A finished log house requires timely insulation, so it is especially important to choose a high-quality and environmentally friendly material that will provide the building with proper air exchange.

There are two categories of insulation on the construction market - synthetic and natural.

Synthetic-based insulation materials are not particularly practical and safe to use, so they are not the best option for wooden buildings.

The right choice is construction moss for a log house. Natural insulation with high performance characteristics.

Selection and preparation

Moss has been used as insulation for a long time in the wooden construction of residential buildings and baths. This is a high-quality thermal insulation material that provides natural air exchange and insulation.

In addition, building moss is the most affordable insulation material in the price segment, which does not require special growing technology.

Two types of moss are used as the main inter-flower insulation material - sphagnum (white moss) and cuckoo flax (red moss).

Sphagnum

The scientific name for white moss is sphagnum. It grows in swampy, moist areas and in coniferous forests.

The plant has a long pile, is bright green on top and white on the bottom. Sphagnum is highly hygroscopic and has low strength, which does not prevent it from insulating wooden buildings.

A special feature of sphagnum is the absence of a powerful root system, which greatly simplifies the process of collecting it. The roots of the plant are small and not deep; when they die, they form peat fertilizer.

Excessive drying out leads to rapid thinning and reduction in volume of sphagnum. This negatively affects the caulking process and insulation in general. The thinner the moss and the smaller in volume, the more it needs to be used between the crowns of the bathhouse frame.

Kukushkin flax

Cuckoo flax or red moss, which is found in lower reaches, swamps or on the edges of forests, has slightly different properties. It is distinguished by tall and dense stems and large bright inflorescences.

Kukushkin flax has a bright red color and looks like flax.

Red moss differs from white moss in its increased density, elasticity and low hygroscopicity. Natural insulation that allows for high-quality insulation of various wooden buildings.

In some cases, construction tow is used, but it is less effective compared to natural moss. Experts assure that this is not the best option for insulating a building.

Tow does not ensure uniform filling of the grooves between the crowns, which leads to rapid wear and damage to the wooden structure. Often the laid tow is taken away by birds and mice to build nesting sites and create burrows. In addition, tow quickly gets wet and retains excess moisture for a long time, which leads to the formation of fungus and rotting of the wood.

Technology of caulking a log house with jute

To perform caulking we will need:

- Small hammer – 300 – 400 gr.

- Chisel 20 mm.

- Caulk trowel or wide chisel

- Rubber mallet

The caulking of the log house must be done after the building has settled and shrinked. First, during assembly, jute insulation must be laid between the crowns. The caulking process involves turning the jute with a spatula from top to bottom and then compacting it in the groove between the logs. In this case, light blows of the hammer are made on the shoulder blade. You will end up with a folded strip of jute in the form of a rope, which is very practical.

The work is carried out in two stages - primary caulking and main caulking. It is necessary to take into account that caulking of a log house is carried out only after the house has settled; for this it must stand for at least half a year.

Primary caulking is done without strong compaction, especially in those places where the logs have not yet settled into place. In such places, the jute is tucked without compaction, but care should be taken to leave room for further shrinkage of the logs. Caulking a log house, its technology is not very complicated, so we will look at it in detail below.

Caulking must be done sequentially - from bottom to top. First of all, the lower groove around the perimeter of the building will be caulked, then the second groove, etc.

It is important to do everything along the perimeter, otherwise caulking a separate wall may cause the building to warp. We also need to take into account that the higher we rise, the less we need to seal the grooves with jute

And the very top two or three grooves are tucked only with the help of a spatula, without hammer blows, this is done in order to avoid the slightest compaction of the jute.

The fact is that the log house will shrink for at least another five years, so the upper crowns will eventually crush the jute tightly themselves.

In a log house, the ends are the weakest point, due to the cut out bowls, so you need to caulk it carefully, without unnecessary effort.

The second caulking, the main one, is carried out together with the finishing, where the caulking of the log house is carried out more tightly. It is advisable to carry out this operation no less than a year and a half after the construction of the building. During this time, the log house will shrink almost completely and, without fear, you will be able to install windows and doors, carry out electrical work and install plumbing.

Periodically, you need to inspect the log house for cracks, especially after a hot summer. After all, even a small gap can lead to wood rotting.

Advantages of moss insulation

Natural moss, used as insulation for a log bathhouse, has a number of key advantages.

- It has long fibrous stems that can be gathered into dense bunches. They provide reliable caulking of the log house;

- It is an environmentally friendly and safe material;

- Does not contain toxic substances or foreign additives;

- Has a pleasant herbal smell;

- Provides reliable protection of wood from rotting, destruction and destruction by parasitic microorganisms;

- Has high adsorbing properties;

- Has low thermal conductivity;

- Provides good air exchange and insulation of a wooden structure;

- Has antiseptic and antimicrobial properties;

- Available in preparation, drying and operation.

The most important performance characteristic of natural insulation is its effective control of high humidity that occurs between wooden beams. In this case, the insulation is able to quickly absorb excess moisture, preventing rotting and damage to the wooden structure.

The high content of natural phenolic resins in the stems of the plant makes this insulation a natural antiseptic that has a detrimental effect on fungi and microorganisms that destroy wood.

Floor thermal insulation device

First, they begin to install a waterproofing barrier. Then the vertical sheathing is installed. It is made from timber with a section of 5 * 5 in increments of thirty centimeters.

Note: Before installing the sheathing, the timber is treated with a special antifungal agent.

Before laying mineral wool on the sheathing, it is cut into strips of the required length and width, twenty millimeters greater than the distance between the beams. Each strip is carefully laid and firmly fixed with anchor bolts. A vapor barrier film is installed on top with an overlap of up to ten centimeters using a construction stapler.

To cover the heat-insulating layer, sheathing with 3*4 cm bars is also arranged. The walls can be covered with wooden clapboard. For thermal insulation of walls, you can also use ecowool, glass wool and polystyrene foam.

The process of wall insulation can be divided into stages:

- Cleaning the surface from dust and dirt;

- Sealing cracks with foam, linen felt or tow;

- Treatment of timber for sheathing with antiseptics;

- Installation of timber lathing;

- Mark where the outermost elements will be installed, since the evenness of the entire structure will depend on the design of the first bar;

- Fastening the bars with screws and dowels in increments of 25 to 30 cm;

- One meter is measured from the starting block and the second is attached parallel to the first. And so on around the entire perimeter;

Note: In the locations of the windows, the bars are trimmed around the window opening.

- Insulation is laid between the sheathing;

- Then a vapor barrier is made on top of the insulation using film or polyethylene.

- Wall sheathing using plasterboard, which is screwed to the sheathing beams.

Note: It is not recommended to use a metal frame for lathing, since metal has high thermal conductivity.

Floor insulation helps create warmth and comfort in your home. Here it is very important to follow the technology of installation of flooring on the ground. First, the bedding is done, then the waterproofing is installed, and then the insulation material.

If the floors are wooden, thermal insulation is laid between the joists in a layer of one hundred to one hundred and fifty millimeters. Then rough or finished floors are installed. And if it is necessary to insulate concrete floors, this can be done using the raised floor method. To install a raised floor, first begin by leveling the surface and eliminating defects. A waterproofing membrane is spread on the concrete surface, logs are laid with a pitch between the beams of up to fifty centimeters.

With the help of beams, the floor is divided into even lines. The voids are filled with insulation, on top of which a membrane is placed and a flooring is made.

Often a log house is insulated with a heated floor system.

Before proceeding directly to the installation of a heat insulator, a number of actions are performed that will stop or slow down the process of wood destruction, as well as reduce heat loss. To do this, do the following:

- Carefully inspect the external walls.

- Remove rotten areas.

- Fill deep imperfections on the log with patches.

- The gaps between the wall parts are caulked.

- The prepared base is treated with antiseptic solutions.

It would also be useful to coat the wood with antiseptic compounds that resist the development of fungus and mold. Some also protect against insects. Such measures will help maintain the strength of the supporting structure much longer.

Procurement of raw materials before the main work

When using moss to insulate a log bathhouse, it is important to correctly collect and dry the raw materials. High-quality prepared raw materials allow you to quickly carry out caulking, as well as effectively influence wood pests and parasitic plants.

Harvesting and active drying of raw materials is carried out in the summer. Often, moss is harvested at the stage of installing the bathhouse frame before its shrinkage begins. Therefore, when carrying out caulking, the material must be dried as much as possible so as not to create obstacles to the process of shrinkage of the log house.

Sphagnum moss is harvested in warm sunny weather, which promotes rapid natural drying. It is resistant to sunlight, so loss of moisture does not affect its insulation characteristics. It is recommended to collect Kukushkin flax in cloudy weather, since such a plant is susceptible to active sun.

It is better to collect raw materials in a forest area under trees. Collected cuckoo flax is carefully laid out in a continuous ribbon on any base, and sphagnum - in small shocks or bunches. Drying directly depends on the degree of moisture of the raw material and can take 3–4 weeks.

Caulking technology

Seam sealing is divided into 2 types, which complement each other:

- Stretch. This type of seal received this name because the material is located along the seam with interlacing fibers. Used for primary caulking. The sealing material is placed with fibers perpendicular to the frame. After building a house, the gaps are small, and it makes no sense to push in a thick layer of insulation. The hanging parts of the material are carefully pushed into the seams.

- Into the set. This method is used after the structure has settled, when noticeable cracks have formed. The process is labor intensive. The fibers of the material are collected in a heap, twisted and pushed into the gap. The size of the rollers is different, because the slots are different (sometimes larger, sometimes smaller).

When carrying out the first caulking, you should not skimp on materials, but you cannot lay a thick layer either. After the secondary compaction, after about 5 years, when the log house finally shrinks, you need to caulk all the seams again. In your work you can be guided by the following sequence:

- Clean the seams from any debris and old worn material.

- Check the caulk one by one (along the perimeter of each row) for any distortions, cracks, or crevices that have appeared.

- Work must begin on the outside of the log house, and then on the inside.

- Do the caulking carefully: fix the edge of the material in the crack, use caulking and a hammer to push the material. This is done in several approaches. If you try to hammer in the entire roller at once, skew may occur and the seal will be broken. The same operations are carried out inside the house.

- You need to move from the lower crown to the upper one.

Synthetic materials

The performance properties of many synthetic insulation materials are inferior to natural ones, but in the assortment of similar materials it is quite possible to choose high-quality options

In this case, it is very important to take into account the features and purpose of the building, since the wrong choice of insulation can lead to unpleasant consequences

Mineral wool

Mineral wool is the cheapest option, but it can be used exclusively for insulating facades. This material is not suitable as inter-crown insulation for houses made of wood (especially timber). Firstly, when compressed by crowns, it quickly loses its thermal insulation properties, and, secondly, the moisture absorption of its fibers tends to zero. The disadvantages of mineral wool are especially noticeable when insulating baths, so in this case it is recommended to choose another option.

Mineral wool is an inexpensive and practical thermal insulation material, but it is better not to use it as an interventional insulation material.

Izover

Isover is the same mineral wool, but with improved performance characteristics. This is a popular insulation material today, which, however, has some features and disadvantages. So, in places where there is practically no gap, it shrinks greatly and loses its thermal insulation properties, but when insulating large gaps it performs its tasks well. In addition, Izover has several valuable advantages: it is not flammable, does not rot, does not attract birds, and is very easy to use. However, this modern material has one significant drawback: it is not very environmentally friendly, and at the slightest damage it releases dust that irritates the skin and mucous membranes. In the case of insulating baths, Izover also cannot be called a successful solution, as it has the ability to accumulate moisture, and in the absence of a vapor barrier, it gets completely wet.

ISOVER insulation

Polyurethane foam

Polyurethane foam is sometimes used as insulation for wooden houses, which has the following advantages:

- quick and easy to install;

- glues logs well, thanks to which they subsequently do not “creep” or warp;

- unlike moss or tow, it seals corners well;

- One-component foam does not burn and does not emit harmful substances.

Polyurethane foam

If we talk about the disadvantages of polyurethane foam, they include:

- the material is not elastic, so microcracks may appear in the wood over time;

- foam does not tolerate frost well and begins to crumble at low temperatures;

- when exposed to ultraviolet light it turns to stone and fades;

- If you compare foam with natural insulation, its environmental friendliness will be very low.

Most often, polyurethane foam for insulating log houses is used in combination with other materials, and installation is carried out in two ways.

Method number 1. The timber is laid half a meter apart, and upon completion of the work it foams. Thanks to this, the crowns dry faster and do not require subsequent caulking. The inside walls are insulated with linen material.

Method number 2. Before using foam, joints and cracks in the walls are sealed with tow and the building is allowed to settle well (usually this takes about a year and a half). After this, five-centimeter cracks are made in the tow, the grooves are foamed and the seams are sealed with sealant.

Sealing cracks with sealant

How to choose synthetic insulation?

If the question arises about using synthetic inter-crown insulation, it is best to focus on foreign-made materials, in particular Finnish synthetic felt. It has good thermal insulation characteristics, does not rot, does not get wet and does not contribute to the proliferation of harmful microorganisms.

Felt

Housing with new technology

The architects came to the conclusion that a warm house can be built from wood, but not using a solid beam, but 2 or more boards, between which a layer of insulation is laid. This new technology should be called "sandwich wall", but is more often called "double timber".

The design of walls, floors, and roofs of double timber differ from logs. They are made according to a special design: insulation between 2 planed boards, which act as timber. Their thickness ranges from 4.4 cm to 7 cm and has a height of 14 cm. They are installed on the edge, and the seating edges are made using the tongue-and-groove system, which ensures tight contact and protection of the seam from blowing. The rigidity of the structure occurs due to the joining of boards at the corners, which is characteristic of a log house (grooves are cut into the boards at 1/2 the height of the board).

A structure using sandwich technology is practically a building made of boards with insulation inside, which can have, for example, three boards that create internal cavities where the insulation is laid.

How to lay moss when assembling a wooden frame

In general, the process of laying a log frame on moss is not so tricky. Actually, moss as insulation is quite easy to use, which is why carpenters have used it at all times.

It will take a lot of time to collect the material and prepare it (dry it), but then everything depends on what kind of moss is used for thermal insulation.

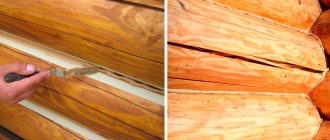

If you use ordinary white moss (aka sphagnum), then the laying technology looks like this: after fluffing it with your hands, we lay it in piles on top of the crown of the log house. The piles should fit as closely as possible to each other. At the intersections of the logs, that is, in the bowls, we place the moss more densely and overlapping. The insulation should extend beyond the edges by about 4 centimeters. We lightly press each pile with our hands, compacting it in this way. Cuckoo flax moss also needs to be fluffed a little with your hands before laying it down. This material is placed crosswise on the logs. Strips of moss should be laid overlapping.

Before you begin laying the insulation, the logs must be treated with special protective impregnations:

These chemicals will prevent wood from rotting or being damaged by fungi, mold or insects.

It is important to do this first, since then there will be no access to these areas of the log house

Another important nuance that you need to know about when laying moss is that the layer thickness should be at least 10 centimeters.

As the crowns are laid, pressure will be exerted on the insulation and it will simply be compressed. If there is not enough moss between the crowns, cracks will form over time, through which heat will escape from the house.

How to insulate the ceiling and roof of a log house?

The first step is to insulate the roof and ceiling. If you have a one-story house with an attic, you will need to lay a waterproofing film on the attic floor, and then pour a 20-25 cm layer of insulating material on top. For this purpose, it is recommended to use eco-wool, glass wool, seaweed or sawdust. There will be no need to cover the insulation material. You can lay boards on top to make it convenient to move around the attic. It is not necessary to arrange the floor.

If instead of an attic the house has an attic floor, then it will be necessary to insulate the interfloor ceiling and roof slope. You will need to lay 5-9 cm of insulating material in the ceiling. If the attic flooring is made of wood, then the insulation will need to be filled between the joists. If the floor is concrete, you will need to use basalt wool or polystyrene foam. To insulate the roof slope under the roof, you need to lay a waterproofing film, then lay a 15-20 cm layer of mineral wool. A membrane is laid on top of the insulation. Next, the sheathing and finishing materials for the attic are installed.

If you do all the above steps, the house will be warm.

Drying

Natural material should be transported separately from the log house, in order to avoid any damage to the dense but soft structure of the moss. Immediately after its delivery, it is necessary to organize drying of the future insulation. There is no need to leave it in bags or dump it in heaps, as the plant will begin to rot and lose its quality. Drying moss is a critical stage in the preparation of the material.

Sphagnum is stored in small loose bunches, reminiscent of miniature haystacks. This technique helps preserve the rather fragile structure of the plant in the best possible way. Depending on weather conditions and the percentage moisture content of the moss, the drying process may take about 7-14 days. In no case should sphagnum be overdried, as it becomes brittle and therefore can crumble even before it is laid between the crowns of the log house. In addition, moss that is too dry is difficult to fix in place, as it blows away even with a slight gust of wind. In certain situations, sphagnum must be watered so that it acquires a certain elasticity.

It is better to immediately lay out Kukushkin flax in ribbons. The dried insulation is rolled into rolls, which subsequently speeds up the process of laying it into the inter-crown space.

Quite often, moss is dried directly in the forest, hanging bunches on dead bushes or low spruce trees. But it's not very convenient, actually. The disadvantage of storing plants in small stacks is poor ventilation, which can lead to the formation of mold. But there is a way that justifies itself in the best way. This is drying moss on racks. The material is laid out on horizontal surfaces formed using stretched ropes intertwined in the form of a mesh.

Moss is placed on the racks 20-30 cm thick. It is necessary to leave a distance of at least 35-40cm between the shelves to ensure proper ventilation of the layers on both sides.

The degree of drying is checked in a simple old-fashioned way. To do this, twist a small bunch and see what happens to it. If he:

Application

Technique for laying inter-crown sealant on a log

Let's look at how to properly use the material in your work.

Moss must be laid in the following way:

- If it is dry, then tamp it in a barrel and fill it with 20 - 30 liters of water. Leave for half an hour, drain the water, and squeeze out the moss.

Remember! Dry moss does not allow itself to be manipulated, so pre-washing will allow the material to become more pliable.

- Take ready-to-install moss.

- Lay it across the log without compacting it. Please note that the seal must lie evenly.

- Make sure that the width of the layout is 200 - 250 mm, and the thickness is 40 - 50 mm.

- Laying in the bowl is made with a thickness of 4–5 cm, and the protrusion beyond its limits is 5–10 cm.

Advice! Lift one end of the log and place it on the bowl, then lift the other end, about 50 - 60 cm higher from the place of laying, so as not to move the moss, and release it into the opposite bowl.

- Tap the entire surface with the headstock.

- Perform all subsequent actions as described in paragraphs 2 – 7.

- Take a construction stapler and secure the laid material every 30–40 cm.

Tow is less problematic to work with, since the finished canvas does not require additional time for cleaning and even laying on the log.

Tape jute is especially convenient to use.

It differs only in the installation methods:

- If the timber is for a bathhouse, profiled, glued, then we lay the insulation without bends. We don't use a stapler.

- If the log is ordinary, profiled with natural moisture, then the material must be folded once with a lock. Make sure that the canvas does not extend beyond the edge of the end.

- If the bathhouse is built from a wild log house, a fire monitor structure, or from a milled log, lay the tow in two layers. Use a stapler to secure the fabric.

Attention! Crumpling the canvas is prohibited, as this leads to poor shrinkage and further damage to the wood.

Log caulking technology

Caulking is a stage in the construction process whereby gaps and crevices are filled with a special material to prevent the inside of a room from coming into contact with the outside environment.

Caulking of a stretched log house.

The goal of the work is to fill the visible cracks tightly, without gaps.

- Select a specific area as the primary task.

- If the material is in a log (just insulated), push the protruding part into the gap.

- Take the caulk in one hand and insert the tool into the crack.

- After it stops falling into the gap, proceed to tapping it with a mallet.

The caulking process goes like this.

- Next, compact the next section on the same log, and so on, along the entire length in a circular direction.

- After external caulking of the bath, proceed to the internal filling.

Remember! One log needs to be compacted, both on one side and on the other.

Modern caulking tool.

After 12 months the process must be repeated.

Laying technology in log cabins

Caulking a wooden frame with jute creates reliable insulation of the structure for the entire service life. The process of laying batting is as important as the construction of the log house itself. Using the wrong caulking technology will result in your home becoming cold, drafty and uncomfortable.

Jute insulation creates good conditions for wood material, as a result of which the structure will serve for many years. Caulking also prevents oversaturation of wood with moisture and dampness, protects against rotting and the proliferation of insects, fungus and mold.

The technology for caulking a log house involves performing the insulation task in two stages. Primary laying is carried out during the construction of a timber house, finishing - after its shrinkage.

Technology for laying jute in log houses

Primary caulking occurs in two steps. In the first stage, a strip of jute batting is laid between the crowns during the construction of the log house. After completion of the construction of the walls, finishing of the seams is carried out. Using jute tape to fill gaps requires following certain rules:

- The crowns are pre-cleaned of dust, shavings, dirt and other deposits. The jute is rolled out on the wall and fixed in one meter increments with a construction stapler;

- the remnants of the tape are cut along the edge of the beam or flush with the laying groove of the log;

- the dowels are driven right through the tape. Cross-shaped cuts are made at the puncture points;

- The actions are repeated on all crowns.

Caulking always starts from the bottom crown, using a special tool. The walls and roof must already be erected. Having completed the installation outside, the process can begin inside the house. The technology is the same.

After the frame has been subjected to shrinkage, finishing processing begins. The first layer of insulation is deformed, the gaps between the crowns widen. Therefore, the second caulking is done again. When wood shrinks, long and deep cracks can appear. They are filled with flax tow and sealed with sealant.

conclusions

As you can see, these insulation options have quite a lot of advantages. However, the question of which one to choose has still not been resolved. Basically, it's up to you to decide.

But, as a little advice, we want to draw your attention to moss, since its use can protect your structure from significant problems. Unfortunately, this cannot be said about jute tow (despite all its positive qualities), which means that this type of inter-crown insulation should be used if you do not want to assemble the frame of your bathhouse with moss

But this is our conclusion and many believe that inter-crown jute can be confidently placed in 1st place when choosing a gasket for the grooves of a log or cobblestone bathhouse. We will not argue with this, since we consider inter-crown jute, along with moss, to be a very good choice as a natural insulation between the crowns of saunas and baths.

How to arrange a façade with ventilation?

You need to insulate the house from the outside using a façade with ventilation. This design will allow the wooden wall to “breathe”.

First of all, you will need to treat the walls with an antiseptic so that you can protect the wood from fire and mold. A sheathing is placed on top of the walls to hold the insulation. To do this, you need to use a block with a cross-section of 5 cm. You need to stuff it vertically, observing a step that is equal to the width of the insulation boards minus 3 cm.

When installing insulation on a log wall, you may encounter inconvenience. It has an uneven surface, so it will not be possible to lay the insulation closely without gaps. You will need to insert insulation into the gaps between the wall and the sheathing bars to provide thermal insulation. Jute is suitable for this purpose.

Insulation scheme for a log house.

Installation of insulation is carried out from the bottom up. A windproof superdiffusion membrane is installed on top of the insulation material for waterproofing. It must be vapor permeable. Such a membrane will be able to keep out moisture and wind from the street, while releasing wind and air into the street, thereby allowing the walls to “breathe”.

A sheathing of 5 cm bars is placed on top of the wind protection. Siding is mounted on this structure. A gap for ventilation between the facade and the membrane will be formed over the entire thickness of the sheathing. You will need to make vents in the lower and upper parts so that air can circulate.

Tips and tricks for protecting a log structure

This procedure includes the following steps:

- Treatment with an antiseptic (from rotting, insects and rodents).

- Installation of a fire retardant layer (for fire safety purposes).

- Finishing (priming and coating).

The correct process allows you to maintain the beauty and safety of a wooden house.

Insulation of a log house from the outside necessarily includes caulking, thermal insulation of walls, ceilings, window and door openings. Further work depends on the design, purpose and age of the building. All processes can be done with your own hands, but to ensure guaranteed insulation from the cold, the owner of a residential building should contact specialists.

External skin

The main function of the outer skin is surface decoration. The choice of materials is varied and can satisfy every taste. Depending on what purpose is pursued during insulation (decorative effect or the ability to protect the tree from external influences or increase insulating properties), the type of sheathing is selected.

There are two types of facade cladding - wet, which involves the use of various plasters and mortars, and dry, with the formation of three-dimensional facades (from siding, facade tiles, metal, PVC facade cassettes, etc.). Due to the fact that thermal insulation thickens the walls, window and door openings become somewhat deeper. This problem is solved by installing new window sills along with trim or siding.

The environmental friendliness of log houses, as well as their preservation of heat indoors, is beyond doubt. It has been proven that a 240 mm thick wooden wall is equal in terms of thermal conductivity to 1 m of brickwork. However, it is often necessary. This is required when drafts are detected in a new house or after purchasing an old building.

Insulation of a house made of rounded logs

Insulation of a log house is carried out when heat loss is detected at the junctions of structural elements. Thermal insulation can be internal, external or internal

Important! Sealing and insulation are not the same thing. While insulation allows the house to “breathe,” sealant does not.

Log cabins retain heat well, provided that all the gaps between the logs are carefully caulked. If the thickness of the walls allows you to withstand frost, then you can limit yourself to caulking, preserving the structure of natural wood both outside and inside.

How to insulate a log house from the outside? Before starting insulation work, the new log house must stand for at least a year so that it has time to dry and settle.

Important! Before starting work, treatment with an antiseptic and fire retardant is mandatory.

What to put between the crowns?

To create a gasket between the crowns of a log house, there are many insulating materials. But not all of them are ideal for these purposes. First, you need to safely cross out synthetic and artificial materials from the list of candidates for inter-crown insulation. They will cope with the thermal insulation task well, but the price of their work will be damaged crowns of the log house. Artificial materials allow air to pass through well only when they are in a fluffy form, and when they are compressed by logs, they cannot do this, which will negatively affect the wood; it may begin to rot.

There is another drawback to these insulation materials - they are made from non-ecological components. And it seems to me that many people choose wood for construction in order to be closer to everything that is clean, safe and natural. The use of artificial, synthetic insulation will disrupt the entire beneficial microclimate of the room

It is for these reasons that, to a greater extent, I do not recommend focusing your attention on these insulating materials

And it is advisable to lay insulation between the crowns from natural materials, which consist of fibers of natural plants. They also have good thermal insulation characteristics, but they are in perfect harmony with the wood and do not cause any harm to it. Among such materials are:

Many builders cannot make the final choice of insulation, deciding which of these three materials is better.

Moss can safely be called the best insulation material. Even with the advent and development of technology, they have not yet been able to invent and create insulation that is superior to moss, unless they came close to its characteristics by producing jute insulation. There are more than a hundred varieties of moss, but only brown and white moss have shown excellent results in construction. They practically do not differ in their properties, they only have differences in appearance. White moss consists of small light green fibers. It does not have a root system, despite this it grows well. White moss produces a very valuable product - peat. Brown moss consists of longer and tougher fibers that are greenish on top and brown on the bottom. Its stems resemble flax in appearance, which is why its second name is cuckoo flax.

Both brown and white moss have bactericidal properties; they themselves are resistant to mold, fungi, and insects and protect the crown grooves from them. They allow air to pass through well, allowing the crowns to breathe. They absorb all excess moisture, leaving the wood dry, and when there is insufficient air humidity, they gradually release it, i.e. regulate the level of humidity and microclimate in the room as a whole.

Laying moss between the crowns is quite difficult, especially white moss. Due to its structure, which consists of long fibers, Kukushkin flax is easier to lay. If you have experience working with insulating materials, then dealing with moss will not be easy at all.

Jute is a more modern insulating material, the properties of which are similar to moss. It is also hygroscopic, breathable, and does not let wind into the room. Jute is not afraid of the influence of biological agents, does not rot and is durable. Insulation from the jute plant is produced in the form of ropes, which are used mainly for decorative work, and tow is ideal for caulking and tape. Tape jute insulation is perfect for laying between the crowns of a log house. Even a non-professional can lay them; you just need to spread the tape on the log so that its edges protrude on both sides, and secure it well with a construction stapler. Then, after erecting the entire frame, carefully bend the remaining edges of the insulation and drive them into the inter-crown groove. Such seams in a wooden house look very attractive, especially since jute has a shade similar to the wood itself.