A frost-resistant outdoor gate closer is a device that is designed to smoothly and completely close a gate (door, gate). Installing this device allows you to automatically close the doors without performing any actions. Homeowners, summer residents and builders are showing keen interest in such modern designs.

Such devices play an important role in long-term operation

Advantages of door closers

The benefit of this mechanism is obvious - the closer will smoothly close a gate or door left open in the bustle. When driving a vehicle into a fenced area, there is no need to return to the gate to close it; the gate closer will do its job perfectly.

The positive side is that it prevents the gate from hitting the frame

The smooth operation of the mechanism allows you to significantly extend the life of the door device, its locking elements, hinges and eliminates the appearance of extraneous noise from closing.

Currently, frost-resistant door closers are a very popular product. Manufacturers offer a wide range of this device on the market. They can be used for gates, as well as installed on doors and gates.

An example of a closer with increased resistance to weather conditions

Terms of use

- Do not secure the door open with a brick, and do not allow children to play with the door. All this leads to premature failure of the mechanism. Doors with lever mechanisms are secured with a spring-loaded stopper;

- “manual additional closings” are also harmful. To avoid them, adjust the closing speed - quickly but gently;

- adjust and lubricate moving parts twice a year;

- if the door leaf is heavy or is regularly pushed with force and it can fly off the support, a reverse braking function is needed;

- Inspect the casing regularly - it must be intact and not allow moisture to enter the mechanism.

Features of door closers

Despite its prevalence and external simplicity, a number of important features must be taken into account when manufacturing and purchasing a mechanism for sashes.

The closer is a moving device, and as a result, friction strongly affects all its components. As a result of the movement of the gate, vibrations occur and it often hits foreign objects.

Each type of such device has its own strengths and weaknesses.

These features determine:

- vibration resistance;

- impact resistance;

- wear resistance.

Very often the device is installed outdoors, so when used, the mechanism will be affected by temperature changes, excess dampness, snow, ice and many other natural factors.

Most often, frost-resistant options have durable protective covers

Based on these features, the design must have the following qualities:

- frost resistance (even at negative air temperatures, the device must properly close the gate);

- moisture protection (as a rule, moisture has a very negative effect on any mechanisms. Therefore, the door closer must have moisture protection, or be made of components resistant to moisture. In any case, humidity should not affect the performance of the device).

Installation methods

Devices are classified according to installation method into:

- models installed from above: on the wall, door frame, door leaf, that is, top installation;

- models installed inside the door, that is, hidden installation;

- models hidden in the floor, that is, floor installation.

Closers are installed in different ways. The simplest one is described in the instructions supplied with the device, which tell you how to properly install the closer in an accessible form. To install you need to follow simple steps:

Cut out a template that can be used to mark the places where screws or self-tapping screws are attached to the door; Mark places for attaching self-tapping screws or screws on the door and jamb; Attach the closer body to the jamb or door with screws or self-tapping screws

In this case, it is important to direct the adjusting screws towards the hinges; The threaded arm must be detached and screwed to the jamb or door using a lashing shoe and self-tapping screws or screws; Install the lever on the closer axis and secure it; After adjusting the length of the rod, close the screws with a decorative cap.

Second method: the door closer is installed in such a way that the adjusting screws face the door hinges. In this case, the length of the forearm should be such that the lever is at an angle of 90 degrees to the door leaf.

The third method: involves installing a closer when the lever is parallel to the door.

After installing the closer, it is necessary to adjust it for comfortable closing of the doors.

The closers are screwed depending on the configuration and installed from below or from above. They are left or right.

A short video with adjustment technology:

Principle of operation

Today there are many samples on the market that have fundamental differences in their design, but the principle of operation of any of them is the same.

When opening the gate, the applied force is transferred to the mechanism of the device. The most common mechanism has a metal spring and piston. It moves along the wicket, the spring is compressed, and the created pressure generates energy directed back to the original movement of the mechanism.

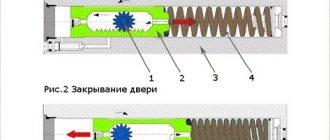

Door mechanism design

When the opening force ceases to act, the energy of the compressed spring begins to return the piston, and therefore the entire gate, to its original position. Due to the fact that the cylinder with the piston contains compressed air and oil, the gate moves smoothly and evenly when closing. There are models with the ability to adjust the piston stroke, which allows you to adjust the speed of closing the gate.

Speed control

Settings

Setting up a homemade mechanism is as follows:

- the speed of movement of the sash in a homemade product is regulated by changing the length of the elastic element (in spring structures) or the weight of the load (in gravitational ones);

- To change the adjustment to the zero position, change the thickness of the shock-absorbing hose.

When setting up, you can take into account other design flaws, for example, install a shock absorber on the load if it touches the wall, enlarge the hole in the ball if the door is difficult to open, etc.

Varieties

Currently, consumers are increasingly buying door closers. Although the operating principle of all mechanisms is the same, today there are many varieties of these devices.

Depending on the type, their price can vary significantly. In order for the buyer to choose the most suitable model, it will be useful to become familiar with their main types.

Installation on the door depending on the opening direction

All closers are usually divided into three types:

- Hydraulic.

- Pneumatic.

- Electrical.

Hydraulic

Closers with a hydraulic mechanism are the most common devices today. Their work is based on the movement of the piston and the compression of the spring. They consist of two parts, one for the gate, the other for its frame. This type can work with any variety of hinges.

Diagram of the hydraulic mechanism

To install a hydraulic closer, no special knowledge or skills are required; it can be done by one person without assistance.

After installation, most hydraulic mechanisms can be adjusted to operate smoothly and quickly close the gate.

Pneumatic

One of the newest types of design is an outdoor frost-resistant door closer with a pneumatic mechanism.

Its operating principle is also based on the movement of the piston in the cylinder, but such models do not have a spring. When the valves open, air is compressed on one side of the piston, and a vacuum is formed on the other. The compressed air pressure returns the open gate to its original position.

The principle of operation of a device with pneumatics

Door closers of this design have many advantages:

- They remain operational in a wide temperature range, as a rule, from −50°С to +50°С, with ice and heavy snow cover.

- The working components of the device are made of high-quality stainless steel, so the device is not susceptible to corrosion.

- The sealing elements are made of wear-resistant polyurethane, which minimizes the effects of friction and allows the device to remain mobile for a long time without maintenance.

- They have a wide opening angle of up to 160°, making them the most convenient in places of construction, repairs, and large groups of people.

- Such door closers can be installed regardless of the side of the gate opening.

- The device can be placed in a vertical or horizontal position. That is why they can be used not only to equip gates, doors, gates, but also furniture in production.

The idea of installing pneumatics on a gate

Electrical

Electric closers are one of the most complex in their design and installation method. Their design can be without a top crossbar. The complexity of this design is due to the presence of functions that are not found in any other types of door closers.

Electrical mechanism installation option

These functions include:

- Safety of use (the closer will not close the gate if there is a small child or animal in the opening).

- Smooth not only closing, but also opening of the gate.

- Maximum quiet operation.

- Automatic opening and closing using a separate button or control panel.

- The presence of a large number of options and settings in itself allows you to select the device that best suits the client’s needs.

- Possibility of temporarily disabling the door closer functions without dismantling the device itself.

- Aesthetic appearance.

Schematic representation of an electric gate closer

General rules

How to install the mechanism correctly? The installation process is simple. Anyone who has the necessary knowledge, skills and abilities can carry out the work.

When choosing and installing, you must follow the instructions

When choosing a door closer, you need to clearly know the conditions under which it will operate. The main criterion when choosing an outdoor mechanism is frost resistance. It should also be insensitive to snow, rain and hail. The door weight must be appropriate.

The instructions are:

- Carefully select the elements that will be responsible for fastening the structure. It is important to consider the force that a person applies when the door opens and closes. If the load on the sashes increases, the same happens with the fasteners.

- Particular attention should be paid to the power of the screws. If they are weak, it is recommended to replace them with stronger ones.

- The wicket door closer must not conflict with the class of purpose. A mechanism intended for indoor use should not be used outdoors. Otherwise, serious problems may arise that require large financial investments.

- Once the product is installed, there is a need to adjust it. This must be done in accordance with the instructions that come with the kit. A standard screwdriver is usually used to adjust the mechanism. If the door closer is equipped with a locking function, this also needs to be configured. To do this, a special nut is tightened on the lever. It is this part that is intended to hold the sash.

Important! A template, applied in the desired area of the crossbar, is included with the mechanism.

Its fastening is carried out according to the markings on the template.

What to pay special attention to when buying a door closer

Choosing a street closer for a gate or wicket is not the most difficult task, but you should still take into account some features. Otherwise, the purchased device may not work properly or may break after working for a very short period of time.

Installation and configuration instructions

The main parameters that deserve attention are:

- power is the main parameter of the closer. A device with low power will fail very quickly if it is attached to a large, massive gate. If a powerful closer ends up on a light, small gate, then there is a high probability of it breaking, the hinges coming off, and the locking device failing;

- the presence of a latch is necessary in order to leave the gate open for a while. This is required when furniture and other things are brought through the passage, and a large number of people pass through. In this case, the absence of a latch will lead to inconvenience and increased wear of the closer mechanism.

Methods of placing mechanisms

Some owners, instead of a latch, place supports from improvised means under the gate. In this case, there is a risk of creating excessive stress in the cylinder, which will also shorten the life of the closer.

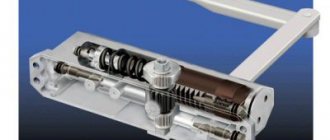

Device and principle of operation

Most modern devices of this type are based on a spring, which is compressed when the door is opened. When the pressure on the door stops, the spring relaxes, returning it to the closed state.

Door closers can be of different types, types and colors

The main difference between different types of closers is the method of transmitting force to the spring: there are devices with a hinged rod or with a sliding channel. But in general, the principle of operation is this.

By opening the doors, we activate a gear that transmits force to a rack (hidden in a metal cylinder) filled with oil. The rack drives a piston, which pushes the spring, compressing it. When the piston moves, oil flows from one part of the chamber to another, providing a certain resistance and slowing down the movement of the door leaf.

The internal structure of a door closer for an entrance or interior door

As soon as the pressure stops, the spring begins to expand, pushing the piston in the opposite direction. At the same time, the oil again flows from one part of the device to another, slowing down the slamming.

As you can see, the speed of movement of the door and the force required to open it depend on several factors: the power of the spring, the ease of movement of the gear, rack and piston. The degree of viscosity of the oil also has a great influence: at low temperatures it becomes more viscous and flows worse; at high temperatures, fluidity, on the contrary, increases, doors close faster. Therefore, the door closers on the entrance doors have to be adjusted with each change of season.

In addition to devices that use gears to transmit torque, there are mechanisms with cam elements. The cams have an uneven, heart-shaped shape; turning it also changes the force required to open the door and the speed of its return to the closed state. This makes it possible to make smoother adjustments. However, the most common mechanisms on the market are those with gears: they are more reliable.

Mechanism installation

First, you need to choose the right device. And here it is important to understand that there are door closers that are designed for use only indoors. Therefore, under no circumstances should they be used outdoors, because... their elements are not designed for operation in subzero temperatures and exposure to high humidity.

Next, you need to select the type of device. In fact, all proposed types provide the necessary functionality. However, there are certain limitations in their use. For example, for electrical appliances, an electrical connection is required. Those. Such points must be taken into account initially.

Adviсe

It is better to fix the closer on the street door from the inside. This will protect it from the negative effects of natural factors. If such an installation is not possible, purchase reinforced frost-resistant models and install them in a place convenient for you.

If the door opens towards itself, the device is mounted in the upper part of the sash on the side of the door hinges. If “from yourself,” then the closer lever is attached to the sash, and the mechanism itself is attached to the jamb.

You will learn more about pneumatic closers in the following video.

Kinds

Today, there are three main types of door closers:

- electric – ensure silent and safe operation. As an additional option, you can purchase a mechanism that will open and close the door with a button, however, for operation you will need to supply electricity to the fence;

- hydraulic - the work is based on the use of a hydraulic piston; these are quite powerful and durable devices;

- pneumatic - the most unpretentious door closers, capable of operating in conditions of low temperatures and high loads. The work is based on the use of an air cylinder with compressed air.

Naturally, when choosing, you should proceed from the budget, operating conditions, as well as the technical characteristics of the device.

Electric view

Choice

To choose the right accessory, you need to consider the following parameters:

- working conditions;

- door weight - the power of the mechanism should be selected with a small margin;

- you need to consider which way the gate opens;

- the device must ensure free opening to the maximum required position;

- possibility of mounting on the right or left door;

- material for manufacturing the unit body;

- possibility of adjusting the mechanism.

Also, when purchasing, you should pay attention to the complexity of installation - the simpler it is, the better.

What points need to be taken into account

In order to correctly install a door closer on an iron door, you need to decide on its technical characteristics when choosing a device. Some models - such as floor structures - need to be installed in advance. Their installation is taken into account at the design stage.

In ordinary houses and non-residential infrastructure facilities, overhead options are more often used - they are attached externally, at the top of the door leaf. In addition, there are hidden options installed in the door frame or the leaf itself. As a rule, such systems are installed by the manufacturer, and during the installation stage they only require adjustment.

Their installation on the front door is most often done with fastening to a box beam. In most cases, branded products are supplied with a detailed explanation from the manufacturer regarding the choice of fixation points for the product. For successful installation, it is necessary to adjust the canvas itself in advance. It should have easy movement on hinges and fit into the opening without distortion.

Requirements for operation

Along with selecting the right model, an important factor influencing the life of the device is its correct operation. Increased attention should be paid to the correct installation of the gate. The gate closer must be proportional to the weight and dimensions of the door.

To avoid frequent breakdowns, it is prohibited:

- Open and close gates unnecessarily many times;

- Apply force to the gate to close it faster;

- Use improvised objects instead of a retainer.

Correct hinge connection plays a decisive role in proper operation

Here are all the most basic requirements, the fulfillment of which will allow the device to serve the period specified by the manufacturer.

Tags: closer, gate, pneumatic, hand, own

« Previous entry