The stove in the bathhouse is lined with bricks to preserve warmth and comfort in the room longer, as well as to increase the efficiency of the heating device. Often, it is necessary to line a metal furnace that has an external firebox. Such a unit cools down quickly, and during combustion it emits a lot of infrared radiation, which makes staying in the steam room uncomfortable.

It’s not difficult to brick a cast-iron stove yourself; the main thing is to carefully study all the rules and pay attention to the nuances.

Furnace "Gefest" PB-03M under the lining. What and how to cover?

#1 POMA Warn

Dear forum users, good day everyone! We need your opinion, criticism, and expert assessment. I plan to open my own bathhouse this year. We purchased a “Gefest” PB-03M stove for brick lining, and we will talk about it. After reading several reports on this topic on this forum, I realized that the stove can be lined with bricks. But according to some comments from experienced forum members, it is possible at a quarter and in some respects this is even better (warm-up speed, firewood consumption, weight...). I don’t want to put the brick on the end, because in this case something else needs to be done for the exterior finishing. Leaving it unfinished is not beautiful. I know firsthand about new compounds on which finishing tiles can be laid (temperatures up to 1300 degrees), but I don’t have the desire to “drag” the chemicals into the steam room. I also don’t really like (understandably) the moment of ligation with the portal of the combustion channel, it’s exactly the size of a brick floor. All this made me think. My first thought is to take the fireplace brick (4 clean sides) and saw it in half. There is a difficulty here, firstly, I heard in the market that the plant has stopped producing such bricks, and secondly, I want to cut it beautifully, so that even from the inside everything is smooth. It’s a pity to kill 50 bricks with your miter saw for this cut. With a grinder, my circle is 125, which means that it won’t work at once and the evenness will be lost. Second thought, next to me is the GKZ (Golitsyn Ceramic Plant), which has been producing IK-2 (a ceramic product) for a long time, half of a full-fledged slotted brick 250X60X65. In common parlance, “chocolate” (my house is covered with it). Everything seems to be fine here, there is no need to saw, the connection is normal everywhere. And even the fact that almost a pallet of bricks remained from last year (you can put them on the combustion channel portal) also speaks for this. But it is confusing that it is slotted and is not intended for such temperatures. I read here on the forum that it seems like it’s possible, you just need to fill the cracks with coarse sand, but it’s still a mess. I am planning a ceramic chimney Effe2 Domus Above is the opinion, criticism.

#2 jaddd Warn

. Everything seems to be fine here, there is no need to saw, the connection is normal everywhere. And even the fact that almost a pallet of bricks remained from last year (you can put them on the combustion channel portal) also speaks for this. But it is confusing that it is slotted and is not intended for such temperatures. I read here on the forum that it seems like it’s possible, you just need to fill the cracks with coarse sand, but it’s still a mess. I am planning a ceramic chimney Effe2 Domus

Most likely everything will be fine, so do it. Cover it with sand and you'll be fine. As a backup option, you can then cover it with clinker.

And why do you think that brick is not intended for such temperatures? It's not dry pressed. This is sintered ceramic that will withstand 200 degrees and will not be there anymore.

#3 POMA Warn

Why might there be a “backup” option? I just wouldn’t want to paste it over with anything. And another question torments me, why didn’t anyone line the stove with 1/4 brick, as I described? This is perhaps the most confusing thing! Do you have any thoughts about the chimney? You can use these in a bathhouse, no?

#4b>

b>

- Bath builder

- 675 messages

- 338 thanks

Installation of cast iron sauna stove Gefest PB-03 MS

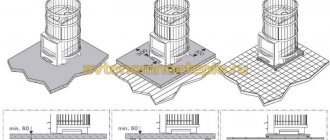

In this article we will consider the installation of a cast iron stove Hephaestus PB -03 MS in a brick portal lined with clinker tiles. This oven was installed on a 200 mm thick concrete slab with double reinforcement.

Before purchasing a sauna stove, you need to make a calculation (it is done relative to the cubic capacity of the steam room), i.e. Length x Width x Height = m³. Each furnace model is designed for a certain cubic capacity and these numbers are in the furnace designation or in the technical data sheet of the product.

Sauna stove parameters:

This stove was taken with a power reserve. At the request of the customer and for safety reasons, the stove was lined with brick. After preparing the opening, we began installing thermal insulation.

Supersil was attached as the first layer Superizol was used as the second and third layers, with the seams glued using Isoboard from Ortner .

LODE Janka F15 and Lode JANKA bricks were used ) were laid on a mixture of Plitonit - Super Fireplace Thermo Masonry according to the dimensions of the stove and the placement of convective channels.

The lower air intake channel is narrowed to a size of 250x130 and is located in the center of the bottom of the sauna stove.

Distinctive features

Hephaestus sauna stoves are a product of the Russian company Technolit. For their manufacture, a special casting technology is used, which increases the thermal conductivity of the models. The company's products are the only bath units, all of whose components are manufactured in the Russian Federation, which allows you to control the process at all stages.

The range of stoves can be divided into the following groups:

with mesh for laying stone

for brick cladding

lined with coil

The presented models differ in the volume of the heated room - up to 45 sq./m and from 45 to 120 sq./m.

The furnaces are equipped with a flame arrester and a secondary gas combustion system. They allow you to maintain the temperature of the stones at 500–700 degrees.

Therefore, the steam is finely dispersed - it is very light and healthy. You can also set the sauna heater to smoldering mode.

Due to the circulation of hot air in the inner chamber, the steam room maintains a high temperature for a long time. All models have a high efficiency of at least 87%, which is ensured by the optimal design of the units.

The furnace firebox has 2 chambers separated by a flame arrester. Fuel gases first move along the side walls, then turn 180 degrees and move towards the outlet along the recesses of the heater.

A unique feature of Hephaestus furnaces is the absence of threaded connections, welds and steel parts in the structure that are subject to rapid wear.

The walls of the units are 10–12 mm thick and are additionally equipped with stiffeners to increase strength. The trapezoidal shape of the heater provides an increase in heating area and heat radiation. The products are equipped with extension cords, stainless umbrellas and a part of the chimney.

The design of the stoves is especially worth noting. They will fit into the interior of a log bathhouse and a classic sauna. The doors are decorated with casting. Models for brick cladding can be decorated with ceramic tiles.

Expert opinion

Lovkachev Boris Petrovich

Bath master who knows everything about steaming

Important! Hephaestus stoves are designed to be fired with wood and special briquettes. It is not recommended to put coal and various debris in them, as this will quickly clog the chimney.

Lining the stove in the bathhouse with bricks

The stove in the bathhouse is lined with bricks to preserve warmth and comfort in the room longer, as well as to increase the efficiency of the heating device. Often, it is necessary to line a metal furnace that has an external firebox. Such a unit cools down quickly, and during combustion it emits a lot of infrared radiation, which makes staying in the steam room uncomfortable.

It’s not difficult to brick a cast-iron stove yourself; the main thing is to carefully study all the rules and pay attention to the nuances.

FAQ

The stones do not heat up in the oven. What is the reason?

Incorrect placement and incorrect choice of stone size. Remove small pieces and stones less than 10 cm in diameter. Provide freely ventilated space between stones. Replace broken stones with larger, undamaged stones.

Why does an unpleasant odor occur when firing a stove?

If the oven is new, there may be residual protective paint on the body. Preheat the oven outside for the first time. A heated stove can increase odors in the air that are not caused by the steam room or stove itself, such as paint, glue, heating oil, spices.

Hephaestus ovens only for Russian steam baths? Is it possible to get other modes, such as a sauna?

The Russian steam bath is the most difficult mode for sauna stoves due to the requirements for a large amount of fine steam. The dry-air sauna mode requires only the heat output of the stove. All Groza and Hephaestus stoves can create both a Russian bath mode and a sauna mode in a steam room, the volume of which they are designed for. To obtain a dry-air mode with a stove in the lining, it is necessary to keep the door open for the water supply during combustion, for intense convection heating

Is it necessary to strengthen the foundation of the bathhouse when installing the Hephaestus stove?

The total weight of the oven when fully loaded ranges from 250 kg to a ton. A thoroughly prepared floor or a separate foundation for the stove is required.

The oven takes a long time to enter mode (gains temperature). What could be the reason?

There are several options. Poorly insulated steam room, low draft in the chimney, low-quality firewood, incorrectly lined with bricks.

Advantages and disadvantages

It is convenient to use a metal sauna stove at home or in the country. It does not require special knowledge in installation, is easy to maintain, heats up quickly and transfers heat efficiently. In addition, the price of the iron stove is affordable and the fuel consumption is economical. But despite the huge number of advantages, a metal device has a number of disadvantages, among which the most significant are:

- Fast cooling. The metal wall does not retain heat for a long time, because the heat capacity of the device is minimal.

- Unsafe radiation. When there is intense combustion, the iron surface becomes very hot, resulting in the release of hard infrared radiation. If the bath area is small, this will negatively affect indoor comfort. And if you are close to the device, you can get burns.

To eliminate these shortcomings and make your stay in the steam room comfortable, it is better to surround the metal stove with a brick wall. In addition to the fact that this option looks beautiful, the lining will increase the efficiency of the heating device, and it will be safe and pleasant to be around the stove. An ideal option for a Russian bath would be to install a Hephaestus cast iron stove, next to which there is a boiler for heating water. The Vesuvius Legend device, which is often installed in large saunas and steam rooms, has similar characteristics. A simplified option for a home steam room are “heat and wash” stoves, the operating principle of which is to constantly add firewood and wash at the same time.

How to drown

For effective operation of Hephaestus stoves, it is important to adhere to the rules for heating them:

- At the beginning of the kindling, the door is kept open, allowing cold air to enter the gap under the cladding, rise upward, removing heat from the convection ribs of the cast-iron walls, and come out in a heated state. A natural draft arises in the air gap, accelerating the movement of air and the heating rate of the steam room. As a result, the air in a steam room is heated in no more than 45 minutes.

- After the stove reaches operating mode, you can close the cast-iron lining door and begin bathing procedures.

- After another 15 - 20 minutes, the cast iron heater with the insert reaches a temperature of over 600 degrees, which allows you to obtain high-quality fine steam.

- To generate a large amount of finely dispersed steam, it is enough to open the lining door and use a ladle to pour water into a heated cast-iron heater with a deposit, quickly creating the desired level of humidity in the steam room.

- To maintain humidity, the door on the cladding is closed, which stops the convection of hot dry air and allows steam to collect under the ceiling into a “steam cake.”

- After an hour, the stove is switched to a long-burning mode to save wood while maintaining a constant high temperature of the heater (by adjusting the draft with slide valves on the stove door and in the chimney pipe).

Further regulation of temperature and humidity in the steam room occurs by combining the simple opening and closing of the blower door and the simultaneous supply of additional portions of water to the heater, due to which fine steam is generated (if necessary).

Materials: what are needed and how much?

To cover a metal stove with your own hands, you need to take a responsible approach to choosing the material so that the brick wall built around the device can easily support the firebox and not crack. It is permissible to use the following brick for lining the boiler:

- Facing red. Great for heat shield. It is recommended to lay solid blocks, but hollow ones are also suitable, however, they will not hold the temperature for a long time, since they are not heat-intensive.

- Fireclay brick. This material is best suited for lining a stove. If you line the wall with refractory blocks, it will not be afraid of even the highest temperatures. The heat capacity of a fireclay block is comparable to red brick. However, this material has a significant drawback - its unattractive appearance. But there is a way out of this situation - after insulation with refractory, you can finish the device with facing porcelain stoneware or other resistant material.

The finishing of a sauna stove will look solid if the walls are insulated with granite or marble slabs. But in order to lay such material correctly, it is recommended to seek help from a specialist who knows all the intricacies of the work. It is important to reliably design device portals. To do this, it is recommended to use a door with fire-resistant glass or made of cast iron alloy.

Step-by-step instruction

Forming the base

In order for a brick-lined sauna stove to be strong and reliable, it is important to lay the foundation correctly. The strip foundation is considered the easiest to assemble and install. To equip it, the wooden floor elements in the house are first dismantled, after which a trench is dug, the bottom of which is covered with a sand-crushed stone mixture. Everything is compacted well and watered. The next stage is concreting the foundation. For the strength and reliability of the structure, it is recommended to additionally lay a reinforcing mesh into the foundation before pouring it. The solution is then left to dry. Until the base is completely dry, further work is not recommended.

Preparation

Before constructing the protective apron, it is recommended to soak the lining brick for 12 hours. To do this, the required amount of material is separated, cleaned if necessary and placed in cold water. This event is necessary to ensure that the blocks do not absorb moisture from the solution during the formation of the order.

How to prepare brick mortar?

The installation of a metal furnace will be reliable if a cement-clay mixture is used as a masonry mortar. Both components are taken in equal proportions and diluted with water to obtain a creamy consistency. To mix the solution well and obtain a homogeneous mass, it is recommended to use a construction mixer. After mixing, you need to let the masonry mixture thicken, and then proceed directly to the masonry.

Cast iron and brick

A small and compact cast-iron stove in a country house, country house, in a bathhouse or steam room is an almost irreplaceable source of heat. It creates comfort and heats the room.

At the same time, an iron stove is always compact and easy to install, and quite quickly heats the room area. But there are also some disadvantages, which we will correct by learning how to line a cast-iron firebox with bricks on our own.

Photo - cast iron in brick

Why do you need to cover metal?

First of all, metal has its own physical characteristics, which influence the comfortable proximity to such a stove:

- It is quite difficult to maintain a stable temperature in a metal firebox. At the same time, this will affect sharp fluctuations in room temperature.

- It is almost impossible to achieve the required air humidity in rooms where such heating equipment is located.

- Low degree of safety, in the sense that heated metal poses a serious danger of getting burns, and sometimes severe ones.

It is precisely in order to eliminate the above properties of a metal stove-fireplace that we will cover it with brick.

Moreover, by using simple masonry, using special material and simple building bricks, we will immediately improve several important indicators:

- Let's increase the heat output of the furnace several times.

- We will reduce temperature fluctuations in the premises.

- We will increase the safety of the stove; now you can even lean against it.

- We will improve the design of the firebox itself and the entire room at once.

And most importantly, you can cover the heating equipment yourself!

Preparation

Before we attack a cast iron stove and cover it with bricks, we need to carry out at least a few works in preparation for the masonry itself.

The first step is to build a good, strong base for the stove. If we are talking about a country house, a bathhouse, where, for example, there is no solid foundation, then we will have to dismantle the equipment and build a reinforced foundation, because the weight of a brick stove is quite large.

Furnace foundation

It doesn’t matter here whether the stove is brick or cast iron; the design still requires a strong base.

Foundation

We can use two types of base for the firebox:

- The foundation is in the form of pillars, the so-called “columnar” foundation.

- Just an ordinary foundation.

The first option involves complex preparatory work and precise calculations, so we will focus on the second option and simply pour a concrete base that will perfectly meet our requirements for installing the furnace.

- Cement, grade 300, durable.

- Sand.

- Crushed stone of medium fraction.

- Fittings.

30-40 cm deep , and install several pieces of cut reinforcement into it.

Advice! Reinforcement is not particularly needed in such a simple and small foundation, but we still recommend its use. It reinforces and binds concrete, increasing its service life.

We make the solution in a ratio of 1 to 2, and try to keep it liquid and fill the entire hole. As soon as the concrete dries, we lay out 1-2 rows of solid brickwork, you can use double sand-lime brick m 150 or solid brick - this will be our base.

Range

The range of Hephaestus stoves is demonstrated on the market in several forms. For example, cast iron units for 45 m baths are popular. The main difference between such stoves is their compactness. The devices are equipped with a short-length remote portal. The decent thickness of the stove walls allows for heat retention.

The positive characteristics of cast iron are the lack of toxicity (harmful components are found in stainless steel and steel). Framing in soapstone prevents the formation of too hot steam. The material is characterized by high thermal conductivity. Warming up of the steam room will be ensured as quickly as possible.

PB 01

The category includes models PB 01M (weight 350 kg) and PB 01S (350 kg). It is possible to increase the telescopic combustion chamber by 10 cm. This feature is achieved by adding special inserts, which are included by the supplier. The company supplies variations in disassembled form. Reconstructing the device on site will not be difficult, as it comes with detailed instructions.