Having your own bathhouse is convenient and practical. At any time you can take a steam bath, sit on the veranda, drinking aromatic tea. Of course, you can go to a paid bathhouse, but this pleasure is not cheap. You need to pay for every hour, so you will have to constantly look at the clock, but in your own bathhouse you can relax and fully enjoy your vacation.

For the construction of baths, different materials are used, the most popular of which is currently timber. Baths made of timber are also divided into several types, depending on what type of this material is used: solid, profiled or glued.

Each of these types has both advantages and disadvantages; the most popular at the moment is laminated veneer lumber.

Glued laminated timber is the best choice for a bathhouse

For a bathhouse, laminated veneer lumber is the optimal building material. It allows you to get a lot of benefits without the disadvantages that are inherent in wood:

- Light weight. Saving on the foundation and eliminating shrinkage from calculations.

- High strength characteristics. Often, when creating laminated veneer lumber, different types of wood are used, which allows you to evenly distribute the load on the part and increases protection from mechanical damage.

Bathhouse made of laminated timber with a large open terrace Source spb-cr.ru

- Resistant to fire, fungus and insects. The use of special impregnations in the process of manufacturing laminated veneer lumber significantly reduces the risk of wood destruction by insects and fungi, and ensures fire safety.

- Durability. When connecting lamellas (individual layers of timber), sorted, clean, dried wood is used, which significantly increases the service life of the material.

- Easy to assemble. Even ordinary timber is produced in a certain, geometrically correct shape, this allows you to avoid the formation of gaps when connecting individual elements. The use of profiled laminated veneer lumber will further strengthen the connection and increase the speed of assembly of the structure, thanks to the presence of special grooves or locks.

Construction of a bathhouse from laminated veneer lumber Source anticafe-sandbox.ru

- Low thermal conductivity of certain types of wood. The characteristic is responsible for the speed of heating the bath and maintaining the temperature by reducing heat leakage.

An additional advantage is the low cost of the material and attractive appearance. You can easily verify this by looking at the timber baths, photos of which are presented in the article.

COVERING THE WASH COMPARTMENT WITH LINKING

Not only PVC, but also linden lining is suitable for lining the washing compartment. The main thing is to install a ceiling hood and treat the boards against mold to avoid the appearance of black spots and insect nests. For this purpose, transparent antifungal agents are used for linden and other types of wood. The water-based coating does not in any way affect the smell inside the room and does not contain dangerous impurities.

In order for the air to circulate naturally under the linden paneling, technological holes are drilled in the board. Don't forget to install sliding guides under the cladding board. They will prevent deformation of the material during the shrinkage of the log house.

Features of the construction of a bathhouse made of laminated veneer lumber

You don’t need to delve into all the intricacies of the question of how to build a bathhouse from timber - just figure out what parameters you need to focus on when ordering from professionals in order to get a high-quality building that will last for decades. A turnkey bathhouse made of laminated veneer lumber, made by a good team, will be much better than a “homemade” one.

Laminated timber bathhouse with a small open terrace Source vsedlyastroiki.ru

Dimensions of a bathhouse made of laminated veneer lumber

Everyone decides for themselves what size a bathhouse made of laminated veneer lumber will be. There are no uniform parameters, but there are important characteristics that will make the selection task easier:

- Number of visitors. For a large group or family, you will need enough space so that everyone can fit comfortably. If the bathhouse will be visited by one or two people, a small building will suffice.

- Seasons of use. If you wash in the bathhouse only in the warm season, then you can neglect thermal insulation and a separate heating system. For a building that operates all year round, the organization of heating and thermal insulation is necessary, which automatically increases the dimensions of the bathhouse.

- Additional areas. Equipping a terrace where it’s so nice to sit after a steam room, building a second floor with a lounge or bedroom, or a room with a swimming pool increase the required size of the building.

Based on the specified parameters and your own taste, it is easy to choose the best option for the dimensions of your laminated timber bathhouse.

Laminated timber bathhouse with attic and balcony Source domostroy96.ru

Foundation

If the main material of the bathhouse is laminated veneer lumber, the structure will be light in weight, so you can avoid laying a capital foundation, but choose one of the three most common types:

- Tape. Allows you to obtain a strong single structure that can easily support a building of several floors at low cost.

- Columnar. At each corner and at the junction of the walls, a pole is mounted, which is buried in the ground. This allows the load from the building to be evenly distributed.

- Pile. Used on moving soils. Deep digging or screwing the pile into the ground allows you to reach stable layers of soil and securely secure the bathhouse.

Depending on the amount of average annual precipitation, floodability of the land, quality and density of the soil, and the overall construction budget, you should focus on one of these options for constructing a foundation.

Construction of a strip foundation Source rockstroy.ru

Waterproofing

A bathhouse means high humidity, which poses a danger to laminated timber, even despite the appropriate impregnation of the material. Protecting individual parts of a building will improve its performance.

- To insulate the foundation, molten bitumen is used, which, after hardening, is covered with a layer of roofing material.

- Waterproofing the walls, ceiling and floor covering in the bathhouse will protect them from water getting inside and prevent rotting.

- Materials for protecting the interior space are selected depending on the type of room. For a steam room, the waterproofing must have additional resistance to high temperatures.

High-quality waterproofing will improve protection from water and increase the durability of a bathhouse made of laminated veneer lumber.

Foil waterproofing material Source iv-proect.ru

See also: Contacts of construction companies that offer the service of building a bathhouse from laminated veneer lumber.

Insulation

When using a bathhouse made of laminated timber all year round, it is necessary to take care of the insulation of the walls and ceilings. This will reduce heating costs, prevent the formation of condensation inside the walls and prevent mold from appearing. Insulation will also protect the bathhouse from freezing in cold weather. Low temperatures can negatively affect the strength characteristics and cause the formation of microcracks in the wood.

Felt insulation for bath walls Source srubdacha.ru

Materials for interior and exterior finishing

A good bathhouse made of laminated veneer lumber involves the use of certain building materials for interior decoration, which are suitable for installation in all rooms except the steam room.

- Plastic deforms when heated.

- Natural stone and brick can burn.

- Cork moisture-resistant material is highly thick, which reduces the usable volume of the room.

Therefore, the steam room must be lined with clapboard made of natural wood, which is sufficiently resistant to high temperature and moisture. You cannot use coniferous wood for this; when heated, they release resin.

Steam room lined with natural clapboard Source poselok.com.ru

For the outer cladding of a bathhouse made of laminated veneer lumber, you can use any materials.

- Decorative brick allows you to give the building a solid look.

- Wood panels create a natural decor.

- The block house imitates rounded logs.

- Thermal panels perform a double function - they give a nice look to the bathhouse and reduce thermal conductivity.

The choice of material for the exterior finishing of a bathhouse made of laminated veneer lumber can be discussed with the designers when ordering a turnkey construction.

Bathhouse made of laminated veneer lumber, trimmed with decorative wood panels Source oooarsenal.ru

WHERE TO BUY LINING FOR COVERING BATH AND SAUNA?

If you want to buy lining made of alder, linden or aspen, consider purchasing from a reliable supplier -. The company specializes in the production of finishing materials and furniture for saunas and baths. By purchasing goods from a specialized company, you can rest assured of the quality of lumber and their compliance with the declared characteristics.

The manufacturer supplies lining made of aspen, linden and alder directly from the base on various types of transport: GAZelle, Valdai cars, Euro trucks and containers. The prepared material is packed in shrink film and delivered to the client with all the necessary documents.

Video description

For a detailed review of a bathhouse made of laminated veneer lumber, watch the video:

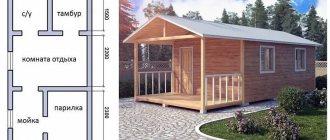

A one-story bathhouse made of laminated veneer lumber imposes certain requirements on the layout and number of rooms. The minimum project includes a relaxation room, washing room and steam room. An increase in the number of rooms requires a corresponding increase in the total area of the building or a decrease in the size of each room.

The advantage of a one-story bathhouse will be its low cost and reduced maintenance costs. The disadvantages include some limited free space and the difficulty or impossibility of combining with living space.

Project of a one-story bathhouse Source banya-ili-sauna.ru

A two-story bath house made of laminated veneer lumber allows you to significantly increase the usable area and delimit zones of space use. The first floor is made functional, there is a steam room, a swimming pool, a shower room, a bathroom, a dressing room with kindling and other rooms with similar characteristics.

Possible mistakes

In order for the structure to be reliable and of high quality, several points must be taken into account.

Experts recommend:

- use only winter wood that contains a minimum of moisture;

- type of material - when new or traditional is suitable;

- characteristics of the terrain, the choice of foundation depends on this;

- time of use – year-round or seasonal;

- owner's capabilities.

Advice! Professionals offer ready-made projects with prepared building materials - according to style, shape, size. They are implemented in the shortest possible time.

Video description

Glued laminated timber is a very popular and in-demand technology on the market.

In this video, we'll figure out how laminated veneer lumber is produced: On the second floor, you can equip one large room for relaxation or make several smaller ones, separated by partitions.

Project of a two-story bathhouse Source shelf93.ru

HAVE QUESTIONS? WE WILL HELP!

If you have any questions

about our projects, technologies and capabilities,

call right now on multi-channel numbers:

8 (800) 333-91-91 (free from mobile)

8.

Send us a request

PYZHOV VYACHESLAV Construction Director

Kadrova Ekaterina Architect

Photo examples of bathhouses made of laminated veneer lumber

Project of a one-story bathhouse with a large terrace Source ytong.by

Project of a bathhouse with a glazed terrace Source avoka.do Bathhouse made of laminated veneer lumber with a porch Source www.rwhouse.ru Project of a two-story bathhouse with an outdoor pool Source stroy-good.ru

One-story bathhouse Source lineyka.net Project of a bathhouse made of laminated veneer lumber near an artificial reservoir Source sk-brusnika.ru Bathhouse made of laminated veneer lumber on a strip foundation Source market.sakh.com Two-story bathhouse with an attic Source remontik.org Bathhouse with a residential attic and terrace Source profipluspz. ru Small sauna for 1-2 people Source rinnipool.ru

Wall and floor equipment

Construction technology involves complete equipment of chopped walls. Such walls are structures consisting of elements located one on top of the other in a vertical position. The constituent elements or glued beams are connected at the corners with special notches.

Each separately constructed row of such timber can be called a crown. A log house is traditionally called the frame of a building built from crowns. The thickness of such a log house is often determined by the width of one laminated veneer lumber.

There are several common ways to connect wooden elements:

The construction of a load-bearing wall must begin by cutting a groove in the lowest element of the structure being built. After this, another beam should be placed in the groove with the need to connect it to the previous one using conventional insulation made of jute, sticks, or moss. The lower beam is combined with the foundation through the installation of a waterproofing layer.

At the corners, the connection can be made into a paw or into a shunt. Often the length of finished walls made of laminated veneer lumber reaches 6.5 meters. When this length becomes above a certain value, it is advisable to equip the vertical elements for compression. After the construction work is completed, each crack and junction of wooden elements will be thoroughly caulked.

At the wall construction stage, you can begin to assemble the floor surface. When installing a drain hole, you need to take into account the need to tilt by about 4-5 degrees. On the finished foundation, you can install special logs on which you can fix the floor covering made of boards.

Arrangement of a columnar base for a log bathhouse

Regardless of the type of foundation chosen, it should be well strengthened with reinforcement, which allows you to give the entire structure good strength and is an excellent fastening for the very first crowns of a log house.

One of the main factors that ensure the durability of a structure is good waterproofing. Therefore, between the base plinth itself and the first crown of the log house, it is imperative to lay a double layer of waterproofing.

First, you need to apply a layer of molten bitumen to the entire horizontal surface of the base and then cover it with a whole layer of roofing felt. After the bitumen has hardened, the process must be repeated again.

Formwork assembly

The formwork consists of wooden panels assembled from edged or unedged boards 25 mm thick and 150 mm wide. A sufficient height of the foundation from the ground level is three boards assembled together, that is, 45 cm. It is not worth saving and making the foundation lower for a wooden house, since otherwise the lower crowns of the log house will get wet from the splashes of falling raindrops and fumes from the ground, and in spring-winter period - from melting snow.

After assembling the shields, they are installed in place of the dug trench opposite each other and fastened together. In the upper part, the boards are secured using a block, which is placed on top of the formwork and screwed with one screw to one board, and another to the other. In the middle and at the bottom, the shields are fastened together with thick wire. To do this, each shield is drilled opposite each other in the place of transverse fastening of the boards, a thick knitting wire is inserted into the resulting holes, the ends of which are twisted together from the outside. Inside the formwork, a thick screwdriver or a long nail is inserted between the wires and twisted together, controlling the distance between the panels with a jig. After twisting the wire, the conductor is taken out, and a firmly fastened formwork is obtained, which does not require side support pegs. After installing all the panels and assembling the formwork, it is necessary to check its horizontalness using a laser or water level.

Expert opinion! It is best to immediately level the formwork and pour concrete, leveling it along its upper edge. In this case, we immediately get a perfectly level foundation horizontally and will avoid further problems with its leveling.

Now you need to lay and tie the reinforcement. For the foundation of a house, it is best to use reinforcement with a diameter of at least 12 mm. For a foundation with a width of 300 mm and a total height of 1 meter, three reinforcement belts of two rods each will be sufficient. If the reinforcement turns out to be short and you have to add more, then the overlap between each other should be at least 30 times the diameter of the rod itself. That is, if 12-diameter reinforcement is used, then the overlap should be 12*30=360 mm. The reinforcement is connected to each other with knitting wire.

Before pouring concrete, it is necessary to provide places in the foundation where there will be holes for ventilation of the subfloor. Asbestos-cement pipes are usually used for these purposes. They are sawed off to the size of the foundation and installed inside the formwork. To prevent the pipes from floating during the concrete pouring process, they are secured with nails or self-tapping screws.

All preparatory work has been completed and concrete can be poured. During and after pouring, it is necessary to “tap” the formwork with a hammer. This is done to release air from the concrete. After pouring, the upper part of the foundation is leveled with a trowel.

In the summer, the formwork can be removed after three days and after two weeks the walls of the house can be erected from profiled timber.

Design

To build a bathhouse, a ready-made standard project , but you can order it individually . When choosing a project, special attention is paid to such factors as the size of the structure, internal layout, and appearance.

Design must be carried out taking into account the availability of free space on the site, the number of people receiving bathing procedures, the operating mode, the climatic and geological features of the area.

The most modest building (project 2x3, 2x4, 3x4 m) includes a steam room and a dressing room . The most common options (4x5, 4x6, 5x6 m) have the following internal layout - steam room (at least 5-6 m²), washing room (at least 4-6 m²), relaxation room, utility closet, vestibule, bathroom. You can provide such structural elements as a terrace, veranda and attic.

Roofing device

The roof of the bathhouse has a rafter system, for which you can use 10x10 cm timber from pine or spruce. Typically a simple single or double slope roof is used. In areas where significant precipitation may occur, preference is given to the gable option.

The roofing system can be installed above or on the ground, followed by lifting and installing individual parts or the entire roof. The upper crown of the log house can serve as a supporting element for installing rafter legs, but it is recommended to use a special element - a mauerlat. It can be made in the form of a rectangular frame made of 15x20 cm timber. Ceiling beams are attached to it.

After assembling the rafters, a sheathing of boards with a thickness of at least 20 mm is installed between them, on which a layer of reliable waterproofing is attached. Roofing material is laid on top. Simple baths are covered with slate. In more expensive projects, tiles and ondulin are used.

Hand cutting bowls

The strength of the entire log house and the appearance of the bathhouse largely depends on the quality and reliability of the connection of the beams in the corners of the building . There are 2 main types - with a remainder and without a remainder . In the first case, the ends of the beams extend beyond the surface of the wall, and in the second, a strictly rectangular joint is ensured within the combined walls.

When forming an angle without a remainder, the following types of connections are used:

- In “half the tree”, i.e. "half a beam " Exactly half of the beams are cut out at the ends, and the length of the cut section strictly corresponds to the width of the beam. The cut out areas are joined and reinforced with dowels.

- Root thorn . At the ends a connection is formed using the tongue-and-groove system.

When creating a corner connection with the remainder, you need to join the beams at a certain distance from the end. To do this, the bowls are cut by hand. Essentially, the “bowl” is cutting out half of the timber at the required distance from its edge. Its width is equal to the width of the beam, and its depth is half the height.

First, 2 parallel cuts are made, and then the wood in this area is selected with a chisel. You can use two options for such linking - “ in the oblo ” and “ in the okhlop ”.

In the first option, the top beam is placed in the prepared bowl, and in the second, vice versa.

Table. Connection types

| Name | Illustration | Description of the lock connection | Description of the insulation method |

| 1. Finnish profile with round bowls | The beam profile itself has connecting tenons at the top and a groove for them at the bottom. Between the spikes there is a stepped recess, which is shallower at the edges and deeper in the middle. Bowls are cut into semicircular shapes | For insulation, use a wide insulation tape in the center, for example, PP-TERMO, and two narrow strips of sealant on the sides | |

| 2. Finnish profile with flat bowls | The profile of the timber does not differ from the previous one, but the bowl is cut flat to simplify the process and save time | A profile with flat bowls is insulated with tape only along the central groove or with a seal (polyethylene foam) only along the outer grooves above the tenons | |

| 3. German profile with flat bowls (one-sided, two-sided or four-sided) | For corner connections, bowls are cut parallel to the cross-section of the beam | The corner joints are sealed with sealant or tape insulation, which is rolled out without tension only in the locks. The insulation is fixed with a stapler with short staples. You can use PSUL or flax jute. The crowns themselves are not insulated along their length, because... the connection of the tenons and grooves is quite tight and windproof | |

| 4. Profile with a reduced number of spikes | This is a domestically produced profile, similar to the German one, but has a maximum of two grooves for two tenons | Insulation is carried out along one or both grooves | |

| 5. Austrian or German profile with a “labyrinth” corner connection | Joining cuts are made only on enterprise machines. Provides a very tight, windproof connection | The seal is not used | |

| 6. German profile, “Tyrolean castle” | The cross section of the lock is trapezoidal, the upper and lower planes form a “dovetail”, i.e. are on a slope | You can use PSUL by inserting it into a rectangular groove on the side surfaces of the paws | |

| 7. Connection of the German profile without residue or “in the paw” | The lock can be cut at a right angle or with a bevel, like half a dovetail. | The lock joint is sealed with jute | |

| 8. T-shaped splices of all types of profiles | Notches and grooves are made in the beams of load-bearing walls, and a tenon is cut through the beams of interior partitions | Jute seal is used | |

| 9. Bay window connections at an angle other than straight | The coupling of parts is carried out due to vertical grooves and tenons | Wind protection is low, but insulation is usually not used |

We invite you to familiarize yourself with: Do-it-yourself frame bath from dead wood, step-by-step instructions, cheap and fast

Which profile is better to choose – German or Finnish?

Before you start building a house, you should decide on the type of profile. There are two main modifications:

- Finnish;

- German profile.

The Finnish (Scandinavian) profile is a flat surface with a wide tenon at the bottom and a groove at the top. When using it, be sure to use an insulating gasket. The Finnish profile is easier to install. The German profile (comb) is distinguished by the presence of many spikes. It can be installed without additional thermal insulation, but violation of storage rules at the construction site or poor drying can greatly complicate the installation process. The main thing you must remember is that if the material is of high quality, then there is not much difference when choosing.

Characteristics

The following are the technical characteristics of the beams. Here are all the parameters to choose the right size, quantity and suitable material for thermal conductivity.

Dimensions

Beam dimensions:

- 100x100x6000mm;

- 100x150x6000mm;

- 100x200x6000mm;

- 100x250x6000mm;

- 125x125x6000mm;

- 200x200x6000mm;

- 200x250x6000mm;

- 250x250x6000mm.

Weight and quantity of laminated timber per 1m3

Weight of material in kg:

- 100x100x6000 (mm) – 31.2;

- 100x150x6000 (mm) – 46.8;

- 100x200x6000 (mm) – 62.4;

- 100x250x6000 (mm) – 78;

- 125x125x6000 (mm) – 48.75;

- 200x200x6000 (mm) – 124.8;

- 200x250x6000 (mm) – 156;

- 250x250x6000 (mm) – 195.

Thermal conductivity

Table of thermal conductivity in relation to other materials

| Material | Thermal conductivity coefficient, W/m*C |

| Glued laminated timber | 0,1 |

| Dry wood | 0,09–0,18 |

| Pine, spruce across/along the grain | 0,09/0,18 |

| Oak across/along the grain | 0,1/0,23 |

| Profiled timber | 0,18 |

| Foam concrete | 0,08–0,47 |