The modern variety of metal stoves for baths provides a wide choice. You can purchase and install a ready-made stove, or you can create it yourself. But, in any case, you can’t do without installing a heat shield. Moreover, there are often several screens:

- One covers the body of the metal furnace itself. This shield softens the thermal radiation from the case. Most often it is made of brick.

- There are screens to protect combustible walls. They are made of any fireproof materials and cover adjacent walls.

- And another type is non-flammable material on the floor. This can be either a brick “podium” for a metal stove, or tiles, porcelain tiles, artificial or natural stone, laid on a layer of glue, or a sheet of metal, under which a layer of heat insulation is placed.

There are several reasons for making a protective screen for the furnace. And they all deserve attention:

- During combustion, a metal stove becomes quite hot, and therefore there is a high risk of getting burned. It is clear that the constructed protective wall will be a salvation. In addition, if you do not protect the walls of flammable materials near the stove, you can also expect a fire.

- In some situations, when a metal stove is made by hand, the brick screen around the stove also serves a decorative function.

- A metal stove of any type does not allow you to regulate the heat flow of air in the bathhouse. A well-made brick screen can correct this and create controlled heat transfer.

Everyone knows about the dangers of hard infrared radiation, and such heat comes from a red-hot iron stove that there is no need to lean against it - even from a distance you can get burned. A brick screen for a metal stove will protect the inhabitants of the steam room and allow you to feel the complete comfort of bath procedures.

Any metal stove is a source of danger

Selecting a protective screen

There is a large selection of specialized materials from which a wooden sauna stove fence can be made. First of all, we are talking about:

- Natural stone;

- Basalt slabs;

- Metal floors;

- Decorative shields.

It is worth focusing on a number of parameters, including price, durability and acceptable operating conditions. Due to frequent temperature changes and high humidity in the room, cheap panels may fail over several seasons.

In such conditions, natural stone performs best. Most often, brick is used for the screen of a sauna stove, since with its help you can independently lay out the required shape of the future protective structure. As work progresses, you can easily make any adjustments to make the bathhouse more comfortable to use. A screen for a stove in a bathhouse with your own hands is the best thing you can do for an excellent and safe holiday.

Video description

This video discusses one of the simplest options for covering walls next to the stove in a bathhouse using mineralite sheets:

Floor protection

A floor screen for a stove in a bathhouse must, among other things, have high compressive strength. This is justified by the large total weight of the heating system, to which the smoke exhaust network, heater and, most often, a container with hot water are attached. Therefore, stands and platforms are assembled here from materials such as brick, natural or artificial stone, steel or cast iron. The latter are easier to find ready-made on trading platforms.

Option for a floor screen for a sauna stove Source prom.st

Additional aspects

It is worth understanding that not all situations require a protective screen at all. For example, for brick kilns with an initially protected firebox, fences are not required. If the screen needs to be installed, then red ceramic materials are selected for it, capable of withstanding severe temperature changes and exposure to moisture.

Conclusion

A DIY sauna stove screen is an important sauna structure that can prevent accidental burns and balance the operation of the stove. By implementing one of the proposed schemes, you can achieve a combination of protection efficiency, good functionality of the stove and good visual qualities of the entire system.

Heat-resistant screens for sauna stoves began to be used relatively recently, since today the stove is a separate device that is not part of the sauna. In the past, stoves were made of stone, so additional fencing for the stove in the steam room was not required.

Today, a brick screen is often created for a metal stove in a bathhouse, since metal is an excellent conductor of thermal energy and can therefore heat up to very high temperatures. Any contact with the metal body causes serious burns that do not heal for many weeks. Thus, a protective screen for a stove in a stainless steel sauna makes your vacation safe.

Types of structures

To begin with, it is necessary to say that there are two types of similar structures that have a similar purpose and at the same time can perform different additional functions. Modern protective screens for sauna stoves quite often combine several different materials and are made in accordance with the design of the stove.

Taking into account these features, the craftsmen try to combine all the properties of similar products in order to achieve maximum results.

Full brick lining will allow for insulation around the entire perimeter of the device

Brick walls and trim

- Very often when creating ovens with their own hands, craftsmen resort to creating brick screens.

- Usually this is a partition that separates the metal product from the walls. It prevents the spread of infrared radiation to wooden surfaces and protects them from high temperatures that can lead to fire.

- The installation instructions also advise installing such structures between metal sauna stoves and the place where people will be. So intense radiation will heat the partition, which will play the role of an additional heater. However, it is worth remembering that when using a simple wall, you should leave a small air space.

The simplest brick partition can become an excellent screen

- Some craftsmen suggest immediately framing the entire sauna stove with a wall of brick or stone so that it can perform both tasks simultaneously. This way the structure will protect the walls of the room and prevent intense radiation from getting outside.

- It is worth noting that the screen for the sauna stove does not need to be used if the structure already has its own lining. This also applies to brick stoves, which actually themselves represent a firebox with thermal protection.

- For the manufacture of such structures, only red ceramic bricks or other materials with similar properties are suitable. The fact is that it tolerates moisture well and can withstand large temperature changes. Some craftsmen use special stones for this, which have low thermal conductivity and at the same time retain heat well.

Some craftsmen recommend simply sewing up the entire stove, which will give it a good appearance and help additionally retain heat.

Reflective surfaces

- Quite often, craftsmen recommend using a stainless steel screen for a bath. It should be noted that this metal must be perfectly polished and reflect infrared radiation.

- Such systems are usually used on back walls near stoves. They protect the surface from intense heating and at the same time redirect the heat inside the room. This allows you to reduce the cost of kindling and maintaining the regime.

Polished stainless steel screens

- Such heat-resistant screens for sauna stoves work very effectively even with brick stoves or when combined with stone partitions.

- Some manufacturers, making structures for heating baths, actively use them to improve the technical characteristics of their products. At the same time, professional craftsmen prefer to additionally mount bath screens made of stone or brick so that they absorb all the radiation, converting it into normal heating.

Screens with reflective surface

- Special attention is due to the fact that the metal also gets very hot and, if it comes into contact with wooden surfaces, can lead to a fire. That is why it is best to protect such a screen for a bath on the reverse side with heat-resistant material or create a small air gap.

- Quite often on sale you can see screens made of metal with a matte surface. Their price may be several times less, but they are less effective, and professional bath attendants claim that such screens are generally useless and only take up extra space.

- It is worth noting that such structures require periodic maintenance, since plaque and stains appear on them over time. To do this, they can be wiped with a special detergent or lemon juice.

Factory product made in the form of a fence

When is protection needed at all?

The need to install protective casings and screens does not always arise. If a fire-safe distance is maintained between the stove and the nearest flammable surface, additional protection is not needed. At this distance, the IR rays are scattered, weakened, and the amount of them that the wooden wall receives can no longer lead to damage.

It is believed that the safe distance from the wall to the brick stove (quarter-brick laying) is at least 0.32 m, from the wall to the metal stove (not lined) - at least 1 m. For a metal stove lined from the inside with brick or fireclay, the distance decreases to 0.7 m.

Thus, maintaining fire safety distances is more possible in large baths, where the issue of saving space is not relevant. In family steam rooms, where every centimeter of space counts, installing a stove 0.3-1 m from the nearest walls is impractical. In this case, the safety distances established by the standards must be reduced using screens and casings.

Video description

This video explains the causes of a fire in a bathhouse with improperly organized fireclay brick protection:

Among the recommendations on choosing quality materials, craftsmen note several points that will allow you to create durable and visually attractive protection. For example, stainless steel quickly becomes unattractive from frequent heating. This can be avoided by using heat-resistant metal paint or by regularly wiping the surface with household cleaners. It is recommended to cover the log house and ceilings with two layers of heat insulation for the purpose of reinsurance.

Protective screens around the stove

Protective screens are insulation panels that cover the side surfaces of the furnace and reduce the intensity of thermal radiation. Screens can be metal or brick. As a rule, they are used for metal furnaces.

Method #1 - metal screens

The most common protective screens are factory-made steel or cast iron sheets. They are installed around the stove, at a distance of 1-5 cm from the walls of the firebox. Depending on the need to insulate one side or another of the furnace, you can purchase side or front (front) screens. Many metal furnaces are initially manufactured with protective screens in the form of a protective casing.

Protective screens make it possible to reduce the temperature of external metal surfaces to 80-100°C and, accordingly, reduce the fireproof distance to 50 cm. The total distance from the firebox to the wall (including a gap of 1-5 cm) will be 51-55 cm.

Installing protective screens is not difficult. Thanks to the presence of legs, metal panels are easily bolted to the floor.

Method #2 - brick screens

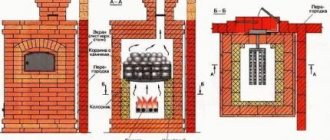

A brick screen can cover all the side surfaces of a metal furnace, representing its outer cladding. Then the stove will be in a casing made of brickwork. In another case, a brick screen is a wall separating the stove and the flammable surface.

To lay the protective screen, solid fireclay bricks are used. The binder is cement or clay mortar. It is recommended to use half a brick (thickness 120 mm). But, if there is a lack of material, it is possible to make a wall of a quarter of a brick (60 mm thick), although in this case the thermal insulation properties of the screen will be reduced by half.

Small openings (sometimes with fire doors) are left at the bottom of the shield for air convection between the brick wall and the stove.

The brick walls of the screen must end at least 20 cm above the top surface of the oven. Sometimes the masonry goes all the way to the ceiling.

The brick screen is not installed flush against the walls of the stove, the optimal distance is 5-15 cm. The acceptable distance from the brickwork to the flammable wall is 5-15 cm. Thus, the use of a brick screen allows you to reduce the distance from the stove to the wooden wall to 22-42 cm (stove - ventilation gap 5-15 cm - brick 12 cm - ventilation gap 5-15 cm - wall).

How to make a protective screen for a sauna stove with your own hands

Rest assured that there is nothing difficult in creating a protective screen for a bathhouse with your own hands.

It is recommended to prepare all the necessary materials and tools in advance, as otherwise this will significantly slow down the progress of work. Having everything you need will help not only not to stop construction and installation, but also will not confuse the overall “engineering idea”.

Made of brick

Brick and concrete mixture are used as the main working material. Mixtures that are designed for use at high temperatures should be used. If you do not want to spend money on purchasing it, then you should add clay to the standard mixture. This will strengthen the future structure.

When calculating, it is necessary to take into account three parameters to determine the required amount of brick, namely:

Keep in mind that in the masonry it is necessary to calculate an additional few millimeters between the bricks for the concrete mixture.

- The manufacturing process is no different from laying bricks. All that needs to be done is to create a kind of brick “fence” around the stove of the required height.

- After installation, it takes at least 5-7 days for the solution to dry completely. A longer period is required due to the confined space - the solution dries worse in it.

- After completing the last stage of work, you should additionally check the strength of the masonry. If necessary, additional basalt slabs can be installed on top of the brick to provide greater security.

Made of metal

Metal structures are more durable, since this material can more easily withstand temperature changes. The complexity of installation and the price of such slabs are slightly higher than their brick counterparts.

The work will require sheet metal: zinc sheets or steel, as well as additional mineral insulating materials that are not subject to combustion and melting at high temperatures. A welding machine and sheet fastening mechanisms are also required.

The thickness of the insulating material should be at least two centimeters, and the height of the shield should be 5-10% greater than the height of the furnace. Remember that the wall of the structure is double, so eight sheets of metal are required to complete the job.

Step-by-step manufacturing instructions

- Prepare all necessary materials and consumables;

- Place the insulating material in an even layer on the sheet of metal;

- A second layer of metal is applied on top;

- Special fasteners are welded using a welding machine to hold the structure together.

- The produced sheets must be installed around the furnace on all sides using fasteners.

- It is recommended to place insulation under the bottom to prevent unintentional charring of the floor and fire in the room.

Features of installing metal protection

Installation of a metal screen is usually carried out in such a way as to create a structure like a box. The outside is stainless steel or sheet metal coated with heat-resistant paint. As a result, an air gap appears between the metal sheets, which ensures good thermal insulation.

There are holes in the lower part of the structure that provide air circulation and prevent overheating of the metal box. To implement such protection, you can use one of two schemes.

Scheme 1

A polished metal sheet is selected, which has much better heat transfer. As a rule, such screens are used on the rear walls of the furnace, preventing heat loss. Of course, you should not attach this protection directly to the wall - the risk of fire will increase many times over.

For proper installation, it is necessary to place a non-combustible layer between the protection and the wall so that there is air space behind the sheet. There should also be a short distance from the protection to the floor - this allows air to blow across the screen, removing heat.

Scheme 2

To implement such a scheme, thermal insulation is first laid on the wall, and then metal protection is placed on top of it. The design will largely depend on the chosen insulation.

Depending on the selected thermal insulation, the arrangement of the protective screen will look like this:

- When using rolled material, the cladding is created in such a way that the distance between the planks is slightly less than the width of the material. The insulation is placed between the planks and fixed with special dowels with a large head.

- If mineral cardboard or asbestos sheet is used as a heat-insulating material, then it must first be attached to the wall, and the metal sheet is fixed on top.

Conclusion

The importance of the above-mentioned bath structure cannot be overestimated, therefore the design of this stage of construction should be carried out at the very beginning. Remember that the safety you provide is exactly the factor that will allow you to enjoy the bathhouse and your work for many years! During the heating of the bath, the surface of the stove heats up to 300-400°C

At the same time, it begins to emit infrared rays and itself becomes a source of heating. The coming heat is distributed throughout the steam room, but first of all it hits the walls adjacent to the stove. If the walls are wooden, then under the influence of high temperatures their charring begins. And there it’s already a stone’s throw away! The only truly effective way to insulate wooden walls from heat is to create protective screens and cladding from non-combustible materials in the bathhouse.

During the heating of the bath, the surface of the stove heats up to 300-400°C. At the same time, it begins to emit infrared rays and itself becomes a source of heating. The coming heat is distributed throughout the steam room, but first of all it hits the walls adjacent to the stove. If the walls are wooden, then under the influence of high temperatures their charring begins. And there it’s already a stone’s throw away! The only truly effective way to insulate wooden walls from heat is to create protective screens and cladding from non-combustible materials in the bathhouse.

Common mistakes and recommendations

Choosing insufficiently high-quality materials and trying to save on resources are the most common causes of breakdowns, malfunctions and fires. In relation to the bathhouse, such negligence is unacceptable. An equally popular mistake is failure to maintain the distance even between the brick screen for the sauna stove and the walls. There are enough ways to competently minimize indents and gaps for this, so you should not allow errors in centimeters. Also, you should not make the decorative side the dominant criterion for choosing protective equipment and structures.