An indisputable fact is that the reliability of a building depends entirely on the strength and quality of the foundation. It is quite possible to fill it with your own hands. This will make it possible to save significant funds in the family budget.

To be sure of the result, it is necessary to reproduce the correct dimensions of the foundation for the bathhouse. They, in turn, are influenced by the composition of the soil, the type of structure, its part and the thickness of the planned walls. In this article we will look at various variations.

Photo of strip foundation

Depth depending on soil type.

Before carrying out technical work on installing the foundation for the bathhouse, it is necessary to conduct a geological survey .

Depending on the identification of the exact type of soil, its load-bearing properties, the possibility of changing quantitative parameters as a result of tectonic changes, the best material for the foundation is determined, and most importantly, its depth is calculated. Correct calculation of the burial depth, in some cases, will save the foundation and walls of the bathhouse from subsidence, cracks, distortion, and deformation.

Fine and dusty sandy soils contribute to strong shrinkage of the bathhouse foundation. To reduce or level out this process, the depth of the foundation can be significantly increased. Instead of the planned 50 cm depth, it would be advisable to increase it to 70-100 cm. With increasing foundation depth, the compression resistance increases proportionally. This value in fine sands is approximately two times lower than in coarse sands. In order to make up for the missing load-bearing capacity, the depth of the foundation is doubled.

Gravelly and coarse sandy soils are quite reliable in terms of load-bearing qualities. Sandy soils are not heaving, so regardless of the amount of precipitation per year or the depth of freezing, you can choose any type of foundation for a bathhouse. Coarse sandy soils exhibit insignificant shrinkage compared to fine ones. On them it will be easy to build a shallow foundation, ranging in size from 20 to 50 cm.

Sandy soil does not retain water, which means it is a light soil. A pile or columnar foundation can be built on it. The depth of the pillars is approximately 1.5 m.

Rocky soils have the best load-bearing qualities of all other types of soils. They practically do not shrink, supporting the weight of fairly large-scale structures. Rocky soils are not heaving because they do not retain water in their pores. The depth of soil freezing will not be taken into account when building the foundation. There is no excess moisture in the soil, so they will not expand due to the conversion of water into ice. On rocky soils, foundations can be installed more economically.

Rocky terrain acts as an unshakable foundation for a building, so shallow or shallow foundations (less than 20 cm) are always built there.

Clay soils . unlike most others, they have a finely porous structure. The main disadvantage of clay soils is their ability to swell. The proximity of groundwater and abundant rainfall contribute to the rapid accumulation of water in the pores of the soil. With the onset of sub-zero temperatures, water turns into ice. The density of water, after turning into ice, increases, which leads to an expansion of the volume of the entire soil. Changes in soil volume place additional load on the foundation, causing its deformation, cracking, distortion, and lifting of the bathhouse building.

Calculations for deepening the foundation on clay soils are carried out taking into account the freezing depth . It is necessary to build the foundation below the soil freezing level, then the loads will be exerted only on the side walls of the foundation, eliminating pressure on the base of the foundation. For example, the depth of soil freezing is 1.5 m, which means the foundation lies at a distance of 1.6 m. The high level of groundwater will not allow the necessary deepening of the foundation.

The base of the foundation is at an indentation of no lower than 0.5-1 m. Sufficient distance will be required in case of capillary rise of water in the soil and in case of an unexpected increase in water level due to heavy floods or prolonged downpours. To drain excess water from the ground, a drainage system is installed around the foundation. They dig a trench deeper than the base of the foundation. They lay the foundation around the perimeter with a pipe and lead it into the inspection well. Water will not accumulate and freeze in the pores of the soil, and excess water will also be automatically drained in the event of a strong rise in the groundwater level.

When installing a drainage system, the depth of the foundation can be changed, taking into account the load-bearing properties of the soil and non-tectonic parameters, which are also important for calculating the depth of the foundation for a bathhouse.

Popular solutions for how to correct the shortcomings of highly heaving soil?

You should not refuse to build on a site where the soil is very heaving. There are five ways to offset this lack of land.

1st method

It is the most expensive, but also the most reliable. To implement it, you will have to select heaving soil that holds water from the pit, and pour gravelly sand in its place. The depth of the pit should be deeper than the freezing level of the soil.

2nd method

You can simply lay the base of the foundation of the selected type below the freezing depth of the soil. True, the lateral heaving force will remain, but to neutralize it, the soil around the pit is either replaced or insulated. This method is only suitable for heavy buildings, in our case a large bathhouse made of heavy logs, but not of light timber.

3rd method

The soil can simply be insulated. To do this, a layer of insulation is laid around the foundation with a width equal to the depth of soil freezing (for example, if the ground freezes to a depth of 1.5 m, then we lay insulation 1.5 m wide). The foundation itself can also be insulated.

4th method

Heaving will decrease if there is less water in the soil, which means it needs to be drained away. To do this, drainage is made along the entire perimeter of the foundation - a half-meter wide ditch, deep to the base of the foundation. A perforated pipe is placed inside, which is additionally wrapped in filter fabric. When laying the pipe, a slight slope is maintained, along which water will flow into the drainage well.

As you can see, among the measures to combat soil heaving there is also a way to combat high groundwater - drainage. In addition to drainage, care should also be taken to drain melt and rainwater through trays or grooves away from the bathhouse.

Useful video

But this video talks about how you can do without drainage with a shallow foundation and solve the problems of frost heaving (not high groundwater!) in cheaper ways:

| Foundation type | Soil type and relief features | Methods for compensating for soil deficiencies |

| Tape | Chernozem; forest and swampy; clay; loam; fine gravel; coarse sand (if the sand is fine, it must be compacted). | To improve the soil under the foundation, it is often placed on a bed of 40% sand and 60% gravel. |

| Columnar | Clays; loams; gravel with clay and sand; fine gravel; sand. | Sand cushions for pillars. |

| Pile and pile-grillage | Soft, wet, crumbling soil; sandy loam and other quicksand; marshy, biogenic soils - peats, sapropels; permafrost; large differences in relief on the site. | On very poor soil, the piles are made longer, preferably screw-cut. |

| Slab | Swampy; quicksand; permafrost. | Sand cushion under the leveling layer. |

The depth depends on the type of foundation.

Height of the foundation for the bathhouse.

The columnar foundation is formed by horizontal pillars located along the contour of the bathhouse walls. The main advantage is considered to be high wear resistance, suitability for many types of soil and cost-effectiveness. Its versatility deserves attention. Depending on the material for the walls of the bathhouse, you can use concrete, wooden, or brick pillars. The standard length of pillars is from 2 m. It is laid at 1-1.5 m. There is a shallow columnar foundation, occupying a height of only 50-70 cm. It is laid at 40-60 cm.

The pile foundation is prepared for construction by drilling wells. It is laid in several ways. The easiest way is to pour concrete mixture into pre-dug wells using a hand drill. Wooden and steel piles are laid. The main advantage of a pile foundation is that the foundation lies below the soil freezing level. A team of workers will be able to install the piles in just 1-2 days. The burial depth is determined for each structure, the maximum is more than five meters.

The screw foundation got its name due to its manufacturing technology. Screw piles resemble the shape of a screw and, thanks to special blades, are easily screwed into the ground. Building a foundation on screw piles has many advantages. For such a foundation you do not need to dig a trench or even level the ground. Suitable for all types of soil, except rocky. Service life more than 100 years. Disadvantages include average load-bearing qualities.

The piles are installed in a certain order. The distance between the piles should not be less than 3 m. The piles lie at least 1.5 m deep into the ground. The maximum depth of the pile foundation is 2.4-2.6 m, since the longest pile length is 3 m. If the required depth is greater, than indicated, piles can be built up using reinforced concrete.

The slab foundation consists of a monolithic reinforced concrete slab. Its minimum thickness is only 15 cm.

A shallow foundation is laid 30-40 cm deep into the ground.

Floating foundations are a type of shallow slab foundation. It differs from other foundations in the presence of stiffening ribs - dense placement of reinforcement along the entire perimeter of the slab.

The peculiarity of the floating slab is the ability to move. Unlike other types of foundation, a floating slab does not compete with the pushing forces of the soil, but moves slightly as they rise in the cold season, due to their lowering with the arrival of spring.

A floating foundation will be an excellent way out of a difficult situation related to soil characteristics. When there is close groundwater and a high level of soil freezing, a floating foundation is built on the surface. The minimum deepening of the foundation is only 40 cm.

How high is the foundation for a bathhouse?

Concrete preparation technology

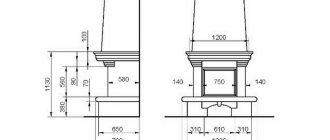

Cross section of a strip foundation.

The main indicator is high-quality concrete. To prepare it, you should follow some recommendations:

Purified dry sand and cement are taken in the required proportions. Mix in a clean container until smooth.

Add clean, free gravel or crushed stone to the homogeneous mass. Mix thoroughly again.

Water is added. There are some tricks when connecting with water. In the cold season, it is better to take water heated to a temperature of 40-50°C, this temperature gives the finished solution viscosity. When working in hot weather, on the contrary, it is better to use cold water to prevent the solution from drying out too quickly.

It is better to pour in small batches so that the poured layers do not exceed a layer of 15 cm. After each pour, the mixture is compacted; water should come out over the entire surface of the poured foundation under the bathhouse.

When carrying out work during hot weather, the surface of the solution should be sprinkled with a layer of sawdust or covered with thick burlap. To prevent the poured layer of concrete from cracking, it is periodically watered with water (every 3-4 hours for a week). It is necessary to keep the concrete moist for 3-4 weeks; to do this, it is periodically watered with water and covered with plastic film.

Depth of the strip foundation for the bathhouse.

The height of the bathhouse foundation from the ground.

The classic depth of a strip foundation consists of a twenty-centimeter, well-compacted sand cushion. Above is a foundation 60 cm high: 40 cm lies in the ground, and the remaining 20 cm extends to the surface. Since the strip foundation has become the most popular, universal option for bathhouse foundations, the correct calculation of its depth needs to be studied in more detail.

First of all, they start from the properties of the soil . Frequently encountered problems related to the structure of the soil when designing a foundation affect the depth of its construction. The risk of cracks arises when erected on rocky soil. In this case, a shallow or non-buried foundation is used. Soil prone to swelling requires the foundation to be sunk deeply below the freezing level. The possibility of foundation failure is characteristic of fine sandy soils. When building a foundation on such soil, a deep foundation is designed to increase compression resistance.

The height of the foundation for a bathhouse made of foam blocks.

Design selection

Since a standard bathhouse does not belong to the category of heavy and critical structures, most builders opt for a shallow strip foundation (MSLF). The depth of the lower plane of the base in this case is no more than 0.5 m, and most often exactly 0.5 meters. The option with a buried foundation is used in situations with weak soils or in cases where the bathhouse has two floors and, accordingly, considerable weight. When you are at the stage of choosing the foundation depth, you can use SP 22.13330.2016 “Foundations of buildings and structures.”

Despite the depth of its foundation, each structure is, to one degree or another, affected by frost heaving. This phenomenon occurs when groundwater freezes and, due to this, the volume of soil under the foundation increases. As a result, the foundation may be shifted, deformed or partially destroyed. There are several ways to solve this problem, which should be taken into account at the foundation design stage:

- Drainage device (required only at high groundwater level);

- Insulation of the foundation and blind area with heat-insulating materials.

- Sand pillow. With high groundwater levels and lack of drainage, it can play a negative role. In the video below, the author talks about this problem, but does not suggest a solution using a drainage system;

Each method will be discussed in more detail in subsequent chapters.

According to the method of construction, the strip foundation for a bathhouse is divided into four categories:

- Made. The belts consist of individual reinforced concrete blocks

- Monolithic. The most common method, which is used as a basis in this article.

- Prefabricated monolithic. Combines elements of both categories. For example, the perimeter of the base is made in a monolithic manner, while the internal “ribbons” are laid out from FBS.

- Strip foundation made of rubble concrete. It is carried out by adding brick fragments or stones of a fraction from 150 to 250 mm to the concrete mixture. An option without reinforcement is possible.

Other parameters affecting the depth of the foundation.

The depth of the foundation depends on the material . from which the walls for the bath are made. A stone bathhouse requires from 1 m, preferably from 1.5 m. A bathhouse made of logs or timber also needs a foundation of at least 1 m. Laying cinder block walls is 1.5 times lighter than brick, so the foundation can be laid from 0.5 m. Aerated concrete and foam concrete blocks need foundation with a depth of 40 cm.

a significant influence on the depth of the foundation for a bathhouse.

Having compared all the factors that influence the depth of its occurrence, having determined the required depth for a specific foundation, you can proceed to the stage of its construction.

Factors affecting the height and width of the foundation

So, first of all you should pay attention to the soil

Ground influence

Preparing a piece of solid ground

The type and composition of the base affects both the size of the foundation for the bathhouse and its type, strip or pile.

Great for tape:

- rocky ground;

- sandy base;

- dry loams.

Columnar is suitable for:

- wet clay;

- peat soil.

Strong rocks make it possible to deepen the trench by only 50 cm, while a soft, unstable base requires twice as much distance, at least one meter. Above the ground in both cases it is necessary that the concrete rises 30 cm above the soil freezing zone.

Not less than 30 cm above the ground

Thus, the size of the foundation for a bathhouse in height is about 80 cm in stable, dense soil and about 130 cm in soft, loose soil.

The width of the foundation for a bathhouse does not depend on the base; it is significantly influenced by the type of structure and the width of the walls. Let's take a closer look.

Influence of foundation type

In this section we will talk about what kind of structure you will use: strip or pile. Let's first consider their advantages and disadvantages:

One-piece construction

It is a monolithic concrete structure along the entire perimeter of the building.

pros

- Very high strength. It can easily withstand two-story buildings.

- Additional thermal insulation. It has a higher significance in our case, since for the full functioning of a bathhouse or sauna, an optimally high ability to store heat indoors is necessary.

- Possibility of creating a cellar or underground in the future.

Which foundation for baths is better and how to make it yourself.

The height of the strip foundation for a bathhouse.

View of the finished block base for a bathhouse.

Building a bathhouse is a less complicated task than building a private house, for example, but still requires skills and a professional approach.

So, initially, having chosen a convenient place, you need to make a foundation for a small bathhouse. The question becomes about the choice of material from which it will have to be built in the future. If the walls are made from lightweight foam blocks, the same preparation is needed; when constructing walls from expanded clay concrete blocks, the base is made completely differently. If construction is carried out using a log house, you can get by with arranging a foundation made of sleepers, timber or car tires.

The monolithic option is taken into account only when constructing a heavy structure. Let’s take a closer look at where and what kind of foundation for a bathhouse is better to build with your own hands and how long it will take to dry.

Preparing the site for laying the foundation

On a built-up site, the construction of a bathhouse must begin in accordance with existing buildings, without disturbing the landscape.

Option for a strip foundation for a bathhouse

Trusting our own logic and the experience of people involved in similar buildings, we draw the following conclusions:

- It is advisable to choose a place to lay the foundation on a natural elevation in order to save on drainage by using gravity. But do not plan a slope towards the north, so that there is no flooding during a flood.

- Ideally, it is good to build a bathhouse on the banks of a river or lake, so that after the steam room you can plunge into cool water. It is better to decide at what distance from the shore the laying takes place, taking into account the flood, in order to avoid polluting the reservoir with runoff from the bathhouse.

- If construction is planned on a finished site, then it is advisable that the bathhouse be covered by a residential building or a fence from neighbors and the road. And perhaps it was combined with other buildings or outbuildings.

- It is better to place the entrance on the south side (so that there are fewer snowdrifts at the entrance), and the windows on the west side (there will be natural light before sunset).

Classic bathhouse design with layout options

Once all the details have been taken into account and the location has been chosen, it’s time to prepare the site. At this stage, all vegetation is removed along with the turf. The site is leveled, with a slope to the south, east or west. All irregularities are removed, bumps are smoothed out and holes are filled.

If the construction of a bathhouse is carried out on an uninhabited area, before work begins, water and electricity must be supplied there and a toilet must be built.

Now you can start marking the outline.

Site preparation and territory marking.

Marking the foundation for a bathhouse.

Construction begins with markings. You will need a few tools: 10 wooden stakes, a hammer, a tape measure 15 meters long, a construction cord of 25 m, or a fishing line, a hydraulic level of 20 m. Let's take a regular foundation made of expanded clay concrete blocks. Such a foundation for a bathhouse can be built with your own hands in a couple of days and does not require a huge investment of funds. Let's take the standard option.

We calculate the width of small pits. We take into account the insulation and piping of the foundation blocks of the bath: 200 mm is the width of the block, and 400 mm is the length. The height of the base part is approximately 600 mm, 3 blocks. It turns out that the pits for development will be: 450 x 450 mm, with a depth of 0.8 meters - this is the standard width and depth for the usual construction of a block base made of expanded clay concrete blocks. Now let's move on to developing pits.

Stages of foundation construction

Markings are carried out on the site and the places where piles will be installed are marked with markers. Separately, the corners of the intersection of walls, additional partitions, and the place for installing the stove are distinguished. The piles are placed at a distance of 1.5-2 m from each other.

Wells are dug for concrete and columnar piles. The screw metal rod is screwed in using a special adjustable wrench and does not require preparation of recesses.

A pillar or pile is installed, the bottom of the well can be additionally reinforced.

After installation in the hole, the pile is cemented with a concrete solution. For hollow piles, additional reinforcement is used; a metal rod is inserted into the middle of the concrete structure and filled with mortar.

On soft soils and on slopes, the foundation needs additional grillage (top frame). It also levels and smoothes out any unevenness of the pillars that may occur during installation.

The concrete is given time to dry, and after 7-10 days work can continue.

This is the best foundation for a bathhouse, which is suitable for most soils, eliminates their imperfections, protects walls from ground moisture, helps avoid damage to the structure during flooding, and even protects against rodents.

Development of soil for a bathhouse.

To make the foundation of a bathhouse with your own hands you will need: a bayonet shovel, a scoop, a pick in case of the presence of stones, an ax for snags, and a cart for removing soil. Having dug to the specified depth, we clearly level all the edges. A foundation for the firebox (sauna stove) should also be provided. We must not forget that the installation of a firebox inside a building requires the preparation of a concrete pad. This is done before the main monolith is poured, after calculations a cushion is made, and then the support pits are poured under the expanded clay concrete blocks.

How to do it yourself?

If you have experience in construction, it is quite possible to make a shallow monolithic strip foundation for a bathhouse with your own hands. There is nothing complicated about it.

You just need to strictly follow all the following steps:

Preparatory stage.- Construction site marking.

- Excavation work and installation of a sand-crushed stone cushion.

- Installation of formwork.

- Manufacturing and installation of reinforced frames.

- Filling.

- Dismantling the formwork.

- Waterproofing device.

Preparatory stage

Preparation for the construction of a strip foundation for a 4 x 6 bath includes the following work:

- choosing a place for a bath;

- determination of soil characteristics;

- calculation of the width of the foundation strip and the depth of its base;

- cost calculation.

Selecting a location

The construction site must be located separately from the house and other buildings . The distance from the bathhouse to other objects should be at least 15 - 20 m.

This standard was adopted for fire safety purposes. The bathhouse should not be adjacent to buildings.

Determination of soil characteristics

If a developer decides to build a bathhouse on his personal plot, then the composition of the soil should be known to him. The foundation of your own house was calculated taking into account the properties of the soil.

If the data has been lost, the soil resistance, freezing depth and groundwater level can be found out at the local department of architecture and land management.

To do this, you can take a copy of the vertical survey with reference to the construction site. You can also take soil samples using an auger.

The local geological exploration service will help determine the characteristics of the soil foundation . Its workers will take soil samples and determine the freezing depth and groundwater level.

Calculation of the width of the foundation strip and the depth of its base

The width of the foundation is calculated by distributing the entire weight of the above-ground part of the bathhouse along the length of the perimeter of the tape.

To do this, theoretically determine the load from the building on the soil by summing up the weight of all structures, equipment and everything that can be in the bathhouse at the same time, including the weight of people. The snow load on the roof of the building is taken into account .

The minimum permissible width of a strip foundation for a 4 x 6 bathhouse should be 400 mm. This is enough to build walls 1.5 bricks thick.

The base of the foundation should be below the freezing layer of soil and not at the groundwater level . So, if the freezing depth is 500 mm, the groundwater level is at 1200 mm, then the laying depth is taken to be 800 mm.

The optimal height of the plinth should be 250 - 300 mm. The height of the shallow foundation must be at least 800 mm.

Determining the price of construction

The estimated cost of constructing a shallow LF for a bathhouse includes:

- costs for purchasing fittings,

- sand,

- crushed stone,

- cement,

- rental of mortar mixers and formwork,

- consumed electricity and unexpected expenses.

If concrete was poured into the formwork using a concrete truck, and excavation work was carried out using an excavator, then the cost of the foundation is adjusted taking into account these costs.

Construction site marking

The markings are made according to the plan using a cord and benchmarks (wooden pegs or pieces of reinforcement):

- Remove vegetation and debris.

- Remove the fertile layer.

- As they measure, benchmarks are driven into the ground, connecting them with a cord.

- Right angles of marking are checked by comparing diagonals.

Benchmarks are driven in every 1.5 - 2 m. To mark the outline of the trenches, two parallel cords are pulled.

Excavation work and installation of a sand-crushed stone cushion

Trenches are dug with shovels and picks . The bottom of the trenches is covered with PVC film or geotextile. The edges are turned up and secured with wood chips or nails to the cut of the soil. This will protect the walls of the pits from crumbling.

The level of the excavation bottom along the entire perimeter of the marking is checked with a laser level and a rod. Irregularities are eliminated by adding crushed stone or excavating soil.

The bottom of the trenches should be 300 mm below the base of the foundation . It is covered with crushed stone and sand in layers 150 mm thick. The pillow is compacted as it is filled by pouring water.

Installation of formwork

Formwork is made from boards and timber, thin metal or dense polymer sheets. Shields in trenches are reinforced with spacers and stops made of timber. From the inside, the surface of the formwork is covered with PVC film or geotextile. The shell is secured with a stapler or nails.

Manufacturing and installation of reinforced frames

For the manufacture of reinforced frames, periodic profile reinforcement ø 8–10 mm and smooth rods ø 6–8 mm are used . The first is placed in two horizontal meshes with cells 100 x 100 mm, and the second is used to form vertical connections. The junction nodes are secured with knitting wire.

The finished sections of the reinforced frame are lowered into trenches and tied together. Supports with a height of 50 - 70 mm are placed under the lower grids so that the gap is filled with a protective layer of concrete that prevents corrosion of the reinforcement. For the same reason, gaps between the reinforcement and the formwork must be at least 30 mm wide.

All the most important things about reinforcing strip foundations are here.

Fill

The formwork must be filled with concrete without interrupting the process for no more than 6 hours . This is necessary so that hardening layers do not have time to form inside the solution mass. For a bathhouse foundation 6 x 6 m with a cross-section of a monolithic strip 400 x 600 mm, you will need about 6 m3.

To produce 1 m3, you will need to make 10 batches. For the entire foundation they will need to be done 60 times. It will take several days to fill. Moreover, you will have to spend time compacting the concrete with a vibrator. The best option would be to order delivery of concrete to the construction site by automixer.

You can find out how to calculate the amount of concrete for pouring a strip foundation here.

Dismantling the formwork

30 days after pouring concrete, the formwork is dismantled . The shields are removed carefully, without using excessive force, so as not to damage the integrity of the side surface of the monolith.

Waterproofing device

After removing the formwork, all chips and cracks in the monolith are rubbed with cement mortar. The side surfaces of the strip foundation are covered with bitumen mastic. It is heated to a liquid state.

Waterproofing compounds are also used, which are diluted with solvents. Additionally, the foundation surfaces are covered with roofing felt. At the end of the work, backfilling is carried out.

Pillow for a stove or firebox.

The height of the foundation above ground level for a bathhouse.

Preparing a pillow for a stove or firebox.

Dig a pit 1200 x 1200 mm to a depth of 600 mm. This depth was not chosen by chance; 300 mm is sprinkled with sand. The pillow is compacted using a hand tamper. The following steps follow:

- A layer of waterproofing material is laid on the bottom so that there is a reserve and the edges protrude outside the pit.

- Place the frame (formwork) at the required height and pour a 200 mm concrete slab.

- Insulation is carried out with 50 mm polystyrene foam slabs, placing it directly on fresh concrete.

- Then pour a finishing layer of screed, 50-150 mm. The insulation under the heating element is ready.

After concrete work on the installation of a load-bearing cushion, it is necessary to lay a network of water supply and sewerage pipes and carry out their complete insulation.

Tip: The base for the firebox should not come into contact with the main foundation, since it tends to expand when heated. The gap is filled with sand after concrete work and dismantling of the upper formwork.

Foundation for a sauna stove

Do you need a foundation for a stove in a bathhouse? Some land owners do not know the answer to this question. To make the right decision, you need to consider how heavy the stove will be. If the heating equipment is compact and weighs no more than 250 kg, there is no need to strengthen the floor. The surface does not need to be reinforced; it is simply coated with a special composition that protects it from fire. It is important that the material from which the stove is made is not afraid of overheating.

If the stove is made of brick, it will need a base. The fact is that such a heating structure weighs from 250 kg to several tens of tons. This means that the foundation must be designed to withstand such a load.

When the stove weighs 750 kg or more, you will need to make a foundation for it. Heating equipment creates an uneven load on the bathhouse floor. As a result, it may sag if the foundation is not strong enough. To prevent this from happening, choose a strong foundation that is not afraid of soil movement.

To equip the foundation correctly, you should be guided by the depth of freezing of the ground. The following features are also important:

- The base for the stove must be mounted together with the foundation for the bathhouse . In this case, the depth of additional reinforcement and the foundation of the building must be located at the same level. You cannot fill the screed after the reinforcement has been installed, since the degree of shrinkage will differ. This may cause the oven to collapse. Professionals recommend making a foundation for a pile-type furnace.

- Since you will not be erecting the walls of the building at the same time as the foundation equipment, the distance between the stove and the wall should be 5 cm . This distance will then be covered with sand, which must be thoroughly compacted. Thanks to this approach, settlement of the foundation will occur evenly.

- The dimensions of the base must be correlated with the size of the heating equipment; this is important to take into account when creating a building project . It is important that the boundaries of the foundation slab protrude beyond the boundaries of the stove by at least 5 cm. The ideal option is a distance of 6–10 cm.

- The location of the chimney should be as close as possible to the center of the base . Only in this way will the load on the foundation be uniform. If the chimney is powerful, the structure should be strengthened and protected. As a result, the load on the base will be increased. No matter what type of foundation you choose, do not forget about this nuance.

- When equipping a stove, waterproofing should be done . To do this, roofing felt is laid in 2 layers and attached to the base. It is best to use bitumen mastic as an adhesive. This product will additionally protect the structure.

A brick oven will deteriorate over time. This means that you will need to protect it as much as possible from moisture, that is, do not forget about high-quality waterproofing. In addition, if a brick stove is installed, there will be increased humidity in the bathhouse. This also needs to be taken into account.

Networks and drain.

Width and height of the foundation for the bathhouse.

Laying pipes for water supply networks for drainage in the bathhouse.

Let's move on to laying pipes for water supply networks. Calculation of the diameter and length of water supply networks is carried out in advance, before all concrete work is carried out. Separate trenches are dug under the water supply pipes to the pipe outlet points. The installation of water supply networks requires special skills and knowledge, but you can prepare trenches yourself. According to the technology, the pipes are laid on a bed of crushed stone. The bottom of the ditches is filled with gravel, the standard layer thickness is 80-100 mm. The ends of the pipes are brought out 100 mm above the floor level, in the right place and closed with plugs.

Subsequently, after all the concrete work and the construction of walls from sleepers, all pipes and internal networks are installed. The depth of laying pipes in the ground on the outside of the room is 1200 mm, and on the inside 600 mm. The installation of networks can be carried out simultaneously with the drainage by laying the pipes together.

The cushion for laying pipes and networks must be compacted. The slope for laying sewer pipes, the height of the inlet and outlet openings, and the drainage angle are measured. Before making the entire foundation for the bathhouse, take care of the wastewater drain. Prepare a hole or pit and drain there. The optimal distance between the bathhouse and the drain is 6-10 meters, otherwise the log house will become damp.

Foam concrete bath

Foam block foundation

A relatively new building material that is gaining popularity in low-rise construction today is foam block. In recent years, many buildings, both residential buildings and outbuildings, have been built from foam concrete.

The popularity of foam block construction is explained by a number of advantages of this material. First of all, this is its lightness, high thermal insulation qualities and ease of construction. Building a bathhouse from foam blocks with your own hands is quite accessible to anyone who is more or less familiar with the construction business. However, this material has one serious drawback - it is very hygroscopic. That is, it has the ability to absorb and accumulate moisture from the surrounding air.

In this regard, the construction of a bathhouse made of foam blocks is accompanied by a number of nuances. Both internal and external foam concrete walls must be well protected from water and steam. The lower rows of blocks should be protected from rain and ground moisture. To do this, you should make the foundation high enough - up to 50 cm, so that splashes from rain jets do not fall on the wall.

In addition, a waterproofing layer should be installed between the foundation and the first row of foam concrete blocks. Failure to comply with the above conditions will lead to premature destruction of foam block structures, therefore, before deciding to build a bathhouse from foam blocks, you should carefully calculate all the pros and cons of such a design.

Having become familiar with the technologies for constructing foundations for bathhouses and the criteria for their selection, any owner of a suburban area will be able to build a reliable foundation for his bathhouse with his own hands. The main thing is to make the correct calculation and comply with the requirements of building regulations.

Insulation of the foundation.

Insulation of the foundation for a bathhouse.

Schematic representation of the insulation of the base of the bathhouse.

The foundation for a frame bath can freeze, therefore, it is insulated from the outside with various materials. Insulation is carried out before pouring concrete. Sheet material made of polystyrene foam or polystyrene is used; they are optimally suited for these purposes. Sheets with a thickness of 50 - 80 mm are used. with dimensions 600 x 1000 or 1000 x 1000 mm.

They are fastened on the outside of the pits (along the outer edge), between the reinforcement frame and the ground. The space is then completely filled with concrete to the required height. The insulation is of high quality and monolithic, durable. Expanded polystyrene does not absorb moisture. The service life of such materials is 25−30 years.

There is another option for carrying out external insulation by filling all the supports for the bathhouse with expanded clay around the perimeter: after all the concrete work, develop cavities around each concrete base and pour a cushion of expanded clay. Such insulation will require additional costs for excavating the soil and installing waterproofing.

Types of soil and their properties

The type of soil is determined during geodetic research, but for the construction of a bathhouse, surveys can be carried out independently. To do this, it is enough to dig a hole up to 2 m deep and study the granulometric composition of the soil section. In some regions, detailed soil maps have been compiled, so it is enough to talk with local residents or old-timers.

The depth of freezing in winter depends on the type of soil. This characteristic determines what kind of foundation is made for the bathhouse, and is a fundamental factor when choosing its type.

- Stone or rocky soil is a massive rock, does not absorb moisture, and does not heave in the cold.

- Peat soil is saturated with moisture, soft, loose, and requires an additional drainage system during work.

- Loams contain up to 30% clay, they have stable levels of freezing and humidity, the most common type

- Clay soil does not absorb water well; when filled with moisture, it becomes runny and liquid. It is better to build a foundation on it from waterproof materials and the structure should prevent soil deformation

- Sandy and sandy loam - dries quickly, does not accumulate moisture, but due to its high looseness, it sags and freezes deeply in winter. When choosing a foundation on fine dusty sand, you have to take into account its saturation with water, the height of groundwater and the depth of freezing.

- Clastic is a mixture of sand, small stone, clay, ideal for construction, it allows moisture to pass through well and freezes shallowly in winter

The design of any foundation must prevent soil deformation, be located below the freezing depth, take into account the groundwater level, the height of soil moisture, and the drying rate.

The choice of base for a bathhouse is influenced by the proximity of bodies of water and the topography of the site. It is appropriate to build a columnar foundation on the bank of a river, pond or on a slope.

Reinforcement.

Reinforcement of the foundation for a bathhouse.

Sketch of foundation reinforcement for a bathhouse.

Now let’s try to figure out how to make full reinforcement and pour concrete pillars under the bathhouse with our own hands, and consider how to arrange masonry from expanded clay concrete blocks. You can start knitting an armored belt right on the site. This will also require marking and calculation. A simple way to knit a spatial frame:

- Draw two parallel lines, and then lay reinforcement cut to size along them and tie them together like a ladder. The edges of the transverse rods must extend 30 mm beyond the edge of the main trolls and rods. All workpieces are measured in advance and a preliminary calculation is made on the length and height of the workpieces as much as required.

- Having installed the blanks in all the holes, they are tied together with knitting wire. First, the lower crossbars are knitted for ease of movement. Then the upper rods are attached.

If the holes are narrow, then the blanks are knitted completely. Then they are installed in the pits entirely, tying only the corners. Carry out reinforcement only with viscous reinforcement; the use of welding equipment is unacceptable.

How to install a bathhouse on a foundation?

- First you need to prepare the foundation. If the unevenness is more than a centimeter, they are leveled with cement mortar.

- Then they begin to waterproof the foundation - it is impregnated with bitumen mastic (you can use liquid glass instead). After impregnation, roofing material is laid on top in 2-3 layers, the pieces overlap, the overlaps of the first layer should not be directly under the overlaps of the second, it is better to do them with a shift. The roofing material should protrude beyond the edges of the top of the foundation by 1-2 cm.

- At the next stage, the lower crown is first impregnated with an antiseptic, and then with waterproofing (the same mastic or liquid glass).

- Before laying the crown on the foundation, you can put a layer of boards, 40-50 millimeters, on top of the roofing material. It is easier to replace a rotten board than to change the crown of a log house .

- A layer of insulation - moss, hemp or tow (1-2 cm) is laid directly on these boards and roofing felt.

- Only after these preparations is the first lower crown placed on the foundation.

- At the corners, the strapping is connected by cutting down half the diameter of the log. If the bathhouse is built from timber, then it can be fastened with metal corners.

- To fasten the lower crown, tension bolts with nuts and washers are also used. The washers are installed to distribute the load more evenly.

- Further installation of the crowns is carried out according to their numbering and letter designations: N, S, W, E. The cardinal directions in this case indicate the specific walls of the bathhouse.

*** Well, now you have enough information to deal with the tasks facing you and decide which foundation is best for you for a log bathhouse. We can only wish you success and the speedy completion of the construction of a bathhouse on your site.

Additional materials from the section on foundations for baths:

- Types of foundations;

- Height and depth;

- How to do;

- With your own hands;

- Base for the stove;

- Which is better.

Foundation for heavy materials made of expanded clay concrete blocks and foam blocks.

Pouring the foundation for a bathhouse.

Concrete mixture for pouring the base of the bathhouse.

It is possible to make a reliable foundation for an ordinary bathhouse with your own hands only if you do not violate construction technology.

The frame is tied, the concrete is being prepared. The calculation of materials is carried out as follows: for the total cubic capacity of the foundation, take the ratio of materials: 12% cement, 25% sand, 45% crushed stone, the rest water and clay. For expanded clay concrete compositions, the filler (crushed stone) is divided equally with expanded clay.

The composition will be warm, but it requires the use of waterproofing materials. Before building a foundation for a bathhouse from such material, calculate the weight of the entire structure. It is suitable for a lightweight structure made of foam blocks, but for expanded clay concrete materials it must be strengthened. It is necessary to change the depth of the foundation, pour it 0.5 meters deeper, this applies to each monolithic pillar.

Cost calculation

The cost of any foundation is calculated as the sum of the cost of concrete and reinforcement. When the volume of the foundation is calculated, it is laid out according to its components according to the principle - to produce one m3 of concrete it is required:

- cement - 0.22 m3 or about 0.35 tons (costs 5,600 rubles/t);

- sand - 0.31 m3 or about 0.45 tons (costs about 100 rubles/t);

- crushed stone - 0.70 m3 or one ton exactly (costs 600 rubles/t).

The cost of fittings at metal depots is usually calculated in rubles per ton. Knowing the length, the mass can be calculated by knowing how many meters of reinforcement are in one ton:

Reinforcement Ø 6 mm – 4,500 meters:

- 8 mm – 2,530 meters;

- 10 mm – 1,600 meters;

- 12 mm – 1,120 meters;

- 14 mm – 820 meters;

- 16 mm – 630 meters;

- 18 mm – 500 meters;

- 20 mm – 400 meters.

Laying blocks with your own hands.

How high should the foundation for a bathhouse be?

Scheme of a columnar foundation made of blocks for a bathhouse.

The foundation in this case consists of expanded clay concrete blocks standing on concrete pillars. To begin with, we mark the directions for the blocks by driving 4 pegs along the outer perimeter of the future bathhouse. Pull and level the cord to the height of approximately the first block. If you made basement formwork when pouring concrete, the masonry is carried out according to its dimensions, placing the blocks on concrete pads.

Lay two blocks at a time, filling the seam with mortar. Lay the next row perpendicularly, the edge of the expanded clay block or foam block should touch the cord. Blocks are mainly used to raise the height of concrete foundations above the ground or when the site has a large slope. Lay the required height and leave it to dry. During laying, place studs between the blocks to secure the frame.

Construction stages (step-by-step instructions)

- A pit is dug manually or using an excavator, which should be at least 10 cm wider than the foundation.

- A drainage layer of sand and gravel is poured onto the bottom of the hole and compacted. If groundwater is close, an insulating layer is made.

- Reinforcement is carried out over the entire area of the future foundation with metal or composite reinforcement. The rods are laid perpendicular to each other with a cell size of at least 15 cm. The reinforcement is tied at the fastening corners with metal wire or welded.

- Formwork is installed on the surface for the future base.

- Fill with concrete mortar, which is periodically compacted with vibrators. Instead of mortar, you can use concrete blocks.

- Cover with film and allow to dry, periodically sprinkling with water to prevent the appearance of small cracks on the surface.

Important! Filling is carried out in one day over the entire base area.

The most reliable type of foundation that can withstand heavy loads, but it is the most expensive and labor-intensive.

With a properly selected foundation, the bathhouse will serve for a long time and will delight you with low heat conductivity.

If groundwater does not reach the freezing depth and reaches a height of no more than 2 meters, a shallow foundation is chosen on shallow, dusty, and sandy soils. In other cases, the depth of the foundation should be 50 cm below the freezing level. This will avoid swelling of the soil and cracking of the base.

At the final stage of construction, work is carried out to insulate and insulate the basement of the future bathhouse.

Construction of a load-bearing structure for lightweight materials.

Slab foundation for a bathhouse.

Sketch of a slab base for a bathhouse.

The weight of foam blocks is small, up to 24 kg, with dimensions of 200 x 300 x 600 mm, unlike expanded clay concrete. We calculate the foundation slab differently than for a pillar foundation. In this case, the entire structure will lie on the slab, transferring all loads to the ground evenly, making it stronger. The construction of a slab (slab version of the foundation) is easier to do than the pillar version, but for a log building it will also work. Depth is not needed for a monolithic surface foundation 1-1.5 meters high; a 40-50 cm deepening into the ground along the entire plane or perimeter is enough, it depends on the configuration of the log house.

The height of the above-ground part of the concrete slab is 10−15 cm. When poured, a monolithic layer (slab) is obtained that carries the entire frame, evenly distributing the load from the building onto the ground. The slab option is suitable both for medium-weight buildings and for structures made of foam blocks, foam concrete blocks; on it you can build a bathhouse from sleepers, build a log house; there are many options for using slab technology, as many as are necessary for high-quality construction of buildings.

The slab foundation for the construction of walls made of foam blocks is arranged as follows:

- Markings are made for the slab, the building is taken in width and length, but with a margin of 800-100 mm. It would be correct to lay only a slab around the perimeter under the bathhouse, and fill everything inside with clay when finished.

- The soil is removed to a depth of 400 mm, the pit is filled with sand, 200 mm thick. For foam blocks this pillow is enough. Now we compact it around the perimeter, there should be no gaps. Although the frame is not heavy, the slab must work over the entire plane; the depth here is not as important as the uniform compaction of the soil and sand.

- Now the formwork is placed around the future foundation, the height of the board is selected according to the protruding part, in this case 150 mm.

- Cards are knitted from 12mm reinforcement, with a cell size of 300×300, laid on a prepared site, having previously placed plastic distances, or spilled small nickels from the solution. After reinforcement, you can pour the solution. Such a foundation does not dry for long, 7-12 days.

Tip: In summer, sand dries quickly; before pouring concrete, moisten it with water.

Depth for timber construction

As you know, saunas made of timber are the most optimal, reliable and lightweight structures that you can confidently make with your own hands. In this case, it is worth noting that you can choose certain foundation parameters, depending on the following points:

- Base load;

- Availability of groundwater;

- Soil type;

- Freezing depth;

- Soil density.

Also, it is possible to build the following types of foundations for a timber bathhouse:

- Strip base (on fertile or marshy soils);

- Columnar (if there is clay, coarse sand or gravel);

- Another type (if there is dense sand or rocky soil).

Important! If you do not want to “miss” the choice of the type and depth of foundation, it is better to do a soil analysis in advance - it can be ordered from specialized organizations

When choosing a columnar type, the depth should be about 1.5 meters for the middle strip. In other cases, it is taken into account that it should be 0.3 m below the established level of soil freezing.

The tape version was discussed above - the depth depends on the weight and the need for a deep base.

Tire foundation.

Foundation tires for a bathhouse.

The use of tires for foundation construction.

You can build a unique and at the same time strong foundation with your own hands from car tires. This is an economical option for a foundation for a wooden building made of logs or sleepers. The method for laying out the elements is as follows: markings are made for the contour of the bathhouse. Then the top layer of earth is removed along the entire perimeter, 15 cm deep and 50 cm wide. The space is filled with crushed stone and sand mixed in a 1:1 ratio. The pillow is compacted under the tires using a manual tamper.

The required number of tires is prepared, about 20-25 pieces of the same size and height (it all depends on the size of the tires and the bath). A perimeter of tires is laid out so that they lie tightly to each other.

Now we insert the threaded studs and tie them to the reinforcement threaded through the tires. We will attach a load-bearing structure made of sleepers and timber to them. The depth of the studs should be the entire thickness of the tires. The height of such anchors must be at least 250 mm so that the supporting beam for the log house or sleepers can be screwed on.

It is advisable to extend the reinforcement along the entire perimeter and diagonally, and then fill the tire space itself. Reinforcement can be carried out directly through the body of the tires by drilling holes and threading the reinforcement through the entire perimeter, so there is no need to tie the outside with a channel or angle.

You can make a set of blocks from tires and bury them directly into the ground. At the same time, the cost of construction will be significantly reduced; there is no need to cast a large slab to build a building from foam blocks or expanded clay concrete blocks. The construction of load-bearing elements from tires is one of the cheapest and simplest options, which is not inferior in quality to slab ones. This is an ideal foundation for a bathhouse made of timber, sleepers or for a solid wooden house (log house).

You can use a block version of the foundation made of tires, where the marking is carried out in the same way as in other cases, but you do not need any pipes, piles, concrete blocks, and expensive reinforcement.

A set of tires (4-5 pieces), placed on top of each other, will serve as a support for the log house or sleepers, instead of pipes and formwork. The construction time for such supports is minimal, the tire foundation dries quickly, since there is not a large volume of concrete in the ground, and within a couple of days further installation of a frame bathhouse or the construction of a wooden frame can be carried out.

Other selection factors

In addition to the operational features of the baths, the following factors influence the choice of load-bearing base design:

- Weight and size characteristics of the building.

- Geological characteristics of the soil.

- Complexity and cost of technology.

Weight and dimensions of the bath

It is quite clear that the more massive the building, the more solid the foundation it needs. The weight of the bath depends on its size and the characteristics of the material from which it is made. For example, the foundation for a 6x6 m bathhouse, made of brick or stone, should be many times stronger than the foundation for a 4x4 log bathhouse.

Considering that the density of building bricks is several times higher than the density of wood (1500 kg/m3 versus 500 kg/m3), the weight of a building made from these materials with the same dimensions will differ by 3 times.

And if the foundation for a log bathhouse can be as light as possible, then the load-bearing foundation for a brick building must be quite solid.

Columnar foundation for a bathhouse

Calculation of the bearing capacity of the foundation

To get a reliable foundation, you need an accurate calculation of the mass of the building and the bearing capacity of the foundation. First of all, you should calculate the mass of the bathhouse by adding up the approximate weight of all structural materials from the foundation to the roof. The resulting number needs to be increased by 10 - 15%: this is the mass of interior decoration, water heating equipment, snow load on the roof, etc.

The next step is to calculate the supporting area of the foundation. To find the area of a slab foundation, simply multiply its length and width. It is somewhat more difficult to calculate the support area for a strip foundation. For example, you should calculate the foundation for a 4x6 m bathhouse: take the design width of the tape (30 cm) and multiply it by its length (the perimeter of the building is 20 m). It turns out 0.3 m x 20 m = 6 sq. m.

Next, the total mass of the structure is divided by the supporting area of the base, the result is an indicator of the specific pressure of the bath on the ground in kg/sq. see. Knowing the composition of the soil on the site, you can use the tables of building regulations and determine whether a given foundation is suitable for the future building.

If the developer does not trust his engineering skills, specialists from the construction company can make the necessary calculations. After all, errors in calculating the bearing capacity of the foundation can result in big troubles - from uneven subsidence of the building into the ground to the destruction of the foundation, and then the structure.

Geological characteristics of the soil

The bearing capacity of the soil directly depends on its composition. Rocky soils consisting of large fragments of stones and dense sandstones are considered the strongest. Such soils practically do not produce sediment and are not subject to the forces of frost heaving.

Frost heaving is a destructive effect that occurs on soils with high moisture content in winter. As a result of the transformation of water into ice, its volume increases significantly, and the moisture-saturated soil begins to bulge upward in the form of mounds and even small mounds.

On rocky and sandstone soils, you can build absolutely any type of foundation, of your choice - from a shallow-buried strip to a monolithic slab.

Clay and swampy soils have the weakest bearing capacity. In the first case, this is due to the property of clay to accumulate water, as a result of which clay soils are very heaving. Swampy soils, in addition to their tendency to heave, are themselves very weak. A building built on swampy soil risks sooner or later going underground, slowly subsiding down to the dense subsoil layers.

Repair of wooden base.

The height of the foundation above the ground for a bathhouse.

Scheme of one type of base for a bathhouse made of blocks.

Sometimes the foundation for a bathhouse is prepared from thick timber, concreted directly into the ground, and sometimes a monolithic version is installed. You need to know some little things before you properly repair the foundation of a bathhouse or build a new foundation for a bathhouse with your own hands:

- For example, a wooden structure made from sleepers or a log frame is tightened from the outside with brackets in places where they settle. You can calculate how to tighten the frame, how many staples are needed. With other foundations it’s a little more complicated. You need to know how long it takes for the concrete itself to dry, and only then install the frame or beams. If the load-bearing blocks burst during installation and their height is small, you can add a reinforcing layer of concrete around the blocks, filling in all the cracks formed in the column.

- By deciding to make the foundation of the bathhouse yourself, you will not only save a lot of money, but also get a good experience. It’s not difficult to build a monolithic or any other foundation with your own hands; you just need to go through all the stages of construction one by one and not violate the technology.

- Make the correct calculations, markings for construction, soil development, reinforcement, and insulation. Do all necessary waterproofing work. It would be a good idea to consult with builders (developers) who have been building this type of foundation for a long time and have good experience.

Decide what material to build the foundation from, logs, sleepers, what the height of the building will be, how many sleepers or timber you need. Do you need a monolithic or concrete foundation for a log house, a wooden one made from sleepers, or a permanent foundation for a building made of foam blocks?

Knowing how to make a foundation for a bathhouse is not everything; you need to make preliminary calculations, and only then can you confidently begin its construction. It’s up to you to decide which foundation is best for a bathhouse, but it’s better to calculate how much materials you will need for this in advance and draw its structure. Having carried out a simple calculation, you can do everything perfectly, because you won’t need heavy equipment here, except perhaps a concrete mixer with a wooden chute and a concrete drain.

conclusions

In each individual case, it is very important to take into account the characteristics of the soil, the size of the structure, the quality of the materials used, as well as other factors that significantly affect the reliability and durability of the object. The width also affects the strength of the foundation,

In any case, taking into account such characteristics, you can easily and confidently make one or another type of foundation with your own hands, as a result of which you will get a truly beautiful and reliable bathhouse and enjoy your vacation.

Attention! If you are not confident in your abilities, it is recommended to turn to specialists with experience who will carefully analyze what kind of soil is on the territory and choose exactly the type of base that is most suitable for you.

Regardless of the depth of the bathhouse foundation you choose, the main thing is to use high-quality materials and follow construction technologies.

Terminology: bathhouse foundation height and depth.

The foundation for the building can be divided into parts: aboveground and underground.

The height of the foundation is considered to be that part of it that is located above the ground surface, and its value is determined by reference to this surface. The depth of placement is determined by that part of it that is located in the soil, and in this case it also means counting from the ground surface.

Height of the foundation for the bathhouse.

The main purpose of the height of the base is to prevent the bottom of the building from coming into contact with the soil. This is necessary to prevent undesirable consequences of a destructive nature, the causes of which may be: shrinkage of the building, moisture, etc.

The depth of the foundation for a bathhouse largely depends on the following factors: the weight of the building, the type of soil on which it is located.

The recess is also intended to protect the structure from negative impacts caused by certain features that appear when the soil freezes.

Useful video.

Watch the video, which talks about the depth to which the foundation should be laid, and explains the reasons for this choice.

Now let's look at the dependence of height and depth on the factors already mentioned.

Preparatory work

You need to make a mark at the selected location

After drawing up the project, the terrain is marked and the workplace is prepared.

It is recommended to perform this activity in the following sequence:

- Determine where one of the corners of the building will be located. Drive a stake in this place.

- Using a tape measure, mark the remaining corners. Check the accuracy of the markings by measuring the distances along the diagonals.

- Pull the cords between the stakes. Use beacons to mark the position of internal partitions. Drive in the following stakes and stretch the cords between them.

- Based on the project, determine the internal boundaries of the foundation.

The final stage will be excavation work. They are carried out in accordance with the type of future foundation and the instructions for its manufacture.

Features of the construction of other types of foundations

As noted earlier for light buildings, for example, other types of foundations can be used for a log bathhouse:

- Columnar - when a solid strip foundation is replaced by supports in the form of concrete, stone or brick columns, installed in increments of 3 to 6 meters, as well as at critical stress points - corners, junctions and intersections of internal walls. A distribution structure in the form of one or several beams made of concrete, rolled metal or wood is laid on top of the columns, on which the walls of the building are erected.

- Pile - in the same places as the columns, piles or a cluster of piles are driven into the ground, after trimming and processing the heads of which, distribution beams are laid at the required height and fences are erected.

- In addition to driven piles, piles can be bored, when holes are drilled in the ground, which are then filled with concrete. Or screw ones - arranged in the form of a giant screw, when a kind of impeller 3...4 times larger than its diameter is welded to a metal pipe. The pile is screwed into the ground using a special device that is mounted instead of a bucket, after which the internal empty cavity of the pipe is filled with concrete.

Such systems, which have a natural ventilated space under the ceiling of the first floor, require additional insulation. However, the additional costs of its installation are more than covered by a significant reduction in earthworks during construction.

Special shallow foundations are very rigid, durable structures of the “floating” type. Just as heavy ships float on the constantly changing surface of the water, these structures and the buildings erected on them “float” on the surface of the soil, which changes its properties and characteristics depending on the season. The most common of them are:

- pile-grillage - in the form of a three-dimensional monolithic frame structure, the horizontal part of which is called a grillage, and the vertical part is bored-type piles. The grillage usually rises above the surface of the ground, leaving a free ventilated space between the ceiling of the first floor and the ground. Very suitable for a wooden bathhouse, a small light country house, a summer kitchen, a building for keeping pets.

- monolithic shallow slab - cast from high-strength concrete directly onto the ground. Its thickness varies from 25 to 50 cm. Where walls and partitions are located, it is often reinforced with vertical stiffeners directed downward. Some methods of constructing such slabs, which came from Scandinavia (Sweden, Finland), are cast in foam non-removable formwork, which then serves as additional insulation.

Before starting construction, including the construction of foundations, you need to:

- familiarize yourself with specialized literature and assess your financial and economic capabilities;

- estimate the number of assistants and auxiliary workers (they can be selected from among relatives, acquaintances and neighbors), and also decide which jobs can be done independently, and for which ones you will still need to turn to professionals;

- prepare tools, equipment, auxiliary tools and mechanisms, then purchase the necessary building materials in the required quantities;

- Ensure that your small team performs work safely and adheres to safety requirements.

Having accumulated the necessary experience after building the foundation of your own bathhouse, you can think about building larger and more important structures with your own hands.

Like the author! 1

Author's rating

Author of the article

Mikhail Lavrentiev

About 15 years in construction. He has accumulated extensive experience in foundation work and shares it on the pages of our online magazine.

Articles written

23

- Even more interesting:

- Strip foundation: what is it?

- Rubble or rubble concrete foundation: what is it and how to pour it

Possible errors and useful tips

The main mistakes that are made when constructing strip foundations for a bathhouse can be represented by the following list:

- Incorrect calculation of the bearing capacity of the foundation leads to its destruction. If a violation of the integrity of the array is detected, strengthening measures must be taken.

- Poor quality waterproofing leads to devastating consequences from the penetration of moisture into the concrete mass. It is necessary to excavate the soil around the perimeter of the tape and re-do the waterproofing.

- A layer of heaving soil that is not completely removed will lead to a break in the foundation tape. Before starting work, loose soil must be carefully removed.

- Incorrectly taken into account the depth of soil freezing will cause fragmented deformation of the monolith. In this case, the entire structure is dismantled and a new foundation is erected.