But wood can be different, and not all are suitable for a sauna.

Bathhouses made of laminated veneer lumber are safe structures that, subject to construction technologies and the correct choice of material, will last a long time. But when buying wood, you should take into account the characteristics, quality, and parameters of the lumber.

Is it possible to build such a sauna?

A sauna is a room in which a person relaxes, enjoys the environment, the walls must breathe. Materials must not contain harmful substances.

There are several reasons why laminated veneer lumber is not recommended for the construction of bath complexes:

- poor air circulation;

- the risk of purchasing low-grade wood, which will crack under the influence of high temperature and humidity and will require finishing and insulation;

- when heated, the glue evaporates toxic substances, you can get poisoned;

- The lamellas may delaminate due to temperature fluctuations, and the walls will lose strength.

Reference! These are the main reasons why it is not recommended to use laminated veneer lumber. But, provided you choose the right building material and follow the technology, it is possible to build a steam room from treated wood.

What should we not forget?

There are some rules that you can follow to build a sauna from lumber. Subject to their compliance, such material is suitable for construction:

buy lumber only from well-known companies that use high-quality adhesives;- upon completion of the construction of the facility, decorate the walls in the steam room with foil material and linden lining (humidity and temperature will have less effect on the wood);

- It is better to buy internal slats from pine, external ones from aspen or linden;

- equip a ventilation system, then humidity will accumulate less and air will circulate well.

If you purchase good quality lumber, a bathhouse made from laminated veneer lumber will be no worse than one made from profiled wood, and in some respects even much better. The construction speed is higher, shrinkage is minimal, and heat is well retained indoors.

Construction of a roof for a bathhouse made of laminated veneer lumber

For private wooden baths, gable roofs are usually used.

They are quite reliable and easy to manufacture. They consist of a rafter system, sheathing, vapor barrier, insulation and finishing material. There are two types of roof rafters - inclined and hanging. Inclined rafters can span a span of up to 7 m without intermediate supports. For larger spans, hanging rafters are used. After installing the entire system, you can install the cornice flooring and trim the gable. Then a sheathing of boards is installed on the supporting structure. We will attach the roofing material to it. Each of its types has its pros and cons, let’s consider each of them:

- Shingles, for example, although durable, are heavy. To support it, powerful rafters and lathing are required. Therefore, tiled roofing is more suitable for a home than a bathhouse.

- A slate roof is lighter, but it will last about 15 years, no more. For a bathhouse, this is a completely acceptable option, because the slate can then be replaced. When installing such a roof, the overlap of one sheet on another follows the length of one wave.

- The lightest covering is metal flooring. Its sheets are fixed to the sheathing using special metal strips, which are located in the places where the sheet is closed and in its middle.

Don't forget to provide the roof of your bathhouse with drainpipes, eaves and gutters so that when it rains or melts snow, water does not flow down the walls.

What types of buildings can be built?

Projects differ in size: baths can be small - 3 x 4 or spacious 10 x 10. When choosing the dimensions of the steam room, you should take into account the size of the land plot. But, the larger the dimensions of the sauna, the more expensive the construction and further maintenance of the building will be.

Baths with terraces, verandas, and barbecue areas are popular. Here the owner receives not just a sauna, but also a place for complete relaxation. After water procedures, you don’t have to sit indoors, but go out into the fresh air.

Another interesting option is projects of houses combined with a sauna. This is already a full-fledged country cottage, which is suitable for permanent residence. The construction of such buildings allows you to save on the site and reduce costs.

Attention! There are projects in which there is a steam room on the 1st floor and living rooms on the 2nd floor. The second option is an extension to the cottage. Such saunas have two rooms: a steam room and a dressing room. There is no need to construct a separate rest room or shower room.

What to look for when choosing lumber?

The reliability of the future structure depends on the quality and characteristics of the building material.

When choosing laminated wood, you need to pay attention to defects:

the timber must be dried, treated with an anti-cracking solution, an antiseptic;- the surface is smooth, even, not deformed, without defects;

- the lumber should not be damaged by pests or rot;

- high quality glue, a certain brand;

- the number of lamellas is 3-7 pieces, the thickness of the timber depends on this.

Low-quality wood is not suitable for construction. When choosing laminated veneer lumber, you must take into account the type of wood.

Attention! Experts advise using larch for the first crowns and Siberian spruce for the top ones. A German profile is suitable; it joins the crowns well and reduces the risk of blowing through the corners.

Glued lumber is made with rectangular and square cross-sections.

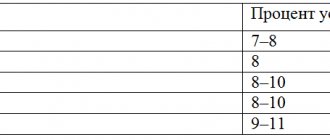

Section of wall lumber:

| Length, cm | Width, cm | Height, cm | |

| Minimum | 100 | 8 | 8 |

| Maximum | 1200 | 38 | 24 |

Section of lumber from spruce and pine:

| Length, cm | Width, cm | Height, cm | |

| Minimum | 600 | 8 | 13,5 |

| Maximum | 1200 | 28 | 27 |

The cost of timber is 16-35 thousand rubles, depending on the type of material, brand, grade, and other characteristics.

To save money, you need to choose the right size:

- bathhouse only for the warm season - timber of 4 lamellas, 6 meters and 140 x 160, 180 x 160, 160 x 160, 150 x 150 mm;

- for terraces and verandas, internal walls – 100 x 150 mm;

- year-round use – 5 slats, 140 x 200 mm.

Lumber with a cross section of 180 x 200 mm is suitable for a bath complex or sauna house. Heat will be maintained in the room even at -25 degrees.

Installation of utilities

This is the final stage in the construction of a bathhouse, and it consists of the following stages:

- development and implementation of a sewer system;

- installation of a heating system, if provided for in the project;

- high-quality layout of the power supply system;

- installation of air vents for air conditioners and smoke removal systems;

- piping for hot and cold water;

- insulation of incandescent lamps in special shades;

- installation of sockets and switches (only in rooms with permissible humidity).

Layout of sewer pipes in a bathhouse

Tools and Supplies

In addition to laminated veneer lumber, other components will be required. Before construction you should purchase:

floorboard;- vapor barrier film;

- timber or log;

- sand, cement, crushed stone;

- ceiling boards;

- mineral wool, polyethylene for insulation;

- material for roofing;

- boards for interior decoration, lining;

- moss, tow for inter-crown insulation;

- waterproofing building material;

- sheet asbestos;

- axe, dash;

- plumb line, mallet;

- drill, chisel;

- level, chainsaw.

Important! For the line, a steel wire is used, which is bent halfway, then it looks like a compass. It is needed for marking lumber.

Video description

Glued laminated timber is a very popular and in-demand technology on the market.

In this video, we'll figure out how laminated veneer lumber is produced: On the second floor, you can equip one large room for relaxation or make several smaller ones, separated by partitions.

Project of a two-story bathhouse Source shelf93.ru

Construction: step by step instructions

The process of constructing a sauna includes the construction of a foundation, roof and walls, arrangement of communications, surface treatment against rotting, installation of insulation, external and internal finishing work.

Floor, base, walls

Preference should be given to strip foundations. Construction of the base:

- Remove soil by 20 cm, clear of debris.

- Mark the place for the trench with pegs.

- Make a groove to a depth of 50-70 cm.

- Build formwork from slats, bars and boards; it should be 0.5 meters above the ground, cover the inside with polyethylene, and fasten it with a stapler.

- Make a frame from reinforcement and place it in formwork.

- Fill the trenches with cement.

It is necessary to make holes in the formwork through which pipes will pass to drain water. Fix a metal or asbestos pipe in them.

Sauna walls made of wood:

- The elements are attached with choppers.

- The lock for the corners is half a block.

- The lock for fixing along the length is the tail of a swallow.

- A layer of jute is laid between the bars.

Important! It is better to cover the first crown with recycled automobile oil. It protects lumber from the formation of fungus, mold, and pests.

Doors, windows, roof and ceilings

To construct openings, before arranging the sauna, it is necessary to mark the bars along the crowns. At the level of the openings, shortened glued material is used.

Arrangement of the ceiling, roof:

The top piping is the end of the structure.- Ceiling beams are attached to the top every 0.6 meters. They should protrude beyond the walls by 0.5 meters.

- The rafter sections are assembled on the ground. The paws are placed on the beam outlets.

- The sections are fastened to the beams with nails and staples.

- The rafter sections are connected using lathing.

- A vapor barrier material is fixed on top of the slats.

- Counter-lattice is in progress.

The final stage of roof construction is fastening the material. Construction begins with rough work.

Communications, processing, insulation

Utility networks are installed at the initial stages of construction. Features of communications construction:

- protect the wires with corrugation;

- lay a pipeline from a well or well;

- if the pipe goes from above, then it is better to use a heating cable;

- the drain can be led to a septic tank or drainage.

If the floor is tiled and the room will be used year-round, then it is better to install a “warm floor”.

The walls between the crowns are caulked to reduce heat loss and prevent drafts. Next, the wood is coated with a fire retardant and antiseptic.

If a bathhouse made of laminated veneer lumber is built in an area with a predominant cold climate, then insulation will be required:

- The walls are covered with plastic film.

- The frame is stuffed from bars on top.

- Insulation is placed in the voids.

- Foil film is attached.

- For ventilation, slats are padded.

Upon completion of the work, you can proceed to the external and internal finishing of the bathhouse made of laminated veneer lumber. The material is chosen according to your choice.

Interior and exterior finishing

Walls made of wood do not need to be covered with anything, but various materials can be used to give an original look.

The choice of finish depends on the type of room:

- steam room - lining made of hardwood;

- shower room – plastic panels, tiles, stone;

- dressing room - different materials.

For external cladding, plastic or metal siding, block house, and decorative plaster are suitable.

This is interesting! A structure made of laminated veneer lumber is no different in appearance from a bathhouse made of simple bars. The difference is the manufacturing technology of the components. The bars are glued together from different parts, pre-dried. The finished material does not crack, does not shrink, or deform.

Construction of a foundation for a bathhouse made of laminated veneer lumber

Any structure requires the installation of a foundation.

Its type and depth no longer depend on the purpose of the building, but on its weight, as well as on the depth of soil freezing in your region. Many builders like to build strip foundations. There are several reasons for this: endurance, durability and simple installation of the concrete strip without the use of cranes and other construction equipment. The work on installing a strip foundation can be divided into several stages:

- Planning and marking of the site for construction.

- Digging trenches with the required depth of soil freezing in winter.

- Installation of a sand cushion 150–200 mm thick at the bottom of the trenches.

- Assembly and strengthening of formwork for strip foundations.

- Production of reinforcing frames and linking them to formwork.

- Pouring the resulting structure with concrete to the design level.

- Covering the foundation with waterproofing after it has hardened.

The bottom of the foundation should be located 200 mm below the freezing point of the soil to avoid its deformation destruction during the winter-summer cycles.

Less commonly, a pile foundation is used to build a bathhouse. Its installation is advisable on soils with subsidence or at the bottom of a reservoir.

Pros and cons of such a sauna

You can use different materials to build a bathhouse. But the most comfortable saunas are those made of wood.

Advantages of a wooden bath:

- excellent thermal insulation;

- environmental friendliness, naturalness;

- good microclimate;

- beautiful appearance;

- long service life;

- speed of construction;

- there is no need to strengthen the foundation.

The disadvantages include: flammability, the appearance of cracks, mildew and mold. But these shortcomings can be eliminated by treating the lumber with a fire retardant. Regular care will prevent the formation of cracks.

Windows for saunas made of laminated veneer lumber

It is convenient to place the bathhouse windows on wooden slats.

To do this, special grooves are made at the ends of the window frames to suit the size of the slats. With this design, the windows move freely up and down. Then thermal insulation is laid into the grooves and trims are installed. Do not use softwood materials to make steam room windows. At elevated temperatures, such wood releases resin. The beams of the wooden floor of the bathhouse are attached to the wall with a reliable notch, imparting rigidity to the overall structure.

Possible mistakes

In order for the structure to be reliable and of high quality, several points must be taken into account.

Experts recommend:

- use only winter wood that contains a minimum of moisture;

- type of material - when new or traditional is suitable;

- characteristics of the terrain, the choice of foundation depends on this;

- time of use – year-round or seasonal;

- owner's capabilities.

Advice! Professionals offer ready-made projects with prepared building materials - according to style, shape, size. They are implemented in the shortest possible time.

Approximate prices

The cost of timber is 18-35 thousand rubles depending on the cross-section and dimensions.

But construction will require other costs:

foundation – 615 thousand rubles;- construction of the box – 1,200,000 rubles;

- roof installation - 390 thousand rubles;

- wiring of communications – 220 thousand rubles;

- finishing – 1,250,000 rubles;

- additional costs – 140 thousand rubles.

The approximate cost of building a bathhouse from laminated veneer lumber in Russia is 3,815,000 rubles. The final price depends on the size of the structure, materials used and other factors.