Firewood and coal remain in many regions the most affordable types of fuel used to heat private cottages. However, stove heating is chosen not only because of the low cost and availability of energy, but also because of the low cost of its installation.

Moreover, in addition to many advantages, a stove with a water circuit for heating a house also has a lot of disadvantages. This option is not always optimal. Let's try to understand the nuances of such a heating system.

Advantages of a stove with a water heating circuit

The advantages of this option include:

- Availability and cheapness of fuel (wood, coal);

- Low cost of installation and operation;

- Reliability, durability;

- Independence from power supply;

- The ability to perform several functions (heating and cooking, and factories offer such a variety as a fireplace stove with water heating).

In comparison with the classic version (a stove without a circuit), uniform heat transfer throughout the house and rational fuel consumption are achieved here.

Masonry and brick

Stove makers have always been in great demand. All specialists and craftsmen in this field must follow some important rules:

- For the manufacture of the combustion chamber, it is necessary to use only those materials that have high fire resistance. Open fire can damage even materials such as stone or brick. This can significantly reduce the stability and strength of the entire structure.

- You should not save on laying brick walls.

- Particular attention must be paid to the tightness of the seams. Even a small gap is dangerous to human health, as carbon monoxide can pass through it.

You can equip two chambers, one intended for heating and the other for cooking. This trick will allow you to use a brick heating boiler in the summer.

Disadvantages of a water-heated furnace

The design also has several disadvantages:

- It takes time to warm up before the system begins to dissipate heat;

- A lot of heat escapes through the pipe (low efficiency);

- Risk of fire if the device is not used correctly;

- The stove is capable of heating only a one-story dwelling, within 150 m2.

Important! If the premises are not heated in winter, it is advisable to fill the system with antifreeze instead of water. This will prevent possible freezing and rupture of pipes.

Positive and negative aspects of stove heating in a private house

In most cases, stove heating is installed if necessary, in the absence of main natural gas. But heating with a stove has its advantages and disadvantages, which it would also be nice to know about.

What are the disadvantages?

Negative points include:

- It takes quite a long time to heat up the stove, and therefore the premises. This occurs due to prolonged heating of the walls and coolant in the system.

- Not very high efficiency of a brick building. To increase it, you have to build a higher chimney, make it a labyrinth type, so that the heat remains inside the structure longer.

- A brick stove occupies a fairly large area, but only on such a scale is it capable of heating several rooms at the same time.

- Unlike heating with natural gas, the stove must be supervised throughout its entire combustion, since brick options require constant addition of fuel. Long-burning cast iron stoves are an exception, since firewood is added once per burning session.

Positive points

Stove heating also has many positive qualities, which are often decisive in choosing it for installation in a private home.

- Autonomy, which means reliability. The house will always be heated, even if the electricity and water are turned off.

- Affordability of construction and operation of the structure.

- Cost-effectiveness in purchasing fuel and no bills for the main gas or hot water supply, which, unfortunately,

- Easy to operate - the oven does not require programming, and if problems arise, they can be eliminated independently, without the involvement of specialists.

- Since the stove does not require communications for its operation, it can be installed or erected in a house located in any region and locality.

Material

Typically, brick is used in the construction of stoves. It is characterized by a number of features. This design is heavy (from 1.5 to 10 tons) and requires a prepared, solid foundation. Due to the massiveness of the unit, a lot of usable space in the room is lost.

The optimal installation option is when the house is still under construction. In this case, it is easier to think through everything and optimally arrange the circuit. Designing in already finished housing creates difficulties: you have to create a solid foundation.

A brick stove with water heating takes a long time to heat up, but also releases heat more slowly. Thanks to this, the rooms are kept warm for many hours.

An alternative to brick is steel; potbelly stoves are made from it. The nuances of such designs:

- Light weight (100-300 kg) and compact, do not require much space, they can be placed on a regular floor;

- They are installed not only at the construction stage, but also in completed houses;

- The body heats up quickly and quickly releases heat, so the owner will have to heat it more often.

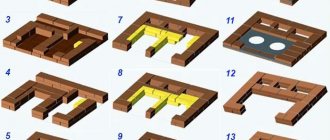

Algorithm of actions: step-by-step instructions

In order for a stove with a water heating boiler to provide maximum heat transfer, it is necessary to design it correctly: follow the order of the masonry and take into account stove construction technologies.

Foundation

The type and thickness of the base are determined by the dimensions of the heat generator. Classic Russian stoves require massive strip pedestals. For small systems, a concrete pad of 10-15 cm is suitable. In some cases, it can be fixed to a frame made of reinforcement.

Brick

Fire-resistant ceramic bricks are used for external walls. The foundation can be built from used material. In this case, it is better to line the internal coatings of the firebox with fireclay stone. The façade will be finished with facing bricks.

Brick is used to install external walls.

Solution

The masonry mixture is prepared according to the classical scheme: sand and clay are poured with water and mixed with cement until a homogeneous consistency is obtained. You can also purchase a ready-made solution with special additives.

Masonry

For a strong foundation, it is important to form high-quality seam binding. They should not coincide, as this will affect the strength of the structure.

It is better to place the seams of the bottom section in the center of the bricks of the next row.

Do you need electricity?

The system can be implemented in two versions:

- Free circulation when heating occurs by gravity;

- Forced way.

In the latter case, a pump and a battery will be required (provide uninterrupted power supply). At first glance, this is convenient: after all, stability is maintained. You can heat not only the first floor, but also other floors.

However, such components significantly increase the cost of stove heating; the design itself acquires impressive dimensions.

Safety regulations

The main rule is not to close the oven view ahead of time. Kuznetsov’s boiler works on the principle of a gas view - cold gases do not mix with hot ones, so the stove does not cool down much. If you close the view ahead of time, carbon monoxide may enter the room, causing poisoning.

The boiler is especially afraid of overheating - the boiling coolant will rupture the heat exchanger. Therefore, in severe frosts, if the power is not enough, resort to additional heating of the room with electric heaters.

When installing a water pump in the heating system, operating efficiency increases.

When firing, some parts of the stove become very hot. Keep small children away from doors and do not let teenagers heat the house.

While burning, keep the door either closed or slightly open, as escaping embers can cause a fire.

An “apron” made of ceramic tiles or a sheet of iron is installed in front of the stove.

Soot is removed twice during the heating season. Its accumulation in the chimney can lead to a fire.

A brick stove is an excellent option for heating a home. The rules for safe use are simple and intuitive.

Fuel

The following types of raw materials can be used:

- Coal (brown, stone, reach temperatures of 1500 degrees);

- Logs (the most accessible, with a long shelf life and low cost);

- Fuel briquettes (they are convenient to store, burn for a long time and evenly).

By the way. Which resource to choose depends on personal preferences. This parameter does not affect the furnace design.

What pipes are needed?

Instead of radiators, pipes (80-120 mm in diameter) are usually used. They are better suited for stoves (provide sufficient water volume in the system).

The main thing here is to choose the right material:

- Stainless steel;

- Metal-plastic;

- Polypropylene.

On a note! For brick stoves heated by wood, the best option is steel. It can withstand high temperatures (up to 100 Cº or more). Other materials are not designed for this load (maximum 95 Cº).

Choosing a heating system depending on the size of the house

- For small, well-insulated houses, consisting of one or two rooms and a kitchen, one heating and cooking stove made of brick will be sufficient.

- For larger buildings, it is necessary to carefully consider the heating system so that the entire house can be heated from one stove. For this purpose, heating is used using a water or steam circuit.

- For a one-story building, such a circuit can be connected to a brick stove or one made of cast iron. When installing a system in a two- or three-story house, a cast-iron stove-boiler is more suitable.

The next thing you need to decide is the type of fuel. The system can be heated with wood, coal, peat, gas, diesel, electricity or several of them. This choice will determine which heating stove to purchase.

Circuit

The pipeline consists of a supply from the furnace and a return to it. In the room farthest from the stove, both branches are connected. In other rooms they run in two lines along the outer walls.

On a note! This option is cheaper than a system with radiators and is easier to install.

At the finish line: building a chimney

When constructing a chimney, please note that the distance from this part of the stove to the wooden walls of the building (house, etc.) must exceed 40 cm. This is due to fire safety requirements.

The size of the part of the chimney extending beyond the roof is approximately 38x38 cm. And its internal diameter is equal to half a brick.

By the way, it is possible to replace the part of the chimney protruding above the roof with a regular pipe. This will greatly facilitate the stove maker’s task, speed up the process of laying the stove, and even reduce the cost of the work.

Another important nuance: the places where the roof comes into contact with heating elements must be treated with asbestos-containing compounds.

Heat exchanger

Various materials are used for stoves with water heating boilers:

- Low-carbon steel, in the form of a coil of pipes with a diameter of 4 to 5 cm (or an assembly of sheet steel, up to 0.5 cm thick);

- Cast iron, use old batteries made from it, preferably compact in size (to fit in the firebox);

- Copper (the most expensive option).

A tubular steel device is more efficient in operation, but more difficult to manufacture. Disadvantage of cast iron products: they are difficult to clean from accumulating soot (ribs get in the way). Copper cameras are rarely used, they are difficult for the owner to assemble, and expensive to purchase.

By the way. The heat exchanger significantly reduces the usable area of the firebox. There must be a gap between them - up to 15 mm (for products made of sheet steel - up to 10 mm).

Improving system efficiency

When choosing the configuration of a boiler for a heating furnace, many factors are assessed and their influence taken into account as a whole. To improve the efficiency of the heat exchanger, the following ideas are taken into account when designing it:

- Efficiency increases if you use materials with increased thermal conductivity. Copper has the best thermal conductivity, but it is expensive. Therefore, the optimal solution would be heat-resistant stainless steel.

- Provide the maximum possible surface area (with given dimensions).

- Calculate the optimal height difference between the forward and return pipes.

- The heat exchanger should not interfere with the combustion of fuel (if located in the firebox) and the removal of gases (if it is installed in a chimney).

- The amount of energy transferred is directly dependent on the area of the heat exchanger and the temperature difference between the different media.

Homemade copper coil for heating from a stove Source ultra-term.ru

Work order

You can make the equipment yourself or buy a factory unit.

When installing yourself, it is important to consider the following points:

- First, the heat exchanger is prepared;

- Then the circuit is mounted and connected to the thermal boiler;

- Before building a furnace, a pit is dug, then a layer of crushed stone and broken brick is made in it (the foundation should be 2-3 cm higher than the floor level);

- The furnace structure is being erected.

How to choose a factory model

The main indicator of a factory unit is power. For his home, the owner can make fairly accurate calculations using an online calculator. It is available on the official portals of most manufacturers.

When calculating the load, the following parameters are taken into account:

- Device location;

- House area;

- Unit operating time;

- Materials used in production;

- Installation conditions (thermal insulation and number of walls, ceiling height, degree of heating of the cellar and attic, number, dimensions of windows).

By the way! Prices for water-heated stoves vary, depending not only on power, but also on functionality (for example, it additionally plays the role of a fireplace).

The design of the furnace unit is not very complicated. The main thing here is to take into account all the nuances. If the structure is made of brick, then it is best to equip it at the stage of building the house.

In order not to depend on electricity, natural circulation is organized. The heat exchanger and circuit are usually made of steel; it can withstand high temperatures and will provide the highest possible efficiency. You can make the design yourself or purchase a suitable option in the store.

Preparatory activities

Organizing stove heating involves preparing drawings, choosing a suitable location for pipes and radiators, as well as competent calculation of power. Next, a register is made or purchased and the structure with a built-in heat exchanger is laid.

Calculation of power and dimensions

The efficiency of a heat exchanger is determined by the materials from which it is made. Cast iron products of the MS-110-300 and MS90-300 series have a power of 0.14–0.16 kW/sq. m for the rib. Taking into account such figures, it is possible to predict the number of sections for heating each circuit. For 10 sq. m of area you need at least 1 kW. For a building of 60 sq. m. requires a register with a power of 5.5 kW.

The efficiency of a heat exchanger is affected by the materials from which it is made.

The dimensions of the furnace system are 1020x1160x2380 mm. The heat exchanger has dimensions of 750x500x350 mm.

Required materials and tools

To assemble the stove you need to prepare:

- A sufficient amount of fireclay and solid bricks with fire-resistant properties.

- Furnace and blower doors.

- Grate.

- Steel corners and strips.

- Valves for ovens and cooking chambers.

- Pre-furnace sheet.

The tools you will need are a basic stove set and containers for mixing the solution.