Long-burning stoves have become increasingly popular in recent years. The operating principle of these devices is based on separate combustion of fuel and released gases in different chambers. Thanks to this design, wood or other material burns more slowly than in a conventional stove, using less oxygen and releasing more heat. Such heating devices, which are also called pyrolysis or gas generator furnaces, are successfully used in private homes, cottages, baths and saunas, industrial and utility premises.

How does a wood stove work?

Long-burning stoves for heating a house differ from the classic one in that they have a two-chamber device. Here, solid fuel first smolders, then the resulting products burn. This way, virtually no soot remains and the maximum possible amount of thermal energy enters the room.

Upon closer examination, the working process of the unit looks like this:

- firewood flares up in the upper part of the stack;

- conditions are created for fuel smoldering;

- pyrolysis gas burns out.

Pyrolysis or gas generation is the process of decomposition of fuel heated to combustion temperature. The main condition here is the presence of oxygen in the required volume for smoldering, but not enough for an open flame. Based on this phenomenon, ovens are also called pyrolysis ovens.

Staged combustion of fuel

The design of the furnace allows you to create conditions for the release and combustion of pyrolysis gas through two channels for air supply. They are located in each chamber. That is, the following actions are performed in turn:

- Fuel is added until the chamber is completely filled (in the case of firewood, large logs are placed down and chips are placed on top);

Laying firewood in a pyrolysis oven Source kak.znate.ru

- a channel opens to supply primary air to the firebox;

- the bookmark is ignited in the upper part until red coals and an open flame are formed, the minimum required temperature inside the chamber is reached at +250-+300 degrees Celsius;

- the door is closed, the air channel into the firebox is first partially closed to ensure the smoldering state of the fuel with its additional drying, then it is completely closed,

- the supply of oxygen to the upper chamber opens for afterburning of the released products at a temperature of about +400-+450 degrees Celsius.

Pyrolysis gas contains methane and carbon monoxide. The heated mass, after unlimited supply of secondary air into the upper chamber, ignites. This afterburning process is accompanied by the release of a large amount of thermal energy. The soot here burns almost completely, and the residual products go into the chimney.

As a result, in a long-burning stove, the fuel decomposes, releasing heat twice. This approach allows you to increase the efficiency of the heating device.

Staged combustion of fuel Source kotel-tverd.sot.kg

Here, wood or coal burns almost completely for more than 1-2 hours, as happens in a traditional single-chamber stone stove. Here, one bookmark is enough for 6-12 hours, which is not a limitation for developers in order to expand the range. Modern units can operate for up to 20 hours or up to 3 days.

Equipment efficiency

In a conventional stone firebox, fuel combustion occurs in a single stage and quickly. Decay products go into the chimney or remain in the form of ash. That is, the product does not burn completely. As a result, the efficiency here is approximately 40%. If the chimney is extended around the perimeter of the room, the indicator will increase slightly, but will increase.

Regular stove Source 1-teplodom.ru

In a two-chamber device, maximum combustion occurs first of solid fuel, then of the released pyrolysis gas. In both cases, thermal energy is released. A small part of the flow goes into the chimney, the rest is spent on heating the room. Thus, the efficiency or efficiency of a slow burning stove reaches 90%.

Since not all units are highly energy efficient, users are looking for solutions to increase efficiency on their own. The solution may be forced air circulation. This way the thermal energy will spread faster throughout the house.

The other option is more expensive and time-consuming. Here a sealed heat exchanger under water is mounted on the chimney. The efficiency of a stove with a water circuit will be increased due to hot water pipelines extending from the device.

Equipment with a water heat exchanger Source brat.teplozhar.ru

The third solution option can be implemented independently or you can consider ready-made proposals from the manufacturer. This is a ceramic cladding that helps to prolong the preservation and release of thermal energy. This is justified by a lower thermal conductivity coefficient compared to metal, which additionally ensures the safety of users (it does not burn, as it does not heat up to a dangerous degree). In addition to the heat-accumulating ability, it is worth highlighting the aesthetic side. Tiles can have different colors, patterns, and textures.

Adjustments to the stove operating mode set by the manufacturer are also made if the fuel burns out too quickly or for a long time. Experts recommend entrusting the solution of such problems to representatives of the manufacturer or service company. A do-it-yourself approach can aggravate the situation, which often leads to equipment replacement.

Preparing for the workflow

Immediately after installation, it is necessary to check the reliability of the structure, the condition of the working parts, the presence of a grate and an ash box. It is advisable to carry out the first warm-up with the ventilation running and the windows open.

This is important so that not only combustion products are removed, but also harmful factory oils that coated the structure during conservation conditions.

The test intense combustion mode should be maintained for about 1 hour, after which the unit should be left until it cools completely. There is no need to touch its internal surfaces at this stage, since after heating the internal heat-resistant paint will gain stability for some time.

Typical wood burning device designs

Heating equipment is available in different designs. Two-chamber units can additionally be used for cooking and arranging a home heating system with water radiators.

Connecting a radiator to a pyrolysis furnace Source gidroguru.com

There are models that fit perfectly into the interior of a private home - long-burning fireplaces.

Basic

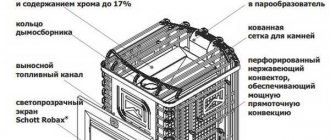

The range of single-function stoves is wide, but all models have a common design solution. This is a hollow metal body with technological holes for channels and openings for doors, internal partitions between the chambers and the ash pan.

Let's look at some design features:

- the bottom of the body is represented by a small compartment, the ash pan is separated from the firebox by a grate;

- for solid fuel, the chamber occupies most of the internal space of the unit;

- the upper afterburning chamber of pyrolysis gas has the shape of a dome;

- the channel for supplying primary air is analogous to the ash pan and/or ash pan in a traditional single-chamber furnace;

- camera doors are often made with a heat-resistant glass insert for visual control of what is happening inside the device, which adds aesthetics;

- smoldering of solid fuel occurs towards the second chamber;

Operation of a wood-fired pyrolysis heating boiler Source strojvodproekt.ru

- the air here takes part not only in the ignition and afterburning of peroxide gas, but in the cooling and self-cleaning of the sash (a small gap is provided above it for its further passage into the firebox);

- the chimney pipe has a cross-sectional diameter of 80-150 m;

- The doors in the side wall of the case are used for cleaning the compartments; they have a solid design without inserts.

Operation of the equipment is allowed in two modes. To quickly heat a room (for example, a country house), the operating mode involves extending the damper on the chimney, open access to primary air. The second option is relevant for long-term heating of a building by maintaining a constant air temperature. This is achieved due to the smoldering of fuel and the combustion of pyrolysis gas.

Mode of ignition or quick heating of the room Source yandex.net

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

With water circuit

Such furnaces are designed to serve houses with a large area and several isolated rooms. Such designs make it possible to solve the problem of heating the entire facility with one device. The design feature here is that the water heat exchanger is built into the furnace body. There are also 2 pipes for inlet and outlet of coolant.

Long-burning stoves with a water circuit consist of compartments and channels, partitions, and a housing with doors similar to the basic version. The design solution of the heat exchanger of the heating device is presented as follows:

- sealed layers of water along the walls, upper part of the body, partitions between combustion chambers;

- water “jacket” on the sides and above the combustion chamber;

- grate made of circuits with water (allows you to use the heat that is released during smoldering of the fuel).

Scheme for a homemade pyrolysis boiler Source oboiman.ru

Flanges or couplings for threaded connection of the heat exchanger with supply and return water pipes from the water heating system of a house with radiators (in the area of the ash pan and the upper part of the furnace). Additional cooling elements can be built into the heat exchanger. A number of models have a thermal insulation layer inside the body to prevent burns, overheating and spontaneous combustion of surrounding objects or decorative trim. If this is not provided, then the unit itself becomes not only a source of heat, but an element of the heating system of the house.

Overview of technical characteristics of wood stoves

The determining criteria for choosing this or that equipment are power, firebox and body material, and weight of the stove. The remaining parameters are indirect, since they do not generally affect performance, installation and operating conditions.

Most ovens are set to operate in a gentle mode - with one load for 3-10 hours. In this case, an area from 75 to 250 sq.m. is heated. Steel, cast iron or a combination of metals, brick can be used as materials for the frame and combustion chamber.

Homemade brick pyrolysis oven Source 1poteply.ru

Let's look at how to choose a long-burning wood-burning stove for a home:

- Heating the house. Depending on the size and power, the units can be used as a main or additional heat source, as part of a heating system.

- Functional. The design can be simple, with a water heat exchanger or water heating tank, with a hob, oven, or water tank. Multifunctional models may include part or all of the listed additions. For example, a heating and cooking stove with a water circuit.

- Power. The volume of heat transfer by the area of the room or house being served is determined.

Recommendations for the ratio of thermal power and heated area are presented in the table:

| Up to kW | Up to sq.m |

| 20 | 200 |

| 30 | 300 |

| 50 | 500 |

| 100 | 1000 |

After determining the basic parameters, the physical design of the products is considered. This takes into account the dimensions that will be optimal for installing equipment in a particular room in a corner or against a wall. A design solution may also be relevant, especially if you plan to locate the stove in the living room or the only room in the house.

Let's take a look at some features depending on the version:

- Wall models. The dimensions of such equipment, compared to corner equipment, are usually larger, and the range of sizes is wider. Accordingly, it is easier to choose a stove based on power for heating a particular room or house. Functionality and design execution can only be limited by technical regulations.

- Corner unit. More often it is a long-burning stove-fireplace. Characteristic features are compactness, relatively low power, and the combination of a steel body with cast iron elements in the fuel and pyrolysis gas combustion compartments. A hob for a kettle can be provided here.

Wall model Source dymohod18.ru

Where to buy a long-burning coal boiler for heating a private home

In Moscow

- Stoves-Fireplaces – st. Yubileinaya, 4 building A, tel. +7 (495) 215–56–94.

- Comfort - Dmitrovskoe highway, 100, building 2, tel. +7 (495) 921–37–61.

In St. Petersburg

- TechnoDom - 57 Stachek Ave., Komsomolskaya Square, tel. +7 (812) 671–00–88.

- Kit-Teplo - st. Litovskaya 8, +7 (812) 295–00–05, +7 (812) 248–18–88.

In conclusion, it is worth saying that the efficiency and economy of the heating system depends not least on the skill of the user, therefore, in order for a long-burning coal boiler to serve well for more than one season, it is necessary to learn how to properly operate the equipment and care for it.

Long burning boilersSolid fuel boilersCoal boilers

How does a coal furnace work?

Since compact heating equipment has been in wide demand relatively recently, the same mistake is often made during the operation of a long-burning coal stove. When heated with wood, this unit not only produces less heat, but can also fail. To eliminate this, you need to understand the operation of the device.

The range of heating equipment is represented by samples for working on coal or with the possibility of using firewood. The former are distinguished by thickened body walls and are designed for a long service life, but are in less demand due to the narrow range and heavy weight. The latter are equipped with removable grate bars to adjust the volume of primary air supply depending on the fuel used.

Construction of a coal pyrolysis furnace Source 24aul.ru

Pyrolysis in the case of coal fuel occurs in a long-burning furnace in this way:

- the backfill goes through the drying stage;

- the bulk, under the influence of a temperature of about +400 degrees Celsius, releases resins and bitumen;

- heavy hydrocarbons decompose into volatile compounds;

- carbonization of coal occurs;

- pyrolysis gas ignites, raising the temperature in the firebox to +600 degrees Celsius, which provokes the combustion of carbon.

Let's look at how coal-fired home stoves differ from their wood-burning counterparts:

- Primary air. Without oxygen supply through the grate, coal stops burning. Therefore, the vent here does not close completely during heating. The device can only be set to operate using a controlled supply of primary air.

- Ignition of coal. To solve the problem, it is necessary to heat the fuel to a higher temperature, which is provided by firewood. To speed up the process, the coal must be dried.

Working condition of coal Source wallpaperscraft.com

- Smoke exhaust. The channel here has an increased diameter to ensure sufficient throughput. Some models do not have a gate valve.

Differences also relate to the consequences of overloading. Firewood has a lower combustion temperature, and there are practically no obstacles to oxygen between the logs. The result is an uncontrolled process of active combustion of fuel.

In the case of coal, a similar development is likely, but to a lesser extent. This is explained by the higher density of the backfill, which contributes to the supply of insufficient oxygen to the upper layers. Since combustion is virtually eliminated, the temperature drops. This leads to the cessation of the pyrolysis process and, as a result, the stove does not heat up.

Design features

The grate is made only of gray cast iron, which copes with the high-temperature load from burning coal. The pitch between the grate bars is increased compared to that used in the firebox of a wood-burning stove. This is justified by the need for sufficient primary air flow.

Cast iron grate Source e.allegroimg.com

The combustion chamber is also made of high-strength heat-resistant alloys of steel and cast iron. The walls here are thickened and can withstand the +800 degrees Celsius required for burning coal fuel. There is also a 2 mm thick protective screen made of stainless steel with a chromium content (over 13%). In this way, manufacturers increase the service life of the unit by protecting the combustion chamber from burnout.

The estimated period of serviceable condition of the housing is within 5-10 years. But the actual service life may be influenced in one way or another by the type of coal fuel.

There are three varieties:

- A – anthracite;

- D – long-flame;

- DG – long-flame gas.

Anthracite coal is not used for long-burning stoves and fireplaces for summer cottages, which are included in the rating of popular ones. Preference is given to the DG variety. This is justified by the most efficient formation of pyrolysis gas.

DG grade coal Source teplishe.com

Advantages and disadvantages

The advantages of coal stoves come down mainly to the properties of the fuel. It has high heat transfer. The smoldering process occurs over a longer period of time than in the case of firewood. With proper operation of the equipment, coal burns almost completely (98-99%). One load of the large fuel compartment can be used for several days.

The advantages of the design are the ability to control the process inside the firebox. In the case of a wood stove, this is complicated by the fact that wood is highly flammable. Due to the absence of such a drawback, coal units control the degree of heating of the coolant in the water circuit.

Coal furnace with water circuit Source ulanude.kotel-t.ru

Disadvantages relate to the design solution. Air injection here is ensured by forced flow movement. That is, if there is a power outage, the fan will stop functioning. Another disadvantage is the impossibility of adding an additional portion of coal before the complete combustion of what is already in the combustion compartment. Since the materials for the production of stoves are used with high technical requirements, the cost of the equipment is noticeably higher than that of wood-burning analogues.

Schemes of potbelly stoves

The main advantage of the stove is rectangular in shape

. unlike oval products made from pipes or gas cylinders, it consists of a larger heated surface area, so its efficiency will be much greater. The optimal size for a potbelly stove is 800x450x450 mm. A stove of this size will not take up much space and will easily fit even in a small room.

The simplest design is the “Gnome” stove, which consists of a box with a pipe welded to it

An important difference between the Loginov stove

is the presence of two plates (

reflectors

) in the upper part of the combustion chamber.

Since the path of gas movement

increases, the heat transfer of such a potbelly stove is significantly higher than that of a conventional metal stove.

Advice

. If you need to reduce the size of the Loginov oven, then it is advisable to change only its width. If the length and height of the structure changes, its efficiency may decrease significantly.

The lineup

The rating of long-burning stoves for a summer cottage, a home using wood or coal includes only popular samples. However, the range of equipment is wider and more diverse. Let's look at what units are offered by leading manufacturers and what users choose.

Breneran

The domestic analogue of the Canadian stove is distinguished by the presence of pipes on both sides of the body. They also serve as footrests. Their role is forced convection of air currents. The output is to heat the mass to +150 degrees Celsius.

One of the Breneran type models Source ul-stroydvor.ru

Products are classified and labeled by power. For example, AOT-6 produces 6 kW of thermal energy, AOT-19 is a more efficient unit - 35 kW. Accordingly, the serviced area of the premises is 56 or 260 sq.m.

The table provides a brief description of the model range.

| Model | Options | Description |

| AOT-06 | Power – 6 kW. The volume of heated air is up to 100 cubic meters. | Used for installation in a separate room. Fuel - firewood. The door can be made of metal or glass. Connecting an air heating system is not recommended due to its low power. |

| AOT-08 | Power – 8 kW. Room volume – 140 cubic meters. | The compact model is more often used for unheated premises: greenhouses, garages, workshops, cottages. Convection channels 7 pieces. |

| AOT-11 | Power – 11 kW. Air volume – up to 200 cubic meters. | Compact oven weighing about 100 kg. When connecting air ducts, the serviced area can be increased to 100 sq.m. |

| AOT-14 | Power – 18 kW. Serviced volume – up to 400 cubic meters. | The sample is relevant for installing a furnace with brickwork and stone cladding. The building area can be 180 sq.m. |

| AOT-16 | Power – 27 kW. Air volume – up to 600 cubic meters. | Without fuel, the unit weighs about 190 kg, which requires attention to a reinforced support base. The stove does an excellent job of heating several rooms through an air duct system. |

| AOT-19 | Power – 35 kW. Building volume – up to 1000 cubic meters. | Such equipment weighs about 240 kg, with fuel up to 440 kg. A gas-generating wood-burning stove is suitable for a house with many rooms and several floors. |

The model range includes heating stoves with a water circuit. Here the coolant circulates by gravity using the principle of convection. However, condensation is often observed here in the area where the unit is located. This phenomenon is explained by the weak tightness of the smoke fitting and the special container for collecting moisture in the lower part of the housing.

The main range is designed for working with firewood. Universal type modifications with cooking surfaces are often served with gas. There are samples that can be filled with gasoline, diesel fuel or oil.

Prices: summary table

Price rating of long-burning coal boilers (table):

| Long burning coal boiler model | Cost, rub. |

| Stropuva S15U | 85 400–90 560 |

| Heiztechnik Q Alfa 15 | 62 240–68 720 |

| Buderus Logano S181-15E | 218 000–250 640 |

| WEEK KO-60 | 115 900–130 500 |

| TIS (TIS) PRO 11 | 64 100–67 200 |

| LIEPSNELE L20U | 81 500–99 770 |

| VIADRUS Hercules U22D | 126 600 –128 530 |

| Galmet CARBO 21 | 103 890–116 750 |

Video description

The video describes how to properly heat the Buleryan series stoves:

The table provides a brief overview of the series of stoves from the Novosibirsk manufacturer.

| Model | Characteristics | Description |

| Siberia BV 120 | Air heating – up to +80 degrees Celsius. Room volume – 120 cubic meters. | With one load, the oven operates for 8-10 hours. Suitable for garages, greenhouses, production sites. |

| Siberia BV 180 | Power – 7 kW. Air volume – up to 180 cubic meters. | The oven operates for up to 8 hours. The design is designed for the use of any solid fuel. A thermometer is installed to control the temperature of the heated air leaving. |

| Siberia BV 480 | Power – 18 kW. Air volume – up to 480 cubic meters | A characteristic feature is pipes with a rectangular cross section. An eccentric lock is provided to ensure a tight fit of the door to the body. |

| Siberia BV 720 | Power – 49 kW. Air volume – up to 720 cubic meters. | Without taking into account fuel, the mass of the unit reaches 157 kg. The main application is warehouses and industrial sites. The duct system is used to heat several rooms in the residential sector. |

The Eurosib company offers several models with a hob. Here we consider 2 series of equipment:

- Tulinka NVU. A characteristic feature is the presence of a cooking surface with holes from truncated pipes. Here they do not protrude beyond the panel. The unit is intended for the private sector. A volume of up to 150 cubic meters is serviced. Fuel - firewood.

- Klondike NV. The serviced building can be from 100 to 1200 cubic meters. The main focus is the harsh climate. Work from one load – up to 10 hours. The material exhibits good resistance to low quality fuel.

Buleryan Klondike HB-1200 Source 2gis.com

The room is heated by convection. Cold air enters and heated air exits into the built-in pipes. The degree of heating of the mass is +60-+015 degrees Celsius. Heating of adjacent rooms is carried out by connecting air ducts to the pipes.

Another characteristic feature is the absence of a grate. The resulting ash serves as a preventative against pipe burning. That is, the removal of combustion products is carried out only partially, in case of excessive accumulation of mass (pouring out of the combustion chamber).

It is permissible to use briquettes, cardboard, wood waste, and brown coal as fuel. It is considered optimal to use logs of length in accordance with the dimensions of the compartment. The operation of the furnace does not involve loading coking coal and liquid fuel.

Butakova

Such stoves are chosen for heating large rooms and baths. Such units are considered one of the best long-burning wood-burning stoves for a home in harsh climates with relatively freezing temperatures. The line is represented by various samples. The table shows their brief characteristics.

| Model | Weight (in kg) | Power (in kW) | Room (in cubic meters) |

| High school student | 55 | 6 | 100 |

| Student | 70 | 9 | 150 |

| Engineer | 113 | 15 | 250 |

| Academician | 164 | 25 | 1200 |

| Professor | 235 | 40 | 1000 |

| Assistant professor | 300 | 55 | 500 |

Several features of models with low and extreme heat transfer:

- High school student. Operates in gas generation mode for 6-8 hours. The chamber holds 34 liters of fuel, the length of the logs is up to 44 cm. Heats the room through convection and the body. Air outlets are located on the sides.

- Assistant professor. Doors can be metal or with inserted glass. Fuel – firewood with humidity up to 20%. The body is steel, the door is made of cast iron. Loading capacity – up to 100 l, log length – up to 60 cm.

The design solution provides for convection heating of the room. There is no separate hob here. But it is permissible to cook food on the horizontal platform of the housing, which also hides the pipes. There are holes in the upper part of the shell for the release of heated air.

Vesuvius

The equipment is used to heat the bathhouse. Therefore, the design may imply, depending on the model, a mesh container for stones (up to 10 kg), an external firebox, and decorative finishing. An important plus is that oxygen is not burned and there is no infrared radiation. Fuel is wood.

Vesuvius stove Legend Source spb.kaminchi.ru

Features of long-burning stove samples are as follows:

- Skiff - a firebox up to 12 mm thick, there is a basket for stones, the body is rounded;

- Optimum Ch - bath model for a steam room of 6-15 cubic meters;

- Skif 16 – the thickness of the walls of the combustion chamber is 8 mm, the volume of the room is from 8 to 16 cubic meters;

- Skif 22 VK – steam room volume reaches 23 cubic meters, remote firebox (8 mm);

- Rusich - traditional stove for a room 18-24 cubic meters, metal or glass door;

- Elite – made with natural stone cladding;

- Russian steam – steam room up to 28 cubic meters, remote firebox, cast iron door;

- Lava – there is a casing for heating the air by convection;

- Legend – efficiency up to 80%;

- Ch 100 – model for residential premises up to 100 cubic meters in size, steel body (5 mm);

- K 250 - an analogue for heating air with a volume of about 250 cubic meters.

The body is made of steel with a thickness of 8-12 mm or 5-8 mm, depending on the purpose: bathhouse or home. For the purpose of safe use, a protective shell is made of organosilicon composition. The grate and door are cast iron; in the case of the Legend model, the entire structure is cast from cast iron.

Ermak

The manufacturer's products are presented in a wide range.

Model Ermak Grid Source 24.teplozhar.ru

However, all equipment can be combined into two groups: heating and cooking units, units of the Stoker series. Such models are often included in the rating of long-burning stoves with a water circuit and fireplaces for the country house.

Here are some popular samples with a brief description:

- Aqua 12-P/E. There is a cooktop with one burner. The grate is made of cast iron. It is permissible to regulate the combustion intensity of wood fuel. The room can be up to 120 cubic meters in size.

- Aqua 18-E. Analogue for heating air with a volume of up to 180 cubic meters.

- Pro 20-E. It is permissible to connect an electric heating element. The volume of the room is limited to 220 cubic meters.

- Pro 25-E. Can operate in three modes: economy, nominal, ignition. The compact unit serves up to 250 cubic meters.

The combustion chamber in the Stoker series has a built-in flame cut-off. This promotes uniform distribution of thermal pressure on the walls of the compartment. The equipment has compact dimensions and attractive appearance.

Termofor

Versatile device regarding application. This is due to high heat transfer and compactness. This is true for a house with a summer house, a bathhouse, a garage or a workshop.

Model Termofor Source ekaterinburg.teplozhar.ru

A design feature of the equipment is tubes welded inside the combustion chamber. They promote uniform distribution of heated air.

The Compact model is included in the rating of long-burning steel fireplace stoves with a cast iron firebox for a bathhouse in a country house or in a private house. The unit serves a steam room measuring 6-12 cubic meters. The equipment weighs only 38 kg. The capacity of the combustion compartment is 10 l, the length of the log is limited to 40 cm.

The Geyser model is designed to produce dry and light steam. The volume of the room is 8-18 cubic meters. The weight of the unit is 59 kg, the weight of stones is 70 kg. Firewood can be 50 cm long.

Sayana is made with a separate mesh for stones. The capacity of the firebox is 36.4 l, basket capacity is 120 kg. Unit weight – 47 kg. Logs are used up to 40 cm long. The size of the steam room is 8-18 cubic meters.

Recommendations for masonry

To lay a stove where you plan to burn coal, you will need 2 types of mortar - clay-sand and fireproof. With the help of the first, the body of the furnace is built from solid ceramic bricks, and the second is used for the internal masonry of fireclay stones. The thickness of the seams also differs: for ordinary masonry it is a maximum of 5 mm, for fireproof masonry - 3 mm.

To prepare both types of mortar, it is recommended to purchase ready-made construction mixtures that are commercially available. Only experienced stove makers can make a good solution from natural clay. You also need to prepare masonry and measuring tools, and then start building the stove:

- Before laying on the mortar, each row of bricks must be laid out dry to try on and adjust the stones to size.

- Before putting the brick in place, it must be dipped in a bucket of water.

- It is advisable to place the stones in one precise movement so that you have to tap less.

- Trim off the remaining mortar on the front side with a trowel, and wipe dry on the smoke exhaust side with a rag.

- Control each row horizontally and vertically.

- Leave a 5 cm wide gap between regular and fireclay masonry, which is then filled with basalt fiber.

- Install a cast iron stove with burners and doors using rolled metal support elements.

The stove solution does not harden, but dries, for which it needs to be given 2-3 days. Afterwards, all that remains is to lay out the chimney, observing the rules for passing through the floors and roof, and at the end make a test firebox. You can fill the stove with coal only after it has completely warmed up, making sure that there are no cracks or crevices.

Briefly about the main thing

Long-burning furnaces operate on the principle of secondary combustion of pyrolysis gas, which is released by smoldering fuel.

Most units are designed to operate on wood or coal fuel. It is also permissible to use gas, liquids, briquettes. It is important to comply with the manufacturer's requirements.

The design solution can be basic (only for heating without frills), with a water heat exchanger, with a hob.

To expand the range, manufacturers offer glass inserts in doors, housing with collector pipes, cladding, mesh under stones (sauna stoves).

The selection criteria are power, the volume of heated air in the room, the weight of the equipment excluding fuel, the capacity of the combustion compartment, and the operating time from one refueling.

Ratings 0

Advantages and disadvantages

This solution has obvious advantages:

- the oven can operate offline for up to 10 days;

- the operating time on one load of fuel increases by 2 times for firewood, and by 3 times for coal;

- low requirements for fuel quality;

- simplicity of design and installation;

- the ability to add additional options.

But practice has shown that there are also disadvantages:

- it is impossible to add fuel until the previous fuel is completely burned;

- you need a dry place to store fuel;

- coal produces a lot of dust and soot;

- high fire hazard if the requirements of SNiP 2.04.05-91 are not followed;

- The ash pan must be cleaned after each firebox, and the chimney before each heating season;

- environmental pollution.