To seal the cracks between the crowns in log and log houses, today they use both traditional moss and tow, and modern tape seals. It is up to the consumer to decide which material to choose. The main thing is to familiarize yourself with the properties and features of each in advance.

What qualities should a sealant have?

The main function of the inter-crown seal is heat insulation ,

which means that the material used for this purpose must have a low thermal conductivity coefficient.

Secondly, since wood is a “living” material that reacts to changes in environmental conditions, the gasket between the crowns is designed to prevent the appearance of blown gaps, and for this purpose it must be sufficiently dense and elastic

. Thirdly, it is required

to be resistant to rotting,

the process of which threatens to destroy not only the material filling the cracks, but also the wooden walls themselves, as well as

the ability to give and absorb moisture, adapting to changes in the humidity regime both outside and inside the room.

The next condition for the effectiveness of interventional insulation is non-susceptibility to biological damage

from insects, rodents and birds and, finally,

environmental friendliness,

that is, safety for human health.

Good old moss and tow

Long-fibered moss

Long-fibered bog moss

(red moss, sphagnum, “cuckoo flax”) with fibers from 15 to 30 cm is an environmentally friendly natural material with a low thermal conductivity coefficient of 0.04 W/(m °C).

Such insulation “can” absorb and release moisture, reacting to the level of air humidity; It is very resistant to decomposition, is never affected by rot, and in addition, contains tannins that have a bactericidal effect and prevent fungal diseases of wood.

Moss is used slightly damp, creating a mossy bedding from it for each subsequent crown of the house. However, the elasticity of this material is low: it gradually dries out and shrinks after a year and a half, resulting in the formation of cracks in the walls. Repeated caulking is done with flax or hemp tow.

Moss is sold at a price of 280 rubles. per bag.

Considering the natural origin of the material, many consider the use of moss to be the best solution when building baths. However, it should be borne in mind that dry moss will instantly flare up from any spark, so for fire safety reasons it is not advisable to use it in baths

Caulking tow

Flax and hemp tow

- short-fiber material made from waste of natural hemp and flax. The density of hemp is 160 kg/m3, and the thermal conductivity coefficient is 0.047 W/(m °C). It is more labor-intensive to use (in particular, due to the heterogeneity of the fiber structure, it is difficult to spread it in an even layer), but, unlike moss, it is suitable not only for caulking walls, but also for sealing joints, window and door frames, etc. Lay pieces of tow across the log, and it continues to hang from under the crowns until the house is assembled. Then its ends are twisted into a roller and sealed into the cracks using wooden or steel caulk and a mallet. The second time the building is caulked after the initial shrinkage. The tow costs 900 rubles. for a 30 kg bale.

The main disadvantages of tow are its instability to rotting, flammability, and also the fact that it is an excellent building material for bird nests, and feathered neighbors will definitely use it.

Please note: it is permissible to caulk only log houses with moss and tow. Having a proven geometry, the beams fit so tightly to each other that they require a strictly uniform layer of inter-crown insulation

Methods for caulking bath walls

To insulate a log house yourself, you will need a mallet, a road builder and a set of caulks - type-set (with a narrow nose), broken (to widen the seams), curved (curved). It is better to choose tools made of wood to prevent damage to the logs.

There are two methods of caulking a bath:

Technology of caulking baths with moss

You can reliably caulk a log house using moss (from 16 thousand rubles), vegetable oil, water, and soap.

The process of insulating a bath is carried out in the following sequence:

Instructions for caulking baths with tow

To prevent insects from infesting the insulation, it must be treated with a disinfectant solution. To caulk a log house with tow, you will need an antiseptic (formalin), water, tow (from 40 rubles per kilogram).

Thermal insulation occurs step by step:

Method of caulking baths with jute

This is the caulking method. First you need to decide on the type of jute. Then prepare it for insulation. To caulk the log house as efficiently as possible, we will need jute (about 6 rubles per linear meter), resin or bitumen (if we use jute felt), formaldehyde (if we use jute tow).

The process should follow the following sequence:

Caulking the log bathhouse with synthetic sealant

We insulate the log house in stages:

The bath caulking technology is shown in the video:

Source

Caulk or sealant for a log house - which is better?

Synthetic caulk works well for sealing gaps between crown timbers. It leaves no cracks or gaps, tightly filling all gaps. It is convenient to apply. In aesthetic terms, the sealant is also good, since it has different colors and can be matched to any type of wood, while fulfilling an aesthetic role.

The sealant itself does not serve as insulation and allows cold to pass through. Therefore, it is used only as an additional material that tightly covers all cracks. The composition of sealants is:

- silicone,

- acrylic,

- polyurethane.

The sealant has an impressive cost, so it is also combined with other, cheaper materials - jute, linen. This combined seam will hold heat perfectly.

The sealant is durable. When using it, you will not need to re-seal the seams. It also prevents insects from getting into the porous insulation.

To insulate a log house with sealant, you need to proceed as follows:

- Place insulation cord into the cracks.

- Fill the cracks with sealant. Start working from the bottom log, from the corner, from the outside of the log house. Move along the entire perimeter of the log house, and then higher.

- Carefully remove all excess sealant with a spatula.

- Treat the inside surface of the frame in the same way.

To answer the question: Caulking or warm seam - which is better for a log house? — it’s worth remembering the many advantages that a warm or heat-insulating joint made with wood sealant has:

- The sealant easily penetrates into all hard-to-reach cracks and seals them tightly. As a result, all cold bridges are blocked. The premises are reliably protected from drafts.

- Considerable strength. It does not crumble or fall out of cracks for a long time, and birds do not peck at it.

- The ability to preserve the walls of the house. Traditional insulation gets wet in wet weather and dampens the wood. As a result, the walls begin to rot. Acrylic sealant is moisture resistant.

- The ability to improve the microclimate in the house due to durable protection from moisture.

- Durability. The service life is 20 years or more.

- The sealant also protects the wood from insect pests, such as wood-boring beetles.

- The sealant tolerates any high and low temperatures, as well as their changes.

- Environmental friendliness. The sealant does not release any harmful substances into the air and is in perfect harmony with the wooden structure.

- Elasticity. The “Warm Seam” sealant is flexible and can change its shape following the expansion of cracks between the logs due to shrinkage of the house. In this case, no cracks are formed.

- The sealant is much easier to work with than traditional caulk. The process takes less time.

Although caulk is more expensive than tow, the caulking job is even more expensive.

Therefore, many owners of log houses prefer a modern method of insulating a log house, namely, using sealant instead of tow, moss and flax.

To make the seams look aesthetically pleasing, they are trimmed with decorative jute. In this case, all traces of sealant are covered.

The use of sealant for insulating a log or log house is called a breakthrough in modern construction.

Caulking a log house with sealant is done quickly and looks very neat.

Some owners of log houses use construction foam to insulate the seams between logs. This is not suitable insulation. Very quickly, within a year or two, it dries out, falls into pieces and falls out of the seams. After this, the caulking must be done again.

In addition, foam does not retain heat and cannot act as insulation.

To caulk a log house, you need to choose a special sealant for wood that retains its plasticity for a long time, does not dry out and does not fall out of the cracks. This sealant must be used in conjunction with insulation.

Construction foam is not suitable as insulation for log caulking. It quickly dries out and falls out of the seams.

Owner reviews

The traditional method of caulking a log house with tow or moss requires special skills from craftsmen. Nowadays such craftsmen are difficult to find. Therefore, hired workers do not always perform high-quality work, charging a lot of money for it. This is what Igor M. from Moscow says about his experience in insulating a bathhouse.

After building a bathhouse on the site, I hired a team and caulked the entire frame with tow. The work turned out to be expensive and long. But the guys were good, they didn’t drink, they worked every day. The job was completed in 3 weeks.

After 5 years of use, some of the logs cracked and gaps appeared between them. The question about caulking came up again. I no longer wanted to spend a lot of money on a team, and I couldn’t find good workers. And then I decided to do the work myself. I chose sealant as the insulation material. Everything turned out great, even better than the specialists.

The bathhouse has stood for 15 years and there are no cracks. Therefore, I advise everyone to choose new materials, namely, wood sealants.

What and how to properly caulk a bathhouse - practical advice from an expert

Simply laying a frame when building a bathhouse is not enough - you will definitely need to caulk the bathhouse, that is, close the existing cracks and cracks formed after the wood has dried out. This article will discuss how to caulk a bathhouse.

The caulking of the bathhouse frame is needed so that it loses a minimum of heat. It is very important to use a well-prepared log house, lay it correctly and do not forget to install inter-crown insulation.

What to choose as insulation - moss, tow or jute - is up to the owner to decide, but it must be present.

The insulation is placed in two layers as follows:

It is worth keeping in mind that when laying moss or tow, tapping such material is not required. If you hit it with a hammer or an ax handle, the moss fibers are torn, and dents appear on the surface of the wood, which after some time can cause the appearance of rotting zones. It is recommended to compact the fibers only by pressing with the palm of your hand. Excess elements in the moss simply need to be removed.

If, when deciding on the best way to caulk the log house of a bathhouse, the choice fell on tape insulation, then you can fasten it with a construction stapler. In this case, it is important what to pierce the bathhouse with, since it can cause harm to the material.

Damage to the wood from the stapler will be minor, but this will allow the material to be firmly fixed. It is best to lay out insulated crowns together so that the log can be taken from both sides and slowly lowered without damaging the insulation.

Jute

One of the best materials. It not only perfectly fills cracks, but also protects the inter-crown space from moisture penetration. Birds don't use it to build their nests, so you don't have to worry about them pecking it off. It is made from wood from the linden family. It is usually imported from other countries. The material is soft and flexible.

Caulking rope

Jute rope. In addition to its direct purpose, such caulking serves as a decorative finish.

Sealant for log caulk

How can you caulk a log house?

There are natural materials for caulking and artificial ones. The first include tow, hemp, jute, moss, and so on. The latter include industrial sealants. Sealants are easier to work with and apply quickly. As a rule, in order to reduce their consumption, a cord is laid in the inter-crown gap, and the sealant, which is distributed with a special spatula before hardening, is applied on top of it.

However, sealants have a number of disadvantages:

You can learn more about how to operate the sealant by watching the available video material. A simple tablespoon is perfect for distributing the sealing agent.

If, when determining how to caulk a bathhouse, you chose a sealant, then carefully study the instructions and make sure that it can be used with exactly the type of wood from which your log house is made, that it is suitable for your region, and also has all the necessary characteristics.

It is advisable to use a synthetic sealant for a log bathhouse if it is used to close caulked cracks. After double caulking the log house with tow, moss or jute, wait until the log house finally settles and reaches working dimensions. Next, a cord is inserted into the seams and covered with sealant.

Each of the natural materials for caulking has its own positive and negative qualities, and preparatory measures are required in any case.

Moss is considered the most common, time-tested material for caulking. It has been used for hundreds of years. Currently, there are many other materials, but they all have slightly worse characteristics. True, new materials are easier to operate, and they also have such positive qualities as antibacterial properties and special resistance to rotting.

Before caulking a log bathhouse with moss, it must be dried and soaked right before use. This action will give the moss fibers elasticity. The moss is laid out in a layer and leveled so that its ends hang down on both sides of the beam. After all the logs have been laid out, the excess moss fibers are shortened, and what remains is wrapped and tucked into the cracks. Thus, the first stage of caulking the log house is carried out. Further stages of caulking will be continued after a year and a half.

Recently, builders are increasingly asking the question of how to caulk a bathhouse with jute. Given that we mean rolled material. Jute fiber has excellent thermal insulation properties and contains natural binding resins. Jute is practically not afraid of moisture, and very rarely becomes unusable due to rotting. Even in conditions of high humidity it does not get wet.

Felt

An excellent material that, like moss, allows the tree to breathe. It is a good filter that does not allow odors to pass through. Additional synthetic inclusions began to be added to modern material, which made it even more durable. The main disadvantage of using this solution is that moths love to feast on felt. Before caulking, it is treated with special compounds that repel this insect.

Lnovatin

Tow

This material is waste generated after the primary processing of natural fibers. The logs are caulked with jute, hemp and flax tow. The properties and quality of such material are determined by the raw materials, the length of the fibers and the level of their purification. During production, tow is pressed into blocks. To use it, you need to pull a strip of material from the block, twist it into a rope and place it in the seam. Although, it is easier to use tow sold in rolls.

In general, tow is not very convenient to work with, since it is very difficult to get an even seam. When caulking a log house, due to the high rigidity of the material, it is difficult to obtain a tight seam from the first approach. We have to resort to a repeat process. If you decide how to properly caulk a bathhouse by choosing between moss and jute tow, then you can confidently say that it is better to choose moss, since it does not harbor fungus and bacteria.

What is it, when is it done and why?

A house or bathhouse made of logs shrinks in the first 2 years after construction. In the first year, the shrinkage of the log house reaches up to 20 cm. This factor should be taken into account when designing a house. This is due to loss of moisture and drying out.

During shrinkage, loose junctions appear in those places where everything was previously sealed. To eliminate this, resort to caulking. It is necessary to take measures to seal the cracks so that there is no heat loss or drafts. These activities are carried out only after the structure has settled.

At what stage can you start caulking a bathhouse?

If the frame was laid on moss or tow, pieces of material of various lengths protrude between the crowns. In this case, you can begin the initial caulking: trim off the excess fibers, and hide the rest in the seams. You should be careful and take your time, adhering to the rules of caulking. If the log house was laid on tape insulation, then further operations are not necessary.

The first caulking is carried out about 6 months after the construction of the log house walls. During this period, almost all the moisture will leave the logs, new mother-in-law will be visible, and most of the crowns and corners will shrink. After this, you can begin installing doors and windows.

Further caulking is carried out after 12 months. During this time, the log house will be completely stable, so that all found defects can be eliminated. Based on the selected material and the quality of the work performed, you may need a new caulk in about 5 years. Sometimes, due to negligent construction work or if insulation was not laid between the crowns, caulking has to be repeated several more times, every year.

Features of caulking an old log house

Often old houses lose heat because the insulation has crumbled and does not retain heat. This situation is especially typical for log houses caulked with moss: over time, it dries out, crumbles, and falls out of the cracks. In doing so, proceed as follows:

- Using a stiff brush, remove as much moss as possible from inside the house.

- Caulk the vacated cracks with a jute cloth using the stretch method, driving the cracks to half the thickness of the wall.

- From the outside of the building, clean off any remaining moss with a brush.

- Caulk the remaining part of the cracks outside.

How to calculate tow for a bathhouse

Before caulking a bathhouse with tow, you should decide on the required amount. Tow compresses quite well, so it is consumed quite heavily. Perhaps no one can say the exact figure. This is because there are a lot of nuances that influence this: the material of the log house, what grooves are cut into them.

If the grooves were made manually, then, often, the consumption of tow will be large. In addition, consumption increases if a sanded log was used rather than a rounded one. Less material will be used for the timber, although in this case its quantity will be determined by the parameters of the timber, the depth and number of cracks that appeared during the drying process.

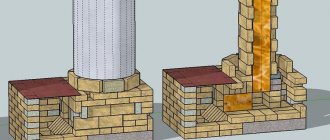

Caulking with sealant

Caulking a timber house using sealant is the fastest way. To work, you will need the synthetic material itself, a cord for filling the cracks, a special spatula for smoothing the seams (you can use a narrow spatula), and a mounting gun.

Progress:

- Place the cord in the cracks and compact it tightly.

- A layer of sealant is applied on top by inserting it into the mounting gun.

- Using a spatula, level the product.

- After moistening a clean rag with water, wash off any sealant that has got on it from the timber.

Having learned how to properly caulk a log house and choosing the appropriate material, you can get to work.

Caulking technology

Before caulking the log house of a bathhouse, you need to study the basic rules of this process. In fact, caulking a log house is quite easy, but it takes a lot of time, and you also need to be patient. For a bathhouse with dimensions of 5x4 m, one person will need about 10 days, spending 7-8 hours daily.

At the same time, you should not overdo it when laying insulation, since this fact leads to the fact that the log house becomes 15 cm or more higher.

The basic rules for caulking include the following points:

Like any other part of construction work, caulking requires certain skills from the master. Based on the fact that there will be quite a lot of such procedures, after some time you will definitely develop them. Over time, as you gain experience, you will notice more and more new inaccuracies that were made in the initial stages of work.

You can eliminate them without much difficulty, bringing the work to almost perfection. Actually, those who do nothing make no mistakes, so caulking a log house with the proper quality is possible even without sufficient experience.

Source

Labor intensity of work

It is also necessary to take into account that when caulking, the height of the house increases by an average of 10 cm. If the technology is not followed and the caulking is incorrect, you can get a distortion in height, which results in deformation of the entire structure. Therefore, it is not recommended to caulk the house yourself; it is advisable to entrust this work to professional craftsmen.

The process of sealing joints and cracks with sealant is not particularly difficult; installation work is carried out quickly without noise and dust. Sealed seams do not in any way affect the height of the building, which remains at the same level. The main thing in work is not to deviate from technology, which also requires professionalism.

Basic principles

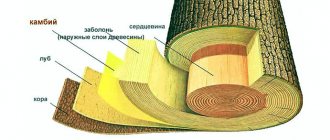

The quality of the log house's assembly is determined by how the crowns are laid. It is important not only to cut out the bowls and grooves correctly, but also to lay inter-crown insulation between two rows of logs or beams.

The insulation is installed during the assembly stage of the log house

What it will be - moss, tow or jute - is up to you, but such a layer must be present. When building a log house, you need to lay insulation in two layers:

Please note that when using moss or tow, there is no need to “tap” the material. When tapped with a hammer or an ax butt, the moss fibers break and dents form on the wood, which are directed across the fibers. Such damage can lead, in the future, to the development of foci of rotting. It is enough to simply compact the fibers with the palm of your hand, leveling and probing the layer; if you come across large foreign objects (cones or sticks are often found in moss), simply remove them.

Laying moss when assembling a log house

When using tape insulation, you can fix it using a construction stapler - damage to the wood from the staples is minimal, and the material is held securely. It is advisable for two people to lay the “insulated” crowns so that they can take the log from both ends and lower it so as not to move the insulation.

What to put between the crowns?

To create a gasket between the crowns of a log house, there are many insulating materials. But not all of them are ideal for these purposes. First, you need to safely cross out synthetic and artificial materials from the list of candidates for inter-crown insulation. They will cope with the thermal insulation task well, but the price of their work will be damaged crowns of the log house. Artificial materials allow air to pass through well only when they are in a fluffy form, and when they are compressed by logs, they cannot do this, which will negatively affect the wood; it may begin to rot.

There is another drawback to these insulation materials - they are made from non-ecological components. And it seems to me that many people choose wood for construction in order to be closer to everything that is clean, safe and natural. The use of artificial, synthetic insulation will disrupt the entire beneficial microclimate of the room. It is for these reasons that I do not recommend focusing your attention on these insulating materials.

And it is advisable to lay insulation between the crowns from natural materials, which consist of fibers of natural plants. They also have good thermal insulation characteristics, but they are in perfect harmony with the wood and do not cause any harm to it. Among such materials are:

- Moss.

- Jute.

- Tow.

Many builders cannot make the final choice of insulation, deciding which of these three materials is better.

When to caulk a bathhouse

The log house is assembled, when is the first time you can caulk a fresh log bathhouse? If the log house was assembled using moss or tow, then remnants of material of different lengths stick out between the crowns. In this case, you can perform the initial caulking immediately: trim the overly long fibers, tuck them inward and tuck them into the seams. There is no need to be zealous about this. This is preliminary work, the purpose of which is to remove fibers. But this must be done following the rules of caulking. If the log house is assembled on tape insulation, nothing needs to be done.

Bath after initial caulking

The first “serious” caulking is carried out approximately six months after the collection of the log house. During this time, the logs/beams will lose most of the excess moisture, new cracks will appear, the crowns and corners will basically “sit” in place. At this time, the first caulking is carried out. After this process, you can install doors/windows.

A second caulk will be needed about a year after the first. A year and a half has passed since the construction of the log house, the log house has become stable. Now all seams and cracks are checked, all defects are eliminated. Depending on the material and quality of work, it may be necessary, in another five years, to caulk the seams again. But there have been cases (usually this is the result of the work of “shabashniks”) when caulking errors are corrected for several years in a row. Most often, this need arises if the log house was built without inter-crown insulation.

We calculate the cost

If you carry out the work yourself, the cost of sealing will be the sum of the funds spent on the purchase of materials.

Based on the cost of one tube (from 400 rubles), which is enough to cover up to 6 linear meters, each meter costs from 70 rubles.

“Vilatherm”, depending on the diameter, costs on average 10 rubles/m.

That is, the cost of one linear meter of the insulated surface of a log house is:

70 rub. + 10 rub. = 80 rub. / linear m.

When ordering work from a contractor, the cost will depend on the need for preliminary work (preliminary preparation, removal of previous caulking), and the diameter of the logs. The cost of services is also influenced by the type of log the log house is made of - chopped or rounded.

The average price for turnkey sealing with a warm seam, including the cost of materials, ranges from 140 to 200 rubles per linear meter, excluding preparatory work.

Anyone can make a home warm and protected from drafts with their own hands using new technology - it just takes patience and time. And the result is a comfortable microclimate, saving money on heating, aesthetic appearance, protecting the house from weather factors, insects, fungi and mold. The “Warm Seam” technology makes the traditionally weak link - the inter-crown space - an advantage of the design.

How much tow do you need for a bath?

Any natural material for caulking is compressed many times during installation and a large amount of it can fit into a log house, even with good inter-crown insulation. No one can say exactly how much tow is needed for a bathhouse: it also depends on what material the log house is assembled from and how the grooves are cut out in the logs. When manually cutting grooves, as a rule, more material is wasted. Also, a sanded log requires more material compared to a rounded one. Less is required for a log house, but even here the amount of tow or moss that will be used to seal the cracks depends on the accuracy of the geometry of the beam and the depth/number of cracks that appear during drying.

Sealing seams between logs - traditional sealing options

Oddly enough, the time-tested methods of sealing joints in wooden houses remain optimal in our time. Our ancestors did not face the question of how to seal the cracks in a log house, because the correct answer grew in most forests and copses. This answer is called "natural moss". It perfectly protects joints and seams not only from wind penetration, but also from dampness. Another thing is that finding a sufficient amount of natural moss is not easy, and the sealing itself will be labor-intensive. When using natural materials to seal the gaps between timber and logs, a very high packing density is required.

Tow for insulating joints in wood can be purchased at a hardware store. The purchase must be made in large quantities at once, because... even a narrow gap can “absorb” a large amount of tow. Natural moss does not need additional means of reinforcement - tow can be soaked in a liquid, flowing solution of cement or gypsum. Natural hemp provides high-quality protection for the joints between logs, and it looks attractive in appearance.

However, the cost of this material is quite high, especially considering the amount of work involved in the joint finishing of an entire wooden structure. Natural caulk for wood is optimal without additional impregnation. In this case, it can be supplemented with the following layers in a month or a year or two. Tow soaked in plaster or cement often crumbles and falls out of the cracks, and the work has to be redone. Tow, hemp and moss are hammered into the seams using a set of long chisels with varying blade widths and sharpnesses. The deeper the installation, the sharper and thinner the chisel blade used.

Caulking rules

Caulking a log house is not a very difficult task, but it is long and tedious. Everything needs to be done thoroughly and slowly, so it takes a lot of time - it took 10 days to caulk a small 5*4 bathhouse (one worked for 7-8 hours).

The main thing is not to overdo it in the efforts made when hammering in the insulation, which can lead to the log house rising by 15 cm or more.

Rules for caulking a log house:

Like every business, caulking requires certain skills. Since there will be more than one such procedure, you will eventually gain skills. As you gain experience, you will notice the mistakes that you made at the beginning of your activity - this will be your chance to eliminate them. Actually, it is not the gods who burn the pots, but it is possible to caulk a log house more or less efficiently even if you have no experience.

Source

Is it possible, using modern tape insulation, to do without secondary caulking?

No you can not. Despite the high surface density and uniform thickness of the insulation layer along its entire length, when settling a house, linen and jute fabric still shrinks up to 5–6% in its height, which is 10–15 cm per floor. This means that the resulting cracks will have to be sealed. This can only be avoided in the case of a building made of laminated veneer lumber, and not at all because of the special properties of the insulation, but only because such buildings themselves are practically not susceptible to sedimentary processes and lose only 1–1.5 cm of height per two floors .

Bath caulking: technology and material selection

A log bathhouse is a tradition that, even after several hundred years, has not lost its relevance. Wood has the highest level of thermal insulation among building materials, while the weight of a log structure does not go beyond the permissible limit. The only drawback of this technology is the presence of gaps between the stacked logs.

When laying and adjusting logs between individual elements, horizontal through cavities will inevitably remain along the entire perimeter of the bathhouse, and before its operation it is necessary to caulk them.

Log caulk: photo

This article will describe step-by-step instructions and main points on the topic - “how to caulk a bathhouse with your own hands.” In addition to describing the technology, it will also provide detailed information about how to caulk the bathhouse, since in this case the correct choice of material plays a decisive role in the success of the entire process.

Advantages of moss insulation

Natural materials are especially highly valued in construction today. Technologies that have long been used in construction in Rus' are today regaining popularity among those who want to avoid artificial, often toxic synthetics as much as possible. Many common insulation materials reduce the environmental friendliness of a building because they impede the passage of air and water vapor. Moss is free from this drawback, as it fits harmoniously into the structure of the house, providing it with protection. Another plus is that cuckoo flax itself has antiseptic properties, so it also helps to increase the durability of the building.

Properly performed insulation using ancient technologies allows you to forget about drafts and ventilated corners, and the room will always be warm and comfortable. One of the advantages will be the forest aroma, which many people like.

Selection of material

Forest moss is the most traditional material that our great-great-grandfathers used for caulking log houses. This is the most environmentally friendly material of all analogues used, since it is of natural origin, assembled by hand and is not treated with chemicals. It has bioactive properties - it does not grow moths and mold.

Moss is especially valued for its antiseptic properties - it does not rot even when exposed to high humidity. At the same time, moss caulk is not only not susceptible to rotting, but also protects nearby areas from damage, which is especially important for insulating a bathhouse.

Also, using moss as a material for caulking allows you to significantly save on the purchase of material, since it can be collected in the nearby forest with your own hands. Even if this is not possible, its price in stores is quite affordable. Natural moss is the most rational solution to the question, what is the best way to caulk a bathhouse?

The most common material for log caulking due to its cost, but flax has the lowest quality characteristics. Before caulking a bathhouse with flax, you should take into account that it contains practically no natural antiseptics - therefore, putrefactive bacteria, which damp wood contains in abundance, will quickly destroy the formed seam, after which nearby areas will undergo degradation.

It quickly deteriorates under the influence of high humidity - its service life is from 1 to 3 years, after which the seam begins to crumble. Insects love it - moths, beetles; in its raw state, mold and mildew quickly grow. Without chemical treatment, you may find a large number of insect larvae in it the next season of operation.

Note! Some of the disadvantages of this material can be mitigated through chemical impregnation, but this will negatively affect the atmosphere of the bathhouse.

Of all the analogues used, flax can be called the most undesirable solution to the question: how to caulk a bathhouse?

Recently, experts have expressed their opinion on the question of what is the best way to caulk a log house for a bathhouse? — is increasingly leaning in favor of jute fiber, which recently appeared on the domestic market.

And this is not without meaning - natural jute is a durable material containing a large amount of natural lingin, which gives it water-repellent properties. Also, jute is much less damaged by insects than flax.

Note! Not to be confused with jute felt, which contains a certain proportion of flax, and accordingly all its negative qualities are present. It is quite simple to distinguish them from each other - 100% jute is gray in color.

Laying moss in the seams

Caulking seams with moss is an old method. And if you decide to caulk with moss, then the first thing you need to do is choose the right material. “Cuckoo flax” is suitable for this process. It has long fibers of a brown-brown color with a reddish tint.

They also use “white”, which is called “sphagnum”. This is soft moss, like cotton wool. This type of moss has bactericidal and antimicrobial properties. This material does not harbor wood pests; it destroys fungal spores. These species are called building mosses.

When constructing a log house, the material is placed between the crowns of logs, and it serves as insulation. The material is subsequently used for caulking. This is done at least 2 times: used after assembling the log house, after its shrinkage. Shrinkage occurs within 1.5–2 years, and sometimes more.

Before caulking, the moss is dried. However, before starting the caulking process itself, it is wetted, otherwise it will crumble in your hands and it will be impossible to do any work with it. Caulking with moss is carried out with special tools: caulking, mallet.

The caulking tool is made from the same wood as the log house. This is done so that the tool and the log have the same hardness upon contact. Then there will be no traces left on the log house. A wooden hammer is used to strike the caulk, which makes it possible to push the moss into the crack with force and tightly fill the space.

Caulk with moss begins from the bottom row, passing along the perimeter. This approach avoids distortions. The crown passes completely from the outside to the inside. Before use, “Kukushkin flax” is formed into 100 mm strips, laid parallel to the log, and cracks and cracks are sealed using special tools. White moss is fluffed up a little before work. The laying is done perpendicular to the log with hanging fibers on both sides of the log by 100 mm, which are then pushed into the gap with tools.

Caulking moss on a log house is not a difficult job, but it does require care. We must ensure that the house does not warp, that the seams are complete, that the logs do not fall out or tear apart from each other. What is needed in this matter is perseverance, time, and patience.

Caulk

There is practically nothing complicated in this process - the main thing is to choose the right material for sealing the seams. You will need a mallet (wooden hammer) and a set of caulking tools. There are two technologies for caulking seams - stretching and tapping.

Stretch

Recruitment

Tools

The main tools for caulking seams are spatulas (caulkers) and a mallet. The blades are made of wood or steel. The wood of the caulk should be softer than the material of the logs, otherwise marks will remain on the walls. Over time, the working surface of the wooden caulk becomes shaggy, then it is replaced with a new one.

Metal caulking is used for corner cuts, where it is especially important to fill the inner space of the bowl. Using a mallet, gently tapping the caulk, compact the insulation bead and push it inside the seam.