The bathhouse - the room in which you steam - is designed to maintain high temperature and humidity. Therefore, it has certain specifics in the choice of materials and designs, namely:

1) To maintain high temperatures even in winter, the structure must be well insulated.

This applies to all structures - walls, ceilings and, especially, the floor, since it cools more than other structures and is in maximum contact with water.

2) Since the bathhouse is always humid, when setting it up it is important:

- properly drain the water; make a hydro- and vapor barrier for its structural basis; use materials in the cladding that do not deteriorate from moisture.

3) Internal lining materials in the bathhouse are operated at high temperatures (up to 80°C with wet steam and up to 130°C with dry steam). This means that it is necessary to line the internal surfaces with materials that can withstand high temperatures well and do not emit harmful substances.

Choosing flooring material

The pros and cons of each of them are assessed individually by the customer. Wood is a “warmer” material, pleasant to contact with human skin and absolutely environmentally friendly.

Being in humid conditions most of the time, the wood will become damp, blacken and rot (and it cannot be treated with antiseptics, because it will “release” chemicals into the atmosphere when the temperature and humidity rise). Therefore, the wooden floor in a bathhouse is usually replaced every 5-8 years, depending on the frequency of use. Concrete is not susceptible to rotting and colonization by microorganisms, so it is more durable.

Ventilated floors

A concrete floor with joists in a bathhouse is an excellent solution if there is a need to raise it above ground level. Just keep in mind that the logs must be strong enough. This method will create the opportunity for excellent ventilation of the underground space through special windows left in the base. This method is often used when baths, due to the peculiarities of the soil composition, are installed on supports in the form of piles.

The sequence of actions is as follows:

- a beam is prepared under the logs, the cross-section of which is 10 by 20 cm. Its installation is carried out in steps of half a meter to make it more convenient to use insulating cotton mats;

- if the area of the room is large, then supporting brick columns are placed under the logs;

- a 5 by 15 block is attached to the lower edges of each joist, creating shelves;

- The rough plank floor is laid on them. Do not forget that all wooden elements must be pre-treated with antiseptic compounds;

- Before installing the subfloor, drainage pipes are laid;

- it’s the turn of the waterproofing material;

- now - an insulating layer. Mineral wool, expanded clay, and expanded polystyrene material are used;

- install a mesh for reinforcement, beacons with the required slope;

- the solution is poured.

It is possible to install a concrete floor in a bathhouse with your own hands. But in all cases it is necessary to remember one important condition. To avoid the occurrence of dampness, the level of all floor layers is determined so that it ultimately does not exceed the upper edge of the plinth part (the casing).

Bath floor options

Perhaps we should start with the fact that the floor of the bathhouse must have a drain through which water is drained, connected to the sewer or going into a drainage hole. For water to flow by gravity, the floor must have a slope going either to the center of the room or to one of its corners. Typically, this slope is 1-2 cm in height per 1 m of floor length.

There are two main types of bath floors, with different design solutions – wooden and concrete.

1.

The wooden floor in a bathhouse is made similarly to the floor in a house, but differs from it in its enhanced waterproofing protection, since it has to deal directly with water and steam. It is a structure of beams that rest on a foundation grillage and free-standing columns. A subfloor is sewn underneath them (the boards must be impregnated with antiseptics and water repellents), on which the insulation is laid.

The latter is covered on top with a reinforced waterproofing layer, on which the finishing coating is laid. These can be boards or ceramic tiles laid on a layer of glue on a cement-sand base. The wood must be dense enough so that it does not absorb water, and the tiles must have an anti-slip coating that protects a person from falling on a wet surface and getting injured.

It is important that the subfloor boards and insulation do not become damp from moisture coming from either above or below, otherwise the insulation will lose its heat-saving properties. And if a layer of waterproofing protects it from moisture from above, then from below it is necessary to ensure insulation of the foundation, drainage and external waterproofing of the basement so that water and cold, which cause frost or condensation, do not penetrate into the basement space.

2. The floor in the bathhouse can be made of concrete. Because a bathhouse is a small room, and such a floor, although quite material-intensive, has a guaranteed service life.

For comfortable use of the bathhouse, it is important to make the floor warm. Its optimal design is as follows: first, the soil under the foundation is compacted at the required height, then the area is covered with crushed stone, which is leveled with a layer of 12-15 cm. It is advisable to impregnate the crushed stone with bitumen.

Concrete is also laid out on this base in a layer of 12-15 cm and leveled using the rule. Then the concrete gains strength in a humid environment for 2-3 days. The next layer is heat insulating.

To make it, expanded clay or expanded polystyrene chips are mixed into the concrete mixture. In principle, it is possible to lay extruded polystyrene foam, which will need to be protected with waterproofing, and again filled with concrete mortar on top. The top layer of concrete is also necessarily covered with a layer of waterproofing, on which, in turn, the finishing coating will be placed.

Work technology

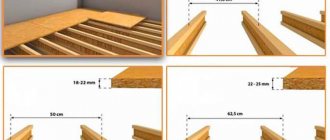

The simplest and most technologically advanced method is when the floor is insulated by laying a heat-insulating layer between the subfloor and the main floor. The thickness of the layer is equal to the thickness of the lag. Depending on the length of the span, it can range from 10 to 20 cm.

If a smaller layer thickness is required, for example, for polystyrene foam, then the subfloor is constructed from short boards nailed to the joists through bars on the sides of the joists. The bars allow you to leave any allowance for the thickness of the lag below the subfloor level.

What can insulation be laid on?

- On a wooden subfloor;

- On a concrete screed;

- On a subfloor made of OSB boards (a common option for pile foundations).

You cannot lay insulation on the ground, soil fill, or sand bed. In this form they are unprotected from rodents and moisture.

In the relaxation room in the bathhouse

In the recreation room you can use almost any thermal insulation materials. Along with polymer insulation, mineral wool, basalt slabs, backfill, sawdust, and cellulose fillers are suitable.

Attention! It is not recommended to use mastics that require heating. All of them have a very high fire hazard

Nowadays, there are enough solvent-based products that can be used straight from the can.

Usually they take the material that is available inexpensively on the local construction market. Also important is its safety for humans and compliance with general requirements for a bathhouse.

Basalt wool is non-flammable and is sold at low prices.

It is used quite often in baths, but it must be taken into account that even after getting wet once, it “shrinks” in volume and its heat-insulating characteristics deteriorate irreversibly.

Also, when using it, you need to take care of insulating the mineral wool from the room.

It is rational to use it only in the relaxation room and avoid using it in the steam room and washing room.

In the steam room of the bath

Information. The insulation of the floor in the steam room of the bath is carried out taking into account the influence of moisture. It must be combined with very good waterproofing. Of all the structural elements of the bathhouse, it is the floor that is subject to the most intense action of water.

One of the options for insulating the floor in a steam room is to use exclusively moisture-resistant insulation materials, for example, mineral ones. A thick layer of expanded clay backfill is created on the prepared base.

Then a drain pipe is installed in the center and a waterproof layer of concrete is poured on top. It is designed to ensure water flow. The field structure is covered with a wooden lattice (finishing floor for the steam room).

Heated floors, which are especially often used in saunas, are insulated using a similar scheme. First, a layer of porous backfill is created. Then - a screed into which the heating cable or pipe coil with coolant is recessed. All this is covered with tiles.

The insulation of the floor in the steam room can be done without expanded clay, for example, using polystyrene foam. In terms of the ratio of thermal insulation characteristics and price, it is much more profitable than expanded clay.

It is used according to the same structural scheme as expanded clay, only the slabs are placed not on a bedding on the ground, but on a subfloor.

The general design of the finished floor is several layers of materials in section:

- Subfloor: board, concrete slab;

- Frame made of boards on edge;

- Expanded polystyrene boards or backfill to the thickness of a lattice of logs;

- Waterproofing layer;

- A layer of screed with an attached slope and a drainage system for draining water;

- Clean wooden grate.

Insulating the floor in a steam room with foam plastic is suitable for server areas, since its thermal insulation properties are much better than expanded clay. Instead of foam plastic, a wide range of materials based on it can be used. Various manufacturers give them their own names, so we do not indicate the exact brands.

What is possible waterproofing of the floor in a bathhouse?

As already mentioned, in the case of a wooden floor structure, waterproofing is installed on top of the insulation, protecting it from moisture that can penetrate through the finishing material of the floor.

The waterproofing layer can be made of a coating material on which roofing felt is laid in several layers. As a coating waterproofing material, you can use mastic, which is sold ready for use. or molten bitumen.

You can also use euroroofing felt as insulation, a new generation material that is less labor-intensive to install.

It can be used if the insulation can withstand high temperatures, since euroroofing material is a weldable material.

Waterproofing the floor in a bathhouse, if it is made of concrete, can be rolled-coating, penetrating, polymer-cement and cement.

The first condition for a high-quality waterproofing device is the preparation of the base, which should be as smooth as possible and free from bumps and depressions.

Before laying waterproofing consisting of roll-coating materials, it is advisable to prime the surface. After which hot bitumen or cold mastic is applied to it, onto which roofing felt is laid in several layers.

Penetrating waterproofing is done using a special powder, soluble in water (for example, “Penetron”, “Infiltron-100”), the effect of which is that it crystallizes in the pores of concrete, not letting water into it, but leaving it permeable to steam.

Polymer-cement waterproofing is a ready-made mixture (for example, “Ceresit CL 50”), or a two-component composition in which a mixture of cement and additives is mixed with a liquid polymer (“Maxseal Flex”). The good thing about the material is that it can bridge cracks up to 5 mm.

Waterproofing, called cement waterproofing (“Hydrostop”), is a dry mixture specially prepared for waterproofing rooms with high humidity. It contains hydrophobizing and polymer modifying additives. The prepared mixture is called coating waterproofing and is applied over a primer onto a prepared and moistened base.

If sheet insulation is used when installing a concrete floor, it should be protected from moisture on both sides using plastic film or roofing felt, covering the ends and ensuring that the seams overlap.

It doesn’t matter what size the bathhouse was built, care must be taken to ensure that wastewater is removed from the premises.

Before creating a floor with a drain in a bathhouse, you need to consult with construction specialists. This is the only way to avoid reworking the entire system in the future. Read an overview of the types of sauna stoves on this page.

The photo shows the drainage device in the bathhouse

Attention and the right approach will guarantee the long-lasting service of the walls and foundation of the building. In addition, only a properly constructed floor can prevent the formation of fungus, rot and unpleasant odors. It is for this reason that it is incredibly important to carry out sewerage.

There are two main ways to bring your plans to life:

- The first option involves installing a drainage system; the second option involves installing a drainage system so that it is connected to the central sewerage system.

The drainage system must be carried out with special care; no allowance should be made for the simplicity of the design. After all, in fact, water will flow into the drainage by gravity.

For this reason, it is necessary to arrange the floors in the bathhouse very dense and with a slight slope. You can also install a drain hole in the floor. A metal or asbestos gutter can be installed underneath it.

Advice! Many experienced specialists say that a trench can be installed between the room where ablution will be carried out and the steam room. To bring this to life you will only need to raise the partitions a little.

This is how the water will flow down an inclined slope into the gutter and be discharged directly into the sewer or drainage well. In most cases, wells of this type are installed close to the building. The overall dimensions of the drainage will depend on the number of people taking a bath at the same time.

Types of waterproofing and materials used

How to properly waterproof the washing room and other areas of the bathhouse and what materials to use? It’s worth noting right away that there are two options for insulating “damp” rooms: traditional and penetrating. Traditional insulation is characterized by the following methods of work.

Coating

An example of the use of polymer coating waterproofing

To treat hygroscopic surfaces, materials with a low level of water absorption are used: dry mixtures, pastes, mastics, etc. Most often, the following types of compositions are used to decorate washing and steam rooms with your own hands:

- Bitumen-polymer. The materials are represented by oxidized bitumen, to which various plasticizers are added to improve technical parameters (water absorption and heat resistance). As a rule, the coating is used under the tiles, so it is applied directly to the concrete screed;

- Cement-polymer. Such compositions can be applied to metal reinforcement due to the universal properties of coating materials. They play the role of both waterproofing and cement screed at the same time. Universal mastics are applied in several layers, which provides the base with high-quality protection from moisture and significant temperature changes;

- One-component. Before use, liquid materials are simply shaken thoroughly until the mixture becomes homogeneous. One-component mastics contain organic additives (essential resins) that have the necessary moisture-repellent properties;

- Liquid mastics. The consistency of mastics is very similar to alkyd paints, which greatly simplifies the process of their application. They are ideal for waterproofing wooden floors in a bathhouse.

Sticking

Rolled film for waterproofing a room

In this case, sheet or roll materials are used to insulate the flooring and walls of the steam room. For their installation, bitumen mastic can be used if there is no adhesive base. Waterproofers are a plastic base made of fiberglass, polyester, polypropylene or fiberglass, on both sides of which a layer of bitumen is applied. There are three types of coatings suitable for gluing a wooden subfloor in a bathhouse:

- Self-adhesive – the back side of the coating has an adhesive base, which greatly simplifies the installation process;

- Fused - before installation, the reverse side of the waterproofing material is heated with a gas burner, after which the material is quickly and reliably glued to the rough base;

- Adhesive - to fix waterproofing coatings, special adhesive compositions containing a sealant are used.

To make traditional waterproofing washable with high quality, we suggest watching a video about coating materials. However, it should be taken into account that incorrect installation of the waterproofing material with your own hands will significantly reduce the service life of the bathhouse. Therefore, technically complex work, which includes insulating premises, should be entrusted to professionals.

Kinds

Today, baths can be built from various building materials: reinforced concrete slabs, brick, wood or timber. Consequently, the floors will have different designs. Read a review of sauna stove manufacturers.

The two main types of flooring that are most popular among the population are:

wooden floors in a bathhouse with a drain - this option is very durable and reliable, but despite this, wooden floors have many disadvantages. They rot and get very wet.

Water flows down through the cracks between the boards; concrete floor with a drain in the bathhouse - this type of bathhouse floor is durable and highly durable. It should also be noted that not everyone can install such floors, because it is necessary to maintain the slope of the surface and make it absolutely flat. When pouring a concrete floor, it is necessary to use additives that affect the waterproofing qualities of the coating.

The photo shows the process of waterproofing a floor with a drain in a bathhouse

As for the device for draining water in a frame bath, removable wooden floors would be the ideal option. This is when all the elements can simply be taken outside to dry.

Traditional recipes for processing lag

Here are examples of folk recipes for how to treat bathhouse floor joists. The most common means is machine processing, used for preserving logs. A large number of recipes are based on a combination of oily waste, various salts and diesel fuel. According to the craftsmen, it will be enough to coat the beams only with oil. With this method you can stop wood rotting that has already begun.

This method is popular due to the existence of a large amount of used oil. Of course, the remedy is effective. The waste contains many active substances that suppress the reproduction of all biological organisms. Due to high chemical reactivity, joists should not be completely covered with used oil. This material cannot be used in a bathhouse. It is considered relatively safe to treat small areas of the most affected areas of timber: the ends and notches. These parts are the most accessible for harmful microorganisms to penetrate deep into the fibers.

How to fill floors?

The floors in the bathhouse need to be given special attention. Their flooring can be done using several methods.

The first option is very simple - the floors are laid on wooden logs without fixing them with nails, and it is necessary to maintain a gap of five millimeters between all floor elements. This option can be considered ideal, because if something happens, you can simply take all the elements of the floor structure outside to dry. You can read the instructions on how to insulate a bath here.

In the event that the first option, in the opinion of the bath attendants, will be inconvenient and very painstaking, you should use the second option. You can make permanent floors that will be particularly durable.

This option involves maintaining a special slope, and a device is installed under the floor system that is responsible for collecting water and distributing it in the receiver. With all this, it is worth remembering about the ventilation of the room. The presence of ventilation is a mandatory element of any bathhouse. The riser can be made from either asbestos or metal.

It is then placed on the drain. The diameter of the drain system cannot be less than ten centimeters. A cap is installed on the “top” of the system.

After some time, the drainage system will need to be cleaned, as well as the drainage system itself. It is performed in several stages.

In the first stage, wastewater is separated from limescale. At the second stage, biological treatment is carried out through a filter system. Soil can act as a natural filter.

In the event that visits to the bathhouse will occur quite rarely and no more than 4-5 people will use the room at a time, then it is worth installing the most primitive water drainage system.

It will be enough to use the most affordable, so-called budget option - this is a device at the base of the construction of a pit for washing departments. As for the walls, it is advisable to lay them out with bricks or cover them with liquid glass.

If the number of people simultaneously visiting the bathhouse exceeds 6-10 people, then a more complex structure should be arranged. It will be necessary to lay a pipe and only then bring it into the drainage or central sewer system. An overview of the types of columnar foundations for a bathhouse here: https://banya-gid.ru/stroitelstvo/fundament/obzor-vidov-fundamenta-stolbchatogo-dlya-bani.html.

At the moment, economical and environmentally friendly systems are very popular among those who like to take a steam bath. These usually include wells equipped with biological filters and septic tanks.

Floor installation with drainage pit

This design is a little more complicated in design, but it is much more preferable.

Floor installation with drainage pit

Installation sequence

- Sand and crushed stone is backfilled onto the ground.

- The backfill is filled with concrete.

- A recess is created in the form of a kind of funnel with flat walls. This part of the structure must be directed towards the wall of the room.

- The funnel contains a container designed to accumulate excess water. This container must be made airtight. Typically, containers made of brick or a concrete ring are used. Remember that in bathhouses, the water collector is first installed, and only after that the base itself is laid. Already such a design can be considered as a kind of waterproofing.

- Floor boards are laid on top with a gap of approximately 0.5 cm.

- The columns that serve as the basis for the logs must be waterproofed. The columns themselves are made of brick or on a sand-concrete base.

- After completing the drainage arrangement and preparing the base for installing the furnace, you can proceed to the floor installation stage.

The waterproofing material is directly applied after all of the above work has been completed. The procedure for installing waterproofing depends on the properties of the specifically selected moisture-proof material, as well as on the characteristics of the floor material. Each of them requires the use of its own types of penetrating and traditional waterproofing.

Video

Watch the video for recommendations on how to organize water drainage in a bathhouse:

In such systems, natural sedimentation of water occurs. After time, the water will be distributed throughout the surrounding area. The sludge settled at the bottom of the settling tank will become a “home” for microorganisms.

They thrive in the alkaline solution of wastewater and feed on what is contained there. They themselves purify water. Installation of a septic tank must be carried out only in low-grade areas.

Any extensions to the house that will be used as a bathhouse or sauna need to be protected as much as possible, since the humidity there will constantly be increased.

Of course, if this is a summer option, then cracks are made in the floor boards to allow moisture to naturally escape.

But if this building is for use all year round, then you need to take seriously the insulation and waterproofing of the floor in the bathhouse.

Recommendations from experts

To ensure that the flooring in the bathhouse lasts at least 10 years, experts recommend paying attention to the following subtleties:

- During the installation process, floor boards must be secured with self-tapping screws at the junction of adjacent elements. In this way, warping of the coating can be prevented;

- During use, wood will inevitably swell under the influence of water. To eliminate the possibility of severe deformations, during the installation of the floor, a technological gap of 3-4 cm is left between the wall and the mounted planks;

- When installing non-leaking floors, it is advisable to place plywood under the larch planks, which minimizes the contact of the wood with the screed.

General information about floors in rooms with high humidity

You can build a bathhouse using a variety of materials, but wood is most often used. Due to increased humidity and the influence of steam, the tree quickly begins to rot and is exposed to other negative factors.

If the insulation is done correctly, then such problems will not arise and the structure will last much longer. Any materials will be damaged even after a single contact with water. Therefore, it is important to take the following steps:

waterproof the floor and foundation;

install a vapor barrier and waterproofing to prevent condensation;

It is worth making protection for the roof or attic.

You should also make a small slope in the area of the floor towards the drainage system so that the water flows into the sewer and does not stagnate in the room. To install the drain, it is better to use polymers or other stainless materials. There should be no metal surfaces under your feet, as they get very hot or cold. It is better to drain away from the place where water procedures are taken.

How to prevent rotting

The main cause of rotting is construction errors. If they are allowed, then even industrial impregnation will not provide reliable protection against rot and mold. During construction it is necessary to provide:

Drainage of water from the foundation. Water should not accumulate under the floor or near the bath; a good drainage system is required.

Water should not accumulate near the bathhouseSource vodolov.ru

- Ventilation holes. Vents will prevent moisture from accumulating. To prevent heat from escaping through them, they are closed during washing.

- Window in the washing room and steam room, wide doors. Through them you can quickly release accumulated steam after washing.

- Quality of materials. A tree without cracks, chips, or signs of rot will remain healthy longer.

- Oven size. It must match the size of the bath. A stove that is too small will not provide the required temperature in the steam room, but will create a humid and warm environment in the corners and under the floor.

- Quality of flooring. If the boards fit tightly, water will not be able to get under the floor.

- Distance from shelves to walls. There should be no gaps between them; this is a direct path to sources of rot.

The bathhouse should be regularly ventilated and cleaned using chlorine cleaners, and the boards should be inspected for rotten areas. This will ensure maximum safety of wooden structures.

This video shows how to clean a sauna perfectly.

Bathroom floor waterproofing technology

The most important thing in installing waterproofing is how moisture will be removed from the room:

1. A solid surface that does not allow moisture to pass through, with an installed water drain.

2. Floor with leaking elements, created from sanded boards, in which there are holes and drainage is installed below. But this option is suitable exclusively for using a bathhouse in the summer.

Features of penetrating waterproofing

The simplest option would be to treat with bitumen mastic applied to a smooth surface, which protects well from moisture, but leaves a long-lasting odor in the room.

If the bathhouse or sauna is large in area, then you can make concrete waterproofing. Processing using polymer-cement materials is well suited. They level the floor and provide seamless protection that better protects against moisture penetration.

Differences between oil and water soluble products

What is the main difference between oil-based and soluble impregnations?

First of all, water-soluble ones are distinguished by their base from which it is made.

The most popular impregnation is acrylic with varnish. This impregnation can be used to treat both the outside and the inside of a bathhouse. But acrylic impregnation has a drawback - it is a gradual washout, you will have to do it again and again in the future. On the plus side, it has no odors, secretions, or color, so you can freely use it indoors, in a bathhouse or steam room.

Oil impregnations are distinguished by their durability and penetrate into the deep base of the wood. With this method, the impregnation will last much better and longer. But they have their own special drawback, a sharp unpleasant odor; when applying this product, you must strictly follow safety rules.

The nuances of waterproofing a wooden floor in a bathhouse

Wood is subject to a large number of destructive processes that can damage its structure. Therefore, the floor in the bathhouse must be properly protected from rotting and fungus. The boards need to be impregnated with special protective substances and have good waterproofing:

before laying the floor, wooden logs must be treated;

Treatment of floor structures from rotting

Since any type of tree is a material that can easily rot, the question remains relevant: “How to treat floor joists?”

As mentioned above, moisture does not get under the flooring from the external environment, but it is present there. This means that condensation is accumulating under the floor surface. The reason for this phenomenon lies in the difference in air temperatures between the room and the basement below it. However, the difference between them can be significant.

All this means that treating wooden joists is really necessary. In addition to rotting, wood is a favorable breeding ground for various insects that can completely destroy the wooden floors of a building. This should not be allowed. Pests need to be destroyed.

There is no perfect solution for how to treat underfloor joists. The choice largely depends on the type of wood that was used to install the floor structure. The water environment can affect each wood species differently. The fact is that the microclimate in the floors of each of the constructed houses has its own characteristics, and they depend on many parameters.

According to both specialists and home craftsmen, a product called “Senezh” has proven itself best, but, unfortunately, it cannot be called universal

When purchasing it, you should pay attention that an individual composition has been developed for each tree species. The cost of the product depends on it

This antiseptic contains approximately 10 different drugs. In addition, the way they are used is also different.

It was for lags that the drug “Senezh Ognebio” was created, which:

- perfectly protects wood;

- applies effortlessly;

- has an affordable price;

- able to prevent fire in a wooden house;

- is an excellent biological protection of bars.

Once applied to wooden elements, the preparation protects against fire for a period of up to 3 years. When a professional antiseptic is used for floor joists, this period increases to 5 years. If we talk about bioprotection, the period of effective action is about two decades.

We invite you to familiarize yourself with: Liquid glass for concrete - proportions and instructions

On the domestic market, the choice of antiseptics for wooden elements is not limited to Senezh. You can treat logs using various high-quality products (read: “How to treat logs in a bathhouse and how to do it correctly”).

Often, owners of wooden houses are faced with a big problem - insect pests that settle in wood cause them a lot of trouble. This phenomenon must definitely be combated. Since the place where the logs are located is always warm, insects prefer to settle and breed there. Entire colonies of pests can render floors unusable and require major repairs.

To prevent this, it is necessary to treat the logs using special protective agents. As practice has shown, the most effective and proven method is the use of resin. It still needs to be prepared for application before use.

The resin is heated by placing it in a metal container. After it softens, you can begin to work. Impregnation for floor joists is applied using a paint brush. After completing this procedure, no pest can penetrate the wood structure. The fact is that such a durable layer almost does not collapse over time.

Waterproofing a concrete floor in a bathhouse

Concrete is a strong and reliable material, but without proper thermal insulation it can freeze during the cold season. Therefore, in addition to protection from moisture, it is best to provide maximum protection against cold penetration into the room.

When making a screed, check the evenness of the surface and apply waterproofing mastic in several layers to the cleaned, dried mixture. A thin membrane or dense roofing material in the form of rolls is also laid.

All seams are soldered using a hair dryer. Afterwards, a reinforced mesh is laid on which a new layer of concrete screed will be placed. Next comes the final finishing of the floor.

Waterproofing with liquid glass

Liquid glass can be used to waterproof floors made of any material.

This is an economical and fast finishing method. After application, the substance turns into a dense crystalline base. The material looks like molten rubber and is very easy to apply to any surface.

It prevents not only the penetration of moisture, but also traps air, preventing the room from freezing. The glass is applied to the subfloor, and after hardening it helps to waterproof, prevent the occurrence of bacteria that are hazardous to health, and protect against electricity and fire. Such protection can be used for no more than five years; it is prone to self-destruction.

Read also: How to insulate the ceiling in a bathhouse?

You shouldn’t mix a lot of glass at once, it crystallizes quickly, and there is a chance you simply won’t have time to apply the entire mixture in a timely manner.

You don’t have to worry about humidity during application; unlike other materials, glass is not sensitive to this and will perfectly protect the room after hardening. It is better to apply the material in uniform stripes, after which you need to level the surface using a spatula. Share:

A bathhouse is a room with a high level of humidity; its walls and ceiling are regularly exposed to water vapor, and the floor is also exposed to water. Therefore, when building a bathhouse, it is imperative to take care of waterproofing the floor in all rooms. The method of its implementation depends on the type of flooring.

The floors of the bathhouse, as a rule, are laid on the ground, and in the washing compartment a large amount of water is poured onto them. Therefore, conventional waterproofing between rough and finished flooring, as, for example, in a bathroom, is not enough in this case. A whole range of measures is required:

- Waterproofing the foundation Waterproofing the base of the floor from the ground side Ensuring water drainage or arranging a drainage system Walls, ceilings and outlets of all communications also need waterproofing

If the bathhouse is built on a concrete foundation, a sand and gravel cushion is placed under it, and after the concrete is poured and hardened, the foundation is vertically and horizontally waterproofed.

First, it is coated with bitumen mastic, roofing material is glued on top of it, preferably in 2 layers, all joints are sealed.

A cushion of sand and gravel is also poured under the concrete base of the floor and compacted well. A layer up to 15 cm thick is sufficient. Before pouring concrete, the pad is impregnated with bitumen.

The drainage system needs to be thought out before pouring the foundation and concrete base, so that, if necessary, lay trenches under the drain pipes, dig a drain hole or pit. In this case, it is necessary to take into account the nature of the soil and the type of flooring. Possible options:

- If the soil is sandy and absorbs water well, 25 cm of crushed stone is poured on top of the sand, and the floors are made to leak. Water seeps through the cracks of the wooden flooring or drilled holes in the floor, passes through the drainage layer of crushed stone and is absorbed into the sand. If the soil absorbs water poorly, the floors are made leak-proof, with a slope towards one of the walls or towards the middle of the room. In the lowest part of the bathhouse, a sewer grate is installed, and under it - an inclined drainage chute, through which water flows into a pit, drain well or septic tank. Before pouring the concrete base, a drainage hole is dug under the floor, a container with sealed walls is installed in it and drained at least 10 cm from the bottom, the end of an inclined pipe through which water will flow into the septic tank outside the bathhouse

If a pit or drainage hole is made directly under the floor of the bathhouse, it is necessary to install a water seal so that unpleasant odors from the septic tank do not penetrate into the bathhouse. To do this, an inclined metal plate is attached to the edge of the pit from the pipe side; its lower edge is not fixed and is located 5 cm from the bottom.

What waterproofing methods are used?

Quite a lot of ways have been invented to provide reliable protection from water. You can also turn to “old-fashioned” methods and use natural materials at hand for these purposes.

This option for protection against moisture is based on the use of clay mixed with sawdust. The protection is good and the cost will be very low. With proper skill, all materials can be obtained almost free of charge.

The ceiling is filled with a liquid solution of clay mixed with sawdust in certain proportions. After drying, the solution forms a dense layer that completely blocks the passage of water.

There is one, but quite significant, drawback of this method - it can be used only when there are no plans to use the room above the ceiling treated in a similar way. It will be impossible to walk on such a covering, or you will also need to install a flooring made of boards to protect the waterproofing.

Another method of insulating the ceiling from moisture involves the use of modern waterproofing methods. Various types of films, membranes and modern varieties of roofing felt or glassine are already in use here. The latter will be one of the cheapest methods of protection.

It is not recommended to use polyethylene films to waterproof bathhouse ceilings, since condensation can also accumulate under them, which will inevitably settle in the insulation layer, gradually destroying it.

Membrane film insulators are much more effective - they do not let moisture in, but do not prevent steam and condensation from escaping, preventing it from settling inside the insulation layer.

Waterproofing the ceiling of a bathhouse using this method will be much more effective, but also much more expensive than traditional glassine or roofing felt, which are also quite effective. However, they have a short service life.

No less often, you can find insulation with a foil layer - such an insulator does not need additional protection from exposure, but it creates a sealed ceiling, which does not always work effectively, since all the moisture remains inside the room, causing gradual saturation of all structural elements of the building with it.

All such waterproofing materials are supplied in rolls, and they are very simple to use - roll out a panel of the required size, and, overlapping, apply the following. Overlapping areas, after complete installation, are isolated with tape.

The last, and most modern method of all, will be impregnation waterproofing. Its effectiveness has already been proven many times, although there are still many skeptics who do not trust such solutions.

The method of exposure of such an insulator is based on deep penetration of the composition into the insulated material, ensuring its complete protection from external influences. At the same time, all vapors and condensate escape from the inside perfectly and do not settle inside the structure.

Another advantage of using this particular method is that there is almost zero chance of doing something not according to the rules or incorrectly. No special skills are required here - you just need to apply several layers of material and wait until they dry.

Waterproofing concrete floor

In the sections of the bathhouse with the highest level of humidity - the steam room and the wash room - a concrete floor is often made with a porcelain stoneware finish; it is more reliable than ordinary floor tiles. On top of such a covering, you can lay several wooden gratings, making a collapsible flooring, which is periodically taken out of the bathhouse for drying. Concrete screed can be destroyed by moisture, so a layer of waterproofing is required between it and the finishing coating.

Waterproofing begins after the screed has dried.

When arranging it, a slope is formed towards the drain, but there should be no depressions or bumps on the surface, and it must be thoroughly cleaned of dirt. The technology for screeding with a slope is the same as when leveling the floor on an open balcony. To reliably protect the screed in a bathhouse, it is recommended to combine coating waterproofing with lining waterproofing.

- First, mastic is applied in 2-3 layers, and if the first layer is spread in the longitudinal direction, then the second layer is spread in the transverse direction. Rolled material is glued on top of the mastic - PVC film, membrane, roofing felt

You can also limit yourself to applying bitumen, bitumen-polymer mastic, or use penetrating waterproofing, which seals the pores of concrete.

Instead of expensive concrete or polymer-cement penetrating waterproofing, you can apply liquid glass. It has excellent adhesion to concrete, fills all cracks well and is completely waterproof after hardening. The main disadvantage of this composition is its fragility; usually after 5 years the silicate mass is destroyed.

If a concrete floor is insulated with high-density mineral wool or extruded polystyrene foam, it is advisable to protect the insulation on both sides. A water vapor barrier membrane is laid on top of the rough screed.

Before finishing the screed, the insulation is covered with rolled waterproofing. It is advisable to reinforce the screed in order to reduce the load on the insulation, so the film or membrane must be dense enough so that it is not damaged by the reinforcing mesh.

How to prepare concrete mortar?

A simple option is to buy a ready-made dry mixture. If you decide to prepare it yourself, then you will need cement, water and sand. For the solution you need to use cement M-400 or higher. For 4 portions of sand you need 1 portion of cement and water. The solution should not be liquid, as in this case the concrete will not be strong enough in the future.

Instead of regular sand, you can use perlite. It has high thermal insulating properties. The disadvantage of the material is its low weight, which makes the sand very dusty, so you can’t work in windy conditions.

To prepare the solution you need to do the following:

- Fill in 2 buckets of perlite or sand and 10 liters of water.

- Add 5 liters of cement.

- Stir, add another 5 liters of water. Stir until the mixture becomes homogeneous.

- Add 1 bucket of perlite and 2 liters of water. Mix.

- Leave the mixture for 10 minutes to make it more flexible.

When the solution is ready, you can proceed to the main work.

Waterproofing a wooden floor

Leak-proof wooden floors are usually made in the dressing room, rest room, where the humidity level is lower and a minimum of water gets on the floor. However, joists and subflooring need waterproofing. Solid floors, unlike leaking floors, can be insulated; the insulation on both sides must be protected with a water barrier.

- The joists and transverse support bars that are laid on them are wrapped in waterproof film or other sufficiently elastic rolled material, not forgetting to protect the ends. A subfloor made of boards or plywood is attached to the support bars and covered with rolled waterproofing in several layers, overlapping and extending onto the walls. The joints of the film are glued with tape, and the roofing material is glued with molten bitumen. Insulation with mineral wool or expanded clay is performed on top of the first layer of waterproofing. The insulation is covered with 3 layers of roofing material, fastened with hot bitumen

Important! There must be a ventilation gap of at least 2-3 cm between the waterproofing layer and the finished floor. Therefore, a sheathing is made on top of the subfloor, and the thickness of the bars must be greater than the thickness of the insulation so that the sheathing protrudes above its surface. The finished floor is already laid on it.

As for leaky floors, the main task is to waterproof the joists on which they are laid. The logs can be treated with an antiseptic and wrapped in a layer of rolled waterproofing.

If they rest on concrete or brick piles, the piles must be covered with roofing felt. If under the slatted floors instead of a layer of crushed stone there is a concrete base with a slope, then it is waterproofed from below. Either geotextiles are laid over the compacted soil under the sand cushion, or the sand and gravel cushion is impregnated with bitumen.

Learn more about waterproofing wooden floors in the bathroom here.

Arrangement of the base

Beacon system for creating a funnel-shaped floor slope in a bathhouse.

Buildings with a bathhouse require a solid foundation, so before you start concreting the floor, you should carefully prepare the base for it. When working with concrete, it is important to provide it with a flat surface; to do this, the soil is compacted and sloped at a slight angle to the well for drainage. A layer of gravel is also poured onto the ground at an angle, and a clay layer is laid next to the foundation.

To prevent the concrete base in the steam room from being cold, the floor should be made of two layers. To do this, lay the first five-centimeter tier of concrete, heat-insulating material is placed on it, after which they begin laying the second layer. However, do not forget to carefully compact the layers. The second tier should be combined with the reinforcing mesh. When the preparation is completed, begin screeding the base.

Return to contents

Video

Consequences of installing a wooden floor in a bathhouse without waterproofing the base. Recommendations for floor restoration taking into account errors.

The floors in any room of the bathhouse need waterproofing, but it should be especially thorough in the washroom and steam room. If the floors are insulated, a layer of thermal insulation is protected from moisture on both sides. Minimal waterproofing is required when installing cold, leaky floors, since they are well ventilated, and the flowing water goes into the ground. Properly performed waterproofing and drainage will extend the life of the floor and the bathhouse as a whole.

Sources:

- semidelov.ru

- banya-gid.ru

- nastroike.com

- delaempol.com

There are no similar posts, but there are more interesting ones.