In the relatively recent past, to ensure independent tight closing of the front door or gate, such simple mechanisms as a spring, a counterweight with a cable and a pulley system, rubber bands or their analogues made from rubber tires were used. Today, to ensure that the door itself closes tightly, closers of various sizes, colors and shapes are used. What door closers for entrance doors are presented on the shelves in specialized departments of stores, what you should pay attention to when purchasing and how to install them - read on.

What it is?

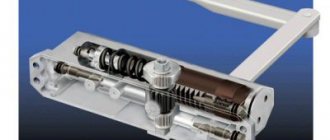

A closer is understood as an auxiliary product. It may vary in complexity and characteristics. The main mechanism is located in the housing, so there are options that can be mounted on entrance doors, near the street. The main element of the housing is the spring. It contracts when opened, collecting energy.

After you exit, the base begins to release energy back through the return mechanism. When the canvas returns to its cavity, the shock absorber is activated. Due to this, the canvas returns smoothly. The operating principle of the shock absorber is based on oil flowing from chamber to chamber.

In more complex designs there may be several shock absorbers. Their number affects the weight of the canvas, but in general, it does not affect the opening/closing technology. How softly the door closes is affected by the viscosity of the oil and the design of the internal oil chambers. The transmission moment between the spring mechanism and the blade is determined by the hinge, which often has a collapsible design.

This is convenient, since it will not be possible to take something out of the building with an active closer; the canvas will get in the way. Thus, we conclude that the door closer is a set of mechanisms that ensure the safe opening of the door, which is very important if there are small children in the house. In addition, it retains heat, which means it does not waste utility costs. It eliminates the destruction of the canvas and also eliminates scratches.

How to increase service life

There are a few simple tips that, when followed, eliminate the possibility of mechanical breakdowns and extend the life of the devices.

- Always take into account the conditions for using the door closer. If it is installed on the doors of public buildings, the frequency of opening/closing increases sharply. In addition, not all visitors handle doors carefully; strong mechanical stress may occur. For such needs, you need to choose the most reliable door closers. Attention is drawn secondarily to the number of adjustments; the main factor is mechanical stability.

When choosing a model, it is necessary to take into account the loads to which the closer will be subjected

- Make sure that the door is used for its intended purpose and does not serve as a barrier for animals, a toy for children, etc. There is no need to increase the weight of the door leaf. We have already mentioned that the greater the weight of the doors, the higher the inertia indicators, and they have an extremely negative effect on the mechanism.

Closers for heavy doors

- Never undertake installation or adjustment of the device without reading the instructions, without understanding the principle of operation of the closer elements, and without foreseeing the possible consequences of your interventions.

You can start adjusting the closer yourself only after studying the instructions

- Do not buy mechanisms from unknown companies. The fact is that they have many connections that require high precision machining of the surfaces of the parts. At the slightest deviation in technology, oil leaks appear. It is impossible to correct the problem by simply adding oil; complex repairs must be made. This requires a lot of time and money, and the result is still unknown. It is much more profitable to immediately buy expensive but high-quality goods from well-known European class=”aligncenter” width=”737″ height=”590″[/img]

Door closers from well-known brands are of high quality and have a long service life.

Find out how to repair the door handle of a metal door with your own hands in a special article on our portal.

Main types

A variation concerns direct installation. Here are the following types of door closers :

- Top mounting. This is the most common type, easy to install, easy to maintain and inexpensive. From the name it is clear that the mechanism is placed on top and rests against the dimensions of the door frame, and the other part against the door leaf. Note that such a product has a body, inside there is a spring, a shock absorber and oil containers. Oil flows over them, which makes the closing process soft. This variety is divided into two subtypes, where the first has a gear drive, and the second has a sliding drive. The latter is considered collapsible, since it can be easily moved to disassemble the closer in order to fully open the door.

- Floor mounting. Such installation takes place where it is important to preserve aesthetic qualities. In addition, the design is designed to smoothly lock sheets weighing even 300 kg. Such products cost a lot, so they are used in shopping centers, for example, for opening glass products. The closer is placed on the floor here. It does not have the usual moving and gear mechanisms, since everything is located in a single housing.

- Hidden installation. A similar design is used where a doorway allows it. Usually they are not installed in ready-made openings, since the gaps in them are not maintained. A popular hidden door closer is a sliding mechanism, which is somewhat similar to conventional modifications, but is only hidden from people in the niche. Hinges with closers are considered more modern. Due to their compactness, they are difficult to maintain and often break down. Such mechanisms are not designed to work with massive canvases and during installation require that the canvases hang evenly.

Closers for heavy metal doors

Closers for solid steel doors must have greater power to provide sufficient force to press the closing leaf. In addition, it is necessary to keep the door from impact, which, in addition to noise, causes additional vibration and premature wear of the door mechanisms.

To ensure operability, heavy doors are equipped with closers designed for loads of up to 600 kg. By design, these can be open-mounted devices and floor-standing models. The mechanism allows you to separately regulate the force and speed when closing and slamming the door. The opening angle is limited to 180°, and the closer operates at 160°. The products provide a partial opening function and the ability to fix the position. An anti-vandal valve is installed to prevent damage in case of manual closing.

With wide folds and a large area of the canvas, additional windage is created, so the closers are equipped with a “wind brake” that protects against impacts and involuntary movement.

Dimensions and specifications

If you are going to install a street door closer on the door, it is best to immediately buy it at the time of purchasing the door leaf. This is important, since it is important to compare the mass of the blade and the mechanism itself, because otherwise, exceeding the load on the closer, it will quickly fail.

Today there are 7 classes of door closers on sale, where each class is designed for its own weight and the size of the canvas. For example, the first class, the most inexpensive and accessible, is designed to work with 750 mm blades and weighing up to 20 kg.

Frost-resistant outdoor door closer

This mechanism is easily suitable for interior doors. On the contrary, class 7 is the most expensive because it is capable of working even with complex and heavy canvases. It can easily handle even 160 cm sheets weighing more than 100 kg. There is no point in buying door closers that are more expensive and better in their class in the hope that more expensive ones will be better.

Inside each mechanism there is a structure that must be cocked when the door is opened. If it is too light, you will personally feel uncomfortable because you will have to put in too much effort. Otherwise, the door may simply slam with force, since the inertia will be stronger than the mass of the leaf, taking into account the time it takes to move to the return point.

Repair

If the mechanism is overloaded, which leads to wear, some parts are replaced. Spare parts for the closer are selected taking into account its type. If there is an oil leak, the condition of the housing is assessed; if the defect is small, the gap is closed with sealant. If there is severe deformation, the part is replaced. When the metal of the rod breaks, a welding machine is used. Corrosion is eliminated by cleaning. The bend of the rod is corrected manually, and the shape of this element is restored. The door closer on a glass door, metal or wooden door is repaired in the same way.

Installation

Before installation, think about whether you are unlocking the door towards yourself or away from you. The location of the loops will depend on this. In turn, on the reverse, opposite side of the loop, a closer is installed. The product delivery package includes all the necessary components, so you don’t have to buy anything.

Unless you can use a screwdriver, drill, level, marking pencil and measuring tape. Every man has such a tool in his arsenal, so you don’t have to buy anything extra. Installing a door closer yourself will help you save up to 20-25 percent of the cost.

Most door closers are supplied with additional screws that will remain after work. There is no need to panic, because they were left on purpose, since the manufacturer puts two sets of hardware at once, for wood and metal. For the rest, carry out the installation according to the drawing diagram included in the kit.

The work requires an assistant who will hold the hydraulic door closer while trying it on. Then you need to drill holes, try on, fix the device, make adjustments and then tighten the screws.

Installation methods

Based on the installation principle, door closers are divided into four types:

- Outdoor installation. Such models consist of two blocks, one of which is attached to the door leaf, the other to the lintel of the door frame. They are connected using movably articulated levers. Installation methods for such models are shown in the figure.

- Hidden installation in frame. A hole is cut out in the lintel of the door frame and a door closer is installed into it. A lever is attached to the top of the door leaf.

Installation methods may vary - Hidden installation in the floor. This type can often be seen on glass swing doors in stores. Installation with a door leaf made of any material is possible, but only at the stage of installation or general reconstruction: it is necessary to make a recess in the floor under the body of the closer.

- Hidden installation in the door. In this case, a recess is made in the upper end of the door into which the device is installed, and the lever is attached to the door jamb.

You can do any of the installation options yourself. It just requires varying degrees of skill. The simplest is external installation. It has the widest distribution.

Adjustment

Aligning everything to the level, tightening the screws and performing the first opening does not mean that you have installed the door closer correctly. You need adjustment of the door closer , which will help make opening and closing softer and adjust the product to your tool. The work will require a chair or stepladder for working at heights, a Phillips screwdriver, a flat screwdriver, instructions for adjusting a specific model, and a hexagon.

First you need to pry off the top cover. In most cases, the lid is snapped onto clamps, but sometimes it is screwed onto self-tapping screws. Use a screwdriver or pry off the top cover with a plastic, unwanted card. Otherwise, there may be scratches on the surface and loss of aesthetic appearance.

You must understand that any changes made to the position of the adjustment screws must be tested. This is due to the fact that the weight and shape of the door leaf, correct installation, as well as other nuances are purely individual.

Adjusting the closer

Therefore, you need to adjust and open/close the door to understand how convenient and smoothly everything works. If you have animals in the house that you don't always want to let in, you can focus on the closing speed and only slow it down at the end so that there is no slamming.

The mechanism design includes two main screws. These are screws 1 and 2 and they are marked this way on most modern door closers. You should not adjust thoughtlessly, since practice shows that changing the position of the screw by more than 2-2.5 turns leads to breakdown of the product as a whole. Therefore, do everything smoothly and check the result after each twist.

Screw number one is responsible for the door opening angle. That is, this is a possible range of degrees, from 15 to 180. The second screw, on the contrary, regulates the speed at which the door will move when it is in the finishing position, slightly open, in the range from 0 to 15 degrees. It is this that influences the cotton and allows it to be smoothed.

Setting the intermediate stroke

Usually the intermediate stroke is adjusted in unison with the main door stroke, but there are other options. For example, if you need to slightly reduce the speed halfway through the door closing. To do this, use the third adjusting bolt. This bolt serves to hold the door leaf in a certain position. For example, you need to add more closets to your apartment.

The screw can be adjusted so that the door remains open for a while, and only then begins to close.

What should you pay attention to before purchasing?

When choosing a door closer, it is important to pay attention to the manufacturer. You should not buy the cheapest option, as this will lead to rapid failure of springs, shock absorbers, and oil chambers. It is important to choose trusted manufacturers whose reviews indicate positive operating qualities.

It is important that the body is made of stainless steel, especially if you are going to use a metal door closer for the front door. You should not use it if the door opens into the inside of the house, since then the closer will be located outside. It will be exposed to precipitation and will rust.

Pay attention to the opening angle. A standard door closer should allow the door to be opened by at least 180 degrees. Indicators are reduced downward due to adjustment. Therefore, it is important that this mechanism be included in the design of the closer.

Closer device

Additional functionality is important. For example, the door closer should include a wind protection function. In the nomenclature it is called Back check. It is designed to slow down the door when it is fully opened. Otherwise, the wind may hit the wall of the house and be damaged. Partly because of this, the handles suffer, since it is the door that hits the wall.

The additional Delay action feature allows the door to close without effort. This means that when opened slightly by 70 degrees or more, an additional return mechanism is activated, which tensions the return spring. Thus, the person who has left the premises does not have to make any additional effort to close it.

Another important function is Hold Open. It is considered important from a convenience point of view. This is an opportunity to effortlessly open the door and lock it in this position. Previously, it would have been necessary to disassemble the hinge mechanism and place something under the door so that it would not close. It is only important to open 180 degrees until it clicks.

Rear doorman

For ease of use of the trunk, we came up with a hands-free access system

. We have already discussed the principle of its operation. And here is how the power drive of the luggage compartment lid works.

An electric motor with a gear reducer that turns the lid by its hinges.

An electric motor with a gear reducer that turns the lid by its hinges.

Moreover, such devices are used both on heavy fifth doors of station wagons and on the lids of sedans.

There are also cars with a hydraulically driven trunk lid.

, but

the drive in the form of a sliding rod with a built-in electric drive

.

Hydraulic drive of the trunk lid of the Volkswagen Phaeton sedan: 1 - hydraulic cylinder; 2 - hydraulic unit; 3 - electric motor; 4 — trunk loop.

Hydraulic drive of the trunk lid of the Volkswagen Phaeton sedan: 1 - hydraulic cylinder; 2 - hydraulic unit; 3 - electric motor; 4 — trunk loop.

Price

The market offers us many options for door closers in different price segments. For example, the inexpensive version SD-2020, which is designed for 25-40 kg. This product is suitable for light weight external and internal doors. In general, a reliable device in the price segment up to 800 rubles, since it is designed for 200,000 opening cycles.

The main thing is not to allow its installation in open conditions, since the housing is not sealed. This type of door closer assumes the ability to open the door up to 160 degrees. The permissible operating temperature is a value in the range from -30 to +40 degrees Celsius.

Apecs DC-22/25-45-MW/ closer, designed for a weight of at least 45 kg. It is white in color, which means it can be installed with white plastic doors. True, self-tapping kits are black, so if you want to achieve high aesthetics, then you should paint them in color or look for white analogues.

This design allows for adjustment, but does not have additional functions. The opening of this mechanism is possible by 180 degrees, which allows you to fully open the closer. The opening mechanism involves quick removal of the moving element to open the door wide.

There are door closers on sale whose mechanisms are hidden in the hinges. These are modern hinges of high aesthetics, which are designed for right and left opening, respectively. This should be taken into account at the time of purchase, otherwise you may waste your money. For example, the left and right loops are from the manufacturer Laflorida (Laflorida), where each is designed for 25 kg.

If you put three of these hinges on a metal front door, you can withstand up to 75 kg. The hinges are designed to fully open 180 degrees, which does not distinguish them at all from the mechanisms we are used to.

Famous manufacturers

Among the most popular manufacturers that you should pay attention to when choosing are:

- Dorma;

- Cisa;

- KDS;

- O&O;

- Ryobi;

- Abloy;

- Diplomat;

- Boda.

The most popular accessories of this type are German, Japanese and Italian manufacturers. They offer an extremely wide selection of high quality products. Each product corresponds to the classification, has a reliable design and durability.