Of course, it’s good to have a spacious and large bathhouse that can easily accommodate a group of friends or the whole family. But not everyone can boast of a large area, especially when it comes to a bathhouse. Even if the area is quite small, this is not a reason to deny yourself the pleasure of visiting a Russian bathhouse - pay attention to the small bathhouses.

Examples of projects

Project of a small bathhouse

Ideally, the bathhouse includes 4 rooms in its design:

- dressing room;

- restroom;

- washing;

- steam room

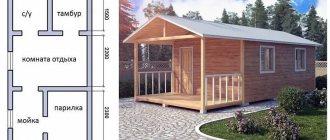

Bathhouse with washing room and rest room

You can expand the functionality of some rooms by combining them with each other. At the same time, the comfort of your stay is not lost. The overall size of the building will largely depend on how many people will be inside at the same time.

- 1.20 mx2.50 m. Very compact solution. In this case, the bathhouse consists of only two rooms: a steam room and a dressing room. The dimensions of the first are 1.20 m×1.50 m, the second - 1 m×1.20 m. There is no rest room, but in the dressing room you can easily change clothes. The washing room can be combined with a steam room. This size will be enough for one person.

- 2.50 m×2.50 m. In terms of the number of rooms - the same as the first option. The size of the steam room is 2.50 m×1.50 m, the dressing room is 1 m×2.50 m. At the same time, it will be possible to organize additional space for storing firewood. In such conditions, two people can comfortably fit.

- 3 m×3 m. This option can be planned in different ways. If you want the steam room to accommodate three people, then it can be made 3 m x 1.50 m in size; the washing room can be made separate by placing a shower stall there. The size of this room will be 1 m × 1.50 m. There is also a dressing room of 2 m × 1.5 m. You can combine a washing room and a steam room, then there will be space that can be used as a relaxation room, which will also serve as a dressing room.

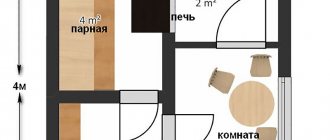

- 4 m×3 m. In this case, you can separate 4 m2 for the steam room (for example, 2 m × 2 m). The washing room will occupy 1 m × 1.50 m, leaving 2 m × 3 m for the rest room. In such conditions, four people can comfortably fit. They will be able to be in the steam room at the same time, and also enjoy communication in the waiting room.

- 4 m×4 m. In such an area you can already turn around well. The steam room can be left measuring 2 m × 2 m. A separate dressing room can be made measuring 2 m × 1.50 m. The rest room in this case is 4 m × 2 m (one side will be 2.50 m). The washing room can be combined with a rest room; for this, an electric boiler and a shower stall are installed. They can be placed in one of the corners of the room, which does not take up much space.

Frame bath 4*5

Layout of small baths

These are indicative examples. You can easily vary the size of the premises within accessible limits. You may want to reduce the steam room because... there is no need for 4 people to be there at the same time. At the same time, it will be possible to expand the space of the rest room.

Note!

All measurements are given in ideal values without taking into account the thickness of the partitions. This was done for greater clarity. If the bathhouse is adjacent to the house, it can be made in the form of one steam room. In this case, the bathroom will act as a washing room, and the rest of the area is available for relaxation.

Types of economy baths

An economical bathhouse in the country is an excellent solution for small garden plots, the area of which does not exceed 10 acres. This means that the structure itself must be ergonomic: up to 6 meters in length and 4 meters in width.

Let's consider the main design options that can be advantageously arranged on a small private plot.

Frame

The simplest frame bath is built on a lightweight foundation, has a wear-resistant wooden frame, lined with high-quality materials.

To provide a small frame bath with additional protection from the negative effects of moisture and temperature changes, the structure is insulated and waterproofed.

Dry logs with a cross-section of up to 112 mm are suitable for constructing a bathhouse. To make a compact bathhouse with an area of up to 13 square meters. m, it is necessary to prepare 80 units of lumber. For insulation, you can use mineral wool, tow fiber and tow.

Frame structures do not require additional external finishing. If desired, it can be done, but this will significantly increase the costs of implementing the project.

Monolithic

Another economical design option for construction on a summer cottage. It involves the use of cheap material - wood concrete, which is prepared from sand, cement, chemical additives and filler. Sawdust from coniferous and deciduous trees, hemp and flax bonfires, rice and cotton straw stalks are used as filler.

There are two technologies for constructing a bathhouse: from sawdust blocks, brickwork or monolithic casting. Monolithic technology involves the preliminary installation of removable formwork, followed by filling the walls with the finished mixture.

Mobile

The modern market offers ready-made ergonomic bathhouse designs with various technical and operational parameters. One of them is a small sauna, which is a tent on a steel base, equipped with a mobile heater and a backpack for transportation.

There are more affordable and lightweight designs that are equipped with a small-sized steam unit.

The undoubted advantage of a mini-bath for use in the country is the ease of assembly and installation in any accessible place. Depending on the design features, dimensions and type of bathhouse, it can accommodate from 2 to 5 people.

Ergonomic

The budget barrel sauna is the most popular and sought-after design option, which has almost all the advantages of a stationary building.

This structure is a large barrel made of wood. It is divided by a special partition into two functional areas: a steam room and a shower room - for health and water treatments, and a dressing room - for installing heating equipment. A mobile barrel-shaped sauna can accommodate from 2 to 4 people in one session.

For the construction of walls, edged boards from deciduous trees up to 6 cm thick are used. A mobile economical sauna does not require a foundation, but to increase the stability of the structure it is recommended to use an additional wooden base made of boards up to 5 cm thick.

If the bathhouse is intended to be used not only in summer, but also with the onset of cold weather, then insulation of the structure is a prerequisite. For thermal insulation, frost-resistant and durable materials are used, inert to rotting and the negative effects of external factors.

Choosing material

Small brick bathhouse

Various materials can be used to build walls. Much will depend on the project you choose, as well as the amount of money planned. For example, you can use ordinary brick. You can read how to build a brick sauna here. The following points will be positive:

- availability;

- ease of delivery;

- relative ease of construction;

- long service life (with proper care - up to 150 years);

- ease of maintenance;

- possibility of combination with the main structure;

- when using new brick there is no need for cladding;

- freedom to choose the form of construction.

The negative aspects include:

- high cost of material;

- the need for good ventilation, because brick has poor vapor conductivity;

- lighting such a bathhouse takes more time than building made of wood;

- high costs for interior decoration.

From foam block

Along with brick, foam block is often used. This is a more progressive material; it has properties characteristic only of it:

- light weight with large size;

- high laying speed;

- ease of adjustment of block shapes;

- good thermal insulation;

- relatively low price;

- excellent sound insulation;

- environmental friendliness;

- If you follow the recommendations, there will be little glue consumption.

There is also a fly in the ointment:

- uneven pores can be a problem when hanging furniture;

- Shrinkage may occur over several months;

- poor bending resistance.

Small log sauna

The most favorite manufacturing method is a rounded log. A lot can be said about its advantages, here are just a few:

- high environmental friendliness;

- pleasant appearance;

- low heat capacity;

- no need for interior and exterior finishing;

- pleasant internal atmosphere.

The negative side is:

- unprofitable to use in small buildings;

- some complexity of construction;

- high cost of material;

- long shrinkage time.

Frame small bath

One of the cheapest and fastest options is the construction of a frame structure. Minimal construction skills will be required for this method. The advantages are:

- no need for a massive foundation;

- availability of materials;

- relatively low cost compared to other options;

- ease of care;

- very fast heating of the steam room with good insulation;

- ease of laying communications;

- seismic resistance;

- no shrinkage.

One of the disadvantages is the need to organize good sound insulation. High level of noise – transmission of various vibrations, which can cause inconvenience. It is also important to ensure good ventilation so that moisture does not accumulate inside, which will lead to the development of fungus and mold.

Making a sauna from boards with your own hands: a cheap and simple option

Features and advantages of a plank bathhouse

A bathhouse made of boards is an inexpensive project that will be a good alternative to buildings made of logs. The presence of a log house is not a prerequisite for the construction of a wooden steam room.

In its manufacture, only flat boards are used - without timber or round timber. The base of the building is a frame that connects the entire structure and rests on the foundation.

The price of the project depends on the method of its use:

A bathhouse made of boards has two main advantages. It does not shrink and provides complete freedom in choosing sizes and layout. The simplicity of the design allows you to quickly complete construction - with a partner, it will take only 2-3 months to build a steam room.

Strip foundation

Strip foundation for a small bathhouse

In the case where a really small bathhouse is planned, there is no point in sinking the foundation to the level of soil freezing. This will only increase the overall cost of the project. With proper manufacturing and waterproofing, you won’t have to worry about the walls being cold. This type of foundation will be relevant for any of the listed building options.

- The first thing that needs to be done is to clearly define the territory that will be allocated for construction.

- Next, debris is removed. In addition, you will need to remove the top layer of soil with grass to make it easier for you to carry out further tasks.

- Using pegs, the boundaries of the future building are marked.

- Special holders are made to make it easier to navigate with excavation. To do this, two pieces of board 50x50 cm (or whatever is at hand) are sharpened on one side and connected using a transverse crossbar from a board 10 cm wide, its length should be about 70 cm. You will need 8 such structures. They are installed two at each corner of the house. Between them two fishing lines are stretched to the width of the future foundation. Be sure to check that all angles correspond to 90°. This way you get clearly defined lines that will be difficult to move even if you hit them.

Scheme of a shallow strip foundationThe soil is excavated to a depth of 50-60 cm. You can throw it in the middle of the territory, then it will be useful for preparing the bedding.

- A layer of sand is placed on the bottom. Its height should be 10–15 cm. In order to compact it well, you will need a manual or mechanical tamper. Additionally, you can moisten it well with water so that it sits better.

- A moisture-resistant brick or something else (granite, for example) is laid at the bottom every meter, which will serve as a support for the metal sheathing. They are needed so that the concrete fills the space underneath well.

- The sheathing is made from a rod with a diameter of 12 mm. Its principle is as follows. Sections 10 cm shorter than each side of the dug trench are taken. You need 4 of them on each side. Every 40 cm they are connected to each other using a knitting wire so as to form a large parallelepiped. The entire structure is placed on prepared stands. All four elements are connected to each other by a bandage of rods, so that ultimately a monolithic structure is obtained.

- Formwork is made from flat boards or laminated plywood. Its height should be such that the foundation rises 30-40 cm above ground level. It is important to make a sufficient number of supports so that the formwork does not begin to creep under the weight of the concrete. Also, in the upper part, individual sheets can be secured together with crossbars.

- A solution is prepared in a concrete mixer or manually in a ratio of 1:3:3. The first number is cement, the other two are sand and filler, usually crushed stone plays its role. For greater rigidity, the solution should not be very liquid.

- The time between batches should be as short as possible so that the layers subsequently become a single whole and do not peel off.

- After filling, you need to go through the vibrator well. If you do not have your own, then you need to rent one. Thanks to it, high-quality filling of all voids is carried out, the presence of which reduces strength and can have unpleasant consequences.

- The top layer is leveled and tightened using the rule.

- After a few days, when the consistency has hardened sufficiently, the formwork can be dismantled. But the foundation will gain full strength only after 28 days. The first few days (or more if it is summer) it needs to be watered so that it does not crack.

At the stage of laying the foundation, the supply of necessary communications is provided. This could be a water supply and sewer drain for washing water.

Sewerage in strip foundation

Note!

If the soil in your area is known to be highly mobile, then a shallow foundation would be a bad option, as it can easily collapse under the pressure of the layers. In this case, it is better to evaluate the possibility of installing piles.

General information

Consider the types of saunas for an apartment

Types of mini-saunas for city apartments

The sauna in apartments should not be full-size, but miniature. We briefly talk about the features of the most popular four types of mini-saunas, and the important fact is that this small sauna can even be bought ready-made.

With electric heater

The construction of a sauna in an apartment usually results in the re-equipment of the sanitary unit, since modernization of communications is important. Consequently, such an event will be accompanied by the collection of permitting documents. But installation can be greatly simplified by connecting using a flexible hose. In this case, running around to the necessary authorities can be avoided, and all responsibility in this case will fall on the manufacturer.

Phytobarrel

If you don’t have enough free space, a compact phyto-barrel is an excellent alternative to the classic options. Such a small sauna in the bathroom can be placed in any free corner. The area it occupies is approximately 1 m2. It is no more tall than a person, and the power of the heating device used in it is approximately 2 kW. The most popular models include barrels made of cedar and equipped with their own steam generator. Although such a mini-sauna is very simple and compact to operate, its installation should be entrusted to the manufacturer. The phytobarrel is easily controlled using a special remote control, and certain models have special devices that make the procedure even more enjoyable, for example, a sprayer for aromatic balm.

Portable sauna

This type of sauna is made of a frame covered with fabric. The principle of operation is similar to a phyto-barrel, and when the head is in it outside the heat zone, such a device is inexpensive, has a low weight and is compact. The main advantage of a portable sauna is that it is easy to use, and the only thing required for operation is an outlet.

Infrared sauna

From experience, we can say that this type of sauna is the optimal solution for indoor use, and it, like an important steam room, can remove toxins and excess fluid from the body, and can also activate the functioning of human organs.

Finnish type sauna

If there is enough space in the apartment, you can completely think about arranging a Finnish sauna. Even in 1 session it can accommodate a couple of people, and the steam in it is dry, it heats up to +100 degrees. This point is the main difference from the saunas listed above.

Turkish steam room

Selecting a location - pantry, bathroom or balcony

A sauna in an apartment with your own hands must be designed correctly, and the first thing to start with is selecting a location and developing a project. The following options can be considered for its placement:

- Combination of a corridor and a sanitary unit that leads to the kitchen. You can even add a bathroom here.

- Balcony or pantry in the case where the sauna will have infrared heating. By the way, a sauna on the balcony is beautiful because it will not reduce the living space of the apartment.

Naturally, the size of the sauna will depend on the number of people

When making the appropriate calculations, it is important to allocate at least 2 square meters of space for each person. The ceiling height in the room should be 2 meters or more

If you decide not to buy a ready-made miniature sauna, but to equip it yourself, then you can leave the one you have. An excellent option would be tiles, and the room for the sauna should be at least 1.8 * 2 meters. This makes it easy to place a bench, and such a sauna will become a practical and also convenient solution for an apartment.

Pile foundation

Sectional view of foundation on screw piles

There are several ways to build a foundation. Piles can be bored or driven. In the first case, a well is drilled, formwork is made, reinforcement rods are lowered and the entire space is filled with concrete. In the second option, ready-made concrete, wooden or metal posts with a pointed end are driven in immediately. The most suitable options for a small bath will be screw ones. They consist of a metal base in the form of a pipe and blades that help immerse the supports into the ground. You can purchase them or make them yourself. If you chose the second option, then you need to act like this:

- The first step is to find out to what depth the soil freezes. To do this, you can contact the appropriate service.

- Pipe blanks with a diameter of 110 mm are purchased. The thickness of its wall should be more than 3 mm. The total length should be such that it can be sunk below the freezing level by 50 cm and at the same time so that it is 30-40 cm above the ground surface. Additionally, you can buy blanks for screws. It is also necessary to make a square cap on the pile. It should be 25x25 cm in size and 5-6 mm thick.

Screw pile manufacturing processIf blanks for augers have not been purchased, they can be made from metal 5-6 mm thick. To do this, you will need a sheet with a size of 30x30 cm. A circle is cut out of it. A hole is made inside the diameter of the pipe. After this, it is cut halfway and the parts are bent to form blades.

- The end of the pipe that will plunge into the ground becomes sharp. To do this, several vertical cuts of 15–20 cm are made in the form of triangles. After that, they are folded inward and boiled.

- The screw is welded on.

- Additionally, in the upper part you can provide holes for a lever with which they will be wrapped in the ground.

- All piles are primed with paint and coated with an anti-corrosion compound. This will extend their service life.

- The distance at which it is better to place the elements between each other is 1 m. Additionally, it is necessary to provide for the presence of supports for the partitions of the building.

Installation of pile foundationTo ensure that the piles go into the ground exactly vertically, you can tape them with tape or attach a level with a magnetic base. It is important that someone constantly monitors the value of the bubble so that any corrections can be made in time.

- After all components are immersed, they must be aligned in a horizontal plane. For this purpose, one standard is selected that has the smallest offset. A mark is made on it. Using a laser level, a rule with a level, or using a water level, these marks are transferred to all other elements. Next, trimming is done using a grinder.

- Holes are drilled in the caps to make it easier to secure the grillage later. It can be made from beams measuring 20 × 20 cm (you can also use logs 15 × 15 cm, 10 × 15 cm or 10 × 10 cm), or by pouring lintels. In the first option, it is necessary to provide a dressing. To do this, in the logs that will be located perpendicularly at the edges, a sample is made to half the depth and to a width equal to the width of the log. After this, they are fastened together with hexagonal head screws (“capcaillie caps”). For a concrete base, a trench is dug between the piles to a depth of 20 cm, a backfill of sand is made, which is compacted. After this, the formwork is set up, the sheathing is laid and the mortar is poured.

Grillage options

In each of the described options, separate supporting elements for the stove should also be provided, especially if you plan to use a heater. This is very important, because its weight can be large, which can lead to damage to the floor and joists.

Note!

Such a foundation will be an ideal solution for frame structures, log buildings, as well as small foam block bathhouses. If the soil in the area where construction is planned is quite strong and rocky, then you can use something between a pile and strip foundation - a columnar foundation. In this case, separate holes with a size of 50x50 cm are dug every meter to a level below freezing of the soil. Formwork and metal lathing are installed inside and mortar is poured.

Sectional columnar foundation

Floors

The design of the floor depends on the type of room. In the recreation room, ordinary wooden floors are made. In the wash and steam rooms, the floors are made of two levels:

- The first level is made of concrete and has a slope towards the drain hole.

- The second level is a finished floor made of boards with gaps for draining water.

If you want to make a floor of porcelain stoneware or tiles, then they are simply laid on the first level at a slope towards the drain hole.

In order to make a concrete floor and drain in a bathhouse you need:

- In the center of the steam room and washing room, install plastic pipes with a diameter of 5-10 centimeters with a socket at the end. The pipes should go out through the foundation to the street and connect to the sewer system.

- Lay down a layer of waterproofing material.

- Spread a layer of gravel 10-15 centimeters thick over the entire area of the rooms.

- Make a cement mortar and pour the floor with a slope towards the hole installed on the drain pipe.

- Install a screen over the drain hole to prevent debris from entering the drain.

At the second stage, wooden floors are made:

- Install wooden logs in all rooms of the bathhouse. Make the distance between the logs 30-40 centimeters. As logs you can use bars with a section of 3x5 cm or 4x6 cm.

- Nail boards with a section of 2x15 cm or 5x20 cm onto the logs.

- In rooms where water is expected to drain, leave gaps of 0.5-1 cm between the boards.

Do not forget, before installing wooden floors, to treat all parts with wood impregnation. When making floors, keep in mind that they should be higher, or at the level of the upper edge of the foundation.

Construction of brick walls

For a bathhouse, it is better to use red brick, which has undergone heat treatment and has a lower thermal capacity. To calculate the amount of material needed, you need to calculate the area of each wall. To do this, the width is multiplied by the length. Then you need to divide this number by the area of one brick. The area of the masonry joints can be neglected, because you will still need to make a reserve in case of battle or marriage.

Calculation of the number of bricks

The wall can be erected using several methods:

- in two bricks with external insulation.

- with air gaps, they are about 6 cm;

- with a layer of insulation between two rows of bricks.

Work begins with the construction of corners. This is an important process because... It is they who will subsequently ensure the correctness of the entire structure. In order to maintain the vertical level of the future walls, two metal profiles of 5x5 cm and a length equal to the height of the future walls are dug into the corners. They are leveled and secured with jibs. A fishing line is stretched between them to the height of one row. After it is laid, the line is rearranged to the height of the next one. The thickness of the seam should be about 20-25 mm. It should be applied at a distance of no more than a meter so that it does not have time to dry. Additionally, the plane is checked using a bubble level. If the second and third types of masonry are chosen, then it is necessary to ensure a bandage between the two walls. This is achieved by laying two bricks transversely opposite each other at certain intervals. Also, each row should be offset by half a brick to ensure the overall interweaving of the entire plane.

Brick wall laying

A lintel must be installed over windows or doorways. Usually it is reinforced concrete. You can purchase it ready-made or pour it directly on site. It should extend beyond the openings by at least 25 cm. Supports are installed and a wooden board is mounted on them. Two rows of bricks are laid out on edge. Between them there are reinforcement rods, which should also extend 25 cm beyond the opening, and it is better to bend them to intertwine them with the existing masonry. Concrete is poured inside. After complete hardening (usually 10-12 days), the lower supports can be dismantled and the logs removed.

Brick lintel

Location Features

In addition to a successful box design, you will need to choose the right place in the country where you can build a bathhouse without occupying the most valuable areas of the territory. On the other hand, the steam room should be located at a sanitary distance from the dacha house in order to ensure a fire safety distance and a minimum of smoke in the area in front of the house.

A typical design for a simple mini bath involves building a room in the space between the remote toilet and the dacha building.

The second option is the most common. In this case, the structure is placed as far away from the house as possible, preferably closer to shrubs or trees that shield the box from the wind.

A bathhouse can be built in the so-called sanitary zone of the dacha, and the site for the foundation, even without taking into account the height of the piles, must be located above the drainage pit or septic tank.

Walls made of foam blocks

The general installation principle will be the same as in the previous case. You should also start with the corners, which must be accurately and clearly set.

Laying walls from foam blocks

In the same way, guides are made from profiled pipes. But there are some nuances:

- In order to achieve the best adhesion, the base row is laid on cement mortar. It is better to make the ratio with sand 1:3. It is very important to maintain a horizontal plane so that all other rows also lie correctly.

- All other rows are fixed with special glue.

- The thickness of the adhesive layer should not exceed 5 mm. Only in this case will it be possible to achieve ideal thermal insulation.

- Every 3 rows, a metal mesh is placed in the seam, which serves to provide additional rigidity.

- Foam blocks are placed on the edge.

- Lintels over doors and windows are made in the same way as in the case of brickwork.

Log walls

Construction of walls from rounded logs

This is exactly the option that pops up in the imagination when it comes to a bathhouse. To make it, you will need to stock up on rounded or profiled logs. It is better to make external walls from this material. Because the structure is small, it is good if the partitions are framed.

- In order for the walls to be consistent and even, the difference between the diameters of the beams should not exceed 30 mm.

- Before laying, the wood is treated with an antiseptic compound that will prevent the appearance of parasites. Be sure to remove any remaining bark.

In the pawThe method of ligating the log house is chosen - in a bowl or in a paw. If the first option is used, then the total length should be approximately 60 cm longer than the length of the walls. For the second method there is no need to increase the dimensions.

- For the first crown, the most massive components are selected. They are laid with the sealing rings facing outwards to ensure good thermal insulation. A plane is made on the bottom side so that the log does not roll off the base. Waterproofing made of bikrost and roofing felt is laid under it. You can make it from foam. To do this, bars measuring 3x5 cm are filled every 50 centimeters. The space between them is foamed.

- Each element has a lunar groove along its entire length. Its width is equal to the radius of the log, and its depth is half the radius of the element on which it will rest. It is most convenient to select it with a chainsaw, but it is better to do it with an axe, because... it clogs the pores, which prolongs the service life.

- To mark the binding, a special tool is used - a dash. First, the timber is tried on, marks are made on it, after which it is removed, trimmed and put in its place.

- Tape insulation is laid in two rows in the groove and the joint element so that it partially hangs over the edges.

- To prevent horizontal movement of the walls, wooden dowels are driven in every 80–100 cm. They need to be recessed to a depth of 2.5 crowns. They must also be installed at a distance of 10 cm from the window or doorway.

Into the bowl

After the construction of the walls is completed, primary caulking is performed. During which the hanging insulation is simply driven into the joints. Complete shrinkage of the building can last more than 1.5 years.

Water system

Due to the lack of pressure water supply, Unkas made the water system gravity-fed with cold and hot water. Hot water can be heated by an automatic heating element.

The soil where the bathhouse is located is sandy, so the used water is poured into a drainage hole measuring 50cm*50cm*50cm, this is quite enough, because the water consumption is small.

The shower is located at the beginning of the tunnel. The firebox door is recessed. Unkas wanted to do the layout differently, but due to the small size of the bathhouse, this is difficult to do.

He hung a cold water tank under the roof. From its lowest point, water flows by gravity through the hose into the hot water tank. In addition, a tap was made for the shower mixer. The height of the cold water tank is 2.5 m, and the hot water tank is 2.0 m. Both tanks are open, with a volume of 50 liters. Tanks and pipes are best made of stainless steel and galvanized steel, otherwise the shower head will clog.

Frame walls

After the foundation is erected, an additional foundation is made for such a structure. It is carried out according to the example of the grillage discussed above. For the corner posts we will need exactly the same timber as for the base. In addition, you will need to stock up on edged boards with a length equal to the height of the future walls, a width equal to the width of the grillage and a thickness of 5-10 cm.

Construction of a bath frame

- At the base, it is imperative to check the diagonals so that they are the same. It is attached to the concrete foundation using anchor bolts. It is advisable to recess the head. For this purpose, a countersunk groove is made in advance. Waterproofing made of bicrost or roofing felt is laid under the grillage on a concrete foundation.

Pie wall frame bathTo secure the corner posts, a tenon with dimensions of 5x5x5 cm is made at the end. A corresponding hole is made in the base. The beam is installed and leveled. It is fixed using metal corners. Jibs are also installed that will hold it.

- The top trim is made. This is a beam that will connect the racks together.

- Additional vertical beams are installed every 50–60 cm. They are strengthened with oblique struts.

- At the locations of windows and doors, embedded lintels are installed for rigidity.

- Floor joists are installed. For them, you can use a beam measuring 15x10 cm. In order for them to be secured in the best possible way, a cut is made in the grillage to half the width of the board. A cut is made in the joists and placed into the cut. Fastening is carried out with self-tapping screws; additionally, internal metal corners can be installed.

- The floor is insulated. In the case of a strip foundation, waterproofing in the form of a membrane or film is placed in the resulting space. Expanded clay is poured from above up to the beams. A separate layer of hydrobarrier is laid on the logs; it is secured to the boards using a construction stapler. Insulation is placed in the cavity between the joists. This can be mineral wool, polystyrene foam or penoplex. Everything is covered with a finished floor on top. If the foundation is columnar or pile, then first you will need to hem the beams from below, and then lay the hydraulic barrier and insulation.

- The outside walls are covered with facing material.

- A hydraulic barrier is laid on the inside. Insulation is inserted into the space between the vertical boards. You can use the same as for the floor. Finishing can be done using a block house or other suitable material.

Frame on a pile foundation

Where to begin?

When planning to independently build a bathhouse on a summer cottage, you first need to deal with a number of issues.

You need to start preparing by choosing a project. Then, in the absence of sufficient experience in the field of construction, it is useful to familiarize yourself with the theoretical part of the construction work on the construction of a bathhouse.

Consider the placement of the building and the supply of communications to it, purchase all the materials necessary for the work. After this, you can begin the interior arrangement and decoration of the room.

The last stage will be the purchase or independent production of furniture for the bathhouse.

Erection of the roof

For small buildings, the ideal solution is a pitched roof. It is necessary to plan its production at the design stage. It is very important to be able to raise one wall higher than the other. When this is done, in the case of a wall made of brick and foam block, waterproofing made of bicrost or roofing material is laid on the upper end. Additional beams are mounted on it, which will serve as a Mauerlat. They are attached to the base using anchor bolts or walled-in studs. Beams are laid on top onto which the sheathing will be placed. They can be secured to the Mauerlat using metal corners.

Bathhouse with a pitched roof

In another option, the walls are made the same. Ceiling beams are laid on the Mauerlat. On one side, vertical boards are installed that will form a pediment, from which the rafters are lowered onto the other wall. At the point where they adjoin the Mauerlat, they are cut to the required angle. They are secured with metal corners. To make it easier to maintain the roof in one plane, the two outermost elements are installed first. A string is stretched between them, which will serve as a level.

Rafter system of a pitched roof

The ceiling must be insulated. A vapor barrier is attached to the top of the ceiling crossbars. Thick foil can play this role. Insulation in the form of mineral wool is placed in the space between the beams. Additionally, it is covered with plastic film. The inside is hemmed using wooden lining or polished edged boards. Read more about insulating the ceiling in a bathhouse here.

Insulation of the ceiling in the bathhouse

Note!

For a house made of timber, when attaching the rafter legs to the mauerlat, it is better to use floating corners. This is necessary to prevent the roof from skewing during shrinkage.

Finish line

An integral part of every sauna is the stove. It can be made independently from sheet material or a large-diameter metal pipe. In another version, it is laid out of brick, but in this case it can take up a large space. For small spaces, it is better to use electric options that are purchased ready-made.

Stove for a small bath

A shelf is installed inside the steam room. It is better not to use coniferous wood for it, because... When heated, it may release resin, causing burns. Good material for it would be aspen, larch, linden or oak. If the space is small, a width of 40 cm will be sufficient; it is more convenient when there is a footrest. The fastening material must be flush so as not to burn the skin (it must also be made of stainless material). It is better if the entire structure is assembled on dowels.

Shelves for a small bath

For wiring, you must use a double braided cable. It is better if it is non-flammable (usually the marking has the prefix “ng”). Be sure to lay the conductor in the corrugation. There are no switches installed in the steam room itself. The lamps used are waterproof with an IP68 index.

Make sure there is good ventilation. To do this, you can install an adjustable supply valve, as well as anemostats with an outlet to the gable through the roof. This will be enough to ensure that all moisture is removed after taking a steam bath.

As you can see, there are no restrictions on what you can build a small bathhouse from. Choose the option that suits you best.

Dimensions and layout of the bathhouse

The dimensions of a building are determined by its functionality.

- If you plan to use the bathhouse all year round, then you need to make a changing room in it.

- The washing process is also important: to reduce the size of the washing compartment as much as possible, you can simply install a hot tub or shower stall in a steam bath.

- And, of course, no bathhouse can do without a steam room.

Bathhouse layout

By adding up the dimensions of these rooms, you get the final dimensions of the building.

In order for the steam room to be as comfortable as possible, it must have a separate locker room and dressing room, as well as a relaxation room. But in this case, its dimensions will increase to approximately 6x3 m. And such a bathhouse can hardly be called small. That is, when drawing up a project, you will have to sacrifice some space.

Scheme

Layout 2.3*4

Layout 4*4

Bath plan 3*4

Plan 3*5

Photo

Miniature bathhouse with dressing room

Frame-panel bathhouse with porch

Mini sauna

Small bathhouse - wild log house