Fans of hot steam, dry or wet, take the arrangement of their home bathhouse extremely seriously. Due to the special specifics of the building, each of its elements must fully meet fairly stringent requirements in order for the bathhouse to be comfortable and durable. For example, the choice of doors plays an important role: should you install a traditional solid wood door or should you give preference to modern plastic? If we know almost everything about how wooden doors behave in a bathhouse, then it’s worth talking about plastic doors in more detail. And we should start by considering the pros and cons of plastic.

What are the requirements for the design of a bathhouse door?

First of all, we should be interested in the material and its characteristics, then the design features.

Material

The main material from which plastic profiles are made is polyvinyl chloride. It is a very common polymer made from ethylene and chlorine and is used to make many things from pipes to clothing to music records. Moreover, in many cases, its initial properties are unsatisfactory for the operation of the final product, so PVC is modified.

When it comes to windows, PVC profiles are protected from ultraviolet rays, because their prolonged exposure leads to photodestruction.

Its thermal characteristics in its pure form are also not very good - it does not tolerate frost well (down to -15, after which it becomes brittle), temperatures above 66 degrees are not suitable for it, and at 150 it already spreads with might and main.

ATTENTION! The figures are for regular, unmodified PVC.

An unpleasant feature of PVC is its thermal decomposition with the release of pure anhydrous hydrochloric acid at 110 degrees. However, all this (or almost all) is “treated” by modifiers.

IMPORTANT! Since we are talking about installing plastic in a bathhouse, it is worth checking with the manufacturer what temperatures a specific brand of PVC is designed for.

PVC profiles contain not only modifiers, but also various stabilizers, pigments and other additives. So there is a lot of “chemistry” here, but during normal use (for example, in residential premises) it does not stand out. Including lead, which is a stabilizer, is not released in a state hazardous to health, because it is in a bound form. However, now it is increasingly being replaced with calcium and zinc.

Regarding combustion: fortunately, PVC does not support combustion. However, in the presence of a fire source, it will release the already mentioned hydrogen chloride.

PVC is not afraid of alkalis or acids, and is dissolved only with special organic solvents. Water is not scary for him at all.

WARNING! One way to reduce the cost of production is to use recycled plastic materials. It can be mixed with primary raw materials in any proportion. Therefore, still, do not chase excessively cheap prices.

Design

A plastic frame is not the simplest design :). It is hollow, but there are quite a lot of partitions in it to give rigidity. By the way, they are also called cameras, which should be confused with cameras between the glasses. The number of chambers inside the profile can only be seen on the cut, which is usually demonstrated by the manufacturer.

However, you cannot limit yourself to partitions alone. The fact is that PVC reacts to temperature by compression and expansion. Therefore, it is additionally reinforced with metal profiles.

ON A NOTE! The metal profile inside the frame can have either a closed cross-section (symbol “O”) or an open shape (conventional “C” or “L”). A closed profile has much better rigidity indicators than an open one.

ADVICE! Since temperature changes in a bathhouse naturally occur, especially in winter, the profile may warp, so we advise purchasing windows with closed metal profiles that will reduce warping.

A bathhouse is a special room intended for relaxation. It has at least two entrances - to the dressing room and the steam room. If there is a washing room, shower room, or locker room, additional ones are installed. Their functions differ, but the design requirements are the same:

- Bathhouse doors should not let out heat, otherwise the temperature will quickly drop. Small cracks are not acceptable.

- Must protect the steam room from the negative effects of external factors - cold, wind, snow.

- The frame must be hermetically installed in the opening, so close attention is paid to the size of the door block in the bathhouse.

The concept of a bathhouse door combines several types of door designs with different functionality and purposes. All of them, performing their specific tasks, serve a common goal - to make the bathhouse as comfortable and safe as possible. Let's find out what the difference between them is.

The products differ in design and are:

- Wedge ones with a solid sheet glued into a micro-tenon-groove and two wedges that ensure reliable fixation of the boards. This assembly option eliminates deformation and cracking of the fabric due to active use in difficult bath conditions.

- Paneled from several components - door leaf, frame, rectangular, semicircular or radius trim and extensions.

- Panel panels, for filling the frame of which a choice of wooden slats, MDF, and veneer are used. The elements that form the frame part have multidirectional fibers, which eliminates the violation of the geometry of the door frame due to high temperatures and high humidity conditions.

Klinovaya

Paneled

Panel

Depending on the installation location, there are external structures used to equip the entrance to the building, internal structures for enclosed spaces - steam rooms, washing rooms, dressing rooms, and interior ones for rest rooms. Street doors must be massive, strong and reliable, preferably with a frame made of iron or steel. Lightweight doors are used inside.

According to the opening mechanism, doors can be sliding or swinging. An immutable rule applies to all single-leaf bath doors. They must open from the room, and not inside it - this is the key to a safe stay in the bathhouse.

Sliding structures are found mainly in large bathhouse complexes, where the style solution involves their use for arranging the interior space. They are absolutely not suitable for steam rooms: with such a design, instant steam leakage is guaranteed. In a modest bathhouse at the dacha there is simply no point in using sliding doors.

Door hinges. For entrance doors, it makes no difference what kind of awnings they have. Another thing is the products that are used to equip the steam room. For safety reasons, they should not have potentially dangerous elements that could cause burns or injuries.

Device

Bath doors also differ in their design. Let's find out more about the most popular options.

- The following types of doors are reliable and wear-resistant: wedge doors with a solid leaf, glued into a micro-tenon groove, and also with two wedges that secure the boards well. This type of assembly prevents the possible appearance of cracks and deformation of products in difficult bath conditions.

- Paneled with several components - door leaf, frame, platbands and extensions. No less popular options found in many baths.

- Sliding and swing door panels are in demand these days. They can be equipped with a special roller system that allows the structures to be opened and closed without hindrance. The sliding door is usually placed inside the bathhouse and does not serve as an entrance part.

What doors can be used in a bathhouse?

Plastic doors made from high-quality German profiles produced by the companies Rehau and KBE, and wooden doors from pine, larch or oak can be installed in places where it will not be hot - in the dressing room, sink. Door structures made of plastic profiles will ensure tightness (no drafts), good heat and sound insulation, and are easy to clean.

The optimal temperature in the steam room of a Russian bath is 60-70°C with humidity up to 90%. Low humidity (15-30%) and high temperature (90-100°C) are typical for Finnish and Turkish baths. At a temperature of 80°C for 3 or more hours, damage to the surface of the PVC profile is possible. Therefore, it is better to choose wood products for a steam room.

Materials recommended for thermal insulation

Having determined the basic criteria of insulation, you can select a material that meets all safety requirements.

Foamed polyethylene with a layer of foil does not burn, allows steam to pass through and retains moisture. The aluminum layer of the material repels heat waves back into the room, which allows you to maintain a high temperature inside the bath. Polyethylene foam is safe, durable, and easy to nail or staple.

Felt is a proven wool insulation material; it does not lose its heat insulating properties even when wet. Natural material does not burn, is resistant to high and low temperatures. Felt is used for the outer door and for the entrance to the steam room.

Ecowool is a cellulose-based material; antiseptic and antipyrine are added to its composition to increase resistance to rot and fire. Natural insulation dries easily from moisture and has natural vapor permeability.

Compliance with safety regulations

Before purchasing a door, check whether it complies with basic safety rules.

- It must open outward so that during force majeure situations people get out unharmed.

- Installing the structure on the outside will reduce the risk of burns from the hinges.

- Handles, locks, and fittings in interior spaces must be made of wood.

Compliance with safety rules will make your stay in the bathhouse safe.

How are they different from regular ones?

Doors for baths are presented in a separate special category in almost all stores. The main differences are in materials and design. The classic paneled design is not appropriate in a bathhouse. It can be seen rarely, but another technology is used - door leaves for bathhouses made of solid wood.

Important! Another feature that can also only be seen in a bathhouse is unpainted and unvarnished wood. Indoors it retains its natural color for quite a long time.

If it needs to be preserved longer and there are special requirements for it, then a safe water-based varnish (water-resistant compound) is used.

Tips for selection and installation

Doors installed in paired rooms are selected according to the following criteria:

- Heat resistance, fire safety, resistance to deformation. These are some of the most important qualities required from bath products. The canvas must easily withstand difficult operating conditions and retain its original shape under the influence of humidity and high temperature. High-quality designs are designed for operation in conditions of sharp temperature fluctuations.

- Ability to effectively preserve and retain internal heat. Good doors are sealed, small in size, equipped with a thermal vapor barrier that ensures minimal heat loss.

- Wear resistance - due to the enormous load that bath doors have to withstand in the above conditions, their strength also plays an important role.

- The absence of harmful fumes when heated - visiting a bathhouse should improve health, and not create a threat to it. Therefore, the thermal and vapor barrier filling of doors must be made of environmentally friendly materials that prevent the release of toxins under the influence of high temperatures.

- Appearance - any owner wants his bathhouse to be different from others in design. Installing original doors provides this opportunity.

- Security. Single-leaf structures that open outward not only contribute to the rational use of the usable space of the steam room, but also allow you to quickly leave it in emergency situations.

External

There are no special requirements for entrance doors. It is important that they provide good thermal insulation and close tightly, helping to retain valuable heat throughout the bath. Any wooden or metal model presented in the manufacturers’ lines fits these criteria.

Ordinary street doors are single-leaf and have a high threshold. In a black bathhouse, which is rarely used today, the entrance is equipped with double-leaf products.

Interior

Many modern bath complexes have a large number of recreation areas. Therefore, the density of door structures that isolate rooms from each other is fundamentally important here in order to limit the access of moisture to them as much as possible.

Openings

When installing the canvas, it is placed in such a way as to leave a small gap at the bottom for a ventilation gap. If the bathhouse is equipped with a ventilation system, then there is no particular need for this. Clearances may also be necessary for sauna equipment to function properly.

Recommendations and tips for organizing openings:

- It is best to install wedge doors in the washroom and steam room, which is considered a classic. Such fabrics guarantee excellent thermal insulation and no heat loss. Can be blind or with a window.

- Massive external doors are the best option because they guarantee reliable protection against burglars. Excessive massiveness of the canvas on internal doors is not only inappropriate, but also dangerous, as it makes it difficult to escape in the event of a fire or sudden health problems. When seconds count, any delay can cost your life.

- Steam room doors with metal handles are a gross violation of safety rules and a potential health hazard. It is permissible to make only canopies from metal, but they must be treated with anti-corrosion compounds.

- Safe fittings - wooden, ceramic, glass, plastic, that is, made of materials that prevent strong heat, and therefore the possibility of burns. Glass products must be equipped with 3-4 element magnetic latches - they remain operational in any situation.

- Using varnish, drying oil, or paint as an antiseptic to treat the inner surface of the canvas entails two negative aspects. Such coatings create a barrier that slows down the natural absorption of moisture by wood and release toxins when exposed to high temperatures.

| The entrance doors to the bathhouse should fit tightly to the door frame, eliminating the occurrence of drafts and blowing, and not freeze during cold weather. | For buildings that are supposed to be used in cold weather, it is better to equip a small dressing room that prevents heat from escaping outside. | When choosing a handle, it is better to choose a bracket than a push set - in this case it will be easier to get out of the bathhouse. To avoid burns, it is better to buy a handle in the steam room made of wood. |

| If you plan to install a double-glazed window in the door, then for the steam room you should choose tempered glass that is resistant to temperature fluctuations. | The threshold in the steam room is set high, which prevents the penetration of cold air and the escape of steam, facilitating rapid heating. | The dimensions of the doors have features that distinguish them from standard entrance doors. The height of the structure is 1500-1800 mm, and its width is from 650 mm to 700 mm. |

Wood species

When assessing which doors to a bathhouse are best, you need to pay attention to the types of wood. The construction of wooden baths has been going on since ancient times and during this time the best wood species were selected and tested

Various woods were rated for resistance to water, degree of swelling and strength. An important factor is the release of aromatic substances when heated. In first place for these qualities is linden and aspen wood.

Information. Aspen is an affordable wood for doors to a paired compartment. The wood withstands moisture well and has a pleasant white color. Linden doors for baths are the best. This is an option that can often be seen in luxury baths. The doors to the linden steam room look very elegant thanks to the bright color of the wood.

Information. Conifers, due to the presence of resinous substances, also have good resistance to water. Of these, the cheapest option is pine. Pine doors for baths and saunas will have a minimal cost, but this breed has many disadvantages. It dries out and cracks a lot. In addition, the structure has sparse layers (a large distance between the growth rings). Pine canvases are protected with varnish or paint. They are not used in their pure form due to these disadvantages.

A good option among conifers is cedar and larch. In many regions, they are not much more expensive than pine, and the appearance and strength of these species are much better. Canvas made of cedar and larch simply sand well and need not be covered with anything.

Is it possible to put plastic...

The answer is simple: you can. The main argument in favor of this is the fact that PVC does not react to water, and the humidity even outside the washing room and steam room in the bathhouse will be increased compared to housing. In this case, wooden windows will need additional protection - varnishing or water-repellent impregnations.

However, not all rooms are equally suitable for installing plastic. So the main subject of debate is the plastic window in the steam room: we will discuss whether it can be placed there a little lower.

to the steam room

Here, too, everything is quite simple: it is possible, it is not advisable. The main reason is the high temperatures that are typical in a steam room. But even here the owner’s preferences should be taken into account. If he is a follower of the Russian bath, then the temperature in his steam room is unlikely to rise above 70 degrees. But adherents of the classic Russian bathhouse will most likely advocate wooden frames.

If all (!) plastic that ends up on the market were properly certified, then we could be confident that, for example, in a certain temperature range, this material will not emit compounds that are harmful to human health. But the situation is far from ideal. Therefore, it’s probably not worth taking risks by putting PVC in the steam room.

In addition, when describing the properties of the material, we talked about its warping under the influence of high temperature. This is the second reason why PVC is not desirable in a steam room.

Easily. In all other rooms the temperature does not rise above 30-35 degrees. Therefore, they can be practically equated to ordinary housing. Unless the humidity is higher.

in the shower

For example, a plastic window would be very appropriate in a washing room - it is easy to care for and heat loss is small. Another question is whether it is needed there for ventilation reasons. After all, well-designed ventilation itself copes with drying the premises. Usually a hood or just a grate is installed in the washing room, and a hood in the toilet. The exhaust can be natural (without a fan) or forced (with a fan).

Plastic is also appropriate in the rest room, where it is most often placed.

Requirements for the materials used when creating door structures for bathhouses may vary.

So, which entrance door to the bathhouse would be better to install from the street. Choose any one - metal, chipboard, PVC. The metal one has a big advantage - it looks impressive, scares off unwanted visitors with just its appearance.

The dimensions require special mention - the design is lower and narrower than the standard one. The width is 75 cm, the height is 180 cm. Select locks carefully, as the safety of the building depends on them.

It must first be insulated, covered with clapboard, and varnished on top. This will make the metal resistant to winter frosts, temperature changes, and weather vicissitudes.

For the steam room

The steam room is the main room of the building, in which the high temperature is constantly maintained. Non-standard operation of the premises requires the fulfillment of certain conditions:

- The door leaf must have low thermal conductivity, retain heat, and not allow cold air inside.

- Be resistant to pressure surges, fungus, rot, mold, and do not emit harmful substances.

- Fits dimensions: height - 160 cm, width - 75 cm;

- Maintain the internal microclimate - failure to comply with the conditions leads to a spoiled atmosphere.

The traditional door to the steam room is a wooden or combined door with glass inserts. Another good option is wood with thermal insulation, as well as clapboard cladding.

Metal and plastic are not suitable in this case - they are unsafe, short-lived, and unstable to temperature changes.

For washing

The washing room differs from the steam room in that the pressure here is low and there is a large amount of water. You need a water-repellent fabric that is easy to clean. For example, glass or made of waterproof materials. The linden structure perfectly meets the requirements. If there is high-quality ventilation, it will last a long time.

Even plastic is used - since temperatures do not reach high values, there will be no harm. Opt for white or wood-look plastic.

Due to excessive humidity, the box will inevitably increase in size and get wet, so the gap between it and the floor is 5 mm, versus the usual 2-3. The width of the canvas is 60 cm.

When the owner asks the question of which door to install in the bathhouse, we consider it not entirely correct. Because usually a bathhouse is a separate building, with its own entrance and several interior rooms. Therefore, it is necessary to separately figure out which door to put into the bathhouse from the street, and which one into the steam room or washing room.

The main task of the front door is to protect the entrance. And it must be protected from dashing people and from cold air. In the first case, a metal door seems to be the most suitable option, because even if there is nothing special to steal inside, no one wants strangers to come in and accidentally burn down your bathhouse.

However, metal does have its drawbacks when it comes to installation in such a humid area. Therefore, this is another question of how to choose the right door to the bathhouse.

It’s worth starting with whether you have a separate dressing room.

IMPORTANT! Let us clarify right away that if the door opens directly into the rest room, then you do not have any dressing room. Some people call it “combination”.

The dressing room, of course, is not quite a vestibule, but functionally their task - to cut off the cold from the street - partially coincides. You can also say that this is a very limited space where you can take off your outerwear. A kind of bathhouse hallway. But rarely does anyone specifically highlight it.

The choice task posed above is different for those who have it and those who do not.

Disadvantages of stopping

- Tightness. PVC structures are hermetically sealed. This complicates natural ventilation and leads to the appearance of mold in the bathhouse. It is necessary to install forced ventilation, regular ventilation, or install special grilles in the lower third of the door leaf.

- Plastic does not rot, but is susceptible to mold, especially in rooms with high humidity, such as showers or Turkish baths.

- Installing a plastic door to the sauna is not advisable. The temperature regime of the sauna has a bad effect on the material of the sashes and frames.

- The surface of the PVC profile is damaged at temperatures above 100 C.

- Door thresholds interfere with air exchange in the sauna; it is customary to leave a gap between the floor and the edge of the door of at least 1 cm. Structurally, it is impossible to do without a threshold.

- Metal fittings suffer from corrosion in high humidity conditions. Regular lubrication and testing of its functionality is necessary.

- Double-glazed windows, when installed in rooms with high temperatures inside, may begin to release sealant components that look like yellow and brown streaks inside the glass. This does not affect the functioning of the door as a whole, but it does look untidy. Such defects cannot be eliminated; the entire glass unit will need to be replaced. In this case, it is difficult to make a claim to the manufacturer, since standard glazing is not intended for use in rooms with temperatures above 100 C.

- Door handles with locks included in the design of plastic doors contradict safety recommendations in the bathhouse. The door should easily open outward so that in the event of a fire or sudden deterioration in health, a person can easily leave the room.

- Metal door handles in the sauna get very hot.

- Due to sudden temperature changes in the bathhouse, plastic doors sag and begin to close with force.

- The appearance of PVC structures does not fit into classic baths and saunas, where preference is given to finishing with natural materials.

- The rubber seal around the perimeter of the sash is negatively affected by two factors at once - high temperature, from which they dry out, deform and crack. The second factor is humidity, which causes mold to appear.

Prices for wooden doors for baths

There are two standards by which window structures are manufactured in Europe and Russia:

- EN 12608 SR "Unplasticized polyvinyl chloride (PVC-U) for the manufacture of windows and doors"

- GOST 30673-99 “Polyvinyl chloride profiles for window and door blocks. Technical specifications"

Class A - the minimum thickness of external walls is 2.8 mm, internal partitions - 2.5 mm.

Class B - the minimum thickness of external walls is 2.5 mm, internal partitions - 2.0 mm.

Class C - all other “non-format”.

In practice, class A differs from B in that it has 15% higher resistance to deformation and better thermal insulation.

ADVICE! Do not install plastic windows in class B and C bathhouses.

By the way, there is also a type of window that is labeled with the word object. They are intended purely for installation in non-residential premises, but outwardly do not differ from their residential counterparts. Keep an eye on the markings on the protective film, because cheapness may result in someone trying to sell you exactly such windows.

The mechanisms are divided into:

- rotary;

- folding;

- tilt and turn.

Modern technologies make it possible to make both triangular and round windows. However, both of them belong to the delights of design ideas, and the majority still install either square or rectangular windows. You should focus on the dimensions of the window opening already specified in the bathhouse design.

BY THE WAY! The shape of the window depends entirely on the preferences of the owner or designer; there are simply no special operational requirements for the shape.

Size

Let's start with the minimum size. In order for the window to contain at least some glass in addition to the frame, its dimensions must be at least 20x30 cm or 30x30 cm. Such a window is quite appropriate in a steam room, if, of course, you decide to put plastic there (although more on this below).

It is difficult to name the maximum window size. There are no restrictions here other than common sense. In principle, a window of the usual size for residential premises is placed in the recreation room.

As you can see in the photo, there are those who put quite large windows in the steam room

* Prices for bathhouse doors are indicated taking into account the average volume discount. The calculation took into account the German Rehau Blitz profile with a single-chamber energy-saving double-glazed window, providing excellent tightness and thermal insulation. An extended warranty is provided for products and installation.

| Product cost: | |||

| RUR 19,750 | |||

| RUB 35,600 | RUR 20,400 | RUB 35,300 | |

| Price with installation: | |||

| RUR 24,800 | RUB 42,800 | RUR 26,300 | RUB 43,200 |

* Prices for bathhouse doors are indicated taking into account the average volume discount.

| 1) From pine | |||

| RUR 41,750 | RUB 79,400 | RUB 44,800 | RUB 87,300 |

| 2) From larch | |||

| RUB 50,600 | RUB 99,200 | RUB 55,500 | RUB 108,900 |

| 3) Oak | |||

| RUB 63,200 RUB 50,600 | RUB 124,000 RUB 99,200 | RUB 69,200 RUB 55,500 | RUR 136,200 RUB 108,900 |

Thermal curtain

The easiest way to insulate a bath door is a thermal curtain. The use of this material requires minimal time and effort. Such insulation of doors in a bathhouse also requires adherence to a certain technology:

- The first step is to form a compacted frame - the simplest way to thermally insulate the insulation of a door. At the same time, do not forget that the strips of material for sealing the opening are attached at a distance of at least 2 cm from the edge.

- Long and short bars are wrapped with insulating material, after which they are nailed at the entrance. As a result, you should end up with an even rectangle.

- Next, a thermal curtain of the required size is made from canvas fabric or leatherette.

- The right side of the fabric is attached to the wall, the edge itself is attached to a wooden batten. At least 8 rings are installed on the top.

- Self-tapping screws are attached to the upper sides of the frame, which will become the basis for wire or nylon cord. Once completed, the cord is threaded through the rings. This method of improving heat retention in a building is accessible to everyone, since it is not only the most budget-friendly, but even a beginner can do it.

What manufacturing options are there?

Entrance doors come in a variety of sizes, taking into account the individual characteristics of the architecture of bath structures. The classic option is external doors with dimensions of 1800x650 mm and a mandatory high threshold.

For washing

Washing room doors are of the usual dimensions, although sometimes they are narrower in width to prevent the spread of humidity, which is necessarily increased in this compartment. The recommended width of doors to the sink is 0.60 cm.

The requirement for resistance to moisture must be taken into account. When choosing solid wood doors, you need to leave a ventilation gap - a gap from the bottom of the door leaf to the door frame, as already mentioned. For ordinary interior doors, a gap of 2 to 3 mm is enough, while when installing a door for a sink from below, leave at least 5 mm, otherwise the swollen door will jam when closing and opening.

For the steam room

In the steam room, clouds of steam form under the ceiling. On average, such a layer has a thickness of 0.6-0.8 m. Therefore, it is necessary that there be a pocket of 0.6-0.8 m between the lintel - the upper edge of the door and the finished ceiling.

The optimal door height is 1.6 m. A high threshold is required. Its height should be about 18-20 cm in order to successfully solve several problems at once:

- Limit access to cold air when entering and exiting the steam room.

- Prevent drafts.

- Act as insurance against hitting your head on the top edge of the door: when we step over something, we automatically bend down lower. That is, thanks to the threshold, we avoid possible injury.

Now about the width of the doors for the steam room. Regardless of what most sources call the standard sizes 700x1900 and 800x1900 mm, there are other opinions regarding the width of the canvas. Many craftsmen advise installing wide doors, and, interestingly, much wider than the standard, recommending 900-1000 mm or even more for the frame.

It is better to refuse non-standard 2-meter structures produced by foreign factories.

The quality and service life of the door block depend on the material from which the door block is made. Different raw materials are selected for different purposes.

Tree

Traditionally, wood was used in baths. The floor, walls, ceiling are all wooden, doors too. You may be given several options:

- Linden. A universal material, used to create doors of any type. The main advantages are low price, pleasant aroma, does not rot. A very good choice.

- Aspen. The wood does not swell, does not heat up, and is suitable for decorating a washing room - it is used for finishing floors, ceilings, walls, and doors. The price of solid aspen is low, it is easy to process, which has a positive effect on the cost.

- Pine. The low price is explained by the wide growing area and ease of processing. Like all coniferous plants, pine smells good and does not rot. Heats up quickly - so this is a bad choice for those who like high temperatures (above 65 degrees). The ideal temperature is 45-50 degrees.

- Larch. Solid larch will decorate the steam room - it is recognizable due to its texture and pattern, which only becomes more expressive under varnish. Since larch is a coniferous plant, it produces phytoncides that kill harmful microorganisms and bacteria.

- Oak. Expensive, durable, weighs a lot, looks solid. Suitable if you want to impress guests. The only negative is that it cracks when overheated, which makes wood an unsuitable option for a steam room.

Wood is used for entrances to interior rooms. An array is taken - this reduces the likelihood of the slightest cracks and joints appearing. It is recommended to use durum varieties. Choose a water-based, non-toxic varnish.

Plastic

Plastic doors are often used at the entrance. They retain heat well, do not deform from cold, and fungus does not form on them.

Plastic is a poor material for rooms. This is an artificial material that, when exposed to heat, releases toxic substances and becomes deformed.

Metal

Metal doors are ideal as entrance doors. There is no need to care for them - the metal is not subject to mechanical damage and is resistant to mold and mildew. Thanks to the thermal insulation lining, it does not release heat and does not allow cold to penetrate inside.

Metal bath doors are not used for rooms because they have high thermal conductivity, heat up quickly, and are easy to get burned on. Also, when humidity is high, condensation forms, so the metal rusts.

Glass

A very stylish option - 8 mm thick tempered glass. The main advantages are appearance, heat resistance (withstands up to 300˚C), variety of decor. There are frosted glass designs, glossy, patterned, transparent, of any color. Glass is easy to clean, safe, and has low thermal conductivity.

The lower part of the glass sheet is shorter according to manufacturing standards, which allows air to circulate. This is important in a sauna, but unacceptable for a bath. Therefore, it is recommended to leave glass doors for the sauna, and use wooden or combined doors in the steam room.

Combined

They are made of wood, glass is used for decoration - decorated inserts, windows. The combined door combines traditional and modern visions of the bathhouse, which makes it more attractive from a design point of view.

Summarize

In a bathhouse, a plastic door can be installed in any room except the steam room. This is an excellent option, since plastic is not afraid of moisture, moderate heating and temperature changes - this applies to winter, when a heated bathhouse cools down.

A plastic door is not suitable for a steam room, since the temperature there is too high - in a Russian bath, on average, 90 degrees, in a sauna with dry steam - 110, but maybe even 120-130 degrees.

If you are planning to install a plastic door, please contact. We have low prices from the manufacturer and excellent quality - this is confirmed by certificates of conformity that are posted on our website. Contact us!

Installation

Well, if the choice has been made, the window has been ordered, then all that remains is to install it. This is usually done by specialists from the same company where the order was placed, but you can install it yourself. And even if you rely on the professionalism of others, knowledge of what features are associated with the different materials from which the bathhouse is built will not be superfluous.

IMPORTANT! The glazing is removed before installation.

Timber or log house

The most responsible is the installation of doors and windows in a building made of trunks - timber or log house. Because a tree consists of cells, and their composition, in turn, necessarily contains water. When drying, it partially goes away, but the cellular structures are almost always (except for cases of special drying with cell rupture) ready to gain it again. That is why they say that wood “breathes”. And this has to be taken into account - first, the bathhouse is allowed to stand for a year after construction.

And if something is installed or secured in it, then it is always possible to “move” - move up and down.

A window frame (casing) in a chopped bathhouse.

Openings for windows and doors in such a structure are always made with a height reserve. And no one installs the structures themselves directly into the opening. Note: even for a door that already has an outer frame, another “box” is made - a casing. Windows also need casing.

What is casing? This is a board with a groove or tenon that corresponds to a tenon or groove cut into a log house or timber. The purpose of the board is both to create rigidity, that is, to hold the logs after cutting the opening in unity without distortions, and to allow the walls to slide along the tongue-and-groove joint.

First of all, we are talking about the verticals of the opening, but casing is done on all four sides.

Further installation of the window occurs inside the casing. Here everything is as usual: the window is inserted, fixed, the gaps are foamed, then everything is closed with platbands on both sides - internal and external.

Brick or cellular concrete are also found as wall materials from which a bathhouse is built (see here about bathhouses made of foam blocks). Installing windows in such walls is no different from the installation process in a new residential building.

- First, places for future anchoring are selected, after which recesses are made in these places.

- Then a frame without sashes is inserted into the opening, which is fixed with wooden spacers. The opening should be slightly larger in width and height.

- After checking the level, the frame is fixed with anchors in the wall.

- All that remains is to foam the gaps, install window sills, install double-glazed windows and hang the sashes.

Unfortunately, anchors or pins do not hold in a foam block wall. Therefore, to mount a PVC window in a wall made of foam or gas blocks, you will have to use an alternative fastening system - on reinforced mounting plates. Regular ones won't do.

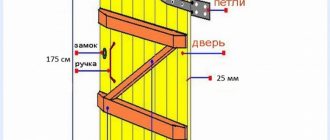

Attaching the box to the doorway

Having made the markings, you remove the canvas and insert only the box into the opening. According to the rules, the dimensions of the opening should be at least 1 cm larger on each side than the box. However, in practice the gap between them may be larger. The main thing is that it is not wider than the platbands with which it will be closed later.

Your main tool at this stage of installing a bath door with your own hands will be a level and/or plumb line. To make your work easier, you should first align the geometry of the opening itself.

Then you need to cut small wedges. When choosing a size, keep in mind that they are driven flush with the wall, because many people prefer not to pull them out after installation is complete. But this is a matter of taste. Although... it is cost-effective to leave the wedges when the door is supported solely by polyurethane foam. But we will not recommend this method.

ATTENTION! Decide on the method of mounting the box in advance - if you decide to mount it with drywall hangers, you will have to screw them to the box in advance.

So, we have three reliable methods of fastening at our disposal when installing a bath door with our own hands:

- suspensions;

- hidden three-point fastening;

- open six-point.

For suspensions

Hangers are freely bending carved metal plates that are attached to the side of the box facing the wall, and then placed on the wall on both sides, fixed with screws and cut so that they can be hidden with platbands.

ADVICE! To ensure that the ends placed on the wall do not rise above the surface of the wall (if this is a problem when installing platbands), the wall should be recessed to the required area.

Useful video

A video that very clearly shows how the box is secured in the opening using hangers:

Hidden three point mount

Its principle is simple. You can use long screws, dowels, or even anchor bolts to firmly connect the box to the wall. But not everyone likes it when the jambs are perforated with fasteners. Therefore, it was decided to make holes where they would be least noticeable - for example, under the hinges or in the area of the lock on the other side of the door.

ATTENTION! Yes, you will indeed hide any signs of fastening, but if you limit yourself to three points, then the reliability will not be very high.

Six point mount

It can be called the most reliable and least aesthetically pleasing, although plastic plugs, the color of which is close to the color of the jamb, are usually used to disguise the screws.

The same screws, dowels or anchor bolts can be used as fasteners.

ON A NOTE! Having pre-drilled holes for fasteners, do not forget to widen it to recess the heads and future plugs.

Useful video

There is nothing complicated in this method, but it is better to make sure by seeing how the installation of a bath door is done in the video with your own eyes:

Which one should it be?

As with any other door, a number of requirements are imposed on the design characteristics of door frames and bath leaves. They must be durable and safe so as not to pose a potential danger to those in the steam room. For example, they should not have elements that can heat up at high temperatures.

Ordinary doors, which are ideal for installation in city apartments or office premises, are not appropriate here. In this case, special structures are needed, made using certain technologies and from suitable materials.

Basic requirements for steam room doors:

External door structures must meet all safety rules, and therefore they must open outward. This will help prevent a possible negative outcome of events, because in the event of an emergency it is much easier to go outside through a door that opens from you.

Manufacturing sauna linens in compliance with all requirements will help to protect the structure and the people inside. The same rules apply to windows.

Useful tips

When installing a door structure in a bathhouse, you should remember some nuances:

- It should be taken into account that the door will shrink after some time: a frame made of raw wood shrinks by approximately 8%, and a frame made of dry wood - by 2%.

- It is not recommended to install locks or latches on door structures leading to the steam room. This is done for safety purposes, so that it is convenient to get into the premises in case of accidents or emergency situations. In addition, at high temperatures, metal fittings heat up, and when exposed to steam, they quickly become unusable and can jam at any moment, which is very dangerous.

- It is strictly forbidden to treat the door leaf leading to the steam room with paints and varnishes.

- A threshold of 15-20 cm is always installed under the entrance door. Under the door structure leading to the steam room, a threshold is not installed, but a gap of 3 cm is made.

- The doors always open only outwards, and the hinges are mounted on the opposite side from the wet room.

Whatever doors to the bathhouse are chosen, it is important that they consist of moisture-resistant and sealed materials that can withstand constant pressure. It doesn’t matter at all whether the door structure is made independently, in production, or purchased in an expensive prestigious salon

The main thing is how comfortable, reliable, aesthetic and easy to use it is.

It doesn’t matter at all whether the door structure is made independently, in production, or purchased from an expensive, prestigious showroom. The main thing is how comfortable, reliable, aesthetic and easy to use it is.

Classification

Plastic blocks are classified depending on two criteria:

- type of glazing;

- location inside the bath complex.

The design and technical characteristics of the structure depend on the location.

By glazing

Kinds:

- solid;

- combined;

- without glazing.

Solid

A large area of the product is occupied by glass. It is limited by a profile frame, which is reinforced with aluminum from the inside. Either 1 double-glazed window or 2, separated by a plastic strip, can be used.

Combined

Door leaves consist of two parts. The top one is equipped with a double-glazed window, the bottom one is equipped with a sandwich panel behind a plastic casing. The demarcation is a plastic profile.

Without glazing

Simple and lightweight doors that do not have double-glazed windows. The entire space is occupied by a sandwich panel, which is enclosed in a plastic frame made of profiles.

By location

Varieties:

- for the steam room;

- for washing;

- at the entrance to the bath complex.

To the steam room

It is prohibited to install plastic door blocks between the steam room and washing room, since they do not meet the technical requirements for this opening. The best options are glass or wooden doors.

To the washroom

Since plastic is resistant to moisture and temperature changes, mold and mildew do not form on its surface, it is suitable for installation in washing rooms.

Outside

Plastic doors can be installed between the street and the dressing room. It is desirable that these are canvases without glazing with two sandwich panels inside.

Overview of species

When arranging a bathhouse, it is important to wisely select suitable door leaves. Entrance and interior options will differ in a large number of characteristics

Let's take a closer look at both the first and the second.

Input

Many bathhouse owners are interested in which door is most suitable for exiting from the building itself to the street. For such purposes, the canvas must be of impeccable quality, reliable and durable. The entrance door should protect the bathhouse not only from heat loss, but also from possible break-in. Such products are made from different materials, for example, wood, metal, plastic, MDF or particle board (chipboard). Entrance sheets must have excellent thermal insulation properties.

Entrance doors made of metal are considered the least “capricious”. They do not rot, do not swell, do not deform and are not subject to mechanical damage. Such door leaves serve for many years without causing unnecessary problems and hassle for the owners. Metal doors effectively retain heat inside the building due to additional thermal insulation lining.

Some users prefer to choose a plastic or solid wood door as an entrance door. Each option has its pros and cons, which we will discuss below. Most often, standard blind doors are chosen for the entrance area. These are the most reliable and closed fabrics that protect bath rooms well from heat loss or external damage.

Interior

Most modern baths consist of several rooms designed for complete rest and relaxation. In such environments, a high density of door panels is of fundamental importance, as they isolate rooms from each other.

It is very important that the access of humidity to certain rooms is completely blocked. We must not forget that moisture can negatively affect the operation of many entertainment systems and electrical appliances located in the bathhouse

For example, the door that leads to the steam room must be designed for extreme operating conditions. The canvas should not suffer from exposure to hot steam, high levels of humidity, or high temperatures. Models made of wood, plastic or glass are suitable. They will not suffer from overheating and contact with moisture.

The standard height of doors that lead users to the steam room is 1.6 m. There must be a threshold with a height of 18 to 20 cm. Common indicators for the width of door leaves for a steam room are 700x1900, 800x1900 mm. Sink doors can be traditionally sized according to the standard, although often their width is more modest to prevent the spread of moisture. The recommended width of doors leading to the sink is 0.60 cm.