0

7333

03.04.2014

Door closers are designed for automatic, smooth closing of doors. The use of a closer is a prerequisite when installing an intercom and a combination lock; in addition, closers are used in public institutions, on entrance doors and gates, and in private households.

How to install a door closer

Device and principle of operation

Most modern devices of this type are based on a spring, which is compressed when the door is opened. When the pressure on the door stops, the spring relaxes, returning it to the closed state.

Door closers can be of different types, types and colors

The main difference between different types of closers is the method of transmitting force to the spring: there are devices with a hinged rod or with a sliding channel. But in general, the principle of operation is this.

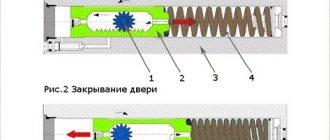

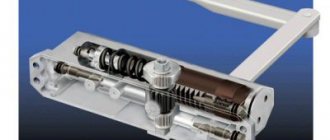

By opening the doors, we activate a gear that transmits force to a rack (hidden in a metal cylinder) filled with oil. The rack drives a piston, which pushes the spring, compressing it. When the piston moves, oil flows from one part of the chamber to another, providing a certain resistance and slowing down the movement of the door leaf.

The internal structure of a door closer for an entrance or interior door

As soon as the pressure stops, the spring begins to expand, pushing the piston in the opposite direction. At the same time, the oil again flows from one part of the device to another, slowing down the slamming.

As you can see, the speed of movement of the door and the force required to open it depend on several factors: the power of the spring, the ease of movement of the gear, rack and piston. The degree of viscosity of the oil also has a great influence: at low temperatures it becomes more viscous and flows worse; at high temperatures, fluidity, on the contrary, increases, doors close faster. Therefore, the door closers on the entrance doors have to be adjusted with each change of season.

In addition to devices that use gears to transmit torque, there are mechanisms with cam elements. The cams have an uneven, heart-shaped shape; turning it also changes the force required to open the door and the speed of its return to the closed state. This makes it possible to make smoother adjustments. However, the most common mechanisms on the market are those with gears: they are more reliable.

Features of choice

When choosing a door closer, pay attention to several points. These are the dimensions of the door, its location (external or internal), as well as the angle at which it should open and a possible method of installation.

Classification by mechanism power

The closer is selected based on the force that the mechanism develops when closing the door. The required power of the mechanism is affected by the weight of the door leaf and its width. These two characteristics are the main ones when choosing a power class.

If we talk about standardization, the domestic GOST R is currently in force. But its requirements are much lower than the world standard EN 1154. Products supplied to the market from European and other manufacturers are certified according to the world standard, products from domestic manufacturers are certified according to GOST.

According to EN 1154, closing forces are divided into seven categories: from EN1 to EN7 (1 is the least significant for light and narrow doors, 7 for the most massive). There are models of only one class E4 or E2. The force adjustment in such devices is within very small limits. But their price is small.

Table for selecting the class of door close depending on the weight and width of the door leaf

There are more expensive door closers that have a wide range of adjustments. Then in catalogs their class is indicated with a hyphen: EN2-5, for example. They are more convenient because, depending on weather conditions, you can adjust the required closing speed.

External or internal door

Despite the fact that closers can be installed on any side of the door, on external doors it is better to install them indoors: atmospheric phenomena will have less impact. But even in this case, a frost-resistant model is necessary.

When installing in the entrances of apartment buildings, it is desirable to install models that are not so easy to break: protruding rods irritate many. Therefore, a model with parallel or sliding traction is needed.

Types of installation of a lever closer

Where to put

Most often, closers are installed on external and entrance doors, as well as on gates and entrance gates. They can be found in apartments and country houses, in office buildings and commercial facilities.

In some door models, the door closer is included in the basic package. The closer must be installed on fire and evacuation doors, entrance areas with an intense flow of visitors, and in access control systems.

On doors, the housing must be indoors. The external location causes corrosion and negatively affects the operation of the hydraulics. Only frost-resistant models, protected from external factors, can be used outdoors.

Installation methods

Based on the installation principle, door closers are divided into four types:

- Outdoor installation. Such models consist of two blocks, one of which is attached to the door leaf, the other to the lintel of the door frame. They are connected using movably articulated levers. Installation methods for such models are shown in the figure.

- Hidden installation in frame. A hole is cut out in the lintel of the door frame and a door closer is installed into it. A lever is attached to the top of the door leaf.

- Hidden installation in the floor. This type can often be seen on glass swing doors in stores. Installation with a door leaf made of any material is possible, but only at the stage of installation or general reconstruction: it is necessary to make a recess in the floor under the body of the closer.

- Hidden installation in the door. In this case, a recess is made in the upper end of the door into which the device is installed, and the lever is attached to the door jamb.

Installation methods may be different.

Any of the installation options can be done with your own hands. It just requires varying degrees of skill. The simplest is external installation. It has the widest distribution.

On a plastic door

Installing a door closer on plastic is done in the same way. The difference is the lighter weight of the canvas. A compromise may have to be made between door closer power classes corresponding to size and weight. It is generally accepted that you should choose the larger of the two classes, but an overly powerful closer can destroy the plastic.

If the installation of a closer on a plastic door is done correctly and carefully, it will help prolong its operation.

DIY installation

Modern manufacturers of high-quality (and therefore expensive) mechanical door closers even include templates for installation in the instructions for the device. Typically these are adjustable models with different force classes for closing doors.

If such a template exists, choose the class required for your case (based on the weight and width of the door leaf). Decide where the device body will be attached: to the door leaf or to the jamb. It depends on which way the doors open.

If you have a template, installing the door closer yourself is not difficult at all.

In our case, we install the body on the door leaf. Therefore, we apply and secure (with tape) the corresponding template, and drill holes directly through it.

The next step is installing the closer body. If there are drilled holes, this is a matter of one minute.

Now you need to correctly install the lever “foot” on the door. The force class depends on how it is installed (see the diagram), we need 3-4, so we choose the lower option.

The class of the device depends on the method of installing the presser foot

The lever itself consists of two halves. One of them is solid, the second is composite. The composite one also has two halves, twisted using a threaded connection. Using this thread, the length of this lever arm is adjusted. The solid shoulder is attached to the body, the composite one - to the foot (they are not yet connected to each other).

Depending on whether the door has a latch or not, one or the other arm of the lever is set perpendicular to the door

Now you need to choose which shoulder will be perpendicular to the door leaf. A solid shoulder is placed at an angle of 90o to the door if the door has a latch. If there is no latch, the assembly arm is set at a right angle. Their position is adjusted by the length of the threaded lever - you lengthen or shorten it. Having exposed the lever, its halves snap into place: bring the ends together and press them against each other until they click. In any case, this is exactly what happens in this model. In others, the connection may be different, but the installation principle is similar.

Features of installing hidden closers

Flush mounted devices belong to one of the following types:

- Floor-standing. Usually used for glass doors, less often - for wooden, PVC and metal doors, when design requirements exclude hinged installation. The mechanism is recessed into the floor - only the mounting plate is visible. Such devices are susceptible to contamination and damage and are not suitable for outdoor installation. Adjusting them is quite complicated and requires special tools.

- Upper. They require special care when marking and installing. They can work on street doors because they suffer less from dirt and damage.

- Built into hinges. Used for double-sided doors, such as arched or saloon doors. They are used where there are large reverse flows of people: subways, shopping centers, etc.

- Hidden in the door leaf. The grooves into which the mechanism is mounted are selected for them. Adjustment requires special tools.

Hidden automatic door closers are limited in size, so their spring strength is insufficient for heavy metal panels. In this case, you will have to return to the classic design of the device.

Installing the door closer of most hidden models can be done by hand, but a higher level of plumbing and general construction skills will be required.

Adjustment and maintenance of the closer

It is impossible to talk about adjustment “in general”: different manufacturers install screws in different places. Somewhere they are located on the side surface, somewhere under the removable panel on the front part, at the bottom or top of the case. Simple models have only two adjustment points, while more complex ones can have five or more. Therefore, each model has its own instructions.

In general terms, we can only talk about periodicity. As the temperature decreases or increases, the viscosity of the oil changes. And its condition changes the speed of door slamming. Doors that close too quickly cause inconvenience: they push the person passing behind. Older people will definitely not like this. Slowly closing doors make you want to help them and push them. But for the mechanism, this help is death: several dozen assistants and you will have to buy another mechanism. Therefore, timely seasonal adjustment of door closers prolongs their life.

We need to talk about adjusting the closers only in relation to each model: they are too different in design

Maintenance of the closer consists of changing the oil in the housing. This must be done once a year. The procedure is described in detail in the instructions and differs for different models, just like the adjustment.

Where is it wise to install a door closer and where is it not worth it?

Most often, devices are installed on those doors for which it is important to be constantly closed: street and entrance doors.

When installing, they try to place the housing not outside, but inside the house or apartment. Frost-resistant models exist, but they are much more expensive, require more frequent maintenance and still have temperature restrictions. It is not recommended to install door closers on lightweight interior panels, especially those with glazing or stained glass. Frequent activation of a spring that is too strong can lead to loosening, rattling and even glass falling out.

The door to the sauna also requires external installation of a door closer or a recessed structure. A conventional device will quickly fail due to changes in temperature and humidity.

Additional functions

In cheap products, looking for additional functions is a waste of time. More expensive models may provide a number of additional amenities.

Fixing the open position (hold-open)

From time to time there is a need to leave the doors wide open. For example, in order to bring in or take out a large item. Holding conventional door closers for a long time spoils the mechanism. In order not to damage the device, there are special models with the function of fixing the open position. They are equipped with a mechanical or electromagnetic latch. The operation of a mechanical latch is simple: when the door is opened at an angle exceeding 90o, the latch is activated. It is easy to remove: you need to pull the canvas towards the closing side. In models with electromagnetic latches, the doors are held as long as there is current in the network. Once the chain is broken, the doors are unlocked (there is a special unlock button).

Opening delay (damper)

This is a feature that prevents the door from opening very quickly. This eliminates the possibility of injury to the person on the other side of the door.

Closing delay

It is necessary in those rooms through the doors of which some kind of cargo is carried out. However, the flow of people should not be large.

Rules to follow when operating door closers

There are several things that cannot be done when the door closer is installed.

- The first common mistake when we try to help the door close faster is to press on it. This should not be done, otherwise the mechanism will break much faster than it should.

- The second no less common mistake is that rolling on the door will have a bad effect on the closer and the hinges. So it’s worth keeping an eye on the children, or clearly explaining that this cannot be done.

- The third mistake is to keep the door in the open position or place some objects under it to fix it in the open position. For such cases, the closer has a locking function. But this is worth taking into account before purchasing a door closer, since there are special mechanisms that are designed to hold the blades open. For such purposes, select the hold-open function.

This concludes my article, my advice to you is to choose closers that are suitable for your door and correctly calculate their class. After all, as you can see, there are many nuances that are worth paying attention to. After all, when you know why a breakdown may occur, you can avoid it. Good luck to you!

Spring closers

Door closers are not only mechanical. There are also spring ones. They are considered outdated, but you must agree that you can install an automatic closer in a house or apartment only on the entrance doors. And then, the question of feasibility remains open.

Spring closers - an option for interior doors

At the same time, in some rooms it is advisable to keep the doors closed. Then it makes sense to install spring closers. They cost several times less and are easy to install. Their disadvantage: they are not adjustable and press with constant force. However, a good option for a bathroom door, for example. You can see how one of the spring door closers works in the video.

Everything about the installation is simple. They are installed on the side where the door hinges are installed. Screw the device to the jamb at a convenient height for you. All. Installation is complete.

Some models have a guide that is mounted on the door leaf. A roller attached to an outrigger rod runs along it. This device is more progressive: it does not damage the doors. But during installation, you need to check the level to install the guide.

There are spring closers in some door hinges. Of course, they are installed during the installation process, but it doesn’t hurt to know that there is such a miracle: hinges with a closer.

How to install a door closer

Installation of various types of door closers begins with preparing the tools necessary for the job. Need to stock up:

- a drill with drills of a suitable size;

- ruler;

- pencil;

- screwdriver

To perform fastening, a “3” drill is most often used. In general, when choosing the size of the nozzle, you should take into account the cross-section of the fastener.

Defining the Installation Layout

Correct installation of a door closer on an entrance or interior door should begin with studying the installation diagram. To do this, you need to take into account the opening direction of the door leaves. If they open inward, then the main part is placed on the sash, and the lever on the door jamb. When the entrance groups open outward, the main part is mounted on the jamb, and the lever on the door leaf. In both options, the screws responsible for adjustment must be located on the side of the door hinges to be able to adjust the unit.

Applying a template

A special template is supplied with the device, showing how to correctly install the door closer components. It is a tracing paper for holes, so the preparatory process of making marks does not take much time. For each element of the closer, the template already has marks. For different models of a certain class, the markings are marked with a specific color. The class of the mechanism is always indicated next to the marking. The templates are double-sided, which allows them to be used when installed to open in different directions.

Step by step installation

To install a door closer, you need to make holes. To do this, align the horizontal red line on the template with the top edge of the door leaf, and the vertical red line with the hinge line. A line running vertically must be drawn with a pencil to accurately determine the line of loops.

After this, you need to find holes on the template for a certain class of door closer and transfer them with an awl to the door or jamb. Then holes are made with a drill in the marked places. Before installation, steel closers must be separated, since the body and lever are installed separately. The installation steps are as follows:

- the body is screwed on;

- a traction lever is connected to it, which is put on the lower protrusion of the main part;

- the lever is connected to the rod by combining their matching parts.

The main thing in carrying out high-quality installation is to follow the instructions. All installation work takes no more than half an hour.

Features of installing hidden closers

A hidden door closer can be floor-mounted, top-mounted or in the form of hinges. The floor mechanism is installed together with the door group. To install hidden closers for interior doors, you should make a hole for them in the sash, being careful not to damage the outer cladding. Fastening is carried out according to the general scheme.

How to put on a gate

To install a door closer on a street gate, you need to decide on its mounting location. If the gate has a top crossbar, then the mechanism is placed on it. If it is not there, then the rod is installed on the side stand, unfolding it lengthwise. After this, the installation of the closer is carried out according to the usual scheme. When choosing models for the street, you should give preference to pneumatic devices that will not freeze in the cold.

How to install on a metal door

A closer of any type for a metal entrance door is mounted according to the scheme described above. To install it, you will need to select a drill of the appropriate size and fasteners with the appropriate cross-section.

The holes for the closer on the steel sheet are made large; the applied force class for spring closers should be no lower than fifth. When using a template, you should choose markup that is appropriate for class.