Home / Features of various rooms / Bathhouse / The wall near the stove in the bathhouse - finishing features

To heat the air in the bathhouse to the required temperature, the stove is heated very intensively and during the process its walls can heat up to four hundred degrees. Naturally, the walls adjacent to it also heat up, and if they are made of flammable material, and most often it is wood, then a fire in this case is inevitable. In order to prevent such a situation, the walls near the stove in the bathhouse are decorated with non-combustible materials. We will find out which of them are best suited in this article.

Protecting the walls of the bathhouse from the heat of the stove: rules for constructing protective screens and casings

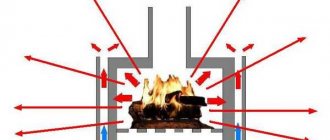

During the heating of the bath, the surface of the stove heats up to 300-400°C. At the same time, it begins to emit infrared rays and itself becomes a source of heating. The coming heat is distributed throughout the steam room, but first of all it hits the walls adjacent to the stove. If the walls are wooden, then under the influence of high temperatures their charring begins. And there it’s already a stone’s throw away! The only truly effective way to insulate wooden walls from heat is to create protective screens and cladding from non-combustible materials in the bathhouse.

Finishing around the stove

The space around the stove needs special finishing for the reason that the proximity of the hot stove to the flammable material of the walls (the same lining) can lead to a fire.

Fireproof board for finishing walls when installing a sauna stove

Therefore, a heat-insulating material, for example, mineralite or superizol, is usually placed on the wall (mounting on ceramic bushings is desirable). A stainless steel sheet can be attached to reflect heat.

Tiles near the stove

If the walls are not made of wood, you can protect them with heat-resistant tiles. Since tiles are used for lining stoves and fireplaces, you can find many varieties on sale, from which the seller will select the right one for you.

Of course, stove tiles are more than suitable for wall decoration, but they can be more expensive, so it’s worth measuring the heating temperature of an object located at the same distance that will separate your stove from the wall.

ATTENTION! Glazed tiles are not useful here either, because glass cannot withstand high temperatures. If you take tiles, then only matte ones.. And one more thing - you need to take into account the fact that in bathhouses on a personal plot in winter, if not used for a long time, the temperature can be below zero

And one more thing - you need to take into account that in the bathhouses on your personal plot in winter, if not used for a long time, the temperature can be below zero.

Some types of tiles are not intended for sudden changes in temperature when heating a bath - this issue should also be clarified with the seller. If you choose the wrong tile, it will crumble.

When is protection needed at all?

The need to install protective casings and screens does not always arise. If a fire-safe distance is maintained between the stove and the nearest flammable surface, additional protection is not needed. At this distance, the IR rays are scattered, weakened, and the amount of them that the wooden wall receives can no longer lead to damage.

It is believed that the safe distance from the wall to the brick stove (quarter-brick laying) is at least 0.32 m, from the wall to the metal stove (not lined) - at least 1 m. For a metal stove lined from the inside with brick or fireclay, the distance decreases to 0.7 m.

Thus, maintaining fire safety distances is more possible in large baths, where the issue of saving space is not relevant. In family steam rooms, where every centimeter of space counts, installing a stove 0.3-1 m from the nearest walls is impractical. In this case, the safety distances established by the standards must be reduced using screens and casings.

Where to put the stove in the bathhouse?

The location of the stove depends on many factors, in particular, on its type, as well as on the location of the firebox (in the same or in an adjacent room). In addition, fire safety is important - there should be at least half a meter from all fuel .

So, those who decide to install a brick oven make a foundation for it, so the location is already determined at the sketch stage. But with a metal stove, sometimes people delay until the last minute, not knowing which model to buy. Therefore, it happens that already finished walls have to be cut and other unnecessary work done.

IMPORTANT! The location of the supply ventilation depends on the location of the stove, so it’s better to think in advance.

In addition to ventilation, it is worth thinking about fire safety, especially in a bathhouse with flammable walls. Often, in order to provide it, part of the wall is made of brick. Which again speaks to the need for planning.

The location of the stove in a bathhouse with a separate steam room

There can be two options:

- or the stove, together with the firebox, is located entirely in the steam room, which means it only heats it;

- or the firebox is moved to the adjacent room, which allows for partial heating of that room too.

The location of the stove in a bathhouse with a separate steam room: option with a firebox from the rest room. Diagram from the article about the hood

In the first case, during the cold season you will have to think about how and with what to heat the neighboring rooms ; in the second, the same problem remains only partially.

Stove in a bathhouse with washing and steam room

Here you can also find several solutions. The firebox can be taken not to the rest room or dressing room, but to the washing room. But this is problematic from the point of view of storing firewood. Therefore there are other options.

Stove in a bathhouse with washing and steam room

You don’t have to remove the stove at all, just install a water tank at the top , which will be connected through the wall to the “samovar” on the chimney pipe in the steam room. “Samovar” is a heat exchanger (! stoves with a heat exchanger are reviewed here), which can be found on sale; with its help, water for the washing room is heated, and from the tank there is heat sufficient to maintain a normal temperature of 30-32 degrees in the washing room.

In some cases, the problem is solved by additional heat sources - a warm floor or a second stove .

Video

The following video shows an explanation of the diagram shown above:

Is a foundation always needed for a furnace?

We already said above that no, it is not always needed. The need for it arises only when the weight of the sauna stove with everything associated (from the water tank to all the bricks that line the floor, stove and chimney) exceeds 700 kg. If the total weight is lower, you can simply lay the base with bricks instead of a foundation, put 12 mm asbestos on top, and on top of it - a steel sheet of any thickness (from 1 mm). The topic is discussed in detail here.

IMPORTANT! A separate foundation for a brick oven is made so that it has its own shrinkage, not related to the shrinkage of the house.

Such a foundation is made thoroughly, deepened to the load-bearing layer. If the stove weighs more than 700 kg, but not by much, then you can make a shallow foundation.

Usually the foundation for the furnace is not brought up to the height of the subfloor, because then the bricks are laid and the height is compared. The area of the stove foundation should be 15-20 cm larger than the area of the stove base on each side .

The video below clearly demonstrates the process of pouring a foundation for a bathhouse yourself. The video is a little dark, but it gives you an idea of the process.

Protective screens near (around) the stove

Protective screens are insulation panels that cover the side surfaces of the furnace and reduce the intensity of thermal radiation. Screens can be metal or brick. As a rule, they are used for metal furnaces.

Method #1 - metal screens

The most common protective screens are factory-made steel or cast iron sheets. They are installed around the stove, at a distance of 1-5 cm from the walls of the firebox. Depending on the need to insulate one side or another of the furnace, you can purchase side or front (front) screens. Many metal furnaces are initially manufactured with protective screens in the form of a protective casing.

Protective screens make it possible to reduce the temperature of external metal surfaces to 80-100°C and, accordingly, reduce the fireproof distance to 50 cm. The total distance from the firebox to the wall (including a gap of 1-5 cm) will be 51-55 cm.

Installing protective screens is not difficult. Thanks to the presence of legs, metal panels are easily bolted to the floor.

Method #2 - brick screens

A brick screen can cover all the side surfaces of a metal furnace, representing its outer cladding. Then the stove will be in a casing made of brickwork. In another case, a brick screen is a wall separating the stove and the flammable surface.

To lay the protective screen, solid fireclay bricks are used. The binder is cement or clay mortar. It is recommended to use half a brick (thickness 120 mm). But, if there is a lack of material, it is possible to make a wall of a quarter of a brick (60 mm thick), although in this case the thermal insulation properties of the screen will be reduced by half.

Small openings (sometimes with fire doors) are left at the bottom of the shield for air convection between the brick wall and the stove.

The brick walls of the screen must end at least 20 cm above the top surface of the oven. Sometimes the masonry goes all the way to the ceiling.

The brick screen is not installed flush against the walls of the stove, the optimal distance is 5-15 cm. The acceptable distance from the brickwork to the flammable wall is 5-15 cm. Thus, the use of a brick screen allows you to reduce the distance from the stove to the wooden wall to 22-42 cm (stove - ventilation gap 5-15 cm - brick 12 cm - ventilation gap 5-15 cm - wall).

What materials can be used to create a protective partition?

The enclosure of the stove in the bathhouse is designed to reduce the effects of heat. Brick or metal are used to make it. Each material has its own advantages and is used depending on specific conditions.

Metal partitions

Steel or cast iron are more often used. To ensure maximum effect, the device must be installed at a distance of 2 cm from the stove. Manufacturers of furnaces and boilers often complete their products with protective partitions. Depending on the purpose, they can be lateral or frontal.

The use of heat-resistant screens allows the stove surface temperature to be reduced to 100°C, due to which the zone of intense heat exposure is reduced by 50 cm. Installing a metal partition yourself is not difficult.

Brick screens

The brick partition is a kind of casing. It completely covers metal surfaces to protect walls from heat. In some cases, brick screens are used as partitions between walls.

Characteristics of a brick partition

| Dimensions | Numerical indicators |

| Distance from brick to stove. | It should be 20 cm. |

| Height. | Most often, brick partitions reach the ceiling. The minimum height is 20 cm above the stove. |

| Distance from the masonry to the nearest wall. | Should not be less than 20 cm. |

To install the screen, just take an ordinary red brick and lay it with mortar. The thickness is half a brick. In some cases, you can use a quarter brick.

Protective non-combustible wall coverings

Walls adjacent to the hot furnace walls are susceptible to spontaneous combustion. To prevent their overheating, special casings consisting of heat-insulating and non-combustible materials are used.

Option #1 - reflective trim

Sheathing consisting of a combination of non-combustible insulation and metal sheets is effective. In this case, thermal insulation is attached to the wooden surface, which is covered with a stainless steel sheet on top. Some use galvanizing for these purposes, but, according to some data, when heated, it can release harmful substances. It’s better not to risk it and buy a stainless steel sheet.

For greater efficiency, the metal sheet of the screen must be well polished. The mirror surface helps to reflect heat rays from the wooden surface and, accordingly, prevents its heating. In addition, a stainless steel sheet, directing IR rays back into the steam room, transforms hard radiation into softer radiation, better perceived by humans.

The following can be fixed under stainless steel as thermal insulation:

- Basalt wool - it has high thermal insulation properties and is absolutely safe when used in a bathhouse. It has increased hygroscopicity and does not burn.

- Basalt cardboard is thin sheets of basalt fiber. Used as a fireproof, sound and heat insulating material.

- Asbestos cardboard is a sheet fire-resistant heat insulator. It has high strength and durability, protects flammable surfaces from ignition.

- Minerite is a non-flammable sheet (plate) specially manufactured for shielding stoves, fireplaces, and easily flammable surfaces in baths and saunas.

A popular example of cladding using a metal sheet is this “pie”: wall – ventilation gap (2-3 cm) – insulation (1-2 cm) – stainless steel sheet. The distance from the wooden wall to the stove is at least 38 cm (SNiP 41-01-2003).

Ceramic bushings are used to attach the sheathing to the wall. They do not heat up and allow the formation of ventilation gaps between the thermal insulation and the wall.

If the distance between the wooden wall and the stove is minimal, then the cladding is made of two layers of fire-resistant insulation, for example, mineralite. In this case, the sheets are fixed through ceramic bushings, maintaining a gap of 2-3 cm. The top sheet is covered with stainless steel.

Option #2 - sheathing with cladding

Of course, protective cladding with stainless steel perfectly protects wooden walls from heat and fire. But it can spoil the impression of the most expensive finish. Therefore, if the steam room is designed in a decorative style, the fire-resistant lining is masked with heat-resistant tiles. The tiles are laid on heat-resistant adhesive, for example, produced by Terracotta.

The best materials for cladding walls near the stove:

- Terracotta tiles are made from baked clay. It is characterized by strength, heat resistance, durability. Terracotta tiles can be matte or glazed (majolica), and the color varies from pastel yellow to brick red.

- Clinker tiles are also made of clay and look similar to facing bricks. Unlike terracotta, clinker tiles are denser. The color range covers almost all colors, ranging from white to black, including green and blue tones, unusual for clay.

- Tiles are a type of ceramic tile. It usually has embossing on the front surface in the form of a design or ornament.

- Porcelain tiles are heat-resistant, durable tiles. Depending on the method of processing the front surface, tiles can imitate natural stone, brick, or wood. The color range includes all natural shades, from white to black.

- Soapstone is a rock of grayish or greenish color. It is fireproof, waterproof and durable.

Related article: Laying floor slabs on a brick wall

Attaching fire-resistant tiles directly to the walls will not have a thermal insulation effect. The wall will still heat up, which can lead to spontaneous combustion. Therefore, tiles are used only as an element of a protective “pie” of the following design: wall – ventilation gap (2-3 cm) – fire-resistant sheet material – tiles. It is recommended to maintain a minimum distance of 15-20 cm from the tiles to the walls of the oven.

Any material from this list can be used as a fire-resistant element in the cladding:

- Fire-resistant drywall (GKLO) is drywall supplemented with fiberglass fibers. Resists thermal effects without structural deformation.

- Minerite is a cement-fiber board, absolutely non-flammable. Minerite slabs are moisture resistant, do not rot, and do not decompose.

- Glass-magnesium sheet (FMS) is a material in the form of plates made on the basis of magnesium binder and fiberglass. It has heat and sound insulating properties and is not destroyed by water and temperature changes.

The protective cladding, which must comply with the ventilation gap, has a very low heat absorption coefficient, so the wall underneath it practically does not heat up. In addition, the use of cladding allows you to disguise the protective “pie” and maintain the finishing of the steam room in the same style.

Selection of finishing material

It is best to finish it from wood, because it smells very nice, but there are some species that are not suitable.

You can finish it with clapboard made of hardwood. Lining made from such types of wood is excellent for lining a steam room in a bathhouse; it can withstand high temperatures, and thanks to the low heat capacity of the lining, the room warms up faster, and the walls will not heat up too much.

Advantages and disadvantages of each material

Linden, which has a snow-white color, does not deform when temperatures change and is moisture resistant. Such clapboard can be sheathed near the stove, as well as the ceiling, since it takes longer to heat up than other types. When heated, it releases a subtle, non-intrusive aroma. And to prevent it from darkening in the future, it is treated with a special substance.

The disadvantages are that it is subject to rotting and perhaps insects will live in it. So when choosing it, keep in mind that such material will have to be changed often.

Larch tolerates both temperature changes and humidity well. This type of wood is considered durable. Well suited for covering a steam room.

The downside is that it is difficult to cut on it, since the structure is very dense. Therefore, you need to work with it carefully and only with high-quality tools.

Birch, due to its loose structure, dries out a lot. This is noticeable when preparing it, so it’s worth preparing with a reserve. But this drying contributes to excellent absorption of the special protective substance during processing.

The downside is that it begins to decompose when wet and even a protective agent cannot save it. In addition, it has a lot of knots.

Aspen, a very strong species, has high strength, is resistant to moisture and does not have cracks, these qualities are an indicator of the good side of wood. Aspen is the most suitable for covering a steam room.

The disadvantages are that it still rots, of course much less than linden. And when choosing such a lining, you should pay attention to resin pebbles and knots, because in a hot steam room you can get burned if the resin comes into contact with the skin.

Cedar, when heated, releases a pleasant and beneficial aroma of essential oils. It is easy to process and cut. Cedar is durable and not afraid of moisture.

The downside is that not everyone can afford such a lining.

List of fireproof materials for finishing walls around stoves

According to fire safety rules, the arrangement around stoves, fireplaces and fuel boilers must be done using fire-resistant special materials, which can simultaneously protect a residential or ancillary building (bathhouse) from possible fire hitting the walls, and at the same time not cause harm to health.

To create a favorable home atmosphere, any stove or fireplace becomes very hot and generates intense heat, which in turn can be a source of ignition or fire. Therefore, it is important to carefully select the right materials when arranging a heat source in a house, bathhouse or basement, if we are talking about a fuel boiler.

Finishing before installing the stove

Installing a stove is the final stage, which is preceded by numerous preparatory work, especially in a bathhouse with flammable walls. There are general rules according to which you can safely place a stove in a bathhouse.

Fire requirements

The floor, walls, and ceiling must be protected from a burning stove.

IMPORTANT! The first rule states that the minimum distance from a very hot object should be at least half a meter.

Let's consider the option when the furnace firebox is located in the room adjacent to the steam room. If the wall is wooden, then an opening is made in it either immediately or after construction is completed. Its size is significantly larger than the size of the fuel channel.

Those who build a special brick wall around the fuel channel do the right thing. Its dimensions can be determined either by the requirements that are in the stove's passport (if we are talking about a metal stove purchased in a store), or, if the stove is homemade, then the minimum distance to the wood of the wall is 38 cm, but it is safer to make 50 cm. If If you use heat insulators that are resistant to high temperatures, then the distance can be reduced slightly - to 25-36 cm .

IMPORTANT! The brick should not touch the fuel channel; a layer of heat insulator is placed between the metal and the brick, capable of withstanding temperatures of 800-1000 degrees. Glass wool is not suitable. Like mineral wool with binders, because the latter are organic matter that will evaporate into the air when heated and will poison people.

The chimney also needs thermal insulation, because the metal one heats up to high temperatures. The insulation material is the same, capable of withstanding high heat.

The ceiling above the stove often becomes the cause of fire, so it is recommended to decorate it with fireproof material ( minerite , basalt cardboard ). The area of the latter should be one third larger than the area of the top of the oven.

When using electric heaters, grounding should not be neglected.

IMPORTANT! Make a separate grounding loop for the steam room.

Floor protection is usually done like this: regardless of whether there is a foundation or not, a base of bricks is made under the stove, on which a sheet of asbestos cardboard 12 mm thick is laid, and a steel sheet is placed on top of it. In some cases, the first brick layer is not done.

IMPORTANT! Asbestos cardboard and steel sheet in front of the firebox should protrude half a meter, and on the remaining three sides they can be 3 cm wider than the base.

By the way, some people place stoves not on bricks and metal, but on porcelain stoneware or other durable tiles made of natural or artificial stone.

IMPORTANT! For those who are afraid of asbestos, we can recommend basalt cardboard . In addition, it holds up to 700 degrees instead of the limit of 500 for asbestos cardboard. There are also fireproof boards that can withstand up to 1100 degrees.

In front of the combustion door, which is recommended to face the entrance door to the steam room , the free space should be at least 1.5 meters .

Useful video

And here is a video on the topic: the guys cheerfully and quickly laid out a brick wall for a stove with an external firebox.

Flood sheet

You can make it yourself from a sheet of tin , or you can buy it in a store that sells good stainless steel flush sheets.

You can place such a sheet under the entire stove, or just in front of the fire door to protect the floor from sparks and embers. There are flooding sheets of different sizes on sale: from small to meter-long.

Instead of metal, it is permissible to use any other heat-resistant material. As already mentioned, this can be tiles made of stone or other material.

Tiles for the steam room in the bathhouse near the stove

Let's take a closer look at the tiles for the steam room. Despite the fact that it can be used more widely in the bathhouse, we are only interested in the stove area. There are suitable tiles with the following properties:

- heat resistance;

- thickness from 8 mm;

- low porosity.

Since we are not talking about decorative cladding, but about a simple refractory base on which the stove will stand, you should not pay attention to glazed types of tiles. They are, of course, double fired, but this glaze will crack and crumble under the influence of temperature .

Tiles for the steam room in the bathhouse near the stove

Porcelain tile would not be suitable if you decided to put it where people will walk, but under the stove it is quite suitable.

Also suitable are: metlakh , clinker , terracotta tiles. When choosing, be guided by the characteristics mentioned above.

In addition to ceramic tiles, it is quite acceptable to place the stove on tiles made of natural stone - here the choice is yours; any not too thin stone tile suitable for a bathhouse will do. That is, not marble(!), but, say, soapstone , serpentine , gabbro , etc.

Decorating wooden walls near the stove in the steam room

If the stove was not located next to the wall, then no protection for the wooden wall would be needed at all. So it’s all a matter of distance - for a brick stove it is 32 cm , for a metal stove without lining - 1 m, with lining - 70 cm. But there is usually little space in the steam room, so the stove stands almost flush with the wall or even in a corner. Or her firebox is brought into an adjacent room, and the length of the fuel channel is 25 cm - there’s no way to keep it further away.

a brick wall is often placed where the stove will be located. The scheme has already been described above - with distances and thermal insulation.

It is permissible to put a layer of plaster more than 25 mm thick on top of the wood on a metal mesh.

You can also use sheets of one or another heat-resistant material, but this is called a “ protective screen ” and its varieties will be discussed below. In some cases, over the screens . Or metal sheets are attached to the same refractory base.

Depending on the type of finishing, it must be done either before installing the stove, or it can be done after. For example, a brick wall or screen must be made in advance.

Video

Video on the topic: a video about how to take into account the shrinkage of a log house when installing refractories.

Types of materials

Refractory materials can be roughly divided according to the method of heat transfer:

- Heat reflective – aimed at reflecting infrared radiation into the room;

- Preventing loss due to its physical and chemical properties.

On video of fireproof materials for walls around furnaces:

But all of them can also differ in the type of raw materials from which they are produced:

- With organic components , for example, polystyrene foam materials, although their fire resistance is very low, they are best suited for walls near stoves with low heat;

- Inorganic is a broad class of non-combustible materials for insulating walls of a wide variety of fire resistance, including very flammable ones, such as wooden floors. These include stone and basalt wool, pressed into large slabs, fiberglass wool, lightweight cellular concrete slabs with fire retardant impregnations, honeycomb plastics, foamed perlite or vermiculite, and polypropylene. However, such a beautiful decorative thing as Leroy Merlin sheet plastic is definitely not suitable.

- Mixed type - these include asbestos-cement refractories, asbestos-lime or silica, foamed from a variety of inorganic substances.

Basic requirements for refractory materials

Many country buildings are built from wood, be it a cylindrical or frame house; without a stove or fireplace it is difficult to survive a frosty winter, so their arrangement is approached very carefully, and the materials placed around the stoves are chosen so that they are:

- Effectively and reliably prevented any attempted fires;

- Environmentally friendly, so that when heated they do not release harmful substances into the home air.

Information from this article will help you understand what composition of mortar for plastering a stove exists and is most often used.

But what are the dimensions of a standard oven brick can be seen here.

You may also be interested in learning about what kind of brick is used for laying stoves.

For walls around stoves

A long time ago, people used asbestos sheets to line the walls around stoves, but it turned out to be very harmful to health and the environment - its microparticles can enter the lungs or be deposited on things, which leads to serious illnesses, and with strong heating they also release carcinogenic substances. substances. Therefore, the best materials can be considered:

Fire-resistant plasterboards. can act as the basis for covering walls around hot stoves, and for decoration, porcelain tiles of the most unusual colors can be used.

The sheets have the following characteristics:

- Fire resistance – up to 30 minutes of fire resistance;

- Does not ignite for up to 1 hour even after a fire has formed;

- Slab parameters – 120 x 250 x 1.25;

- On the front and back sides there is cardboard treated with gypsum, inside there are fiberglass threads that will resist fire;

- The ends of the sheets are covered with cardboard material, and there is a joining chamfer along them;

- Fastening can be done either using adhesives or self-tapping screws.

Fireproof minirite slabs. The material has excellent heat-resistant properties and is produced exclusively from environmentally friendly substances, including:

- Compositions of white or gray cement make up up to 90% of the total material;

- Included are mineral fibrous materials;

- For strength and durability, fiber reinforcing boards are used.

Asbestos fiber is completely excluded from the composition, which improves the quality of the material for a home stove. It is easy to fix it to the wall with screws close to the wall itself; for reliability, you can mount 2 sheets of minirite. Note! When installing, it is necessary to leave a small distance, since the material may increase in size when heated. For other walls, you can choose a similar decorative brick finish.

Protective stainless steel sheets are a slightly expensive but reliable fireproof material that can be used to protect not only the walls of the house, but also the basement when installing a heating boiler. But in order to provide the greatest protection, special fiberglass with thermal protective properties should be placed under the stainless steel - the structure will reliably protect the house from any attempts to start a fire. Choose the substrate carefully so that it does not contain harmful phenolic resins; when heated strongly, they release substances that are too hazardous to health.

Heat-resistant material made of basalt fiber pressed into mats - it is hygroscopic, has a high degree of resistance to fire, and can remain unchanged at temperatures up to 900 degrees Celsius.

Superisol sheets for wall insulation are a practical and versatile thermal insulation material, with low specific gravity and excellent strength and durability.

Related article: How to paint the walls on the balcony inside

Insulation of walls with heat-resistant terracotta tiles . The main advantage is the complete environmental purity of the material; they do not contain any chemical coloring compounds, and have excellent vapor permeability and fire-resistant properties. Glazed ceramic tiles for interior wall cladding also look beautiful.

For finishing walls under a boiler

A gas or steam boiler heats up very much to ensure heat transfer to the house at the required temperature of the carrier. Therefore, experts recommend equipping walls with porcelain tiles with a high degree of fire resistance. The characteristics are the most reliable - it can withstand high temperatures without visible signs of fire.

It is also possible to use sheets made of fibers impregnated with gypsum; installation is very easy by gluing them to the walls, but it is not recommended to use plastic brick panels for interior wall decoration, since they do not meet fire safety requirements.

Recently, sheets made of xylolite fiber have begun to gain popularity, since they meet all environmental properties in terms of cleanliness and the absence of any harmful emissions, even at elevated temperatures of about 1000 degrees. The material is also very flexible; these properties make it possible to sheathe the most curved wall surfaces. It can withstand humid and damp air perfectly, its main characteristics do not change.

But what solution should be used for plastering a home stove and how to choose it is described in great detail in this article.

You can find out where and how kiln red solid brick m 200 is used by reading this article.

For those who are used to doing everything with their own hands, it is worth paying attention to how to make a solution from clay for laying stoves.

But if you want to do everything quickly and without unnecessary hassle, you should turn your attention to a ready-made mortar for laying stoves. In order to make the right choice. It’s worth following the link and reading the article.

But what is the price of red stove brick and how to choose it for your construction site, you can find out from this article.

Options for washing and steam rooms: materials

Let's briefly look at the materials suitable for finishing bath sinks and steam rooms.

Wood

In the photo: finishing the steam room of a bathhouse with wood (lining)

To decorate the steam room, it is strongly recommended to use hardwood, such as linden, aspen, and alder. These rocks are suitable for walls and ceilings, finishing doors and windows.

For the floor, you can use more resistant species, for example, larch. Conifers should not be used because of the resin they contain, which flows out when the temperature rises. But on the floor the temperature is usually low, so there are no restrictions.

However, it is worth saying that linden and aspen have low resistance to rotting and biocontamination (for example, by fungi). Therefore, we still recommend additionally protecting surfaces made of this wood with impregnations and varnishes.

There is no point in using wood in a sink, unless it is a design decision. In this case, it is worth recommending conifers - they are more resistant to water.

Stone

An option for decorating a steam room in a bathhouse is stone tiles. Of course, we are talking only about partial finishing, for example, near the stove (more on that below).

What types of stone are best suited for finishing walls in a steam room? You will be surprised, but there are practically no restrictions here - the main thing is that it is not rock salt, for example. But pink Himalayan salt is often used as interior decoration. Of course, it will not dissolve as quickly as table salt in a pot of soup, but its composition is the same as salt in a salt shaker.

The wall behind the stove, of course, heats up, but the stones are quite capable of withstanding such temperatures without harming themselves. But the situation will change if you decide to cover the stove with the same stone. The temperatures there are somewhat different. And it’s worth focusing at least on those stones in the lining of which ready-made stoves are sold, for example, soapstone.

As an option, you can decorate part of the steam room not with smooth tiles, but with cut pebbles or cobblestones, which are mounted on the mortar with the convex side up. It turns out to be quite a nice decor. As you can see, even street cobblestones can come in handy.

In the photo: interior decoration of the steam room with stones around the stove

You can use stone in a sink, but this is rarely done, because it is easier and cheaper to cover the walls and floor with ready-made ceramic tiles.

Tile

The tiles in the steam room are used either on the floor or on the wall behind the stove. As for the floor, rough tiles, for example, Metlakh, behave best here. In general, it can be recommended for wet rooms. But it is better not to consider all varieties of smooth glazed tiles as a covering for the floor of a steam room.

In a washing room, it is also better to use rough tiles on the floor, and for the walls... here, in general, you can see more clearly how sober visitors will wash in your washing room. If not particularly so, then give up smooth tiles there too, eliminating unnecessary opportunities for injury.

In the photo: finishing the shower room of the bathhouse with tiles

Sealant

Special mention should be made of such finishing material as sealant for steam rooms in bathhouses.

Sealants in a steam room can be used only in two cases: if it is a bathhouse made of logs and needs to seal the joints between the logs, as well as sealing cracks in the logs themselves, and the second option is to seal the joints, for example, foam glass, if it is used as a heat insulator .

In the first case, we can recommend special sealants for wood that have a certain elasticity, because wood tends to constantly change volume under the influence of moisture. In addition, it is worth asking the sellers which wood sealants can withstand steam room temperatures well (name the numbers at which you are used to steaming).

We came across a report from one bathhouse owner in which he praised the Perma-Chink wood sealant he used for seams and Check Mate for sealing cracks. However, we cannot say with certainty that this was not promotional material.

As for the sealant for the heat insulator, then you need to take silicone without impurities, for example Ottoseal S 73.

The wall near the stove in the bathhouse - finishing features

To heat the air in the bathhouse to the required temperature, the stove is heated very intensively and during the process its walls can heat up to four hundred degrees. Naturally, the walls adjacent to it also heat up, and if they are made of flammable material, and most often it is wood, then a fire in this case is inevitable. In order to prevent such a situation, the walls near the stove in the bathhouse are decorated with non-combustible materials. We will find out which of them are best suited in this article.

Features of the decorative lining of the stove

High-quality finishing of a sauna stove must meet basic operational requirements: withstand high humidity, temperature changes, ensure durability and safety of the surface. The lined stove should quickly heat the bath rooms and create a comfortable microclimate inside.

Lining a stove in a bathhouse has a number of advantages, including the following:

Insulation methods

There are several techniques that allow you to reliably insulate wooden structures from the heat of the stove. Some of them involve a fairly large amount of work, while others are much simpler.

The construction of a box made of brick or stone will require the most time - it will be necessary to lay out several walls that will protect the wood from heat. In addition, this protection option requires a gap between the wood and the brickwork from 5 to 15 centimeters. There should be about 10 centimeters between the casing being built and the walls of the stove. All this eats up useful space and requires some mason skills to work on.

Factory screens are installed quite simply and are not that expensive. They could be an ideal solution if they did not require even larger technological gaps between different surfaces. Therefore, such finishing of the wall near the stove is possible only in a fairly spacious bathhouse. If you need to save space, it is better to look for another solution that allows you to reduce all the gaps from wooden partitions.

The third option allows you to reduce the distance to 15 centimeters, which is already more acceptable. At the same time, this method allows you to create the most beautiful design, which is important. However, there will be a lot of work and the costs in this option may be much higher than in the previous ones. In addition, this insulation method requires a more detailed consideration due to the characteristics of the assembled structure.

What types of stoves can be used in a sauna?

Today, the choice of steamer is extremely diverse: you can buy a stove and make it yourself, or buy it and modify it, but there are a lot of options. Let's reduce them to several main types. Ovens are:

- brick;

- metal (including with brick lining);

- electric.

Brick kilns

Traditional stoves for the Russian “white” bath are brick .

They have a number of advantages, since there is a direct connection between such a stove and the requirements of a Russian bath. In particular, a brick oven provides uniform heating , and most importantly, light steam , that is, formed at a high temperature, from which the steamer does not have breathing problems, as from heavy low-temperature steam.

But a brick oven also has its drawbacks . Built entirely of brick, it will be heavy, expensive and will require some skill in maintenance (! inexpensive stove options are presented in a separate article). You need to decide at the design stage, because there will be costs for a separate foundation for it.

Heaters in brick kilns come in all types:

- flow-through , where stones are washed by fire;

- blind , where the stone is separated by a solid sheet of metal from the fire;

- open - with stones on the surface;

- closed - with a door covering the heater compartment;

- bell-type - a type of closed blind with more efficient heating.

Metal furnaces

A very common option because it is more budget-friendly compared to a solid brick stove. The material used is either cast iron or steel - both of different grades.

IMPORTANT! A metal stove without a surround will overheat the room. This is good for a sauna, but not for a Russian bath.

The fact is that metal heats up quickly, and stones heat up slowly. And always during heating, most of the heat is released into the room . Bare metal will give off too much heat to the room, which should not heat above 40-60 degrees. And the stone must heat up to 400 degrees to produce light steam. This creates a big contradiction: in order to heat the stone to get good steam, you will have to greatly overheat the bathhouse .

The solution to this problem is usually to install a brick lining around a metal stove. This redistributes the heat released during combustion, the brick accumulates it and releases it more softly and for a long time than metal.

On the other hand, they are suitable for saunas , where the air temperature is higher and the steam is much less.

The disadvantages of this type of stoves include the fact that they not only heat up quickly, but also cool down quickly . Therefore, the bath procedure has to be interrupted in order to heat the stove again.

The cost of a metal stove will be lower than a brick one also because it does not require such a solid foundation . A foundation is sometimes necessary, but it can be shallow, and in some cases they are generally limited to a layer of refractories under the stove and that’s it.

There are a lot of varieties of metal stoves - both homemade and factory-made. One of them is worth mentioning separately.

Electric heaters

Electric stoves were originally created for saunas . But then models appeared that are capable of working in Russian bath mode. Those who have decided to opt for an electric stove should find out whether the selected model has one or two modes . However, there is a simple criterion:

IMPORTANT! Models with a load of stones of 20-40 kilograms are intended exclusively for saunas; you simply cannot pour a lot of water on them. Models for Russian baths begin with a load of stones of 60 kilograms.

Electric heaters are usually bought by those who expect to get quick results with a minimum of effort . There is no need to cook firewood or wait for the stove to heat up (! The corresponding section is dedicated to wood stoves). It all comes down solely to electricity costs (well, electric heaters themselves cost a lot). The second advantage of these stoves is that they are quite compact , and up to a certain weight they can also be mounted on the wall, freeing up space in the steam room. Floor models allow free rearrangement - they are not connected to chimneys and foundations .

How to assemble a protective screen yourself

The essence of the assembled protective structure is its multi-layered nature. After everything is installed, you will get a kind of pie, if you count from the surface of the wall: a ventilation gap directly at the partition, non-flammable heat-insulating material, decorative cladding. It is this finishing of the walls in the bathhouse around the stove that allows you to maintain a uniform design style for the entire room and maximally protect the wooden partitions from fire.

Important: the ventilation gap should not be less than 3 centimeters. This distance will allow the air to circulate and take away the bulk of the heat. For air circulation, technological openings must be provided in the lower part of the casing.

The structure is easy to assemble. Pieces of fire-resistant material are mounted on the walls as the foundation of the entire structure. Next, a sheet of thermal insulation material, for example, a glass-magnesium sheet, is attached. After this, the outer surface of the sheet is decorated with decorative material - tiles, porcelain stoneware or soapstone.

The last option is the most beautiful and durable, but it costs more than the others.

Important: the dimensions of the assembled screen must exceed the dimensions of the oven by 25 - 30 centimeters in all directions. Under the stove itself, it is necessary to place a base made of non-combustible material.

If the wall of a sauna or bathhouse near the stove is decorated with a material such as ceramic tiles or porcelain stoneware, one of its properties must be taken into account: the material itself practically does not change its size when heated, but the solution in the seams between the tiles can expand significantly. Therefore, the seams should not be very thin - when expanding, the composition can cause the glued tiles to peel off from the base. In addition, you should use porcelain stoneware with caution - if it gets splashed with water during steaming, it can crack.

Kinds

A modern bathhouse can be one-story or two-story with a relaxation room on the second or first floor. Often, these buildings are equipped with cozy bedrooms and kitchens, if space allows. More expensive buildings have separate spaces with a swimming pool and barbecue.

A wonderful relaxation area can be created in a cozy bathhouse with an extension, terrace or veranda. Relaxing in such a building brings a lot of pleasure; bathhouses with verandas are especially relevant in the warm season.

Material

To decorate the walls, floor and ceiling in a leisure room, it is permissible to use various materials, which will be discussed below.

Lining

This material is environmentally friendly and safe - it does not have a negative impact on human health. In addition, the lining boasts good thermal insulation properties. This finishing is made from pine, oak, aspen, linden and other types of wood.

Wooden shields

These materials are most often used when decorating the ceiling in a leisure room. Such canvases seamlessly hide various imperfections of the ceiling bases, making them perfectly smooth and aesthetically pleasing. Wooden panels are installed on a pre-insulated surface.

Boards

Wooden boards can be used to finish the floor in a bathhouse. It is advisable to choose well-polished materials, the thickness of which is at least 3.5 cm. Do not forget about covering such floors with stain or clear varnish.

Stone

The rest rooms, decorated with stone, look rich and presentable. This material not only has an excellent appearance, but is also not afraid of humidity, high temperatures and mechanical damage. Most often, the walls in baths are decorated with granite, cobblestone, sandstone or marble.

Of course, finishing with natural stone will cost the buyer a tidy sum. In addition, the weight of such cladding is often quite significant. Before you start installing stone parts, you need to make sure that the walls in the leisure room are quite reliable and strong.

If you don’t want to spend a lot of money on finishing, then you can use artificial stone instead of natural stone. For example, in such a setting, brick-like coverings look interesting.

Porcelain tiles

This strong and durable material can be used to decorate the floors in the recreation room. Many consumers choose porcelain stoneware because it is not afraid of mechanical damage, heavy loads and temperature changes.

Wallpaper

This finishing material is flexible. If you decide to decorate a relaxation room in the bathhouse, then it is better to choose fabrics based on non-woven fabric, plaster or fiberglass. Ordinary paper materials will quickly become unusable if glued to them in such conditions.

Drywall sheets

When choosing plasterboard for lining the leisure area in a bathhouse, it is better to give preference exclusively to moisture-resistant canvases. Simple gypsum plaster sheets do not tolerate high humidity, so they will not last long in a sauna building.

Dimensions

Modern bathhouses in the country have different dimensions. They come in both large and small. The common dimensions of these buildings are the following dimensions: 1.9x2.1 m; 2.6x2.5 m; 3x3 m; 3x4 m; 3x5 m; 3x6 m; 4x4 m; 4x5 m; 4.5x6 m; 4x6 m; 5x5 m; 5x6 m; 6x3 m; 6x6 m; 6x8 m.

You can pamper yourself with a spacious room only in large baths or two-story buildings. To increase the area, many users turn to terrace-type extensions.

Protecting a wooden wall from the heat of a stove

Wooden baths require especially careful compliance with fire safety rules when arranging them. The source of the fire can be anything, an unextinguished cigarette, coals falling from the furnace of the firebox, an uncleaned chimney, but the main source of threat remains the stove itself.

Related article: How to demolish a concrete wall in an apartment

The surface of the stove heats up to 300° - 400°, the heat falls on the wooden walls, which leads to their excessive heating and charring. It is extremely difficult to stop the process of ignition of wooden surfaces; the best way to avoid a fire is to prevent it. There are two truly effective ways to insulate the surface of wooden walls from the heat of sauna stoves - protective equipment in the form of a screen or the construction of special cladding from non-combustible materials.

Installing a stove in a steam room

The installation of a purchased stove is always described in detail in the instructions supplied with it. If the stove is brick, then it is installed by a stove maker. Homemade options remain.

Heavy stoves are placed on a foundation, while light stoves are placed only on a brick or other heat-resistant base.

We have already told you how to protect the wall from overheating if the firebox is in an adjacent room. If the firebox is in a steam room, you need to take care of good ventilation of the room , because otherwise the oxygen will quickly burn out.

The walls, floor and ceiling are protected with fireproof materials. After installing the stove on the prepared base, you still need to prepare a system for heating water and install a chimney. The latter needs special attention because it also poses a fire hazard .

Box for the passage of the chimney through the ceiling for installing a stove in a steam room

The chimney should be wrapped with thermal insulation material (basalt cardboard, for example) from the exit point through the ceiling of the steam room and to the roof cap . At the exit through the ceiling, the chimney passes through a metal box for the heat insulator, and at the exit from the roof (if the roof is insulated) - through another layer of heat insulation, bonded to the pipe with a heat-resistant sealant or (if the roof is cold) - through a special sealed penetration.

Features of installing the stove on a wooden floor

This is also done if the total weight of the stove with all screens and chimneys is less than 700 kg. However, if your stove is supported by 4 legs, then they will put more pressure on the base at the support points than the same stove without legs. Therefore, you need to distribute the load by placing the stove on a solid base between it and the floor.

IMPORTANT! Another condition for installing a stove on a wooden floor is a thick floorboard and strong joists under the floor.

You can lay a sheet of refractory material on the floor - asbestos or basalt cardboard, with a sheet thickness of 12 mm. On top of it is a metal sheet. We have already written about how they should protrude beyond the furnace.

Instead of metal, you can put brick, ceramics or natural stone.

When is this required?

There are times when there is no need to protect walls. If the stove is located at a safe distance from the wall from a fire safety point of view, the installation of protective screens and other measures can be neglected. The distance from the walls that is required to reduce the heat from the source varies:

- A stove laid in a quarter of a brick should be located no closer than 35-40 cm from the wall;

- A metal stove without lining should be placed a meter away and no closer;

- A metal one with a lined furnace can be installed 70-75cm from the wall.

However, not every steam room has the opportunity to fulfill these requirements, due to the small area. The layout of steam rooms with an area of 6-8 m² can hardly accommodate the necessary set of items for the steaming procedure. Therefore, the need to insulate walls with special sheathing is relevant.

Oven protection for people and walls

It's time to talk about a protective screen, as well as a fence that will protect steamers from accidental burns.

Video

Watch another short video about how this is done in one bath:

https://youtu.be/OfH_e4ER6VE

Protective screen for the stove in the steam room

Only metal stoves create problems with overheating in the bathhouse . To combat this, several types of screens have been created, each of which is better or worse suited to solving the following problems:

- protection of the steam room from overheating, hard infrared radiation, converting it into softer radiation and heat accumulation;

- protection of a wall made of flammable material from overheating and fire;

- regulation of heat exchange in the steam room.

The first place in popularity will be the brick screen . This is a masonry of solid bricks on either 2, 3, or 4 sides around the stove. In this case, there must be a distance of 5-10 cm between the screen and the oven.

IMPORTANT! Masonry is most often done in half a brick - this is the middle position between masonry in a quarter of a brick and in a whole brick. The thinnest one does not prevent overheating, but it does not take so long to heat the bathhouse. The thickest masonry is closest to the parameters of a brick oven - the temperature will not be high, it will take a long time to heat, but the heat will be soft and long-lasting.

For heat exchange, holes are made at the bottom of the brick screen . They can be closed with doors, or you can simply insert bricks into them. When they are open, hot air from the stove enters the steam room and accelerates heating.

IMPORTANT! Holes are required at the bottom of the screen. In other places - at the request of the owner.

The height of the brick screen should not be lower than the height of the stove, but how much higher it will be is up to the owner to decide. With one caveat: you shouldn’t build it all the way to the ceiling, because otherwise you’ll have to invest in the foundation as well. Add the weight of bricks and mortar to the weight of the stove and chimney to calculate the total weight and stay within the weight limit for a stove without a foundation.

By the way, masonry mortar is a mixture of clay and sand, without cement .

Watch the video to see what the mortar should be like and how to lay bricks correctly:

Another type of screen is made of metal. Metal screens are available with convection and without convection.

Convection - two-layer, hollow inside. The voids between the ribs are filled with air, and it conducts heat poorly, so it acts as a heat insulator. Such a screen is enough to lower the temperature and prevent the wall from catching fire. The holes in the screen are designed to allow air to circulate.

There are other screens that are simply a polished sheet of metal. Polishing reflects some of the infrared radiation , reducing its absorption by the metal. This screen is designed to be mounted on a wall, but not directly on wood, but on a layer of refractory or on slats of thermal insulation. In the latter case, cooling occurs due to the air gap, so the rail should be several centimeters thick.

Refractories such as basalt or asbestos cardboard are attached directly to a wooden wall , and a sheet of metal is attached to them. It is good to use ceramic dowels for fastening.

Often, lining a stove with natural stone is accompanied by insulating the stove corner with the same material. This combination looks good.

A cheap version of a metal screen can be made yourself from two sheets of steel for the roof and 3/8-inch metal pipes. The tubes are attached to the wall, then the first layer of profile is placed on them. Then another layer of tubes and a second profile sheet. The structure should be 10 cm above the floor level and below the ceiling level by the same amount.

A plaster wall between the stove and a wooden wall can also be a type of screen

Stove fencing in the steam room

Fencing a sauna stove in a steam room: the “brick + tile + wood” option

For the safety of those in the steam room, a fence is usually placed around the stove to prevent them from accidentally touching the hot metal. It differs from a screen in that it is usually made of wood and is not intended to block thermal radiation.

Knowing who will visit the bathhouse in the future, it is worth making a thicker fence in advance that will prevent small children from sticking their hand to the stove. If the bathhouse is only for adults , then simple railings around the stove with supports in the corners are sufficient.

The type of wood matters: resinous ones are not suitable . Alder or linden is best .

***

Now all that remains is to apply the acquired knowledge in practice. Good luck!

Application of protective screens

Screens are shields made of brick or metal that protect walls from intense thermal radiation. Similar protection is used when installing metal stoves.

- Metal screens are made from steel or cast iron sheets, these

casings surround the heat source with a distance of 3-5cm.

Advice! When purchasing a metal sauna stove, you should give preference to a model equipped with a metal casing. Its cost is not much higher, but the issues of wall insulation are eliminated.

Additional frontal or front shielding, which is located on the walls depending on the location of the stove, will not hurt. The protection guarantees the wood from overheating, reducing the temperature by 100 degrees or more, and provides the opportunity to save space in the steam room. A stove protected by a casing can be installed at a distance of 50-55cm from the wall.

Installation of screens is simple. The casing, equipped with legs, is secured to the floor by side or front screens - with galvanized nails or self-tapping screws.

- Brick screens are masonry used to cover the stove with

on all sides, the same casing, only made of brick. Another method is to lay half a brick between the firebox and a wall made of solid fireclay bricks laid on a solution of clay and cement. The width of the wall should be 120mm, although there is an opinion that it is permissible to put 60mm in a quarter of a brick, but it should be remembered that in this case the thermal insulation value is reduced by exactly half. It is recommended to raise the height of the masonry 20-30 cm above the surface of the firebox, but if you raise it to the ceiling, it will not be worse.

The screen should be placed at a distance of 10-15cm from the wall, 5-15cm from the stove, that is, the space saving is 30-40cm

Important! Functional openings for heat exchange should be made at the bottom of the masonry.

Protective screens are effective; they reduce the temperature to a level acceptable when using high-temperature fuel units. The same function is performed by wall cladding made of non-combustible materials.

Thermal insulation of the steam room

Everyone knows that before covering a steam room, the room must be insulated and a vapor barrier installed.

The choice of material for decorating a steam room in a bathhouse with your own hands is great. Today, there are several types specifically for the steam room. Such materials that tolerate temperature changes well and do not emit harmful substances when heated do not rot and do not contribute to the appearance of fungus. They are also fire resistant and will last for many years.

Basalt and mineral wool are the most popular cladding materials. And foil film is excellent for vapor barrier. The foil material is sheathed on the walls and ceiling and used for waterproofing them. It looks like a roll of basalt wool only with a layer of foil.

Ceiling insulation

We attach the foil material to the ceiling using a stapler, with the reflective side facing the room. We overlap the joints and seal them with aluminum tape.

We fasten the sheathing for the future ceiling (for cladding to hide the foil layer) using screws across the beams. You can read about how to vent a chimney through the ceiling here.

Also, do not forget in the attic, before filling the ceiling with insulation (earth, expanded clay), put a film on it so that dust does not get inside the room, or cover all the cracks between the boards.

Thermal insulation of walls

The technology for covering the walls in the steam room is the same as for the ceiling. Just before insulating the walls in the bathhouse, you need to smooth out all the cracks and joints. The insulation is attached parallel to the floor, from top to bottom. Laying is done in three layers: hydro-, heat-, and vapor barrier.

The first layer of waterproofing is needed to prevent condensation from settling on the walls. The second layer is for insulation; it is laid in a timber sheathing. The third layer is needed to protect the insulation from moisture.

Floor insulation

A floor made of concrete is certainly more durable than wood, but such floors are cold, so people still give their preference to wood.

For a wooden floor, the foundation is poured, beams are laid, and logs are placed on them. The voids formed between the joists and beams are filled with insulating material, most often expanded clay or sand. Next, a vapor barrier and the “first floor” are laid, and insulation material and waterproofing are placed on it, and only then we make the finishing floor.

For a concrete floor, a base is made of concrete and crushed stone, 12-15 cm thick. Waterproofing can be installed after the concrete mixture has completely dried. It can be roofing felt or bitumen mastics. The concrete is coated several times with bitumen mastic, and only then we apply waterproofing. The insulation can be mineral wool, perlite or expanded clay with a layer of 10-15 cm. The next layer of the floor is made on the heat-insulating surface.

Covering bathhouse walls with non-combustible insulating materials

To prevent the walls from overheating, you can use materials with increased thermal insulation properties and inertness to high temperatures. Two types of materials are used:

- reflective;

- fireproof with lining.

The first type includes materials for wall cladding, consisting of thermal insulation with fire-resistant properties and a metal covering in the form of a sheet.

Insulating walls with reflective sheathing

A protective cake with reflective materials is done this way. First, the thermal insulation is attached using ceramic bushings directly to the wooden walls, then it is sewn up with a stainless steel sheet.

Advice! It is better not to use galvanized metal, since heating may release heavy metals harmful to the human body.

Stainless steel with a polished surface reflects the heat flow inside the steam room, reducing heat loss. In this case, reflected heat is more useful than direct heat. For thermal insulation use:

- basalt cardboard or cotton wool, the only material with increased hygroscopicity, non-flammable, environmentally friendly;

- asbestos cardboard, which reliably protects against flames and has a long service life;

- mineralite, an artificial material made specifically for these purposes.

Protective sheathing requires ventilation gaps of 2 cm from the wall to the insulation, 2 cm from the insulation to the steel sheet. If it is necessary to install the stove as close to the wall as possible, make a double skin of non-combustible insulation, use ceramic bushings to maintain gaps of 2-3 cm and sew them up with a steel sheet.

How to properly insulate a steam room in a brick bath

In order to avoid errors when insulating a steam brick bath, you should choose the right material. For example, mineral wool will provide high-quality thermal insulation if installed outside. When heated, harmful substances can be released, so you should not place the layer inside. But foil materials and pure foil are perfect for insulating a steam room. By installing such a layer, you will ensure that the temperature is maintained at the desired level for a longer time. You should not choose polystyrene foam, which is a fire hazard. When heated, it can be harmful to humans, so it should not be used for thermal insulation of a steam room in a brick bathhouse.