Cast iron stoves "Kalita" are designed to create conditions as close as possible to a traditional Russian bathhouse, in steam rooms up to 30 cubic meters in volume. They have increased resistance to high temperatures and can accommodate up to 350 kg of stones for steam generation. The steam is light and pleasant, since heating of the room due to infrared radiation, characteristic of iron stoves, is completely eliminated.

"Kalita" is a successful replacement for traditional sauna heaters. The massive cast iron firebox, unlike metal options, retains heat in the stove for a long time. Natural stone is used for lining the stove, which also increases the heat capacity of the structure and allows it to be heated in 1.5-2 hours. The stones are heated from all sides.

Advantages of the oven

The stove can be easily and quickly installed in its designated place in the furnace room, relaxation room or steam room. The light weight of the structure does not require the construction of a foundation, as for a massive Russian stove. The process is carried out using a dry method without the use of cement, so the bathhouse is ready for use immediately after installing the stove, which takes no more than two hours. You can do the assembly yourself; the help of specialists in this matter is not important.

The bath is heated evenly both along the perimeter of the steam room and along the height, so the floor does not remain cold. The uniform distribution of temperature along the height allows a large number of people to steam at the same time, since the lower shelves are also used. The heat capacity of the cladding is 2.5 times higher than that of conventional stove bricks, which allows you to steam in the sauna longer without additional heating of the stove. Important advantages of Kalita are also:

- durability of the structure,

- practicality,

- wide range of models,

- compatibility with German ceramic chimneys.

The therapeutic effect of the bath, in which Kalita is responsible for heating, deserves special attention. The warmth from natural stone helps to increase immunity, improve metabolism, normalize blood pressure and improve the health of the respiratory system. In turn, the finely dispersed steam created has a beneficial effect on the nervous system, calming and relaxing a person.

Features of the design and operation of the furnace

"Kalita" weighs no more than 250 kg and is available in several sizes. All models are united by a cast iron structure, lined with natural stone. The thickness of the walls of the case is 10 mm, the thickness of the finishing is 50 mm. Cast iron contains a large amount of graphite, which protects the walls from corrosion and prevents the formation of scale.

The cladding is made either from one of the materials used, or from several by combining. The natural stone reliably hides the cast iron body, so when touched, a person does not get burned. At the same time, such stone retains the heat of a bath better than ceramic brick. After warming up, the bathhouse remains warm for more than a day, so after all the procedures you can hang your laundry in it to dry.

Bath stones are placed in a special closed or open box. The maximum weight of stones placed depends on the model, for example, the Kalita Russian Steam stove can hold 120-180 kg, while the Prince model can hold up to 350 kg. The combustion unit can be configured in one of the following options:

- tunnel and door made of stainless steel, with glass;

- cast iron tunnel and door, large glass, stainless steel handle;

- stainless steel tunnel, cast iron door, arched glass.

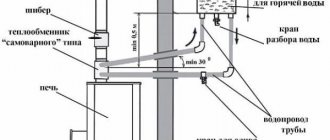

The length of the combustion tunnel allows you to mount the stove in the wall between rooms and add firewood without entering the steam room. The doors in each version are hermetically sealed, so that smoke does not enter the room. The stove is equipped with a chimney of domestic or foreign production. The design also provides for the installation of a tank for heating water for the bath.

The oven provides 2 operating modes: convection and accumulation. In the convection mode, the oven quickly warms up (in 1-2 hours), and then in the accumulation mode the required temperature is maintained by continuing the fire.

Cast iron stove "Kalita" with open heater

Wood stoves Kalita Russian steam5.000

The warranty period is the period during which the customer, having discovered a defect in the product, has the right to demand that the seller or manufacturer take measures to eliminate the defect. The seller must eliminate the defects unless it is proven that they arose as a result of violations by the buyer of the operating rules.

When does the warranty begin?

- from the moment the goods are transferred to the consumer, if there is no specification in the contract;

- if it is not possible to determine the date of purchase, then the warranty starts from the date of manufacture;

- For seasonal goods, the guarantee starts from the start of the season;

- When ordering goods from an online store, the guarantee begins on the day of delivery.

Warranty service includes:

- elimination of product defects in certified service centers;

- exchange for a similar product without additional payment;

- exchange for a similar product with additional payment;

- return of goods and transfer of funds to the buyer’s account.

Rules for exchange and return of goods:

Exchange and return of products of good quality

The seller guarantees that the buyer, within 7 days from the date of purchase of the goods, can refuse the goods of proper quality if:

- the product has not been put into use and is in marketable condition, is in packaging with all labels, and there are also documents for purchasing the product;

- The product is not included in the list of products of good quality that cannot be returned or exchanged.

The buyer has the right to exchange goods of good quality for another trade offer of this product or another product identical in value or for another product with an additional payment or refund of the difference in price.

Exchange and return of products of inadequate quality

If the buyer discovers defects in the product after purchasing it, he may request a replacement from the seller. Replacement must be made within 7 days from the date of the request. If an examination is ordered to determine whether the goods comply with the specified standards, the exchange must be made within 20 days.

Technically complex goods of inadequate quality are replaced with goods of the same brand or with a similar product of a different brand with recalculation of the cost. The return is made by canceling the sales contract and returning the amount in the amount of the cost of the goods.

A refund

The refund period depends on the type of payment that the buyer initially chose.

For cash payments, refunds are made at the checkout no later than 10 days after the buyer submits a return request.

The cost of the goods is credited to the customer’s card, if non-cash payment was used, occurs immediately after receiving the request from the buyer.

When using electronic payment systems, the refund is made to an electronic account within 10 calendar days.

Finishing and execution options

The sauna stove is lined with soapstone or coil. It is also possible to use them together in different parts of the structure. The heat capacity of soapstone is 5 times higher than that of brick. The stone is able to retain heat for 24 hours after a four-hour fire. The heat given off by soapstone coincides with the radiation of the human body, so it has a beneficial effect on the health of bathhouse visitors.

The coil differs from soapstone in its greater hardness and ease of polishing. However, it is inferior to soapstone in terms of heat capacity, it is 10-15% lower. The color of the stone is similar to malachite with veins of white quartz. The combined option of using natural stone in cladding can be done as follows: legs, corners and top slabs are made of a coil, the rest is made of soapstone.

The range of stoves includes models with an open or closed heater, steel lining, and a door with a lift mechanism. The classic model has the simplest design, the arched stove has the original design, and the “Extreme” has the highest temperatures. The Kalita Russian Steam stove is a premium model, characterized by a larger working surface and a stainless steel drawer (for stones).

For professional use, the most suitable model is the “Prince-Kalita”, which is distinguished by the presence of a closed heater with a special mechanism for opening it. The visor in the “Prince” furnace is equipped with a smooth-running counterweight, so it can be easily fixed in the desired position. The door of the “Prince” model has a lift mechanism, which allows increasing the draft into the chimney when moving it to the upper position.

In this case, the air flow enters the lower part of the tunnel and eliminates smoke in the room. The chimney outlet of the “Prince” stove can be upward or to the side. It is recommended to use dry firewood or wood briquettes and waste as fuel for a cast iron stove. The bath heating process is carried out as follows. First, the convection process starts, in which air from the lower part passes through the gap between the stone lining and the cast-iron walls, heats up and enters through the convection holes into the upper part of the oven.

To regulate the combustion intensity, a damper on the combustion door is used. After 2 hours, the mode of maintaining the bath temperature at the desired level begins. The convective holes are closed with plugs, and heat begins to flow from the heated stone from the lining and the heater.

To increase the amount of steam, you can splash a little water on the stones. Flash steam generation creates the required microclimate.

Cast iron stoves "Kalita"

Range of stoves

The sauna stove is the heart of the sauna.

It is this that primarily determines the entire microclimate in the bathhouse. Without the right stove, it is impossible to create a regime that is balanced in temperature, humidity and overall air quality, not only in a steam room, but in a bathhouse in general. It is precisely these conditions that the furnaces of the Kalita model range meet in the best possible way. The volume of the steam room is 18-34 m3. + - more details...

The parts of the combustion unit of Kalita furnaces are cast from high-quality cast iron, the structure of which contains lamellar graphite, which makes the cast iron more resistant to corrosion when operating at high temperatures. The wall thickness of the parts of the combustion unit is 10-12 mm. The side walls of the combustion unit are decorated with special register ribs, which not only increase the heat transfer surface area of the entire unit, but also give it additional rigidity. The use of cast iron as a material and the perfect design of the combustion unit itself ensures excellent thermal characteristics, high reliability and durability of the stove. Since the combustion unit is the most critical part of the stove, including in terms of its fire safety, special attention is paid to the quality of the cast iron from which it is made.

Castings from each melt are necessarily checked for compliance of the chemical composition of the metal with regulatory documents. Tensile testing of castings is also carried out using special tensile testing machines. The tensile strength of cast iron used in the manufacture of parts for the combustion unit of Kalita stoves is at least 200 MPa.

Unfortunately, metal wood stoves have a low coefficient of performance (COP). And the low efficiency of the stove means excessive fuel consumption and a long time to warm up the steam room. A significant part of the heat generated during fuel combustion simply “flies down the drain” and does not go to heating the room. In this case, the first elements of the chimney find themselves in a zone of high thermal loads, the temperature of the outgoing combustion products reaches 800°C. The main reason for this shortcoming is the suboptimal organization of the movement of fuel combustion products inside the furnace and the lack of special design solutions to increase the amount of heat released by the combustion unit into the room. A significant part of the furnaces on the market today are so-called “direct-flow furnaces”, which to one degree or another have the disadvantages noted above. When designing the combustion unit of Kalita stoves, special attention was paid to minimizing these disadvantages.

The container for stones is a non-removable structure of complex configuration, causing not only turbulence (turbulization) of gas flows inside the furnace, but also their organized gas circulation, and as a result, a decrease in the speed of their movement and an increase in the time spent inside the combustion unit. The amount of heat transferred to the elements of the combustion unit increases, optimal heating of the stones for steam generation is achieved, and the temperature of the outgoing combustion products is significantly reduced. Unfortunately, it has not yet been possible to replicate this complex and original design in any similar cast iron product from other manufacturers, despite their “external” similarity to Kalita.

But it’s not enough to heat the combustion unit; you need to transfer this heat as efficiently as possible to heat the room and the stones for steam generation. For this purpose, the walls of the combustion unit are equipped with a developed system of ribs, increasing the area of the heat transfer surface of the combustion unit by 80%.

These and a number of other technical and design solutions made it possible to increase the efficiency of Kalita stoves by 15-25% higher than that of its analogues.

Only natural, environmentally friendly materials are used as materials for the external design of the stove: natural soapstone stones or coils. Natural stone cladding converts hard thermal radiation from a hot combustion unit into softer, more comfortable and pleasant radiation from the stone massif of the external cladding. Due to its large mass, stone cladding is capable of accumulating a significant amount of heat and then slowly releasing it, maintaining a consistently high temperature in the steam room with virtually no additional heating of the stove, at least in the domestic use of the steam room. The use of natural stone to decorate the outer body of the stove not only corresponds to all the thermophysical processes when using a bathhouse and specifically a steam room, but is also an excellent solution for their style and design.

Depending on the client’s wishes, several options for the design of the combustion tunnel are possible, without changing the technical characteristics of the furnace. The combustion tunnel can be made of stainless steel or cast iron and be equipped with various types of doors: with forged finish, made of mirror stainless steel, with a vertical lift mechanism, cast iron, etc.

The high thermal power of the combustion unit, natural stone cladding, reliability and ease of use allow Kalita stoves to be the undisputed leaders in the sauna stove market. And a number of technical innovations: a container for stones built into the firebox, a steam gun, and a convection regulator make these ovens unique in their own way.

The Kalita stove is the perfect combination of tradition and modernity.

To meet the numerous wishes of our Clients, a new combustion unit “Kalita+” with a thermal power increased by 15% was developed and put into production in 2014. The Kalita+ combustion unit is equipped with a cast iron door with a large panoramic glass. This unit can be equipped with any of the furnaces of the Kalita model range.

Traditionally, the Kalita series of wood-burning stoves is a massive cast-iron firebox, which, together with natural stone cladding, provides a unique form of heat transfer into the steam room.

With the advent of the “Kalita+” option, all stoves in the “Kalita” line are equipped with a cast-iron combustion unit increased in height by 50 mm and a cast-iron door with a large panoramic glass.

By choosing “Kalita+” you get: - an increase in the thermal power of the furnace; — possibility of increasing the volume of a steam room; — reduction of heating time for a steam room; — increasing the size of the furnace loading window; — possibility of more convenient fuel loading; — increasing the heat storage capacity of the furnace.

Using any of the Kalita stoves in a steam room creates a special atmosphere, which is characterized by a mild microclimate, stable temperature, and comfortable thermal energy transmitted by the stove.

From January 2021, the new Kalita+ replaced the old Kalita model. Now Kalita=Kalita+

+ — Certificate of conformity for the stove-heater for baths “Kalita”

+ — EAC Declaration of Conformity for Kalita stoves