The construction of the bathhouse has been completed, but sometimes it seems that something is missing in the design. And only looking at the chimney, many realize that the most impressive element is missing - the cap.

But first you need to determine what it is needed for, besides decoration, and whether this design will harm the draft. This is where the fun begins.

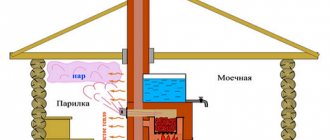

At first glance, the cap on the chimney is designed to protect it from foreign objects, precipitation, birds and debris.

From a fire safety point of view, this design should help, because debris in the smoke exhaust system can catch fire when the stove is lit.

A chimney clogged with fallen leaves will definitely reduce draft. But this can also happen due to the presence of an umbrella on the pipe.

Important! Umbrellas, caps and other structures reduce draft and can cause reverse draft.

Do I need a cap?

The regulations governing the safety of the installation and use of chimney umbrellas vary from country to country. If in Europe the legislation strictly prohibits the installation of nozzles on chimneys, while there is no such restriction for ventilation, then the legislation of the Russian Federation has a nuance. The wording is vague, which is why there is no direct prohibition.

Obviously, the existing disadvantages must be taken into account, so when installing the cap the following should be taken into account:

- If the efficiency of a round steel pipe is less than 85%, then you should not install a mushroom-shaped nozzle. As a replacement, you need to use a cone nozzle.

- When using a heat generator with high efficiency, you can install a roof-shaped nozzle.

- For stoves and TT boilers, umbrellas are a suitable option. To protect the nozzle from gases, a stainless steel plate is installed.

- If the gas outlet is realized using side vents, then gable or hip hoods should be used.

Cone-shaped cap Source 1-line.pro

You need to choose the type of chimney hood to install based on the type of pipe. Conventional mushrooms are suitable for ventilation, and cone-shaped nozzles are suitable for gas ones.

Features and purpose of the end and cornice strips

Each of these strips is manufactured using a similar technology as the metal tile sheet from which the roofing deck is formed.

The strips are made from a metal profile, which in turn consists of passivated and galvanized steel 0.4-0.5 mm thick.

The profile is also subject to subsequent coating with a polymer protective layer - this coating can be polyester or plastisol, and as for composite-type metal tiles, a basalt-tiny coating is used in its manufacture.

If we talk about the functional load carried by the elements in question, it consists of the following:

- The cornice strip is an oblong element consisting of a material similar to the rest of the covering. The main function of the eaves strip is to protect the front eaves board from moisture when exposed to precipitation and, as a result, to protect the entire space under the roof from moisture.

- The end strip for metal tiles, in turn, has an identical design as the eaves, but unlike the second one, it must be fastened on the side ends of the roof slopes, and not in the eaves part. By overlapping the end, the end strip has a dual function:

- Protects the sheathing from getting wet.

- Protects the roofing deck from wind loads (prevents roofs from being torn off by strong gusts of wind).

As a result of the latter, the end strip received its second name - wind strip for metal tiles.

Installation of cornice strips

Installation of eaves strips on metal roofing is carried out in accordance with the following rules:

- They start with the installation of a frontal board, which is attached to the ends of the rafter legs using galvanized nails. A replacement for the windshield can be a cornice board attached to special rafter grooves.

- After this, the cornice must be hemmed using corrugated sheets or tongue-and-groove boards. At the same time, a support beam is attached to the wall of the building, which will serve as a second support for hemming the roof eaves overhang.

- Before installing the eaves strip, attach the brackets for installing the gutter. They can be mounted either on the eaves board or directly on the rafters.

- Then a cornice strip is installed, the installation of which must precede the installation of metal tiles. The strip is installed tensioned over the brackets for the drainage and secured with self-tapping screws to the cornice and/or front board. The distance between the screws is assumed to be around 30-35 mm.

Attaching the cornice strip

At the end of laying the roofing carpet, the main material of which is metal tiles, the end strip is mounted in order to cover the ends of the metal tile roof with your own hands.

The end plate is installed as follows:

- It is installed at a wave height of the metal tile above relative to the level of the sheathing. In this case, the corner of the roof end must be completely covered.

- Fasten the end strip on top and sides with self-tapping screws. The upper screws secure the strip to the crests of the metal tile waves.

- The overlap when extending the planks is allowed to be up to 50 mm.

- The joint between the roofing and the strip must be carefully sealed.

If, when forming the roofing deck, you correctly installed both the decking itself and the pair of eaves + end strips, the metal tiles will probably serve for a very long time. Protection of the under-roofing components of the roofing pie under metal tiles with slats plays a significant role in this.

Pros and cons of a house chimney umbrella

The main advantages of the hood are:

- Reduces the likelihood of the draft overturning by preventing wind flow from the street.

- Protection from debris and precipitation.

- The net will prevent birds from building nests.

- Increasing the service life of a brick pipe.

- Appearance.

Attention ! You should not believe the information disseminated in advertising of such devices. The cap cannot increase the efficiency of the boiler or increase the draft in the pipe.

Formed icicles on the canopies Source obustroeno.com

See also: Catalog of companies that specialize in the design, installation and repair of roofs

But there are some reasons that do not allow caps to be used everywhere. The main disadvantage is the creation of aerodynamic drag. The fungus located directly above the pipe will prevent gases from escaping. Subsequently, this will lead to a decrease in traction.

The second disadvantage of the design is the possibility of the formation of icicles. Due to the low temperature of the gases, up to 120 degrees Celsius, water vapor, upon reaching the hood, quickly cools and forms ice, which prevents carbon monoxide from escaping through the pipe from the house.

Manufacturing technology of a rectangular exhaust unit with a weather vane

Drawing of a rectangular chimney cap. (Click to enlarge)

- Cut a rectangle out of a sheet of iron, taking into account when bending it so that there is 10 cm for the chimney to fit.

- Oblique cuts are made on the sides at equal distances; when joined, these cuts will produce trapezoidal segments.

- Next, four posts are made, attached to the corners of the rectangle, secured with rivets.

- Bend the ends, you get a hole, as in the drawing.

- Separately, cut out a rectangle: bend it into an arch, fasten it - this is a ready-made hood; for originality, you can make a weather vane.

- The finished structure is installed in the chimney pipe.

The pipe is attached to the installation according to what the chimney is made of.

Umbrella or deflector

Building codes indicate that installing baffles on pipes from gas boilers is strictly prohibited. The reason is the possible formation of ice on horizontal sections of the pipe, which will lead to deterioration in traction. The deflector is an aggravating factor due to which the freezing process will occur faster. For exits from gas boilers, only primitive umbrellas can be used to prevent the entry of debris and precipitation.

A weather vane with an interesting design that can destroy the chimney Source kaminych.rf

The shape of the installed cap depends on the shape of the chimney. If the house uses a sandwich chimney system, then the chimneys are equipped with a special skirt to ensure thermal insulation. In brick pipes, it is enough to equip the cap with a base to protect the bricks from the effects of precipitation. Deflectors are allowed for installation on metal pipes of boilers that operate on solid fuel.

It is worth abandoning weather vanes. Such structures are constantly exposed to wind pressure, which creates vibration that gradually destroys the brick pipes. As a result, not only the cap, but also the chimney itself quickly wears out.

Causes of breakdowns and their elimination

There are three types of work and troubleshooting:

- Preventive maintenance

- Major renovation.

- Partial renovation.

Prevention is carried out to remove soot. No professional help needed. It is necessary to monitor all parts of the stove, clean it from soot and ash.

- The stove smokes and burns poorly. It is necessary to check the draft of the stove and whether the fuel is suitable for this particular stove.

- Poor heat output from the oven. It is necessary to check how tightly the vent and the firebox door close; you need to use a special tourniquet.

- Strong draft, all the heat will go outside and the room will not warm up.

- If there is good draft, the gases will escape through the chimney and carbon monoxide will not form.

- The oven does not warm up. There are cracks in the chimney. The cracks need to be sealed. The main channel is narrowed; the narrowed channel needs to be disassembled.

- No traction. Clean the pipe using a weight. If this method fails to clean, you will have to disassemble the chimney to clean it. If the soot is from resin, then you need to light a fire in the chimney and clean it using this method; there are also chemicals.

- The stove begins to smoke. This problem occurs when the stove is constantly fired. It is necessary to disassemble the stove and repair the internal masonry of the chimney. The riser is clogged. It is necessary to disassemble the chimney closer to the clogged riser and clean it. From strong wind. Install the deflector.

- When wet spots appear on the pipe. This is the formation of condensation. Line the pipe with glass wool, do not heat the stove with raw wood or fuel, make the firebox larger, and make the entire chimney pipe much shorter.

- If after heating the stove for a long time and it still does not heat up, it is necessary to clean the chimney of soot.

- If cracks appear, they need to be covered with a clay solution.

- After not heating for a long time, the traction will disappear. This means that there is cold air in the pipe. You need to set fire to a piece of paper, and there will be traction again.

Operational breakdowns

- Poor draft and accumulated soot in the chimney pipe.

- The material in the structure is destroyed.

- Destruction occurs at the wall channels.

- The heads begin to freeze.

You can also buy a cap for the chimney pipe; the price is relatively inexpensive.

What are fungi for ventilation pipes made from?

Before making a canopy for the pipe, you need to decide on the material. Most often, non-ferrous and ferrous metal is used to make fungi; the thickness does not matter. The most widely used products are products made from galvanized sheet metal.

The most common material is galvanized sheet Source by.prom.st

The finished product is painted in color to improve its appearance, since black steel has an unattractive appearance. To improve the appearance, the product can be additionally decorated with forged elements. But caps made of black steel will have a significant disadvantage - weight, which is why the design is not suitable for all roofs.

If weight is an important parameter, then copper and alloy steel mushrooms should be considered. The disadvantage of structures made from these materials is their high cost. Therefore, the second criterion when choosing material for a canopy is the financial capabilities of the building owner. To save money, canopies are often built with their own hands, using high-quality materials.

Information on the purpose of the calculator

The online brick calculator is designed to calculate the amount of building and facing bricks for a house and basement, as well as related parameters and materials, such as the amount of masonry mortar, masonry mesh and flexible connections. Also, the calculations can take into account the dimensions of gables, window and door openings of the required number and size.

When filling out the data, pay attention to the additional information with the Additional information sign

Since ancient times, brick has been the most popular, widespread and familiar building material for the construction of long-term and reliable structures. This situation persists for a number of reasons, despite the emergence of new, modern and cheaper building materials. There are several most common types of bricks for any construction needs:

- Adobe - made of clay and various fillers

- Ceramic - (most common) made from baked clay

- Silicate - made of sand and lime

- Hyper-pressed - from lime and cement

- Clinker - made from special baked clay

- Fireproof - (fireclay) made from fireclay

Ceramic brick

(clay) are divided according to purpose into façade, ordinary and clinker. Ordinary brick (backfill) may not have an ideal geometry and in most cases is used for laying rough walls of houses, plinths, garages, which are subsequently plastered, painted and protected with facing materials and coatings. Its color has various shades of red.

About facing

(facade) are used for the construction of walls without any additional finishing in the future. There are also various special types of facade bricks that can withstand high mechanical loads and adverse atmospheric influences, and are usually used for paving paths, building all kinds of retaining fences, stairs, and walls.

K linker

It has an ideal smooth surface, various shades of red and black colors and is highly dense.

With silicate

is a light-colored lime-silicon artificial stone. Sand-lime brick differs from ceramic brick in that it is not fired during the manufacturing process. It is quite hygroscopic, and accordingly is not used for the construction of objects that will be operated in humid environments, such as the basement and basements.

Also, sand-lime brick is not used in the construction of furnaces, pipes, chimneys and foundations, since it withstands external destructive loads quite poorly.

Oh fireproof

is divided into several types and is used for the construction of structures exposed to high temperatures, such as stoves, fireplaces, chimneys and smelters. The most common is fireclay brick, it has a yellowish tint, made from special fireclay (chamotte) and, unlike ordinary clay brick, can easily withstand high temperatures (up to 1400 degrees), as well as numerous heating and cooling cycles without loss of strength.

Irpichy can be solid (volume of voids no more than 25%), hollow and porous-hollow. It is believed that depressions and voids in the material not only reduce weight, but also significantly increase the overall strength of the masonry by increasing the contact area between the brick and the mortar.

The most common standard brick size: 250 - 120 - 65 mm (length - width - height), the so-called first “normal form” (1NF).

When calculating the amount of brick required for work, they usually use a rule called “format”, in which the dimensions of the brick itself are increased by 10 mm (this is the standard joint thickness), that is, it turns out: 260x130x75 mm.

Below is a complete list of calculations performed with a brief description of each item. If you haven't found the answer to your question, you can contact us via feedback.

DIY visor

Before you make a fungus on a tin pipe with your own hands, you need to create a sketch depicting the future structure. In this case, it is necessary to take into account the following nuances:

- slope angle from 30 to 45 degrees;

- the edges should protrude by 50 mm;

- the height from the chimney to the umbrella is at least 100 mm.

Necessary parameters for making a hood Source izhartezia.ru

The easiest way is to create a round mushroom suitable for ventilation systems. This will require standard tools: drill, metal scissors, hammer, rivets. How to make an umbrella for a pipe with your own hands:

- Take a wooden plank.

- Screw 2 screws into it at a distance of more than 15 mm relative to the radius of the pipe.

- Using the created device, draw a circle on a metal sheet.

- Cut out the prepared circle.

- Draw a sector with an arc length of about 120 mm.

- Cut out the wedge and secure the edges of the workpiece in a vice.

- Prepare 3 holes along the edge of the seam to connect the part using rivets or M4 screws with nuts.

The leg for the manufactured umbrella can be a thin sheet, bent 3 or 4 times. For a novice specialist, this will take a little more than half an hour. Experienced professionals will be able to complete the task in 10-15 minutes.

Ready-made version of the manufactured visor Source stb26.ru

Installing an end strip for metal tiles

- The length of the end of the slope is measured and the number of whole planks is counted. If necessary, the latter is cut to the required length.

- Installation starts from the bottom of the slope and goes up. In this case, the products are laid with an overlap of at least 50 mm.

- The horizontal part of the end strip for metal tiles should completely cover the crest of the roofing, and the vertical part should cover the sheathing boards at their ends.

- The element is fixed using roofing screws of a similar color, both in the vertical and horizontal planes. In this case, the screws are screwed from above strictly into the ridge of the metal tile. The distance between the screws should be 30 - 50 cm, and it is most convenient to screw them in with a screwdriver, starting from one side, so that the bar does not warp.

End plate fastening diagram

Don’t forget about sealing the gaps between the plank and the roofing. In addition to the protective function, the wind strip for metal tiles also has a decorative function. A roof decorated with this element has a more finished and harmonious appearance.

Useful advice! When fixing the plank with self-tapping screws, you must be very careful not to smear the sheathing on the board. If this happens, then under no circumstances should the self-tapping screw be removed, as it will cover the hole made.

Scheme for fixing the strip with self-tapping screws

When carrying out roofing work, great attention should be paid to safety. The ladder or scaffolding must be securely fastened and not pose a hazard

It is most convenient to attach the wind strip for metal tiles from scaffolding installed along the gable of the building. This will allow you to move freely along the entire length of the edge of the slope. Before attaching the additional element, it is worth sewing up the lower part of the sheathing, hanging over the pediment, with facing material. This will allow you to avoid inconvenience in the future, since the installed bar may interfere with this process.

Metal roof structure - end view

When installing the product, pay attention to the alignment of both planes, since “waves” or “torsion” will not only reduce the protective functions of the element, but also spoil the entire appearance of the roof. Smooth fastening can only be ensured by strictly following installation rules and using measuring tools

Useful advice! The end strip for metal tiles should be fastened with self-tapping screws and rubber washers “under tension”. This will prevent water from getting under it and the wind from loosening it, subsequently causing rattling sounds.

The wind strip performs not only decorative, but also protective functions

Principle of operation

Installing a cap on the chimney will not only protect against water and debris getting into the chimney pipe, but also allows you to optimize the draft in the heating device. This happens as follows:

- the air flow rests against the wall of the upper cylinder and is forced to go around it from all sides;

- sliding along the surface of the cylinder, the air stream turns upward, at this time the smoke coming out of the channel is sucked in;

- the air movement inside the chimney becomes more intense, a zone with reduced pressure is created at the top of the chimney, where smoke from the combustion chamber rushes;

- if the wind jets are directed vertically or at an angle, they penetrate into the upper cylinder through the gap and suck gaseous combustion products into the pipe.

Characteristics of popular models

Deflector models differ in both size and sensitivity to wind. The most popular models are TsAGI, Khanzhenkov, Volpert-Grigorovich, “Smoke Tooth”, “Hood” aka “Net”, “Shenard”. The first of these models was developed at the Aerodynamic Institute named after. Zhukovsky.

TsAGI is most often used in ventilation systems due to the difficulties that arise when removing soot. The second model is essentially the same TsAGI, but slightly improved by the inventor. Essentially, this is an additional cylinder around a pipe with an umbrella cover immersed inside the cylinder at a certain distance.

Homeowners choose the TsAGI deflector most often. It has a cylindrical shape. The device is made of galvanized or stainless steel

The Volpert-Grigorovich deflector has proven itself well as a draft amplifier on chimneys. It works effectively in areas with prevailing low winds. The design includes 2 cylinders - the lower one with two outlet pipes and the upper one with a cover.

The “smoke tooth” is mounted in a door specially provided in the chimney. Due to the fact that the design includes 2 handles, you can regulate the air flow.

Covers for chimneys are made in a variety of shapes. Sometimes they are coated with heat-resistant enamel. Some specimens look very decorative

The “Hood” deflector has a rotating design. It consists of a semicircular trough-shaped air trap mounted on a rotating rod mounted inside the pipe. An increase in traction power by installing a weather vane deflector occurs due to turbulence that occurs under wind load.