There are many options for making a heated floor in a bathhouse. Thanks to the diversity, everyone is able to find exactly the option that best fits into a specific situation.

For example, you can install heated floors in a bathhouse from a stove, or, as an option, use electric analogues. Each option has its own characteristics, both in terms of characteristics and in terms of installation work.

This article will discuss the most popular types of underfloor heating:

- water heated floor;

- cable heated floor;

- infrared heated floor.

The issues of insulating wooden floors in a bathhouse or sauna will also be discussed.

Which heated floor to choose for a bath

According to physical properties, warm air masses rise upward, and even in a steam room, where it is hot, the floors are cold. But such a dissonance between the heat from above and the cold from below makes bathing procedures uncomfortable.

Modern technologies make it possible to improve the microclimate in the bathhouse by installing different types of heated floors under the floor covering:

- cable - are a heating cable laid under the finishing coating, powered by electric current;

- infrared - a film with infrared plates inside that heat up when energy is supplied, the simplest structure in terms of self-installation;

- water - a pipeline located under the floor in the bathhouse, the coolant is heated water.

However, the bathhouse has high humidity, so many building owners do not risk installing electric heated floors themselves.

In this regard, water heated floors are considered more popular. After all, the bathhouse is equipped with a stove, and it is possible to heat the coolant from it, so this combination is also economically profitable.

Film heaters

These heated floors also run on electrical energy, but they do not have a heating cable. Instead, a film with a semiconductor coating is used.

Physically, the principle of operation is no different from a powerful infrared LED, only instead of a crystal, semiconductors on film are used. When current is applied, the film begins to emit infrared radiation on one side. The other side of her remains cold.

Information. Film floors are expensive, but they have good efficiency. Baths are more compact than living spaces, so it is easier to use expensive materials there.

Film heaters are popular in saunas. There they are used openly. You can purchase a roll of heating film and use part of it to build a heated floor, and install part of it in open heaters.

System Features

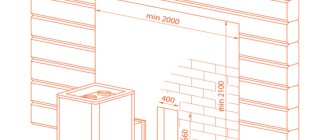

When installing a heated water floor in a bathhouse powered by a wood-burning stove, there is no need to install a boiler. However, a heat exchanger needs to be built above the firebox. Any stainless steel tank that is not prone to corrosion is suitable for this. A circuit extends from it into the room where the heated floor will be installed.

To return the waste liquid to the tank, you will need to install a small pump. Without it, the design will only work when the stove is located below the level of the floor covering. The diameter of the pipe with this scheme should be taken equal to 16 mm; the usual 24 mm ones will not work.

The main feature of the stove floor design is the inability to adjust the temperature level. The recommended temperature of heated floors in the bathhouse is 40 degrees, but the heat carrier from the stove will heat up to boiling water.

Video

WARM FLOOR in a bathhouse using a OVEN? Sauna stove Gorynych-3.

Therefore, it is necessary to make a mixing block in which hot water will be mixed with already used water, thereby reaching the desired temperature level.

Since it is not possible to install a large container in the furnace, you can place a battery tank near it and stretch steel pipes from it to the heat exchanger.

Common mistakes that accompany self-installation

To ensure stable operation of the system, it is important to eliminate the conditions for the occurrence of the following defects at the preparation stage:

- You can start assembling the heated floor only after 2 weeks have passed from the moment the rough screed is formed. Otherwise, the concrete will crack;

- before installing the finished floor covering, you should test the heated floor scheme so as not to brick up any errors;

- when creating a “pie” it is important to use high-quality insulation materials;

- you need to remember about the limitation regarding the length of one pipe - 100 m;

- a mandatory measure is fixation of compensation tape around the perimeter.

If the installation of the system was carried out taking into account the indicated vulnerable points, you can expect long and uninterrupted functioning of the heated floors.

Advantages and disadvantages

A heated water floor in a bathhouse, heated by a stove, is a complex structure that has its positive and negative sides.

The main advantages of the “warm floor” system:

- equalizes the temperature level, there are no hot or cold places, thereby increasing the comfort of bath procedures;

- the screed with which the circuit is filled has the ability to accumulate heat and release it over a long period of time;

- the presence of a stove allows you to save on heating water for the procedure without using additional sources;

- environmentally friendly heating device - there is no electromagnetic radiation, as when using electric heating, which has a positive effect on human health;

- the ability to heat large houses;

- the absence of a favorable environment for the formation of fungus and mold - this will extend the service life of the bath.

In addition, the bathhouse is heated from two sources: stove heating and heated floors, which increases the rate of exchange of warm air masses and reduces the time required to prepare the bathhouse. And uniform heating of the steam room leads to the absence of drafts.

The main disadvantages of heated floors in a bathhouse from a stove:

- It is quite difficult to do the installation yourself; you will also need special equipment;

- Carrying out repair work yourself is also not easy;

- the “pie” of the water structure significantly lowers the ceiling level;

- there is a need to re-equip the furnace;

- the need to drain the coolant from the system so that it does not freeze and destroy the pipeline, or constant heating of the furnace;

- complex process of temperature regulation;

- you cannot install leaking floors, as the insulation will get wet and the functioning of the system will be significantly reduced;

- When heating the coolant tank, a lot of thermal energy is consumed, and less is left for heating the steam and washing compartments.

For your information! If you replace the water with antifreeze, there will be no need to drain the coolant or constantly heat the stove during the cold season.

It is worth noting that making any heated floors in a bathhouse yourself costs a lot of money, but over time it will pay off.

Why install a heated coating in a bathhouse?

The bathhouse is most often located a short distance from the home. In this independent building, the main element is the heater stove and heated exhaust elements that serve for steam generation. But it’s no secret that a bathhouse with just one stove, without additional heating elements, takes a very long time to heat up and staying in it until then is extremely unpleasant.

And, even after heating the entire room, the floors often remain cold. And, since a huge number of receptors are concentrated in the legs, when we step on a cold floor, we immediately risk getting sick. To eliminate this point, it is best to make a coating with heating from a stove.

This procedure does not require special skills, the purchase of expensive equipment and control systems, and, due to the fact that the bathhouse area is not so large, the cost of purchasing materials will be minimal.

Installation of a water floor from a sauna stove

Initially, water heated floors were not intended for installation in a bathhouse. Therefore, when laying such a “pie” in a bathhouse, it is required to equip it with additional elements.

The installation of a water heated floor from a sauna stove includes several components:

- The heated floor contour is the main working element, which is laid evenly across the entire floor of the room with a certain pitch, filled with a concrete-cement mixture screed. You should choose the right pipe model; in this situation, not every one will be suitable. It is best to use copper, metal-plastic or stainless steel corrugations. However, many people prefer cross-linked polyethylene pipes with increased heat resistance, with a service life of at least 30 years, or polypropylene pipes, with a warranty period of at least 50 years.

- The mixing unit is an important part of the system, since the stove is not capable of heating the coolant to the required level. It heats the water almost to the boiling stage; in this state it cannot be supplied to the circuit. Therefore, a mixing unit is needed, in which boiling water will be mixed with the waste coolant to the required 40 degrees, and in this form it will be sent into the pipeline. It is used to regulate, configure and automatically maintain the temperature level of the heated floor in the desired mode.

- Heat exchanger - a container, coil or register located above the firebox, where the liquid from the furnace is heated. When using antifreeze as a coolant, you will need to equip a separate heat exchanger, then the antifreeze will not be able to get into the washing water.

- A circulation pump is necessary to ensure that the coolant is evenly distributed and moves through the pipeline. Without it, a warm water floor cannot function, as it provides the circuit with additional pressure for fluid circulation. When selecting the pump power yourself, you need to take into account the area of the heated room; the larger it is, the higher its performance should be.

To reduce the load on the pump, it is recommended to divide the pipeline into several parts of equal length.

- Drainage is necessary to remove excess liquid from the steam room and washing room of the bathhouse. You can equip it with your own hands, taking into account the following two points: by constructing a water outlet - a drainage hole, through which the water will flow into the pipe and be discharged into the sewer pit; fill the screed with a slope in the direction of the drain hole - then all the water will flow towards the slope.

Installation technology

Depending on the base material, it is practiced to install a wooden, polystyrene, or concrete heated water floor.

Concrete

It is widely used in Russian latitudes, it is based on a concrete screed with a flexible pipe; it also uses insulation in tandem with polyethylene film. Mineral wool and penoplex are optimal as thermal insulation materials. Concrete is mixed with special additives (they are also used in the construction of swimming pools), which prevent cracking of the dry mass under conditions of frequent temperature changes.

Preparing the base:

- the screed is made with an inclination corresponding to the direction of drainage of water, the maximum angle is 10°;

- the completely dried layer is covered with a polyethylene vapor barrier;

- insulation is laid on top - mineral wool, penoplex;

- holes are formed in the material into which beacons for future screed are placed;

- The top of the “pie” is covered with a metal reinforcing mesh with a cell size of 10x10 cm.

Polyurethane foam tape is fixed along the perimeter along the walls: a soft membrane compensates for the potential expansion of concrete and prevents it from cracking when heated.

The pipe is laid in a spiral taking into account the following recommendations:

- between the turns you need to leave gaps no wider than 40 cm, a distance of 25 cm should be maintained from the outer pipe to the walls;

- When laying a pipeline, the permissible radius of its bend should be taken into account - this is five times the diameter. The product is sold in the form of reels, they are unwound as they are used, fixed with clamps so that there is space for pipe expansion;

- the pipes are combined into a circuit in a manifold cabinet.

After trial testing, the concrete screed is poured again.

It is important that the ambient temperature is kept in the positive range; a vibrator is used to compact the mass. The optimal layer thickness allows you to leave 2 cm of concrete above the pipes; usually it ranges from 7-8 cm. If a tiled floor covering is planned, 5 cm is enough.

Wood

The flexible pipe is placed in the grooves left between the slats; this space should be wider than 2 cm. Chipboard panels are considered the most budget-friendly base material. Operating procedure:

- The base is leveled and debris is removed.

- A sheathing is formed from timber with a cell side of at least 60 cm, and fiberboard or plywood is stuffed onto it.

- The finished raised floor is covered with a vapor barrier and insulation on top.

- Lay out the boards, in the gaps between which the pipe will be placed. Their height should exceed 2 cm.

- The grooves are insulated with foil to prevent heat leakage downwards, and pipes are placed on it.

- All ends are connected to the manifold cabinet.

- A finishing layer of cladding is formed.

To fix the foil in the gaps, you can use small nails or a stapler. If the raised floor is assembled from fiberboard, foil is glued to the smooth surface of the slabs using double-sided tape.

From polystyrene plates

The base is assembled from segments with ready-made grooves; pipes are inserted into them. Plates are inserted into the gaps to promote more uniform heat distribution. A low and light structure is formed that does not “eat up” the usable space in the room. No labor-intensive concrete screeds are needed here. Polystyrene does not allow moisture to pass through and retains its heat-insulating properties throughout its entire service life.

Installation features:

- the first layer is laid insulation in the form of mineral wool;

- polystyrene foam is installed starting from the far corner, the plates should be placed so that their grooves coincide;

- distribution plates are placed in the holes;

- A flexible pipe is fixed on top.

Polystyrene boards

After checking the functionality of the system, a final floor covering is formed.

Principle of operation

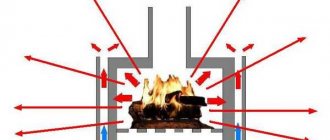

The device is a pipeline with a coolant inside, which is powered by a sauna stove heated with wood or other fuel. The stove must be converted to heat underfloor heating.

After ignition, it warms up the system, full heating is achieved by the time the steam room is ready. Water circulates using an installed pump; it is included in the mixing unit. Warm pipes heat up the screed and flooring, which in turn transfers it to the room.

Scheme and structure of the “pie”

If we consider the installation of a warm water floor in a bathhouse from a stove in the form of a “pie,” then it consists of:

- subfloor - concrete or wood;

- waterproofing layer - it prevents the formation of condensation;

- insulation - reduces heat loss;

- reinforcing mesh - protects insulation;

- foil reflector - directs heat in the desired direction;

- heating element - pipes laid in a spiral;

- concrete screed - having a slope in the direction of drainage;

- finishing coating.

When laying a heated floor on the ground yourself, you need to equip a sand cushion, fill it with expanded clay on top, and spread a waterproofing layer on it.

In addition, additional installation of a mixing unit, heat exchanger and pump will be required.

Electricity as it is

Electric heated floors come in several types. The heater can be in the form of a wire - double or single. The two-core one is more convenient to install, it does not need to be ringed, it is laid in one direction and a plug is simply placed at its end.

The single-core wire is laid with the expectation that both ends need to be connected to the controller. Don't forget about the temperature sensor. Its installation is also mandatory and is done on the floor between the turns of the cable.

A system with a single-core wire is easy to install, but has a significant drawback: it produces high electromagnetic radiation. When using a two-core wire, electromagnetic radiation is much less due to counter magnetic fluxes.

For floors made in the form of rolls or mats, electromagnetic radiation is significantly lower. But there are restrictions on their use.

The power of thermal mats ranges from 150 to 450 W per square meter of surface. For bath floors, 250 W per square meter is considered optimal.

Preparatory work

Before starting work on the construction of a heated water floor in a bathhouse, you need to draw up a detailed diagram, indicating the size of the heated room, the length of the circuit, the location of the pump insertion, the area where the mixing unit and heat exchanger are connected. In accordance with this drawing, the amount of material required for the heating structure is determined.

After which, you can proceed to the installation work itself, which begins with preparing the base and draining:

- Remove the soil between the foundation walls and compact the surface. Before this, lay sewer pipes for wastewater. Through them, water will go into the sewer.

- Pour a layer of sand and crushed stone (15 cm) and compact it well.

- Lay expanded clay insulation, its thickness is 150 - 200 mm. It is required to make a slope in the direction of the drainage.

Operating rules

Operating a water heated floor from a sauna stove assembled with your own hands is not difficult and does not require much effort. The main thing is to adhere to several rules:

- in the cold season, water should be drained from the pipes every time;

- constant operating pressure must be maintained;

- Eliminate breakdowns in the pump and shut-off valves in a timely manner.

If, when installing a heated water floor in a bathhouse from a stove yourself, you followed all the rules, then the system will delight you with comfortable conditions in the bathhouse and trouble-free long-term operation.