrance door is a completely different matter; it is made with a reinforced profile: a closed steel loop 2 mm thick is inserted into the door leaf. This design ensures the safety of the door and prevents it from sagging.

Plastic is an artificial material, due to which it has a number of advantages:

- tightness. Thanks to this, there is no need to protect the bathhouse from drafts;

- hygiene. Plastic does not harbor mold, mildew, or insects;

- color variety. There are thousands of shades of plastic, so you can choose an option to suit any interior; the collection of shades even includes ones that imitate wood and other materials;

- moisture resistance. Plastic is not at all afraid of exposure to water, it does not deform or swell;

- ease of care. This material is unpretentious and can be cleaned with various abrasives.

The disadvantage is the high price. Of course, you can buy a cheap plastic door without a metal profile, but this option will not be durable. High-quality and reliable doors made of plastic are quite expensive.

Metal entrance door to the bathhouse

The metal door has good performance characteristics. Such doors are installed not only in bathhouses, but in apartments and private houses. Metal doors are highly stable and durable. They, like wooden ones, are environmentally friendly and do not emit harmful toxic substances.

Determine the purpose and choose the method of making a homemade pen

Most often, a handle is used to open or close a door. In this case, you can make a latch, hook or bolt from wood that will fix or lock the door.

The products shown in the photo were made on a lathe. The small button-style handle consists of only one piece and is better suited for furniture.

To open a heavy door, it is better to make a full-fledged handle from three parts. I would choose the option with a crossbar that is inserted into the supports (above right), which provides the greatest strength to the craft.

Carved handles are good in their own way. There are an indescribable variety of options for such products. To make something like this, you need to have a set of cutters and artistic taste. At the same time, it is quite possible to process simple handles with a knife.

I advise you to take a close look at overhead handles: they can be simple, reliable and even sophisticated at the same time. Such fittings can be cut with an ordinary hacksaw or jigsaw.

If a three-piece handle is secured with self-tapping screws through the main element through the stands, the product will be very durable. The height of the stands should be ensured to provide sufficient clearance for fingers.

Flat handles are the most popular, and they are made from boards. I recommend the option located in the photo below right: it is the most reliable, since the handle opening is located below the screw heads. In this case, the craft will not break along the fibers.

To make fittings, you need to apply drawings of the parts on the plane of the board, and then cut the workpiece with a jigsaw. Of course, sanding will be required.

Holes for fastening should be provided. They are drilled out at the top with a large diameter to hide the screw heads.

It is very convenient to use tree branches to make your own door handles for buildings in the country. At the same time, the uniqueness, simplicity and reliability of the craft are ensured.

Accessories made from natural materials can be decorated with carving elements, applied with drawings or icons using a burner, or treated with a blowtorch. A more complex version uses linings cut with a jigsaw. To attach a handle from a branch, you need to prepare several holes for self-tapping screws so that the fittings do not wobble and are held securely.

What kind of doors are there?

Before tackling the question of how to install a door in a bathhouse, you need to understand what we are installing. We have already talked about bath doors, let’s briefly go through the essence of the issue. The main materials for their manufacture are:

- Wood. This material is the most popular and most widespread. It is accessible, well processed, and has good environmental performance. With a certain approach, from wood of various species it is possible to obtain, if not a unique, then at least a product that is far from ordinary. Wooden doors come in a wide range of ready-made industrial options, to suit every taste, color and budget. Amateur craftsmen are given a great opportunity to show themselves in all their glory by making a door with their own hands;

- Glass. Glass sheets appeared in bathhouse use relatively recently. The point here is the peculiarities of industrial technology. Just some three decades ago, in domestic realities, not only a glass door leaf, but a normal window was a rarity. Today's industry's ability to produce thick, hardened material of increased strength, while being injury-resistant, is incomparable to what it was decades ago. Technologies for decorating glass sheets have radically improved. We admit that the home craftsman’s arsenal has also been replenished with tools, primarily made from super-hard materials, which greatly simplify glass processing, although this material remains very difficult to work with and requires accuracy, skill, prudence and technical savvy. Glass has almost zero water absorption, so they are widely used in oriental baths - hammams, which are characterized by an extremely high absolute humidity, and as a result - the danger of swelling of hygroscopic materials, which, of course, includes wood. Glass also offers interesting design solutions when arranging modern steam rooms, in fashionable innovative keys. In the end, glass, when used carefully, is very durable and does not require special measures to protect it from pathogenic microflora - a real scourge of wood;

- Combined designs are primarily a combination of glass and wood. They embody the positive qualities of both materials. Among other things, this option is somewhat cheaper than a canvas made only of glass, and it is also somewhat more convenient and easier to install the accompanying fittings.

We install a door in a log bathhouse

The entrance to the bathhouse is a metal door or a heavy canvas of beams. But in the room itself they install an accordion door (locker room) or a compartment. Sometimes you can find an interior book.

Installation of the structure is carried out in the following sequence:

- They create a pigtail. It will serve as a guarantee of the service life of the door and will prevent the logs from loosening.

- Install the box in accordance with all the rules for proper installation. The use of a level and plumb lines is mandatory.

- After fixing the canopies, the canvas is mounted.

- Fastening platbands.

- The last step is fixing the handles.

https://youtube.com/watch?v=zunCYIKCjcY

The opening can be tied with timber using screws or “tenon-to-groove”.

Useful tips

The dimensions of glass doors for a Russian bath must be selected so that there is no distance between the panel and the floor. When installing glass door structures in a hammam or Finnish sauna, it is necessary to leave a gap at the bottom for ventilation, so such doors are made slightly smaller in height.

A few simple and useful recommendations for installing and maintaining glass door systems:

- It is necessary to periodically inspect the hinges and monitor their condition, because due to the heavy weight, the fittings become loose and the fabric sags. If necessary, tighten the screws.

- You should not install a glass door in a newly built room. You need to wait several months for the structure to completely shrink.

- Do not use abrasive products to care for the canvas, as scratches may remain.

- The door to the sauna or bathhouse should open exclusively outward. This ensures a quick safe exit from the steam room and saves usable space.

- It is recommended to use doors made of frosted or tinted glass, as well as with a printed pattern or design. Transparent glass may be accidentally overlooked.

With the correct installation of a glass door system in a steam room, the necessary conditions are created for taking bath procedures. This design will last for many years if you follow a number of simple tips for hygienic care of glass sheets.

Installing a door frame

To carry out high-quality installation work, you must have the following set of tools:

- long measuring device;

- sharpened axe;

- chisel;

- hacksaw for wood;

- screwdriver

The wooden walls of a log house have a distinctive feature in the form of an uneven structure, since after installation such a structure usually settles. To install the box, 4 beams are used. Along the vertical ends of the doorway, grooves are cut for the ridges on the doorway. At the ends of the beams, fastenings are prepared taking into account the thickness of the door leaf. The door frame is fixed using a tongue-and-groove system and is additionally secured with screws or dowels.

Door hinge insertion

Precise cutting of door hinges

Precise insertion of door hinges begins with marking the door leaf. To do this, measure 20 cm from each edge of the door where the hinges will be installed.

Since we will cut the door hinges with an ordinary chisel, we should take into account some features of this method so that the hinges “sit” as accurately as possible. And since the doors that we often have to work with are laminated, accuracy when inserting is of considerable importance. This will be discussed below.

Installation of door hinges in photo examples

Naturally, the top of the hinge will coincide with the mark on top of the door leaf, and the bottom on the bottom. Moreover, when you measure 20 cm from the edges of the canvas, indicate with arrows which direction the loop will move, so as not to get confused.

Then we apply a loop along the edge of the mark and, with a sharpened pencil, outline it in fact; we will make an inset along the intended contour, because the loop map usually does not have strict geometry, and if inset in fact it will fit like a glove.

In order not to confuse the loops later, we make a mark on the back of each loop with a marker.

Since we will insert the hinges with a chisel and there is a risk of it moving during work, we need to make guides for it. To do this, use a wallpaper knife to carefully cut the loop outline mark.

Then we use a chisel to sample the cut area and get a recess step from which our chisel will no longer slip.

Next, we make a horizontal mark for the recess we need.

Then, using a chisel along the edge (place the chisel with its sharpened side towards the selected area) and a hammer, we go around the contour, going deeper into the thickness of the loop map and make a selection for fitting the loop.

Moreover, the hinge should not sit flush, but have a protrusion of half a millimeter (both on the door and the frame frame), this is done to allow for additional adjustment during the installation of the door.

Then we put our loop in the groove and use an awl to make a marking for the screws, and move it slightly to the side so that the screws press the card tightly to the edges.

We use a 3 mm drill to drill out a place for the screws so that the wood does not crack when screwing.

We put the hinges in the grooves and screw them on. The door is ready, it's time for the door frame.

We measure the hinges on the door leaf from top to bottom (sometimes they shift), write down the exact dimensions, add 3 mm each and make a mark on the frame frame.

The only difference is that all the marks are now from the top of the loop.

We repeat the entire process described above, your hinges will be embedded perfectly, all that remains is to assemble the frame and install the door.

Inset door hinges | Video explanation

Now installing door hinges manually will not be difficult for you.

Manufacturing and installation of doors

A DIY wooden sauna door leading to the steam room

Before we begin the actual work with a hammer and nails, let’s read the accompanying information about dimensions, material and other necessary nuances.

General provisions

The dimensions of bath doors should not exceed 170 cm in height. A higher opening will release an unacceptably large amount of heat at the moment of opening. After all, hot air accumulates just from above, and it should not be given an open path to escape.

The width of the bath door should be about 70 cm for the same reasons. It is also contraindicated to use double doors. It is much easier to make one flap airtight.

Advice: you should not make a massive product according to all the rules of burglary protection. There is nothing for thieves to steal there, but in the event of an unforeseen situation, such as a fire, leaving the dangerous premises will be problematic.

The best material for steam room doors is wood, linden or aspen, due to its high thermal insulation properties, resistance to temperature changes and environmental friendliness. Handles for bath doors should be made of the same material - your hand will not slip and get burned when touched.

Screw-in hinges are best suited for bath doors. Since they are easier to adjust, which may be necessary as a result of shrinkage. (See also the article Designing a bathhouse: how to do it yourself.)

After the boards are knocked together, it is necessary to install insulating material on them.

Only tempered glass is used in bath windows and doors. Although it is better to avoid their participation in the interior, as they will require additional insulation. (See also the article How to insulate a brick bath.)

Manufacturing progress

- We prepare tongue and groove boards five centimeters thick.

Advice: rather than choosing a tongue and groove yourself, it’s easier to buy ready-made products. Because their price will not differ much, but they will save a lot of time and labor costs.

- We lay them out in a row and even them out. For padding we use PVA glue.

- Next, we outline the selection of grooves.

- Using a scoring saw, we make two cuts on the marks at an angle of forty-five degrees and a depth of a quarter of the thickness of the wooden product.

- Using a chisel, remove the wood between the resulting grooves.

- We place dowels in the form of wooden blocks five centimeters thick into the grooves.

- After assembling the entire door, we check the strength of the structure and the evenness of all sides.

- We fix the key bars with nails and trim the protruding ends.

Now we move from the question of how to make a bath door with your own hands to the question of how to install it?

Installation progress

Installing a bath door in a log house also has its own subtleties:

- We determine the dimensions of the bath door: so if the canvas is, for example, 8 cm thick, then the frame posts should be 12 cm wide and 5 cm thick. Thus, you will need two vertical posts: a hinged one and a hinged one, and two horizontal ones, the cross section of which will be 5 cm by 8 cm.

- We produce two bars of 1.9 m and two of 7 cm. Using a chisel, we select quarters for the canvas 2 cm by 8 cm parallel to the longitudinal edges.

- In the body of the hinge stand we cut out openings for the hinges.

- We lay long pieces on a flat surface, and quarters on top.

- On the loop side, using a wedge, we make a gap of three millimeters, on the rest - five millimeters. This will prevent difficulty closing.

- We attach horizontal products and cut them in accordance with the edges of the long bars.

- We create quarters in the corners and connect the elements into a box.

- We apply the door leaf and fix the hinges in the prepared openings.

- We install the entire structure in the opening and fix it with self-tapping screws.

- We test the door for free opening and closing. All is ready.

Self-production

We will do this option:

The task of making a wooden door to a bathhouse with your own hands is quite realistic, you just need a certain tool. Below is a list that gives a simple/mechanized attachment:

- saw / jigsaw;

- planer/thicknesser;

- screwdriver/screwdriver;

- quarter plane/milling machine attachment;

- sandpaper/belt sander;

- chisel or chisel;

- hammer;

- roulette;

- level;

- square;

- pencil.

If you prefer ready-made tongue and groove floor boards, then some tools will not be needed. Otherwise, you need to adjust the geometry of the boards to one standard, and then cut quarters on both sides in a mirror-like symmetrical manner:

An alternative to laying boards overlapping can be a tongue-and-groove connection (otherwise known as tongue-and-groove), but this requires a milling machine (or a finished board with tongue and groove).

The quarters are cut either with a plane (with the mentioned attachment) or with a milling machine.

Finished boards can be glued together with PVA. To compress the joints, a wedge or its equivalent is used: a frame or two stops, between which our canvas is wedged. After 12 hours the canvas is ready.

The resulting shield still needs to be secured with wedges. To do this, you need a beam, which is given a trapezoidal shape in profile, and which slightly narrows from one edge to the other. The length of the beam is 20-30 cm greater than the width of the door. There should be two such wedges.

A dovetail groove is cut under each wedge on the door. You can do this with a router and then select it with a chisel. If the wedge is not trapezoidal in profile, then the groove may not be widened. Then you can cut it with a jigsaw.

The wedges are driven into the grooves, after which a through hole is drilled at the beginning and end of the wedge for a wooden dowel - 4 dowels in total. They are hammered and trimmed. The wedges are also cut to the width of the door.

It is customary to install an oblique spacer (brace) between the wedges, which is necessary so that the door does not subsequently become deformed.

Finally, the canvas is sanded.

All that remains is to make a door frame and hang the panel on hinges or awnings. The easiest way to make a box is from ready-made box timber, where a quarter has already been selected. Or from ordinary timber, but you will have to cut a quarter yourself.

The box for connecting the planks is either edged at 45 degrees, or a tongue-and-groove design is made, or, in the most primitive case, it is simply attached end-to-end with self-tapping screws. (The ends at 45 degrees are fastened obliquely)

IMPORTANT! The sauna uses self-tapping screws only with anti-corrosion coating.

When choosing hinges, take stainless ones, preferably brass. Suitable designs are overhead and mortise. For more information about hinges, see the article about door fittings.

Features of choosing a door

Wooden doors to a sauna must meet some parameters that are worth knowing before making a purchase. There are certain requirements that are worth listening to.

For example, standard sizes are used for the rest room and the front door, but they should be different for the washing room and steam room.

Door size

A wooden door for a sauna is made according to slightly different parameters. Everything here leads to saving terla.

And first of all, this concerns the dimensions:

Doors should be smaller and they usually correspond to a height of up to 180 cm. Sometimes a size of 150 cm is even used

The width ranges from 55 cm to 70 cm; Here you also need to pay attention to the manufacture of the threshold. It is not recommended to make it less than 15 cm

These dimensions are used only for steam rooms and washing rooms.

Selecting the material

As we said earlier, wood can be considered the best option.

But you can also use combinations, for example using glass:

It's very easy to order!

Buying doors in our online store is profitable! All presented models are distinguished by high quality, original design, optimal prices and a guarantee from the manufacturer. We will promptly place your order and organize careful delivery to any location in Russia!

Get a 10% discount on Eco Flue chimney (except discounted ones) upon pickup!

We also inform you that the discount on pickup when paying by card or when ordering from the Market basket does not apply.

Advantages of glass doors in a steam room

By and large, these shortcomings cannot be taken too seriously, because most of them are easy to fix. But the advantages of these products should be discussed separately.

As for the material, it is better to choose stainless steel hinges, which do not rust or wear out too quickly.

The fittings also include door latches. In inexpensive models of glass doors, ball latches are often installed, however, they are short-lived, wear out quite quickly and can jam at any time. It is unlikely that anyone will object that it is not particularly pleasant to be locked inside a steam room when you urgently want to get out and cool off. But magnetic latches are the best option for a sauna. They are very durable and never jam.

- glass sheet;

- hardwood timber measuring 4x80 mm;

- door hinges;

- fittings (wooden or metal);

- closer;

- soft silicone seals;

- platbands;

- fastening elements (anchors);

- polyurethane foam;

- means for impregnation of wooden structural elements.

Door installation tools:

- electric screwdriver;

- hammer;

- hacksaw;

- building level;

- construction pencil;

- tape measure, square.

Installing a steam room door with your own hands

Therefore, if maintaining high humidity is not critical for you, feel free to install glass; it will not sweat. However, it must be said here that the atmosphere in a steam room with high convection is not compatible with the regime of a Russian bath. This microclimate is already closer to a Finnish sauna.

Another important disadvantage of glass structures is that they have a minimum height of 1.8 meters. When arranging a steam room for use in Russian bath mode, this can become a big problem. To get a good steam cake, there must be at least 40-50 cm from the top edge of the door to the ceiling, which leads to the need to design a steam room with ceilings of at least 2.3-2.4 meters.

In a Russian bathhouse, where high humidity is of particular importance, only glass doors should be installed in wooden frames with a threshold and a seal around the entire perimeter. Often when purchasing glass doors, they are taken without a threshold or without a seal, which leads to excessive ventilation of the steam room and disruption of the necessary microclimate.

Glass has a feature that can be a significant drawback in wooden baths. This feature lies in the impossibility of changing the dimensions of the canvas. If a wooden bathhouse changes the geometry of the internal walls during the shrinkage process, then you can always trim the wooden door a little and continue to use it.

Since there are some details you may or may not like:

- This material is environmentally friendly and will not harm a person even in a wet environment;

- Glass doors to the bathhouse perfectly tolerate high humidity and temperature and therefore will last for quite a long time, and under the action of the listed loads will not change their structure;

- The disadvantage can be considered the possibility of damage to the canvas by mechanical means. But this issue is being resolved and it is possible to apply an armored film to the surface;

- Glass doors to the bathhouse are sufficient (see Installation of glass doors in residential and public buildings) and this is completely possible to do with your own hands and without resorting to outside help;

- This design visually enlarges the room and therefore for small rooms it is simply a godsend;

- A glass door for a sauna will not require a lot of maintenance, unlike a wooden structure;

- Glass bath doors are transparent and this confuses some. But this issue is easily resolved and the glass can be tinted, we will talk about this below;

- The price of the material is not high and is significantly lower than some types of wood.

If you take them into account when purchasing, then you will not be disappointed at the end of the installation:

Glass doors for baths should be selected according to glass thickness, this indicator should not be less than 7 mm

- The glass door for a bathhouse must fit well enough to the jamb, otherwise there will be a draft and if you installed such a door in a steam room, then heat will escape;

- The fittings for glass doors to the sauna should not be heated, otherwise you may damage the skin.

How to choose

The materials from which doors are made must withstand high temperatures and humidity - therefore wood and glass are most preferable. Glass doors and inserts are made of high-strength heat-resistant glass; for wooden structures, wood species are used that release beneficial substances when heated, such as linden, aspen, and fir. Hardwood species are used for the frame - oak, larch, aspen.

Features of different types of wood:

Advantages of different types of doors for a bath:

Door materials

Each owner of the plot can independently decide which design and style of the bathhouse to choose. Manufacturers made sure that everyone could choose the most suitable material for the job.

Design option for a wooden door with forged elements

Most often, the choice is made on the following raw materials for making doors:

- Wood.

- Glass.

- Plastic.

- Metal.

Each of these materials has its own advantages, disadvantages and features. Therefore, before placing a bet on any of them, you need to familiarize yourself with the nuances.

Wood

There are different materials for making doors leading to the bathhouse. People choose to finish the structure using eurolining prepared for the process, while other owners prefer to buy a solid frame and carry out the construction on their own.

Homemade wooden door for a bathhouse

In any case, wood is at the top of the list of materials for bathhouse doors.

Material advantages

- Resistance to moisture.

- Adaptation to temperature changes.

- Wood itself is a heat insulator, so the owner of the site will not have to spend a lot of money on additional materials to insulate the canvas.

- And of course, aesthetic characteristics. Wood fits perfectly into the overall interior of the bathhouse. A wooden door will look harmonious and create a pleasant atmosphere in the room where you can steam.

Flaws

The material requires additional processing and not all types of wood are suitable for bathhouse door construction.

Important nuances

Also, due attention should be paid to the question of what material to make the door handle from. It makes the most sense to also use wood for this purpose, because metal, plastic and similar materials under the influence of high temperatures can become deformed and also heat up, which reduces the level of safety in the bathhouse;

Therefore, when the question comes about what material the entrance door to the bathhouse should be made of, it is worth paying attention to wood

Therefore, when the question comes about what material the entrance door to the bathhouse should be made of, it is worth paying attention to wood

It is best to give preference to aspen or linden wood. Internal doors leading to the steam room can be achieved by installing a glass door.

Glass

To enter the steam room, as well as the shower room located inside the steam room, glass doors are often installed.

Advantages

- This design looks harmonious in the opening.

- The glass door is easy to clean.

- The material tolerates high temperatures well, which are not uncommon in a steam room.

- There are many designs of glass doors, so everyone will choose the best option for themselves.

Flaws

- the cost of such a design is quite high, because the glass must be durable and quite thick if the question is about a door;

- You won’t be able to make such a door yourself, unless the owner of the site with the bathhouse has his own workshop for the production of glass products.

In any case, the glass in the doorway of a steam room or shower looks elegant and harmonious.

Plastic

If you prefer plastic, you need to choose a heat-resistant one; other options are not suitable for installation in a bathhouse.

The process of installing a plastic door to a bathhouse

Advantages

- Heat-resistant plastic is a fairly durable material.

- This door raw material is durable.

- Withstands changes in air temperature.

- Able to tolerate high levels of indoor humidity.

Flaws

The material is not natural, which means it will not release aromas into the air that one would like to hear in a steam room or dressing room.

Design options for plastic doors for baths

Metal

If you wish, you can create an armored metal door with your own hands, however, this will require additional materials and tools.

Advantages

- Such a canvas will certainly protect the dressing room from drafts.

- This design looks harmonious.

- A large selection of designs of such canvases will help satisfy the needs of even the most demanding apartment owners.

Flaws

- high price;

- such a canvas is not suitable for installation at the entrance to the steam room.

The choice of material depends solely on the preferences of the owner of the land plot. Any raw material will fit perfectly into the space of the bathhouse, the main thing is to do the work with soul.

Preparatory activities

Choosing a wood species

It is better to avoid coniferous wood. Although it is less susceptible to rotting, it contains resins. This means that their fumes cannot be avoided. Therefore, a DIY door to a steam room made of pine or spruce is not the best solution. What is recommended?

Aspen, oak, alder. But experts advise using mainly linden or larch. The first is interesting because when the temperature rises, it releases substances that have a beneficial effect on the body. However, in terms of durability, it is clearly inferior to larch; This tree becomes stronger when wet, therefore it can stand at the entrance to a bathhouse or steam room for years.

Selection of lumber by size (cm)

For solid wood canvas:

- Cross members: timber 6 x 6 (8).

- Door: tongue and groove board, the optimal thickness for a bathhouse is 2.5 - 5. The width is chosen so that you do not have to cut samples to length, depending on the dimensions of the opening.

For prefabricated fabric:

- Box and frame: timber 6 x 4 (6).

- Door: board 12 x 3.5.

- Sheathing: wooden lining, thickness 1.2.

Wood processing

- This mainly applies to hardwood: impregnation with antiseptics is mandatory. Otherwise, in a bathhouse, a wooden door will not last long. There are enough appropriate drugs, but when choosing, you need to familiarize yourself with their component composition. The product used should not release toxic compounds at high temperatures.

- All wooden parts are carefully sanded (by machine or by hand).

Taking measurements of the opening

Before determining the required dimensions of the block, you need to perform a number of activities:

- clean the opening. This will make the process of making a bathhouse door with your own hands easier, since the dimensions will be taken as accurately as possible, and you will not have to do any adjustments;

- check the correctness of the geometry and, if necessary, align the opening.

- The height is measured in two places, along the edges of the passage in the wall; width - at several levels.

- If the bathhouse is made of wood, then a door without a frame is not installed. Therefore, its dimensions are taken into account. This is a separate topic and should be studied if necessary.