For the most part, owners of country plots set up a bathhouse on their property, it doesn’t matter if it’s a permanent home or a summer house.

Traditional construction requires wastewater disposal. Of course, you can buy a ready-made system, but the designs are expensive. There is always a solution - to make a septic tank for a bathhouse with your own hands.

The first thing to decide is whether the building will be equipped with a toilet.

Drains from a bathhouse without a toilet contain epidermis, soapy water, a little grease and leaves from brooms. This allows the installation of any system without pumping. The presence of a latrine in a building changes the nature of the water; therefore, not every septic tank can cope with sewage waste.

Installation

Before starting excavation work, the sewer pipe must be removed from the house. It is from this place that you will dig a trench with a slope towards the septic tank. Next, we make a septic tank from a barrel in the following sequence:

- From the place where the sewage system exits the house, we dig a trench 1 m wide to the place where the septic tank is installed. At the same time, we make a slope of the bottom of the trench taking into account a 2 cm drop for each meter of length. We are digging a pit under the septic tank. Its dimensions should be 20 cm larger than the size of the barrels. At the bottom of the pit we make ledges 10 cm high to install each communicating container at different depths. The first camera will be located above everything.

- Since the septic tank has impressive dimensions but is light in weight, groundwater can easily lift the container to the surface. To prevent this from happening, a concrete pad is made at the bottom of the pit. To do this, first a cement-sand mortar is mixed, then a sand cushion 10 cm high is made at the bottom of the pit. It is leveled and compacted. After this, a reinforcing mesh with outlets for attaching the septic tank is laid at the bottom. The bottom is filled with a layer of concrete 150-200 mm high.

- After the concrete pad has hardened, you can begin installing the barrels. Each barrel is mounted on a separate step so that the next container stands 10 cm lower. There should be a distance of 100-150 mm between the cameras. We attach the barrels to the reinforcement outlets in the bottom using a steel cable.

- In the first chamber, at the required height, we cut a hole for a supply pipeline with a diameter of 110 mm. We put a rubber seal into the hole and additionally seal it with mastic. Now insert a tee into the resulting hole. Then we will connect the supply sewer pipe and ventilation to it.

- At a height below 100 mm from the first hole, on the other side of the first barrel, we make another hole for overflow. We also seal it with a rubber seal and insert the corner fitting.

- Cover the first barrel with a lid and install a ventilation pipe.

- Now we cut a hole on the side of the second chamber and insert the corner fitting into it. We seal the hole with a rubber gasket. We connect two daughters with fittings with an overflow pipe.

- On the back side of the second container we make a hole at the level of the middle of the barrel to install an overflow into the third chamber. Install the cover.

- The third chamber is a sealed well with a hole for overflow from the second chamber. We connect the second and third chambers with a pipe. We install the cover. If a drainage well is used instead of the third chamber, then to equip it you need to take a corrugated pipe with a diameter of 1 m. A hole for overflow is cut in its wall, and a gravel-sand layer 300 mm high is installed at the bottom. It is better to lay a layer of geotextile under the layer. Through it, water will filter into the ground.

- Backfilling of a septic tank is carried out with alternating layers of sand and concrete. After making a layer 200-300 mm thick, it is moistened with water and compacted.

- The upper part of the treatment plant is insulated with foam plastic and backfilled. Only manhole covers and ventilation pipes should remain above the ground.

Video guide to building a septic tank from barrels:

At what distance should the septic tank be from the bathhouse?

How to choose a place to install a septic tank

Construction and sanitary standards strictly limit the distance from low-capacity treatment facilities to a residential building. According to the standards, it must be at least 5 m.

The bathhouse does not belong to residential premises. But taking into account the possibility of foundation subsidence due to accidental leaks, the septic tank is installed no closer than 3 m from the outer wall. If it is not possible to maintain the gap, it is recommended to lay the sewer pipe in a sealed case.

Metal barrels - temporary wastewater collection system

When arranging a septic tank from iron containers, it is necessary to dig a pit of suitable dimensions and be sure to concrete its bottom. Then prepare two barrels and drill holes on their sides. You will insert the outlet of the drainage pipe and the inlet of the overflow pipe into them. Remember - the pipe product coming from the house is always inserted into the first barrel with a certain slope. Due to this, wastewater will flow by gravity into the septic tank without any problems.

Important pro tips to follow when installing a sewer system made of metal barrels:

- the second metal container should be installed in the pit slightly lower than the first;

- use barrels with a volume of at least 200 liters;

- high-quality insulation of the septic tank on all sides is mandatory (there is no need to lay heat-insulating material only at the bottom of the pit);

- The tanks are backfilled with soil; the top of the septic tank is covered with roofing felt and lids made of wood or iron (do not forget to make a hole in the coating through which wastewater will be periodically pumped out of the tanks).

Construction of a sewer system from metal barrels

If you want to increase the volume of the structure in question, it is possible to install several barrels on top of each other and weld them together. In addition, additional iron jumpers can be mounted. They will provide more reliable fastening of the barrels. All joints between barrels should be thoroughly waterproofed. For this, hot bitumen is most often used.

Let's say it right away. No matter how you set up a system of iron barrels, after 3-4 years the metal tanks will have to be replaced. They will begin to rot and rust under the influence of aggressive wastewater.

Make a septic tank for a bathhouse or choose a ready-made one - which is more profitable and practical

It is difficult to unequivocally answer the question which system is better. It all depends on the amount of water consumed and how often the bathhouse is used. The level of wastewater also plays an important role.

The main disadvantage of ready-made septic tanks is their cost. Making a homemade structure will cost 3-4 times less. At the same time, it will last no less than an industrially produced septic tank.

If you come to your dacha only in the summer, buying expensive equipment is not practical. Make the system yourself from scrap materials.

If you have a bathroom, toilet, sauna and swimming pool, it is better to immediately buy powerful cleaning equipment.

Choice of material: metal or plastic

In order to save money, very often a septic tank in a country house is made from barrels that previously served another function. For example, they could be used to store grain, sand, cement and other bulk substances. The container can be metal or plastic, the main thing is its tightness.

If the question of purchasing a barrel still arises, then it is better to give preference to plastic. And that's why:

- wider range on the market;

- resistance to corrosion and aggressive effects of wastewater;

- absolute tightness over a long service life;

- installation without the use of lifting equipment due to its low weight.

To be completely objective, it should be clarified that the last point is only partly an advantage. The small mass of plastic makes it necessary to attach the container to a concrete base to level out the buoyant effect of groundwater. In this regard, a septic tank made of iron barrels is considered more preferable, since it does not require anchoring.

Any barrel that meets the tightness requirements can be suitable for a sewer sump.

Nuances of calculating the required volume of capacity

To organize a septic tank from concrete rings, it is necessary to calculate the volume based on daily water consumption. According to the standards, one permanent resident receives 200 cubic liters of water per day.

Image gallery

Photo from

Specifics of a single-chamber septic tank

Installation of three chambers in one well

Average volume of a two-chamber septic tank

Volume of multi-chamber septic tanks

The first container for settling wastewater should have a volume of at least three times the consumption (200 l) for each person. The second container with a bottom for settling should have a volume equal to 1/3 of the size of the first.

The rules for constructing a two-chamber treatment plant can be found in our other article.

The number of rings can be determined by dividing the volume of the container by the volume of the ring. Their sizes come in small, medium and large.

For the calculation, the parameters of an average-sized ring will be used. KS-10-9 whose internal diameter is 1 m and height is 90. One ring has a volume of 700 cubic liters

For a family of two:

Volume of the first container = (200*2)*3= 1,200 liters. Volume of the second and third containers = 1,200/3 = 400 liters.

Number of rings for two containers = (1200+400)/700= 4 Number of rings for three containers = (1200+400+400)/700= 5

Bottom line: 2 rings for the sump, 2 for the sedimentation tank and one for the drainage well.

For a family of three:

Volume of the first container = (200*3)*3= 1,800 liters. Volume of the second and third containers = 1,800/3 = 600 liters.

Number of rings for two containers =(1,800+600)/700=4 Number of rings for three containers =(1,800+1200)/700= 6

Result: 2 rings for the sump, 2 for the sedimentation tank and two for the drainage well.

Do-it-yourself septic tank from barrels. Step-by-step instruction

After preparing everything you need, you can begin installation. This process is carried out in stages:

- Digging a trench.

- Bottom cushioning.

- Laying geotextiles.

- Backfilling of crushed stone.

- Installation of barrels.

- Pipe installation.

- System check.

- Backfilling the trench.

Careful measurements should be taken before digging a trench. To make your work easier, you can lay out all the parts on the ground: pipes, barrels. Then mark the contours of the system and start digging holes. To facilitate the work, you can use the services of an excavator, due to which the hole will be of the required size.

Then you should pour a layer of sand at the bottom of the trench, which will serve as a shock-absorbing cushion. The places where the first 2 barrels (filtering) will be located should be concreted. The place under the 3rd (last) barrel is covered with geotextile and filled with crushed stone.

Installation

Before installing barrels in a pit, it is advisable to first connect them together with pipes. After all, doing such work in a pit will be very inconvenient. Holes for pipes are cut in the upper side parts of the barrels.

The joints must be treated with sealant. For these purposes, it is best to use a car one. The first two barrels will filter the wastewater, so they are installed with a bottom. In the first barrel, solid waste falls to the bottom, and in the second, smaller particles settle at the bottom. The third barrel receives 65% purified wastewater, and this liquid goes into the ground. That is why the bottom of the last barrel should be cut off.

The barrels must be connected to each other with pipes through which the liquid will flow from one compartment to the other. When such a structure is ready, it should be installed in the prepared pit. At the bottom of the third barrel it is necessary to pour a layer of crushed stone to a third of its volume. Then a sewer pipe is connected to the first barrel, which departs from the house. In order to guide the pipe at an angle, it is recommended to use wooden pegs, which are mounted at different levels. Using a building level, which is applied to the top of the pegs, the required angle is set. Then a layer of sand is poured, followed by a layer of gravel on top so that it does not cover the tops of the wooden marks.

Ventilation and insulation

Ventilation of the installed septic tank should be provided. To do this, a pipe with a protective canopy at the top is brought out to protect against precipitation.

If the barrels are installed above the freezing point of the soil, then they should be insulated. When all the parts are connected and the joints are treated with sealant, the system is checked. To do this, water is supplied to the first container, and then possible leaks are checked. If they are missing, then you can backfill the septic tank.

The pit is completely filled with gravel. Then a layer of geotextile is laid on top of the barrels, and after that they are backfilled with soil. It is necessary to ensure that the lids of the barrels are not covered, otherwise it will be difficult to reach them during servicing in the future.

The area is sandy, the groundwater level is low, water is below 4 m or there is none

The combination of low groundwater level and well-draining soil are ideal conditions for constructing a septic tank made of reinforced concrete rings. Moreover, in this case, you can do without a filtration field, so the capabilities of a filter well are sufficient. There may be several design options; we have identified the simplest and most effective.

Scheme 4. 3-chamber septic tank with one hatch

Description:

- Compact 3-section septic tank with filter well.

- 1 hatch for servicing the entire system.

- Saving on additional rings - they are needed only for one well.

- Filter layer throughout the entire volume around the wells and between them.

- The bottom of 2 wells is concreted. There are no holes in the filter well, there are holes in the walls of the lower ring.

The following video shows the construction process without unnecessary comments. The main part of the work is carried out in 1 day. For increase

Conclusion:

This scheme saves space for installing external sewerage; there is no need to buy additional rings and hatches for 3 wells.

Scheme 5. 2-chamber septic tank with a filter well

Description:

- A simple diagram of a 2-chamber septic tank with a filter well.

- Can be installed and put into operation in 1 day.

- You can get by with wells made of two rings.

- The bottom of the first well is necessarily solid.

The simplified wastewater treatment scheme is due to the excellent drainage properties of the soil. In the video below, the author explains in detail the role of each structural element of the treatment plant. The video also contains a lot of food for thought, which will make you feel more confident when installing a septic tank.

Conclusion:

scheme for permanent or seasonal use. Takes up little space on the site, copes with volley discharges of wastewater. Large drainage layer resource. Pumping sludge from the first chamber no more than once a year.

Characteristics and cost of materials

Plastic or metal containers are suitable for sewage. To anticipate possible installation errors, you should know about the advantages and disadvantages of materials. The comparison table will help you figure it out:

| Plastic | Metal | ||

| pros | Minuses | Advantages | Flaws |

| Light weight, easy to ship and install | It is required to be securely fixed to the foundation so that the spring flood does not destroy the system | Robust design, no additional fastening required | |

| Frost can compress the container | Tough, not afraid of exposure to cold | ||

| Completely sealed | Waterproof if the walls and bottom are intact | ||

| Are not afraid of corrosion and the harmful effects of chemicals contained in wastewater | Over time they are destroyed by rust, the service life depends on the reliability of treatment with an anti-corrosion compound |

Mostly products made from other liquids are used, which are sold wholesale and individually. Prices for used ones are low. There are few manufacturers of new barrels for the construction of a small septic tank.

It is better to buy unwashed barrels of fuel and lubricants. They form a film on the inner surface that protects against corrosion.

Manager V.N. Martynov

Cost table for 200 liter barrels:

| Salesman | Product material | State | Price | Characteristics |

| Novera, Chelyabinsk | Metal | Boo | 500 | Washed, with cork |

| PromTorgSnab-NN, Nizhny Novgorod | Iron | Boo | 700 | With clamp and cover |

| Bel, Kemerovo | Plastic | Boo | 1000 | |

| Steel | Boo | 300 | ||

| Stainless steel | Boo | 1000 | ||

| Trading House "Brig" | Plastic | New | 1700 | Durable, wear-resistant material |

How to make an aeration field

If the groundwater in the area is high, it is necessary to use a different septic tank design: instead of the last chamber - a filtration well - a filtration field is installed. It is done like this:

- A trench is dug in a suitable place, which at one end rests against the second tank of the treatment plant. The depth of the recess is 60 - 70 cm, and the width should be such that two drainage pipes with perforated walls can fit in it.

- The inner surface of the trench is covered with geotextile. The cut must be wide enough, since it will also need to cover the pipes laid in the trench.

- The trench is filled halfway with crushed stone, which must be leveled and compacted.

- It is necessary to lay perforated pipes on the crushed stone layer, connecting them at one end to the second barrel. Holes in the barrel should not be cut next to one another, but at a certain distance, so that the angle between their axes when viewed from above is 45 degrees.

- A 10-centimeter layer of crushed stone is poured over the pipes. Then the entire structure is “wrapped” in geotextiles, laying its edges with an overlap of 15–20 cm.

- The filtration field must be covered with soil. Now you can grow a lawn or flower bed here.

Instead of geotextiles, you can use banner fabric - a durable waterproof material coated on both sides with a thin layer of PVC.

How to do without a factory container

Modern building materials make it possible to build any container for wastewater. You can make an inexpensive and high-quality system yourself. Two types of sewage system can be installed:

- Septic tank for a bathhouse without pumping;

- Closed sump.

The latter option eliminates the drainage of wastewater into the soil. He needs frequent release from water. An alternative is to install a well with drainage. This is how human waste products sink to the bottom, and the purified water moves into the next container.

If a septic tank that is not pumped out is installed incorrectly, it can pollute the environment. If all the requirements are met, then this design will become very convenient without requiring any costs.

To create a pit for draining water, you can use a septic tank for a bathhouse made from a barrel. You will need three pieces. Two of them will be settling tanks, the third will be a drainage device. The drainage from the bathhouse contains only soapy water, because of this the help of a sewer truck is not required.

Important! A septic tank can be installed if the groundwater level is below four meters.

To install a septic tank for a bathhouse with a toilet, barrels made of plastic, iron and metal are used. There are different types, the most popular is a septic tank for a bathhouse made from a 200 liter barrel.

Many people use plastic barrels as a septic tank. They are convenient and economical in terms of water consumption. However, if a washing machine or shower is installed at the dacha, then the container will not be able to cope with the amount of water being processed. These designs are convenient because they allow you to increase the volume of sewerage. You just need to add the missing number of barrels.

Have you decided to make a septic tank for a bathhouse without pumping? What material to choose? Bricks and Eurocubes, poured concrete and rings made of the same material are suitable for this. It is better to take clinker brick, of all types it is the most resistant to aggressive environments.

The shape of the structure can be round or rectangular. It is imperative to take care of waterproofing. For this purpose, a special mastic is used. Cement mortar is used inside.

A septic tank for a bathhouse made of concrete is a more profitable design. On its basis, a screed of sand and cement is installed, then formwork made of plywood or boards is installed, and the mortar is poured.

It is impossible to install a septic tank made of concrete rings without the help of special equipment. This is a more expensive method. When laying concrete rings in a pit, a concrete base is constructed.

The next stage is the installation of concrete rings. The structure is strengthened with a solution of sand and cement

The issue of tightness is given due attention

Ready-made models

If you don’t have time to worry about how to make a septic tank for a bathhouse with your own hands, it makes sense to purchase practical and functional devices at an affordable price. Popular models:

| Model name | Characteristics | Price range |

| Septic tank “Triton” Mini – 750 l/Micro – 450 l | Double-chamber/single-chamber. Light weight – 70/40 kg. Withstands temperatures down to -30 ⁰С. Equipped with a post-treatment system. | The cost of the kit with infiltrator, lid, neck is about 21,000/12,000 rubles. |

| DKS 15 and 15M | Capacity – 450 liters per day. Autonomous, easy to maintain. | About 29,000-33,500 rubles. |

In addition, there are a large number of deep cleaning stations such as “Topas”, “Unilos”, etc., the price of which will be much higher. However, the optimal solution for a bathhouse is simple installations with mechanical filters and sedimentation tanks, which, if necessary, can be equipped with a soil purification system.

Making a septic tank from barrels with your own hands

You will need two barrels. Their minimum volume is 200 liters. It is advisable to take large-volume barrels. The material from which they are made must be resistant to corrosion and caustic substances. This system is ideal for sewerage in a country house. You can do almost all the work yourself, if you have certain skills, desire, and tools.

Also buy a couple of tens of meters of drainage pipe, vent pipes and fittings (also vent). The size of the pipes depends on how far from the house the septic tank will be located. You need to cut a hole in the top of both barrels. Its diameter depends on the size of the flange you insert there.

In the first barrel for the septic tank, you need to cut another hole on the side, according to the diameter of the fan fittings you purchased. Due to the fact that there is a radius of curvature on the side surface, installation of a flange is not possible. The joint must be treated with a waterproofing mixture. It is not advisable to take silicone; it is better to purchase mastic.

Since drainage pipes need to be connected to the second barrel of the septic tank, we make two holes in the side surface. The first barrel should be 20 cm higher than the second. It is better to make a concrete pad as the basis for them. Do not forget to check the integrity of the containers and the quality of the waterproofing provided before connecting to the sewer system.

After you have installed the containers, connected them, connected the drainage pipes and made a drainage filter from crushed stone, you need to check the slope of the pipes using a level. If necessary, increase it. The constructed septic tank must be filled very carefully so as not to damage the container.

Connecting a septic tank from a barrel in a country house to the sewer system

It is necessary to allocate a place for installing a septic tank. Although you will make it from barrels, you will also need the service of sewer trucks. Therefore, it is necessary to ensure free access to your septic tank. Next you need to dig a trench. Its size depends on what kind of barrels you use and what climate zone you live in. In the case when, literally after 30-80 cm, a layer of permafrost begins, the arrangement of the septic tank is practically no different. You need to make a layer of fur coat from crushed stone, sand and tar paper. Thanks to natural processes in the drainage mass and coat, the wastewater will not harden, even in severe frosts. At the same time, it is better to equip the sewerage system in winter. If this is impossible due to timing, then you need to ensure that the frozen ground does not thaw.

The slope of the sewer pipe connected to the barrel should not be less than 2 cm per meter of length. Also, if during installation it is necessary to make turns of pipes, then the angle must be at least 90 degrees. In this case, it should be possible to clean such corners. To do this, you need to build a rotary well. The trench must be dug in such a way that it does not go through areas where physical damage to the pipes is possible. Unless otherwise provided by the project, there cannot be less than 30 cm of soil from the top edge of the pipe to the ground.

After you have dug a trench, you need to pour fine crushed stone onto its bottom, followed by sand. Compact the resulting cushion. Lay a pipe and put crushed stone and sand on top again. This is an economical option. If funds allow, the side walls of the trench are lined with red brick. This is done to ensure that during heavy rains or a seasonal rise in groundwater levels, the sewer pipe does not move with the subsequent formation of a leak.

In order not to damage the sewer system in the future, it is necessary to draw up a plan for its placement on the site. In addition, beacons are installed along the pipes. They do not have to be tall, 10 cm is enough. But at the same time, their color should be bright enough to catch the eye.

Popular articles:

We choose an inexpensive septic tank for a dacha, design and installation on a turn-key basis. What is better than a septic tank Tank or Topas (Topaz)? Autonomous sewage system Topas (Topaz) for a dacha, country house, sewer system for a private house Malfunctions Topas, their causes and solutionsSeptic tank Tank for a dacha antiseptic for a country house

Advantages and disadvantages

The popularity of concrete septic tanks and the large number of positive reviews are due to a number of undeniable advantages of these structures:

- The availability of materials and simple design make it possible to build treatment facilities yourself.

- Operation does not require the installation of drainage pumping equipment, which greatly simplifies use and significantly saves the budget.

- High mechanical strength and durability of concrete rings guarantee a long service life and overall reliability of the septic tank.

- Ease of maintenance of two- and three-chamber models is due to the absence of the need for regular pumping of liquid masses.

- Due to its large useful volume, the septic tank is suitable for permanent use as the main sewerage system. The risk of overflow and backflow of dirty masses is eliminated.

- The walls of the tanks are highly resistant to the aggressive effects of sewage.

- The large weight of the concrete rings ensures good stability of the structure and does not allow groundwater to displace it from the ground.

- Due to the frost-resistant properties of reinforced concrete products, rings can be used for arranging septic tanks in any climate zone. However, in places with a sharply continental climate and in northern latitudes, additional thermal insulation of the pipeline system and tanks will be required.

The disadvantages of concrete septic tanks include the need to carefully seal the joints between the rings. It is also noted that it is impossible to use structures in flooded areas due to the increased hygroscopicity of concrete. The weight of the rings requires the use of construction equipment during their transportation and installation, which is also considered a disadvantage of the design. In addition, single-chamber tanks require regular pumping of sewage, and multi-chamber tanks require periodic cleaning of the sump. Many users also note that if the septic tank is not properly maintained, an unpleasant odor may spread.

Making a septic tank from barrels with your own hands

To ensure normal wastewater treatment, it is advisable to use two chambers in the septic tank: in the first, heavy substances settle to the bottom, and in the second, the clarified water settles before it is discharged into the ground.

Below we will look at an example of arranging a septic tank from double-plastic barrels with our own hands. This instruction can be considered universal, since most of the points apply to the installation of metal containers.

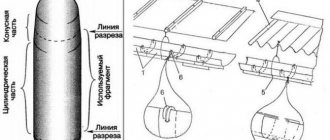

Installation diagram

The design of such a treatment plant is not particularly complicated. The barrels are sequentially connected to each other via an overflow pipe, with the second container located 10-20 cm deeper than the first. Holes are cut in each tank for connecting sewer pipes and ventilation outlets

It is important to maintain the correct position of the inlet and outlet openings relative to each other: the inlet should be located 10 cm above the outlet

Installation diagram of a septic tank made of two barrels

The clarified water can be discharged into a filter well or a filtration field can be used. The well is used when the groundwater level is low and the soil has good water permeability. For its installation, a bottomless barrel is used, in the lower part of which a 30-centimeter gravel cushion is made.

The filtration field has a higher capture area, due to which water is drained even in conditions of low soil throughput. In this case, water is discharged from the second chamber of the septic tank into a drainage pipe, which is located in a layer of gravel or crushed stone.

The number of drainage pipes in the filtration field directly depends on the volume of wastewater

List of materials

To complete the work you will need the following materials:

- two barrels with a volume of 250-1000 l (depending on the amount of waste);

- sewer pipes with a diameter of 110 mm for external installation (orange);

- corners and tees for connecting pipes;

- glue and sealant for PVC;

- fine crushed stone (2-3.5 cm);

- cement;

- sand.

The set of tools for installing a septic tank from plastic barrels is standard: a shovel, a rake, a level, a jigsaw and a container for mixing the solution.

Stages of work

- Holes for sewer pipes and a ventilation riser are cut in the barrels using a jigsaw. For the inlet hole, 20 cm is removed from the top edge, and for the outlet hole, 30 cm. The gaps formed between the holes and pipes are filled with sealant.

Connections of elements of a homemade septic tank from plastic barrels

- The size of the pit is calculated in such a way that there remains 20-30 cm between the soil and the wall of the tank. The walls of the pit are leveled and the bottom is compacted.

- Before installing the barrels, the bottom of the pit is filled with a layer of concrete, in which several eyes or pins should be provided for anchoring the septic tank.

The tank is secured with a strong cable or straps

- To protect the walls of the septic tank from seasonal soil movements, the gap between the barrels and the soil is filled with a sand-cement mixture. To prevent the barrels from deforming as a result of the pressure created by the backfill, they are pre-filled with water.

- In the immediate vicinity of the septic tank, a hole is dug for a filter well or a filtration field is made to drain purified water into the ground.

- When all installation work is completed, the barrels are covered with a layer of soil. If desired, this place can be hidden from others using grass and other vegetation, leaving only inspection hatches and ventilation on the surface.

Septic tank as an element of landscape design

After completing all the steps in this instruction, you can build a simple septic tank from plastic or metal barrels with your own hands. For the installation of more complex treatment facilities, it is better to use the services of professionals.

Owners of country houses do not want to give up the usual city amenities and have to install a sewer system on their site themselves. Often it is a simple cesspool made from a barrel or something else, but if there is running water and household members actively use plumbing fixtures, its capabilities will clearly not be enough.

The dacha sewerage scheme includes a sewage collector, internal and external pipeline networks. Depending on financial capabilities, the collector is built from bricks, concrete rings, large car tires, Eurocubes or 200 liter barrels.

The principle of operation of a septic tank

The main task of the treatment plant is the accumulation and filtration of wastewater. The design is a sealed container in which there are 2-3 interconnecting sections. If the system is autonomous, the fluid moves by gravity through the overflow pipes. Volatile septic tanks use pumps and airlifts.

Figure 1 - Non-volatile septic tanks

Figure 2-Design of a biological treatment station

After the water enters the septic tank through the sewer pipe, the cleaning processes begin:

- In the first compartment, solid particles precipitate, and most of the fats, detergents and other components with a dense structure are retained.

- In the second chamber, anaerobic fermentation develops without oxygen. Microorganisms come into play and break down organic compounds to produce methane, hydrogen and carbon monoxide.

- In the third section, which is equipped with the latest generation designs, anaerobic fermentation passes into the aerobic purification stage. Bacteria, in the presence of oxygen, decompose the residues into sludge that precipitates. The output is water with a contamination level of no more than 2%.

Septic tanks with three chambers allow for better water purification than two-chamber ones. To speed up the decomposition process, special bioenzymes are used. They develop their activity at temperatures from 10 to 35°C and access to oxygen. It was noticed that there are absolutely no odors around the treatment plant.

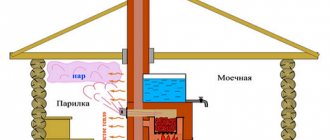

Option #1: drainage sewer ↑

The easiest way to make a sewer system for a drainage-type bathhouse with your own hands. It is suitable for small steam rooms designed for several people. For drainage, a small well measuring approximately 1x1 m is used. The depth should be below the freezing level of the soil. If the ground freezes to 0.7 m, then the well is dug to 1.5 m.

Clay is laid in a layer of 10-15 cm at the bottom of the finished pit. It should be positioned so that a slope is formed in the direction of the drainage. The clay layer is leveled so that the smooth bottom of the well takes on the appearance of a tray. The next layer is bulk material - crushed stone, gravel or sand. The thickness of this layer should reach 0.5 m and be above the freezing level. The hole is filled with soil on top of the bulk material.

Instead of a well, you can install a drainage pad. It is a trench 1 m long and deep, 0.3 m wide, filled to 20 cm with bulk material, and above - with soil to ground level. The pipe that leads from the bathhouse to the drainage well or pillow is thermally insulated.

The construction of a well and the laying of pipes should be done very carefully, because... If the drainage system for a bathhouse is not properly installed, the water will constantly freeze in winter, and the system may not work. Even worse, constant dampness will lead to the destruction of the floor in the room, and washing will be uncomfortable.

Drainage system for a bathhouse

If the liquid is not absorbed into the soil intensively enough, a pit is built where the wastewater is collected and then flows out further. To normalize the outflow of water, the pipe is laid at a slight slope in the desired direction. Any waterproof materials are suitable for pit construction.

The drain must be equipped with a water seal. To do this, the pipe is inserted at the bottom of the pit - 9-12 cm from the bottom, and a plate is placed on three sides. It does not need to be fixed so that there is a gap of 5-6 cm to the bottom. Thanks to this simple design, a water seal is formed that will protect the bathhouse from unpleasant odors of wastewater. When choosing pipes, it is better to give preference to polyethylene.

Construction of a pit

Most often, the floor is arranged in two ways:

- Leaking. The flooring is made of boards that are not attached to the joists, but are simply laid with small gaps - 5 mm. Thanks to this device, the boards dry out better and are less susceptible to destruction.

- Capital. The boards can be laid without gaps, but in this case it is necessary to make a slope. A tray is installed below to collect water. From the tray, the waste flows into the pipe and then into the pit.

Wastewater treatment is carried out through soil and sand. Lime, sediment, and organic compounds are trapped between particles, so the drainage system sometimes needs to be cleaned.

Bath floor

If the drainage system in a do-it-yourself bathhouse provides for a large distance between the water drainage point and the drainage system, then it is necessary to build an inspection well. It is made of concrete rings or laid out with bricks. The diameter of such a well must be at least a meter.

To prevent the building from freezing in winter, it is equipped with a double lid. Insulation is placed between the covers, which can be used as sawdust or soil. The inner wall is finished with any insulating material. The outer part of the well is also insulated.

Manhole diagram

Which septic tank is better for a bathhouse with a toilet?

If there are more serious contaminants than soap and skin particles, biological wastewater treatment facilities must be used. All organic matter will very quickly be processed by anaerobic and aerobic bacteria.

Purified water does not contain environmentally harmful components or unpleasant odors. Complete decomposition of waste helps to avoid soil contamination and the spread of infections.

Do-it-yourself septic tank made from barrels for a summer residence, which plastic barrels are suitable?

The best option for suburban housing that cannot be connected to a central sewer system is a homemade septic tank made from barrels. You need two containers, or preferably three. Their volume should be 200-250 liters each. The material from which they are made must be resistant to caustic substances from fecal matter and corrosion. They should only receive waste from the toilet, and for domestic waste a larger design will be required.

One of the most popular options is a septic tank made of plastic barrels.

Advantages of a septic tank made of plastic barrels:

- Thanks to their light weight, they are easy to transport and install yourself.

- Plastic is resistant to aggressive external influences.

- When completely sealed, penetration of untreated wastewater into the soil or flooding by rain or groundwater is excluded.

The disadvantages of plastic barrels for a septic tank for a summer residence include their lightness. It can cause it to rise to the surface when the groundwater level rises, thereby disrupting the operation of the sewer system.

Design of a sewer system and location of a septic tank

If your task is to sew your own dacha, then you don’t need to start with purchasing materials and selecting tools. The beginning of everything is drawing up a project. Designing a sewer system is one of the mandatory stages when installing a sewer system. The project includes both internal and external sewer systems, and therefore must be tied to a specific house and a specific site.

After the project has been prepared, you can determine the size of the pipes that will make up both the external and internal systems, as well as determine the necessary material for the work (for example, insulation for pipes, etc.) and the type of collector.

It should be noted that the diameter of the pipes is easier and more reliable to determine using regulatory documents - they indicate the diameters required for different volumes of wastewater. This is a very significant point, since pipes make up the lion’s share of the cost in a country sewer system, and an error can lead to significant financial losses. So, if the diameter is insufficient, then the sewerage system will simply choke, unable to cope with the required volume of wastewater, and if the diameter is too large, then the pipes will cost more - unnecessary, unnecessary expenses.

And also when designing a country sewer system, it is very important to choose the right place for installing a septic tank. This is especially important given the small size of dacha plots - you have to think about how to install a septic tank in order to comply with all the necessary conditions established by the regulations, and at the same time not reduce the usable area of the plot too much

How does it all work

The left barrel is the last! All water from it is pumped out by a drainage pump into a pit on the street (or a filtration well/filtration field - as appropriate). And the first barrel on the right is where the toilet drain goes, everything that doesn’t sink floats in it, and everything that has turned into silt sinks.

To speed up biological processing in the first barrel, constant aeration is carried out with an aquarium compressor (you can use something more productive - then the design will begin to strongly resemble a full-fledged automatic treatment station, such as Unilos Astra). It will also be useful to periodically add bacterial cultures through the toilet (there is a large selection in stores).

When summer comes, I’ll insert the pump into the first barrel and throw the end of the hose into the garden, clean the bottom of the silt, and then put everything back into place.

you need either a drainage pump with a float (price 1,500-2,500) or make a float for the baby so as not to constantly run around with the pump!

Digging a hole for ourselves

It is necessary to dig a hole (manually or using equipment, depending on your luck) for future installation, about 2.5 m by 3.5 m. The depth of the inlet pipe for draining wastewater.

To prevent freezing, you need to arrange it at least a meter deep. And from it to the bottom of the septic tank you need from 80 cm to 120 cm.

There's no need to dig any deeper. The horizontal dimensions are indicated for a family of 4 people; if you do more, it means your intervention is needed less often, which is only a plus.

But the cost of concrete will increase quadratically depending on the size. The dimensions shown in the figure guarantee 10 years of worry-free operation.

After pouring the concrete, due to the thickness of the walls, the dimensions will be reduced to 2 by 3 meters in plan. According to building codes, the volume of the chamber must exceed a three-day drainage.

Although, of course, calculating the volume of a septic tank is a purely individual matter. In any case, a bath and laundry day is taken as the norm.

When everything is washed, the floors are washed, etc. The proportions in the plan can be any, the main thing is that the volume matches

However, for any changes in size, the distance from the bottom point of the inlet drain pipe to the bottom of the septic tank must be left unchanged: the same 80-120 cm.

The remaining dimensions should take into account the thickness of the walls or the volume of concrete slabs that are used to create a two-chamber structure.

Naturally, the full depth of the septic tank is equal to this depth, plus the level of the drain pipe from the surface of the earth, which in turn is tied to the level of the pipe exiting the house, and the required pipe drop at a distance from the house to the septic tank.

Let us repeat, to prevent the pipe from freezing, it must be buried at least a meter.

It is highly advisable to dig a hole down to soil that allows wastewater to pass through well: sand and gravel, stone (not rock).

If you have clay soil on your property, dig deeper. Even if there is no aquifer at three meters deep, dig more, while simultaneously reducing the digging area, until your labors are crowned with victory and water begins to accumulate in the hole without rain.

The most ideal option is reconnaissance by combat digging.

Perhaps the local authorities or the management of the holiday village will tell you this.

Otherwise, you risk doing the same job twice. There have been cases when people rebuilt their septic tank after a year or two due to the fact that pure clay does not allow water to pass through. And then it turned out that only 50-60 cm had not been dug!

What are the differences? What types are there and in what case should they be used?

A large number of septic tanks for bathhouses have been developed. They have significant differences, representing containers made of plastic, metal, reinforced concrete of different volumes.

In addition to the material, these devices differ in their operating principle. The most recognized and effective method is biological treatment. Microorganisms that feed on waste in wastewater independently process human waste products.

Another simple method is partial purification and additional purification in the soil. So, passing through a layer of crushed stone, the wastewater ends up in the soil. This contributes to their more thorough cleansing.

Almost all designs work according to the same scheme. The first stage is to separate the dirty water from the feces by allowing them to settle at the bottom of the container.

Second stage: the water moves into the second compartment. Here it is further cleaned.

The third stage - the wastewater is clarified even more. At the last stage, the water is completely purified. Special filters can be used for this. The result is water that is not suitable for drinking; it is used only for technical needs.

Septic tanks can also be divided by type of installation. There are solid structures (made of reinforced concrete), as well as prefabricated ones.

Prefabricated reinforced concrete septic tanks are considered the most popular.

Arrangement of a simple

Building a simple septic tank for a bathhouse is not at all difficult if you figure it out and put in every effort. Many people choose this path, since the design will cost many times less.

The owner of the house can set a goal and equip a container on the site intended for wastewater, which over time is pumped out or cleaned in a special way, if the design provides for this.

It must be taken into account that every adult leaves about two hundred liters of waste per day. When calculating a design for one, you need to multiply this figure by three. As a result, we get six hundred liters. This is exactly the volume of a septic tank per person.

What to make from and how to make it: what to consider before starting construction

When arranging this structure yourself, you need to maintain certain distances. The septic tank can be located five meters from the house, but only if the container is sealed.

Otherwise, no closer than thirty meters (open reservoir).

The basic rule is that the septic tank should be located taking into account the minimization of the costs of constructing the pipeline, but at the same time eliminating the risk of violating sanitary standards.

According to the rules, it is necessary to plan and install sewerage at the time of laying the foundation and erecting the floor.

Make sure there is a hole in the base of the building for the pipe.

Before arranging the screed, develop trenches by laying pipes in them.

Do not forget that the steam room must also have a drain, because after each visit you need to clean and wash this room.

If the sewerage system will drain wastewater from different rooms, then it is necessary to provide ventilation. You should also take care of the water seal.

What to consider and how to properly dig a drain: soil excavation

As a rule, the installation of a septic tank for a bathhouse, which can be purchased in advance, is preceded by a complex of earthworks (development of a pit, trenches). It is necessary to take into account the type of soil and groundwater level.

Initially, it is necessary to outline the route for the pipes and the area where the tank will be located. Then the soil is excavated.

A ditch with special pits for rings is being developed. The dimensions of the pit must correspond to the dimensions of the reinforced concrete products.

The diameter needs to be 10-15 cm larger.

After the first ring is installed in the hole, the edges of the structure are treated with sealant. Then the next part of the well is installed.

The soil is being excavated from under the reinforced concrete products placed in the pit.

After the structure settles a little, the remaining rings are installed.

When everything is ready, sand is poured between the pit and the shaft. A reinforced concrete screed is installed at the bottom of this structure.

In what cases is a regular drainage pit suitable?

If the steam room is located far from the house, then it is better to arrange a separate container for it. A septic tank for a bathhouse without pumping it yourself can be the best option in this case. Running pipes to a system that processes wastewater from your home is a bad idea.

When installing a septic tank for a bathhouse, you should take into account the contamination of the drains. Usually the bulk is soapy water with a small amount of particles of human skin and hair. In this case, a septic tank for a bath without pumping without a toilet is suitable.

Installation of a septic tank, filtration well and filtration fields

The installation work flow diagram is as follows:

- Place two plastic barrels in the pit.

- Connect the pipes to the cameras.

- Backfill the tanks using a composition consisting of cement (dry powder) and sand. This backfill perfectly protects the structure from destruction during soil movements. The mixture is supplied in layers of 0.25–0.3 m, and each layer must be compacted. At the same time as filling, pour water into the containers. This way you will protect the barrels from deformation.

- Pour a cushion of sand and crushed stone onto the installation site of the third tank (a well for filtering wastewater), place the last barrel on the resulting pie and pour fine crushed stone into it (about a third).

Your septic tank for your dacha is ready!

If, instead of a filtration well, you planned to construct filtration fields, the arrangement of the latter is carried out as follows:

- To install drainage pipes, dig trenches of the required size. They must have a slope (per meter of pipe products - 2 cm).

- You lay geotextiles at the bottom of the trenches, and throw its cuts on the sides over the sides of the ditch.

- Cover the geotextile material with crushed stone (height 0.3 m).

- Place pipes for drainage on the crushed stone layer. As such, it is allowed to use homemade products (make holes in ordinary steel pipes). But it is better to use factory perforated pipes.

- Fill the trench with a layer of crushed stone and lay geotextiles on top (the overlap width is about 0.1 m).

All you have to do is fill the ditch with soil. Fields for filtering wastewater have been made.

Purchasing a ready-made treatment plant for an autonomous sewage system is the right decision from a technical point of view. However, it is not always justified in terms of price. Few dacha owners will decide to purchase an expensive deep cleaning station if living in a country house is seasonal and most of the time the sewer system is idle. In this case, it is more advisable to use a non-standard approach - for example, making a septic tank from barrels. This design will be much cheaper, and its efficiency will be sufficient to satisfy domestic needs.