Dimensions

As already mentioned, they are delivered disassembled.

This decision by the manufacturer is due to the large mass of the unit (from 100 to 900 kg), which makes it more convenient to install the stoves directly on site. They are distinguished by a powerful body with reinforced walls with a thickness of 10 to 60 mm. The walls are equipped with vertical stiffeners. They can withstand significant loads, for example, when laying a large number of stones. Model parameters are indicated in millimeters.

Each product has its own dimensions:

- PB 01M – 711x495x887 mm;

- PB 01S – 887x600x860 mm;

- PB 01MS – 887x600x860 mm;

- PB 02M – 855x458x645 mm;

- PB 02S – 855x600x750 mm;

- PB 02MS – 855x458x645 mm;

- PB 03M – 755x418x590 mm;

- PB 03S – 755x500x700 mm;

- PB 04M – 645x394x490 mm;

- PB 04S – 645x450x570 mm;

- PB 04MS – 645x450x570 mm.

The combustion stove "Hephaestus" is designed in such a way that the steam room receives dynamic and fast heating. The heating of the stones occurs thanks to the equipment with a flame cutter, which evenly distributes the flue gases. The heater of the stoves has a unique three-section design. The equipment provides unique steam, which is considered ideal for a Russian bath. Wet steam is considered light and good for health.

Depending on the standard sizes, one or two specialists can do the assembly. The manufacturer prepares the kits in such a way that the work associated with their installation will not cause difficulties. To facilitate the installation process, the manufacturer pre-divides devices into two main categories. The devices are united by common requirements.

To connect the models, framed with soapstone, a chimney and a strong foundation are installed. Variations in the appearance of the finish can be adjusted by the owner himself. Usually stoves are lined with bricks, and they take on the appearance of a Russian stove.

Considering that the dimensions of the stoves are adjusted in accordance with the dimensions of the room, it is worth paying special attention to the use of certain types of fuel. Hephaestus stoves should be heated with wood or fuel mixtures

Do not use coal or wood waste for this. The best option is to fire the stove with hardwood logs. Firing a stove with wood has an advantage over other options. For example, the aroma of wood has an effect called aromatherapy.

Materials: what are needed and how much?

Red facing brick can be used in the work.

To cover a metal stove with your own hands, you need to take a responsible approach to choosing the material so that the brick wall built around the device can easily support the firebox and not crack. It is permissible to use the following brick for lining the boiler:

- Facing red. Great for heat shield. It is recommended to lay solid blocks, but hollow ones are also suitable, however, they will not hold the temperature for a long time, since they are not heat-intensive.

- Fireclay brick. This material is best suited for lining a stove. If you line the wall with refractory blocks, it will not be afraid of even the highest temperatures. The heat capacity of a fireclay block is comparable to red brick. However, this material has a significant drawback - its unattractive appearance. But there is a way out of this situation - after insulation with refractory, you can finish the device with facing porcelain stoneware or other resistant material.

The finishing of a sauna stove will look solid if the walls are insulated with granite or marble slabs. But in order to lay such material correctly, it is recommended to seek help from a specialist who knows all the intricacies of the work. It is important to reliably design device portals. To do this, it is recommended to use a door with fire-resistant glass or made of cast iron alloy.

Nuances you need to know when starting cladding

In general, the laying of bricks for cladding in terms of technology is no different from the laying of stove walls. However, when deciding to line a cast-iron or iron stove with brick, pay attention to the important points listed below.

- every 4th row of facing masonry with wire or steel strip. The firebox opening (including the opening of the remote firebox) is reinforced with a metal corner.

- During the DIY cladding process, you will need a heat insulator. Asbestos or basalt cardboard can be used as it.

- Review all purchased bricks for defects (chips, cracks, etc.). Take the time to lay out the material on the floor, adjusting brick to brick so that the pins touch with the smallest possible gap. Follow the same order when you lay the bricks on the mortar.

- The masonry mortar must match the chosen type of brick. However, there is no need to rack your brains here. Usually, when purchasing building materials, you will immediately be offered a dry mixture, which you only need to dilute with water according to the instructions.

- Watch the thickness of the seams, do not make them too wide. The thinner the seams, the better thermal conductivity the lining will have.

- Be sure to check the verticality of the corners with a plumb line, as well as the horizontality of the rows with a level.

Heater models

The Gefest company produces cast iron stoves for heating rooms with an area of 15 to 120 m². There are five lines of bath heaters in total: PB 00 M and 000 M, PB 01, PB 03, PB 04 and PB 02.

The first series includes four models of cast iron stoves, which provide heat to rooms ranging from 80 to 120 m². The second also includes four models, however, they are capable of heating a steam bath measuring only 35 m². The third consists of ten models. They heat a bathhouse up to 25 m² in size. The latest, but at the same time the most popular series, includes four stoves that can heat a room of up to 15 m².

Let's look at the most popular Gefest models from each line separately.

PB 00 M I 000 M

This category includes four models with increased power that can heat a large room.

- PB 00 M. The dimensions of the stove are 117x73x110 centimeters, weight - 700 kilograms. A device with a power of 35 kW is capable of heating a bathhouse up to 80 m² in size.

- PB 00 MS. This model is similar in power to the previous one, however, it is larger in size and weight. Its dimensions are 117.1x95x120 centimeters and its weight is 720 kilograms. Both units have a 20 cm cross-section for the chimney outlet.

- PB MS and M. These units are designed for operation in premises with an area of 120 m², respectively, they have greater power - 45 kW. Their weight is 950 kilograms, however, the dimensions differ. The PB MS oven has dimensions of 138x72x110, and PB M - 138x92x120 centimeters.

This series also consists of four models, however, their performance is much lower - 18 kW, but it is enough to heat a sauna with an area of 45 m².

- PB 01 M. This model is made in soapstone and has some design features, including non-standard steam movement. The dimensions of the stove are 71x49.5x88.7 centimeters, and the weight is 350 kilograms.

- PB 01 S. The unit is equipped with a mesh heater and has a removable portal, thanks to which the owners have the opportunity to heat the sauna stove from the next room. The design allows you to lengthen the combustion tunnel by 11 centimeters, as it has special inserts that come complete with the main elements. The oven dimensions are 80x60x96.7 centimeters.

- PB 01 MS. This stove allows you to heat a large steam room in the shortest possible time, as it has a niche with a capacity of 300 kilograms of stones.

The series devices are suitable for heating rooms of 35 m². Despite the presence of ten models, only three are in particular demand.

- PB 02 M. Thanks to its design features, this model can heat two rooms - the bathhouse itself and the adjacent room into which the fuel tunnel leads. The unit requires a full brick finish, which is mandatory for this stove. The basic set also includes a glass door for the firebox, resistant to temperatures up to 1200 degrees. The dimensions of the sauna stove are 64.5x45.8x85.5 centimeters.

- PB 02 S. This device is equipped with an open type heater. The peculiarities of the internal arrangement of the walls contribute to freer convection of warm air between the stones. This significantly increases heat transfer and ensures uniform heating of the steam room.

- PB 02 MS. The unit is excellent for both creating hot air at a high level of humidity for a steam room, and for providing completely dry air necessary for a sauna. Its specific gravity is 300 kilograms.

Sauna stoves of this line are designed for use in rooms up to 25 m². It, like the previous one, consists of ten models, several of which are the best-selling.

- PB 03 M. This unit is capable of heating a bathhouse in literally 15-25 minutes. The temperature reaches its maximum level within an hour after heating. The design of the model is quite simple, which allows the owner to cover it with brick himself. The dimensions of the oven are 59x41.8x75.5 centimeters, and the weight is 195 kilograms with an empty box.

- PB 03 S. This device has an open type mesh heater. Design features allow you to extend the remote fuel pipe, which is very convenient and practical. The weight of the sauna stove is 205 kilograms. The combustion chamber door is completely sealed.

- PB 03 MS. The model provides very fast heating of the room due to the special structure of the heater. The minimum weight of loaded stones is 200 kilograms, after which the weight of the product will be 400 kilograms. The size of the stove is similar to the previous one and is 70x50x85.5 centimeters.

The most popular series is Gefest PB 04. All models are designed for use in bathhouses up to 15 m² in size, as is known, this is the most common size of such a room in Russia.

- PB 04 M. A wood-burning stove with a closed heater can heat both the bathhouse itself and the adjacent room. It can work in bath and sauna mode. The wood-burning unit should first be lined with bricks. Weight is 110 kilograms.

- PB 04C. The device is equipped with an open heater; its design facilitates rapid heating of the bath, eliminating cold zones. The elongated combustion chamber allows you to warm up the adjacent room. The firebox channel has additional inserts that allow it to be extended by several centimeters. The weight of the unit with an empty stone box is 125 kilograms.

- PB 04 MS. The model has a built-in steam generator, which ensures the stove operates in two modes: bath and sauna. The heater has a capacity of 150 kilograms. The weight of the product with a full heater is 270 kg.

offers customers furnace equipment for heating rooms from 15 to 120 m³. There are four categories of Hephaestus bath heaters.

Design of the Hephaestus stove-heater

| Category | Description |

| PB 00 M and 000 M | These are cast iron sauna stoves. The line includes 4 models designed for heating rooms from 80 to 120 m³ |

| PB 01 | This series includes 4 models. This cast iron stove can heat a steam room with a volume of up to 35 m³ |

| PB 03 | The series includes 10 models, but only three of them are in demand. Such sauna stoves can heat a room with a volume of up to 25 m³ |

| PB 04 | This is the most popular line, consisting of 4 models. Such production devices are capable of heating a room with a volume of up to 15 m³ |

One of the most popular models is Hephaestus PB 03 M. With its help, the air is heated in a maximum of 20 minutes. In less than an hour, maximum heating is reached. Model PB 03 C is equipped with an open mesh heater. It differs from other models in having a sealed combustion chamber door.

Hephaestus PB 03 MS is equipped with a unique heater, thanks to which the air quickly warms up. "Technolit" produces models from the PB-03 series: PB-03 PS, PB-03 "Panorama", PB-03 C, and also produces other cast iron stoves from all other series.

Technologies for laying a brick furnace and lining a metal firebox

A brick stove in a country house, in a country house or in a private bathhouse always means comfort, warmth and rustic aesthetics with romantic evenings by the hot fire. Such a stove will heat you even in places far from civilization with its gas pipelines and electrical communications, and will allow you to save a lot on utility bills. If it is impossible to build a brick building, even lining a metal stove with brick will give an excellent effect. Its environmentally friendly warmth will add health and longevity, like our grandfathers and great-grandfathers in ancient times.

Which is better - brick or brick lined?

Before installing a brick stove in a house or bathhouse, the question arises, what is the best way to do this - build it out of brick right away or cover an existing metal one? Each of these options has both its pros and cons:

- Laying a brick stove provides a longer cooling period after the fire goes out and a long service life - the brick does not burn out the way that can happen with metal over time. But its design requires the participation of an experienced craftsman in the construction, as well as more complex chimneys.

If you have a metal stove, especially a steel one, which cools much faster than a cast iron one, you can line it with bricks to increase the heat capacity and maintain air humidity that is comfortable for breathing. But as experience shows, such a move is beneficial for a very small room (bathhouse) and in the case of a long stay in it - longer than one day. Such a fireplace will take both a long time to cool down and a long time to heat up, not immediately warming up the cold house, and for a visit to the dacha in winter for just one day, such inertia is useless.

INTERESTING! Using a ready-made metal stove with a brick lining will save fuel due to long-term temperature retention and the secondary combustion function that modern fireboxes are equipped with.

Preparatory work

Regardless of which method of constructing the furnace you choose - building from brick or covering a metal device with brick, you will first need to make preparations: properly arrange the installation site and select the materials necessary for the work.

Preparing the site

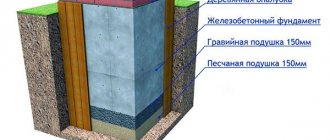

A brick structure usually has quite an impressive weight, so any technology for laying a brick oven necessarily includes the construction of a stone or brick foundation. This is also done to ensure better fire safety. The dimensions of the foundation should usually exceed the length and width of the future masonry by 10-15 cm.

You can build a suitable foundation in one of the following ways:

- A solid foundation implies the construction of a pedestal on which the rest of the structure will be supported. This work is carried out in several stages:

- Construction of a stone “pillow” in the ground - the base of the foundation. To do this, a hole up to 25–30 cm deep is dug in the ground, which is filled with crushed stone and waste bricks, and then filled with a solution prepared from grade 300 cement mixed with sand in a 1:2 ratio.

- The cabinet itself is laid on top of a well-dried base in 2 layers of brick.

- A columnar foundation means the construction of several columns made of brick or the installation of ready-made ones made of concrete:

- After marking the places where the posts will stand, you need to dig holes for them 40-50 cm deep.

- The holes are first filled with river sand to about ¼ of the depth, and then, similarly to what was described above, they are filled with crushed stone below ground level at about 8-10 cm and filled with cement mortar.

- Brick columns are laid out while constantly checking their position with the level. When installing concrete pillars, their bases are concreted.

- A concrete slab, channel or brick platform is installed on top when there are no empty spaces between the pillars.

IMPORTANT! When building a cabinet or columns for the base of the stove, do not forget about waterproofing both the “bottom” of the structure, which directly touches the ground, and the places where the main brickwork begins.

Selection of materials

To lay a brick stove, use simple or special stove bricks, which can be:

- Ceramic;

- Silicate;

- Full-bodied clay;

- Fireproof (or “fireclay”).

Ceramic and silicate options are usually used for cladding, and for lining a metal stove with bricks, building a firebox, chimneys and pipes - solid clay, which heats up well, can withstand temperature changes from low to very high, is strong and moisture-resistant.

ATTENTION! If you are going to use coal or gas as fuel, the combustion temperature of which is slightly higher than that of firewood, then it is better to use refractory bricks for the firebox. It is created from fireproof fireclay clay and can withstand up to 1500-1800 0 C.

You can also use one that has already been used. In this case, it must be especially carefully cleaned of the remnants of the old solution.

How to cover a metal stove

Lining the stove with bricks begins with marking the perimeter of the future structure. In this case, a distance of 10 cm between the metal base and the laid out wall is considered optimal. If it is larger, then most of the heat will go to heating this distance, and the wall will warm up more slowly. A smaller gap shortens the life of the metal.

Solution

The masonry mortar can be prepared in one of the following types:

- From cement mixed with fireclay clay,

- Made from cement mixed with porcelain tile adhesive,

- Made of clay and sand.

Old masters prefer clay mortar. There are a great many types of clay in nature. Each of them has its own properties, so the proportions of the composition will be different in each case. If there is too much clay, the dried composition will crack, and if there is too little, it will not set well. For the sample, you can prepare a solution in which sand and clay are almost equal and dry it. The results of this experiment will indicate what changes need to be made.

INTERESTING! Modern technologies make it possible to use the simplest solution - a ready-made “kiln mixture” prepared on the basis of red clay.

Installation

The work is carried out taking into account the following rules:

- It is better to soak the brick in water in advance, this will increase the adhesion of its surfaces to the solution substance.

- The masonry is made half a brick thick, starting from the corner of the structure. We start the first and each odd row with a whole, each even row with ¾.

- We completely fill the seams with mortar, and remove the excess immediately.

- We check the parallelism of the rows with a level, and the verticality of the walls and corners with a plumb line.

- It is worth leaving holes here and there to ventilate warm air and warm up the room faster.

- Be sure to leave an opening in front of the firebox door for maintenance.

- Masonry stops at the level of the heater.

Do-it-yourself stove laying

Laying a brick stove can be a real art in the presence of an experienced stove maker who has not only the skills of proper laying, but also the ability to design brick products.

Design

The design of the stove can be different and depends on your wishes and its purpose:

- “Dutch” can be used purely for heating. It takes up little space and is equipped with a ducted, ductless or combined chimney.

- In the “Russian” you can cook food and bake pies, as it is equipped with a stove and oven. It also has a bench located above the firebox and a channel chimney system.

- The “Swedish” with a couch or fireplace has a stove, an oven, a section for drying mushrooms and fruits, as well as a complex chimney system.

Correct masonry

The mixing of the mortar and the laying itself are carried out similarly to the case of lining a metal firebox. Here, for greater strength and accuracy of the structure, you can use metal corners and so-called “studs” with a diameter of 16 mm. With their help, both the internal frame and the entire external finish are formed.

ADVICE! When the width of the masonry is no more than 1 m, to create perfectly even seams, you can use iron rods with a square cross-section (pre-lubricated with machine oil), on top of which the mortar and a new row are placed. Then the rods are carefully pulled out without further settling of the laid row.

When installing the pipe, you should not forget that the distance from it to the elements of the rafter system of the house should be at least 15 cm.

Design

Maximum creative abilities will have to be used by those who lay brick stoves with aspirations to architecture and style. Here are the possible:

- Arches,

- Columns,

- Curly elements and much more.

To lay out the arches, you can use templates cut out from plasterboard according to pre-prepared drawings. Shaped brick elements can be cut using a grinder.

Desire, imagination and a little knowledge will help you create a hot miracle in your home - a brick stove based on ancient models, decorated in a modern style. All that remains is to insulate the house itself - and you will be provided with warmth and comfort in any weather.

Video: lining a metal stove with bricks

Describe your question in as much detail as possible and our expert will answer it

Cast iron stoves Hephaestus for rooms from 45 to 120 m

The stoves included in this group are characterized by higher power ratings; they weigh quite a lot, but are also able to effectively heat large rooms:

- PB 80 M (weight - 700 kg, dimensions - 1171x726x1100 mm). Productivity - 35 kW, heated room - up to 80 m³.

- PB 80 MS (weight - 710 kg, dimensions - 1171x950x1200 mm). The technical characteristics are completely identical to those described above. The cost of such a bath unit is approximately 260,000 rubles, the same as the 80 M model.

- PB 120 M (950 kg, 1200x926x1382 mm).

- PB 120 MS (950 kg, 1100x726x1382 mm). This model, just like the 120 M, is capable of effectively heating baths with an area of up to 120 m³. This is due to the fact that the equipment has high power - 45 kW. The difference between m and ms is in the dimensions and external design of the case. Cost - 300,000-360,000 rubles.

Step-by-step instruction

Forming the base

In order for a brick-lined sauna stove to be strong and reliable, it is important to lay the foundation correctly. The strip foundation is considered the easiest to assemble and install. To equip it, the wooden floor elements in the house are first dismantled, after which a trench is dug, the bottom of which is covered with a sand-crushed stone mixture.

Everything is compacted well and watered. The next stage is concreting the foundation. For the strength and reliability of the structure, it is recommended to additionally lay a reinforcing mesh into the foundation before pouring it. The solution is then left to dry. Until the base is completely dry, further work is not recommended.

Brick cladding

Since ready-made stone cladding for Hephaestus stoves made of soap chloride is quite expensive, you can choose a more economical option and cover the structure with brick or natural stone. In this case, the following recommendations should be taken into account:

- the distance from the convection openings to the wall must be at least 50 cm;

- the body is designed specifically for cladding work;

- a brick-lined stove can be lined with a heat-resistant ceramic form, granite or marble;

- When carrying out work, you need to use ready-made mixtures, which include fireclay clay.

Installation and brick lining of the Hephaestus cast iron stove does not cause any difficulties at all, so you can do the work yourself. Naturally, all this is possible only if the basic requirements of the manufacturer are met and the master has minimal construction skills.

What else is the highlight of Hephaestus?

Economical - The stoves are designed with two combustion chambers, the first is the main firebox, the second is the gas afterburning chamber, making the efficiency higher than that of stoves with only one firebox. Fresh heated air enters this afterburning chamber along the technological path and the gases that have not burned out in the furnace are burned out. The afterburner also allowed Hephaestus to meet European standards and be in demand in Europe.

Factory warranty - Thanks to high-quality materials and successful design, the factory is confident in its furnaces and provides a 5-year warranty on the product, and an estimated service life of more than 30 years, with proper operation.

Door with glass - If you purchase a stove with a door with glass, keep in mind that special ceramic glass from the German company Robax is installed at the factory. The door itself, like the entire oven, is made of cast iron. An air control valve is located under the glass; it regulates the air supply to the firebox.

Remote combustion tunnel - All models come with a distance of 200 mm from the door to the firebox. If necessary, you can purchase an extension of the combustion tunnel (it is called a combustion tunnel adapter) with a width of 100 mm, if you have a wide ceiling and 100 mm is not enough, then by purchasing another such element, you can lengthen the portal by 200, these elements are joined to each other and so This way you gain the desired length.

Equipment - All stoves are equipped with a starting cast iron chimney element, 234 mm long (working size 111 mm). The first chimney pipe is always the most thermally loaded, and made of cast iron, it lasts as long.

Convection operating scheme - Hephaestus stoves heat the steam room not only by thermal radiation, but also by convection. Regardless of whether you line the stove with brick or buy it in stone, the design of the stove provides convection spaces; they help remove heat from the walls, cooling them and, as a result, the air heats up faster.

Furnace lining – factory lining of furnaces is made only from natural stone from Karelia and the Urals, soapstone and coil stone are used. Both stones are volcanic rock, confidently withstand temperature changes when cold water hits heated surfaces, the stone does not crack or fly into fragments.

According to their characteristics, the stones differ primarily in color, one is green, the other is gray. Serpentinite, also known as coil, is more durable in its structure and, as a result, lasts longer and this point is reflected in the form of a higher price. In terms of heat capacity, soapstone chlorite is ahead of the coil, but since the volume of stone in cast iron stoves is significantly less than the bricks used in a Russian stove, this volume of stone will not retain heat in the steam room for a long time, so this plus is not significant.

There is also a difference in the technical properties of the stone, but these points primarily affect the processing of the product and for the common man they are also not significant. In general, choose the color and service life of the stone.

Functionality - according to operating experience and testing results, the Hephaestus stove heats the steam room to 80 degrees in 40-60 minutes. In this case, the stove operates in forced mode, i.e. You open both dampers - one on the door, the second on the chimney and burn with medium-sized dry firewood, in this case you effectively use the available firewood.

Wet firewood does not produce as much heat as dry firewood. Large wood burns longer, but produces less heat; it is better to use it to maintain the temperature in a heated steam room. After you have warmed up the steam room, you need to switch the oven to economy mode, i.e. close the air supply on the door and slightly cover the damper on the pipe, in this mode the stove uses wood economically and maintains the temperature in the steam room.

Hephaestus sauna stove with closed heater

This line of stoves is marked with the mark ZK; it differs from all other stoves by the presence of a cast iron lid that covers the heater. This gives the effect of finer and heated steam. This modification of the stove is recommended for bathing gourmets.

Assembly of Hephaestus furnaces

The assembly process is described in detail in the accompanying passport for the stove. Everything was assembled without bolted connections according to the assembly diagram; there are only 19 oven elements (in the PB 04 oven). During assembly, all joints and grooves are coated with heat-resistant sealant. The resulting design is confident and rigid.

Hephaestus PB-03

Hephaestus PB-03.

Photo by TechnoLit Cast iron sauna stoves GEFESTUS are made of alloy cast iron with parts up to 40 mm thick. The unique design of the stoves makes them one of the most reliable. The trapezoidal-shaped heater, which has no analogues , distinguishes the “GEFESTUS Classic” model from other GEFESTUS series.

The special shape helps to heat the charge over 500⁰C in a short time - only at this temperature a light, finely dispersed steam is obtained, which is extremely important for creating the “Russian bath” mode in the steam room. Convection fins on the side walls increase heat transfer from burning wood to the steam room. Due to this, the stove, despite its considerable thickness and weight, quickly reaches the soaring mode.

- Purpose

- Material

- Country of origin and manufacturer

- Firebox

- Kamenka Mass of stones

- Recommended length of firewood

- Chimney diameter

- Steel thickness

Purpose

The Hephaestus cast iron bath stove is a high-tech product designed for heating a steam room, with the possibility of long-term generation of high-quality fine steam in the “Russian bath”, “dry air sauna” or “mixed” modes , which allows you to obtain the most comfortable combination of temperature and air humidity to create a microclimate for your steam room. The oven is intended for individual (non-commercial) use.

Material

Country of origin and manufacturer

Manufacturer: Techno Lit, country: Russia.

Firebox

The design of the stove is designed for installation in a steam room with the firebox exiting to the adjacent room.

Cast iron stove Hephaestus PB-03. Photo TechnoLit

Kamenka

Mass of stones

40 kg. It is recommended to use stones from jadeite, gabbro-diabase, crimson quartzite, peridotite, soapstone, etc.

Fuel

It runs on solid fuel - wood.

Recommended length of firewood

Chimney

Chimney diameter

Soapstone lining for the Hephaestus PB-03 stove. Photo TechnoLit

Housing material

The body is made of heat-resistant cast iron.

The stoves are supplied with a stainless steel ash box.

To increase the heat-accumulating mass in the stove heater, it is recommended to place special cast iron castings - Hephaestus cones - in 1 layer at the bottom of two recesses.

Steel thickness

Door material

Heat-resistant cast iron, without glass insert.

Steam room volume

The maximum volume of a steam room is 25 m3.

Power

The combination of a massive cast iron heater-evaporator and the high thermal power of the Hephaestus furnace (18 kW) allows you to obtain a wide range of comfortable microclimatic conditions.

Hephaestus PB-03 in coil lining. Photo TechnoLit

Dimensions

- Width - 410.

- Depth - 520.

- Height - 605

- Removal of the portal - 200.

Built-in water tank

Heat exchanger

Location

Guarantee

The warranty period is 5 years from the date of sale, but not more than 5.5 years from the date of shipment. If the owner discovers manufacturing defects during the warranty period, the manufacturer undertakes to repair or replace the defective part free of charge. The warranty does not cover the grate and flame arrester. Also, the warranty does not apply to ovens used for commercial purposes; used in non-original stone cladding; operated without a damper installed in the chimney. In the absence of a sales mark in the product passport, the starting date of the warranty period is considered to be the date of manufacture.

Serpentinite is used for lining the Hephaestus PB-03 furnace. Photo TechnoLit

If the passport is lost, the consumer loses the right to warranty repair of the stove.

The service life of such furnaces is more than 30 years , but if in the distant future the furnace fails, you can replace an inexpensive part in it, rather than the entire furnace.

Features/advantages, recommendations

- GEPHESTUS cast iron sauna stoves are 2-chamber combustion units equipped with a pyrolysis gas afterburning system, which quickly heats the heater with a charge or switches the stove to a long-term burning mode.

- The adjustable length of the combustion tunnel will eliminate problems when passing through a wall of any thickness.

- The oven belongs to the category of devices with a burning surface; the maximum temperature of the surfaces reaches 700º. The minimum distance of the vertical surfaces of the furnace to flammable materials should be 500 mm, the minimum distance above the furnace is 1200 mm.

- There must be free space between the protective barrier and the floor, as well as the ceiling . If the floor in front of the stove is made of flammable material, then the fire-resistant space should extend to a distance of 100 mm. on both sides of the door, and at a distance of 400 mm. in front of the door, a metal sheet with a thickness of at least 1 mm is used as a protective barrier. The side or back of the oven should be at a distance of 50 mm. from a brick wall.

- The distance of uninsulated pipes connecting the stove and chimney to combustible materials should be 1000 mm. in the horizontal direction and 1200 mm. in the vertical direction.

- The safe distance of chimney modules to flammable materials should be 100 mm, the insulated part of the pipe should be 400 mm. below the ceiling or ceiling.

- The stove can only be installed in a wall made of fire-resistant material (brick, concrete, etc.).

Outer casing type

Possibility of covering with stone or brick

The most efficient operation of the stove and the possibility of obtaining any modes in the steam room are ensured by the original “Hephaestus” cladding made of natural stone : soapstone, coil, serpentinite. It allows you to regulate the intensity of the convection flow of hot air from the maximum heating mode (with the door on the lining open) to the complete stop of convection, has extremely soft thermal control and high heat-accumulating properties to maintain the temperature regime.

Video

What is interesting about Hephaestus stoves for a bath, the main advantages

The most valuable thing about Hephaestus stoves is the body made of thick alloy cast iron with an extremely long service life. Now in stores there are stoves made of black and stainless steel; in 90% of cases, their lifespan is limited to 8-10 years, if you steam once a day off. Cast iron Hephaestus lives without problems for 30 years or more, with proper use.

How is this ensured?1. The actual wall thickness is from 10 to 60 mm; having such a thickness of the firebox walls, in these furnaces there are no such concepts as *started the firebox*. Iron stoves have a thickness from 2 mm (chromium steel with 13-17% chromium) to 10 mm (regular black steel). 2. The production uses cast iron grades SCh20-25 and ChH10, which combine such properties as increased ductility, resistance to corrosion and reliable resistance to temperature changes.

When cold water gets on the furnace elements, these materials can withstand temperature changes without any problems.3. The furnace elements are manufactured using a tongue-and-groove system, which minimizes problems with thermal deformations; the design does not have connections in the form of nuts and bolts, as well as welds.

Types of bricks

To choose the right material, you need to take into account certain nuances. An iron stove heats up significantly during operation, so it is recommended to choose one of the following types of bricks:

- Refractory. This material is the most optimal in terms of operation, however, it is also the most expensive. This is the most preferred type of brick.

Refractory brick is best suited for cladding, but it is expensive Source selmo.com.ua

- Silicate. It is not recommended to use an iron stove for cladding, since the components included in the composition react poorly to elevated temperatures. Therefore, already laid brick needs additional finishing.

Sand-lime brick is not often used for finishing, but it is the most budget option Source ytimg.com

- Red . Due to its high heat resistance and excellent thermal performance, this brick is often chosen for organizing a screen. Solid products are considered the best option, while hollow bricks are not recommended because they both heat up quickly and cool down quickly. This material has an attractive appearance and, when installed correctly, can decorate the interior of a bath room.

Attention! If wooden elements are located near the brickwork, they must be treated with protective compounds to prevent the surfaces from spontaneous combustion.

Red brick will be an ideal solution for finishing a stove Source t-spectr.ru

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

Mini oven

The Hephaestus gas mini-stove is perfect for a summer house, a country house, and also for use on hiking trips. It can cook anything that can be cooked in a full-size oven. Its advantage is its small size. Hephaestus has been producing gas mini-ovens for many years.

They are available in three versions: a hob, a gas oven, as well as a combined version of a gas hob and an electric oven. The gas oven has a usable temperature range of 50-260 degrees. This household appliance has many advantages:

- practicality;

- compactness;

- durability;

- safety;

- easy to wash.

These gas stoves can be suitable for even the smallest kitchen. They are covered with heat-resistant enamel, which can be easily cleaned from grease and various contaminants. They also have a “small flame” function, which allows you to simmer food over low heat. Another convenient addition is the adjustable legs, which allow you to fix the device at the required height.

The gas oven is equipped with a double glass door, due to which the heat remains inside the oven, and the outer surface does not heat up.

Clients about our work

Andrey, 06/20/2014

First of all, I would like to note that the store works with all payment methods. This is extremely convenient. The choice of products is extensive; you can consult with specialists on all questions. Delivery was free for me, everything was done efficiently, on time.

Sergey Ivanov, 08/09/2014

I finally decided to take on the arrangement of a long-built bathhouse on a summer cottage. After some deliberation, I ordered this stove and was satisfied. We haven’t used it much, but so far I’m happy with everything. The steam room was designed to be quite spacious, and the stove copes with its task well, no problems with heating.

The sellers are competent - there were no arguments like “Take another model,” the communication was calm and knowledgeable, especially considering the fact that I had previously studied the market. The order and delivery were processed quickly, I was also pleased with the delivery itself - everything was on time, as agreed. Thank you!

Galina Komkova, 08/26/2014

I ordered a Hephaestus PB-04Optima bath stove from this store. I want to say thank you very much, I liked everything very much! A very polite operator answered my call to the company and gave detailed advice on the cost of the stove and the conditions and delivery time. The order was processed promptly, the delivery was also pleasing - everything was done quickly and on time! Moreover, the stove was delivered from Moscow to Chita. I also liked the stove itself - reliable, beautiful and looks great in my new bathhouse.

Polina, 08/16/2014

The store was recommended by friends. I was pleased with the choice. The old stove had fallen into disrepair and was long overdue for replacement. The new one fits perfectly into our usual environment. In the store, I especially want to note the friendliness of the staff. The manager answered all my questions in such a way that there was no longer any doubt about which stove to order.

Briefly about the commander in chief

Experienced craftsmen say that the lining of the stove in the bath should be half a brick. This is the most suitable option. You can install a damper in a whole brick, but this structure will take much longer to warm up, and the foundation for this wall will require a more massive one.

The entire technological process consists of the following stages:

- preparation of materials;

- choice of location;

- foundation organization;

- laying the base;

- choice of brick and laying method;

- preparing bricks for cladding;

- furnace lining;

- first firebox;

- decorative finishing (if required).

Brick cladding of a sauna stove is needed not only for beauty. This event can significantly improve the atmosphere in the steam room. Moreover, the work is carried out with low material costs and with high quality, if you correctly follow the masonry technology and entrust it to specialists.

Ratings 0

Brick lining of the Hephaestus furnace

— Any Hephaestus stove weighs up to several hundred kilograms, plus the weight of the lining, which means you need to be sure that its weight will not break the floor; in a good way, you need to pour a separate foundation for such a heavy weight.

— For long service life of cast iron, it is necessary to maintain the firebox ventilation built into the stove design. Convection cools the walls of the firebox and the cast iron overheats less and burns out less. This is ensured by the presence of a distance between the brick and the walls and the mandatory presence of special holes in the base of the masonry to supply air to the walls.

Hephaestus stoves lined with brick are cheaper than those with stone cladding and a brick appearance; for greater beauty, you can additionally cover the brick with nice ceramic tiles; there are many options for tiles and it will look very good.

Advantages and disadvantages

Gefest sauna stoves have many advantages. The main one is the ability to achieve the required temperature in the room in a short time. At the maximum indicator, the heating level of the furnace body reaches 7 thousand degrees, and the smoke reaches 3.5 thousand.

Additional advantages of the units:

- Economical fuel consumption. This is ensured by the presence of a flame arrester in the design, which ensures rapid circulation of air inside, rather than releasing it directly into the chimney. As a result, the heat is retained for a long time and there is no need to add firewood to the firebox to maintain the desired temperature.

- The ability to produce “soft” steam, for which the Russian bath is famous.

- Long service life if the operating rules are followed.

- Presentable appearance.

- Resistance to any mechanical damage due to the strength of the material.

- Compactness.

- Availability of temperature control function.

The units also have disadvantages:

- quite high price;

- the need to think about lining the stove, since cast iron cracks if hot water gets on it;

- heavy weight of the units, which can lead to problems with transportation and installation.

Attention! When installing Hephaestus stoves, it is necessary to leave free space between the floor, ceiling and protective barrier. Installation of products is allowed only in walls made of fire-resistant materials, for example, concrete or brick. Wooden buildings require the installation of special protective screens.

Characteristics

Gefest company is considered one of the best among domestic enterprises. For many years, the brand has been producing cast iron sauna stoves and related stove products. Russian bath stoves from this company occupy a leading position in their niche.

The units have a high level of thermal conductivity and are manufactured using a special casting technology, with the help of which the base of the original product has optimal quality without any damage.

Gefest sauna stoves are available in two modifications: with coil lining and with mesh for stone laying.

Gefest company is considered one of the best among domestic enterprises. For many years, the brand has been producing electric and gas stoves, air purifiers and many models of built-in appliances for home and garden. Russian bath stoves from this company occupy a leading position in their niche.

The units have a high level of thermal conductivity and are manufactured using a special casting technology, with the help of which the base of the original product has optimal quality without any damage.

Gefest sauna stoves are available in two modifications: with coil lining and with mesh for stone laying.

with mesh

with cladding

Masonry mortar

The inner surface of the brick lining of the stove can heat up to 350-400 degrees, so a regular cement-sand masonry mortar is only suitable for the screen of a sauna stove, spaced at least 7-8 cm from its body. In other cases, you need to use a clay-cement mortar, because stove clay is fragile and hygroscopic.

To prepare a solution for lining a stove with bricks, you must first sift the dry clay through a sieve with a mesh size of 1.5 mm. Next, the fat content of the clay solution is adjusted:

- A test portion of clay is mixed with mountain or ravine sand of fraction up to 1 mm in a 1:1 ratio by volume.

- Cover with water and knead until the dough becomes thick.

- Roll into a rope (sausage) approx. thick. 2 cm and length approx. 30 cm.

- Allow to dry not in direct light for 1-3 hours at a temperature of 30-15 degrees, respectively.

- Bend the tourniquet into a ring.

- If the rope is deeply cracked in several places or broken, the initial (base) solution is thin, you need to add more clay.

- The tourniquet bent smoothly or only the dried crust cracked - the base solution is greasy, you need to add more sand.

- The tourniquet cracked more or less evenly along its length to no more than 1/4 of the thickness - the fat content of the base solution is optimal.

A test portion of the working solution is prepared by replacing 1/8-1/3 of the clay with cement from M400; Usually they give 1/5 to start with. The dry mixture is gradually mixed with water, kneading until the cream becomes thick. Then check the solution for fluidity: dip a clean trowel into it and remove it, holding the nose down. There are 3 possible cases here:

- The solution drains, leaving stains on the trowel or completely exposing the metal - there is a lot of water;

- The solution drains, leaving a lumpy layer with lumps on the trowel - there is not enough water;

- The solution drains, leaving a thin, even layer of water in moderation.

Now you need to check the solution for stickiness (adhesion); This is important for laying half/quarter bricks. Take a brick, dip it in water, and apply a 3-5 mm layer of solution onto its bed with a trowel. Immediately take a dry brick and place it on a layer of solution, without pressing down, immediately lift it. The mortar should not stretch behind the dry brick; sticking of several small, match-head-sized lumps is acceptable. If the mortar follows the dry brick, the proportion of clay in the base mortar must be reduced, respectively. increase the proportion of cement.

Next, the dry brick is again placed on the mortar, tapped with the handle of a trowel and left for 5-6 minutes. They try to lift it, the wet brick should rise with it. If it remains lying or gradually comes off while hanging, you need to add more clay in the base solution and, accordingly. less cement.

Tips for use

After purchasing a sauna stove, some questions arise regarding use, the answers to which we will give below.

Installation

Gefest stoves are sold disassembled, which simplifies the delivery process with subsequent assembly and installation.

It should be noted that the design of the units is so simple that it can be installed independently without turning to professionals.

According to the assembly method, all heater stoves can be divided into two types:

- With lining. To install these models, you will need to connect to the chimney system and prepare a solid surface. This type includes bath stoves in soap chloride, which has medicinal functions. The manufacturing company provides customers with several cladding options, which depend on a particular model.

- Brick finish. Models of this type involve brick cladding. Their body is specially designed for such work. In this case, the appearance completely depends on the taste preferences of the owner.

The second type of stoves is cheaper, since soap chloride is a fairly expensive material.

The device can be covered with either brick or natural stone. When working, you should take into account some features and recommendations of professionals. The distance between the wall and the convection holes should be at least 55 centimeters.

Once the brick lining process is complete, you can cover the stove with ceramic, tile, granite or other heat-resistant material.

Gefest sauna stoves should be heated either with wood or with special fuel bars. Under no circumstances should coal or wood waste be used. It is recommended to heat the unit with hard rocks.

When heated, wood-burning soapstone chloride stoves begin to release beneficial substances that have an aromatherapy effect. Wood-burning stoves ensure even heating of the sauna, which ensures comfort and relaxation.

Installation

It should be noted that the design of the units is so simple that it can be installed independently without turning to professionals.

According to the assembly method, all heater stoves can be divided into two types:

- With lining. To install these models, you will need to connect to the chimney system and prepare a solid surface. This type includes bath stoves in soap chloride, which has medicinal functions. The manufacturing company provides customers with several cladding options, which depend on a particular model.

- Brick finish. Models of this type involve brick cladding. Their body is specially designed for such work. In this case, the appearance completely depends on the taste preferences of the owner.

With lining

Brick finish

The second type of stoves is cheaper, since soap chloride is a fairly expensive material.

The device can be covered with either brick or natural stone. When working, you should take into account some features and recommendations of professionals. The distance between the wall and the convection holes should be at least 55 centimeters.

Once the brick lining process is complete, you can cover the stove with ceramic, tile, granite or other heat-resistant material.

Gefest sauna stoves should be heated either with wood or with special fuel bars. Under no circumstances should coal or wood waste be used. It is recommended to heat the unit with hard rocks.

When heated, wood-burning soapstone chloride stoves begin to release beneficial substances that have an aromatherapy effect. Wood-burning stoves ensure even heating of the sauna, which ensures comfort and relaxation.

Video description

An example of how to line a stove in a bathhouse with brick is shown in the video:

You can finish the masonry at the level of the heater, bringing it only to the top of the heating unit body. Or you can extend it to the ceiling, also lining the chimney. It depends on the design of the stove, its location and the desires of the owner. You just need to remember to promptly remove the protective film from the structure.

If old bricks were used in the work, the heat shield can subsequently be lined with porcelain stoneware or tiles. If you purchase new material for the work, you can choose a stone of a different color or with a decorative surface, and immediately carry out the masonry with jointing.

Another option for decorative cladding using brick-like clinker tiles Source giropark.ru

Preparation for use

Before using the bathhouse in operating mode, the masonry should be allowed to dry under natural conditions for several days. But even after this, you cannot immediately heat the stove at full power. It is better to use it 2-3 times in test mode, burning one load of firewood, so as not to raise the temperature to the maximum.

Thanks to this, the solution dries well and evenly and adapts to operating conditions.