The design and appearance of the entrance door to the bathhouse can rightfully be considered the hallmark of the establishment. The first important element that greets lovers of light steam has always been and will be the porch and, of course, the door. Its finish, shape and design of the canvas. From how well the entrance layout is chosen, you can judge the quality of the steam room and all the most important attributes, without even entering the room.

Materials

The door to a bathhouse or sauna must be strong and durable enough so that even after several years it retains its original appearance.

It must be resistant to moisture, temperature changes and pressure. Among other things, it is important that it represents reliability and safety. Therefore, only certain types of materials that can withstand the effects of bath conditions are suitable for such difficult requirements.

The most authentic Russian bathhouse is always built of wood. All the elements in it are wooden, and therefore the door leaf is made of natural wood. It must be moisture and heat resistant, have an attractive design and have a beneficial effect on people's health.

Wooden structures are an environmentally friendly product and therefore absolutely safe for use. They have low thermal conductivity, which helps not to release steam from the steam room. A warm bath should maintain a high temperature for a long enough time so that all visitors have time to take a good steam bath.

But besides its many advantages, wood still has some disadvantages. For example, its constant presence in a humid environment can deform and shrink the structure, which will force the owners to change the damaged door. And the tree is often a breeding ground for insects and fungus formation

Therefore, it is very important to treat the door with a special compound before installation.

Most often, linden is used in the manufacture of wooden sheets for bath structures. It has high performance characteristics, which are necessary for rooms with high humidity and frequent temperature changes. Linden and larch produce the best products, which also have a low price.

Another suitable species is aspen. The aspen frame meets all requirements and does not dry out or crack over time. Alder also has the same qualities.

To improve the health of the human body, it is best to use cedar products. And if you want to make the visual perception of space a little easier, then it is better to use an abash.

Of course, natural oak has good performance. It has a unique structure, and therefore costs many times more than other types of wood. Door frames made of oak look massive and solid.

Glass doors are made of tempered glass, which is highly durable. It repels moisture well, withstands high temperatures, does not deform or crack. Glass products are characterized by increased safety and at the same time have a low cost, which allows them to be installed in modern saunas. Glass is a material that does not require constant maintenance. It is enough to occasionally wipe them with glass cleaner.

Combined designs combine glass and wood. This combination allows you to get a beautiful and comfortable product that meets all the necessary requirements. This canvas consists of a wooden frame and a glass insert, which can have absolutely any size.

Metal doors are best installed at the entrance to the building. The metal has high strength and stability, and therefore is able to protect any room from drafts and other weather conditions. By finishing the metal with clapboard or solid wood and adding thermal insulation material, you can get a beautiful and functional product.

Linings made of lining are good because they are able to retain heat inside the room and at the same time not allow external noise and sounds to enter. If they are pre-treated with a special product, they will be able to withstand moisture. The main advantage of lining is its affordable price, and the ability to paint it in any shade makes lining products the most popular.

Steel structures have increased positive qualities. They are stronger than iron products and are more resistant to external influences. A steel door should only be installed at the entrance to the bathhouse, as it can become very hot and can burn people in the steam room.

As an alternative, it is possible to use foamed PVC. Such products are resistant to moisture and the formation of mold and mildew. Many people use floorboard structures, which help unify the interior of the room.

Considering numerous reviews, we can say with confidence that an aspen, linden or oak door is better suited for bath structures.

How to choose

Nobody argues about the reliability of the entrance structure. But we are not talking about a safe option. The presence of a complex mechanism can lead to trapping people inside the room if a fire occurs. Therefore, the outdoor model for the bathhouse should be standard, with hinged doors. If the choice fell on a single-leaf metal or wooden model, then the locking mechanism should be elementary.

Only for a steam room, the design must have certain functionality. Many people prefer to buy glass products. Especially when it comes to indoor small saunas and infrared saunas. Combined or wooden products are chosen for a regular bathhouse. Although glass ones are superior to their wooden counterparts in many respects. Therefore, whether to purchase a wooden or glass model is up to everyone to decide for themselves.

Basic requirements for such structures

The classic Russian bathhouse is a wooden frame, so the internal contents must correspond to the style. Traditions require the installation of wooden elements, which must have such properties as resistance to temperature changes, not heating up, and not being afraid of constant humidity. Among other things, they must have an attractive appearance.

Wooden elements have many advantages:

- Ecological cleanliness.

- Presence of natural aroma.

- Therapeutic effects on the human body.

- Pleasant sensations for visitors to the steam room.

- Low thermal conductivity.

- Attractive design.

There is one serious drawback to such products. Constant exposure to extreme conditions leads to deformation of the structure and shrinkage and, as a result, the need to completely replace the product.

The fabric parameters for the steam room are slightly different from the standard ones. A small threshold (10 - 15 cm) is made at the entrance itself to prevent steam from escaping. If the ceiling height is 220 - 250 cm, then the height of the canvas should be 160 cm.

Decor

Decorating bath doors is an important point in the design of a building. After all, not all decorative methods are suitable for rooms with high humidity. For example, wallpaper or vinyl stickers would be inappropriate here, because after a short period of time they will simply peel off.

Iron and glass structures do not need additional decoration, as they themselves look very aesthetically pleasing. And it’s difficult to decorate metal or glass without special equipment.

It is possible to make carved canvas at home. Two methods can be used for this: overhead and on the surface of the tree itself.

The applied method uses carved elements that are attached to the canvas using glue. This method is good because it does not require removing the product from its loops, and the patterns themselves can be purchased ready-made.

Carving a door leaf is a complex and painstaking job. You can use blind and slotted threads. Carved doors, as a rule, are installed at the entrance of a building to add a luxurious and solid appearance to it.

Antique structures will look very organic in a bath structure. This design will create a rustic atmosphere of past centuries, which will allow city visitors to feel like real villagers. You can age wood yourself. This may require staining or brushing technology.

Often, owners of a sauna building think about whether it is necessary to paint wooden door panels, because inside the building there is constant high humidity, which can damage the paint. Designers advise painting wood with a paint and varnish that can withstand any external influences.

Completing of the work

Required Tools

We choose a tool that is familiar to us. Not every household has a milling machine, although it is more convenient and quicker for them to select grooves when staking and tying. But you can get by with a chisel and hammer. True, then the process will take much longer.

- Milling machine (or chisel).

- Hammer.

- Mallet.

- Clamps for fixing the door leaf (or a workbench with stops).

- Electric saw or jigsaw (or regular wood saw).

- Drill with a set of drills and grinding discs.

- Screwdriver.

- Planer, jointer (preferably electric).

- Vernier calipers, tape measure.

- Hydraulic level (or plumb line).

You can buy tongue-and-groove boards, or you can make them yourself - provided that you have a milling machine or a hand cutter and you know how to work with them.

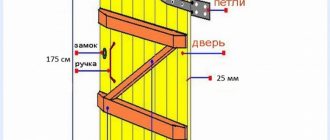

Now instructions on how to complete the work will be offered. All work is done by hand, so this will be a guarantee of quality.

For a bathhouse, a completely carved door is quite rarely made; most of the time, individual elements are made; we will talk about their production below.

Examples of carved overlays

So:

- First, a full-size drawing is made. To do this, it is best to apply it on tracing paper. Draw in full size;

- We transfer the drawing to the plane of the wood. To do this, we use carbon paper;

- A jigsaw is used to cut out parts. It is best to use files with a narrow blade and a large tooth spread;

We use a jigsaw for work

Attention: Before starting finishing work, you should select a file. The cleanliness of the seam will depend on this. Make control cuts on millet waste wood.

- When making the outer contour of the pattern, we enter through the outer edge of the workpiece;

- While working, you will need to rotate the saw; this is done in two ways. In the first one, when you reach the turning point, you will need to make several cuts in the direction of the turning point, the direction of their cutting is selected so that when you reach the point, you can make the turn without any problems. In the second option, this is done by cutting a larger radius and subsequently reducing it. Here everyone chooses what is more convenient in each individual case;

Attention: New jigsaws can make cuts at different angles. These are 90 and 45 degrees. Take advantage of this opportunity. Then you can make quite voluminous compositions.

- If you want to make a closed shape, then you need to make holes in the middle of the element that will be removed. The diameter of the hole should be slightly larger than the width of the jigsaw blade so that it can move freely. After this, we rest the jigsaw at an angle of 90 degrees against the workpiece, then turn on the jigsaw and carefully make the cut.

After making the individual elements, they are simply glued to the surface of the wooden door. For this, wood glue is used. After fastening, you need to putty the joint and polish it.

What manufacturing options are there?

The quality and service life of the door block depend on the material from which the door block is made. Different raw materials are selected for different purposes.

Tree

Traditionally, wood was used in baths. The floor, walls, ceiling are all wooden, doors too. You may be given several options:

- Linden. A universal material, used to create doors of any type. The main advantages are low price, pleasant aroma, does not rot. A very good choice.

- Aspen. The wood does not swell, does not heat up, and is suitable for decorating a washing room - it is used for finishing floors, ceilings, walls, and doors. The price of solid aspen is low, it is easy to process, which has a positive effect on the cost.

- Pine. The low price is explained by the wide growing area and ease of processing. Like all coniferous plants, pine smells good and does not rot. Heats up quickly - so this is a bad choice for those who like high temperatures (above 65 degrees). The ideal temperature is 45-50 degrees.

- Larch. Solid larch will decorate the steam room - it is recognizable due to its texture and pattern, which only becomes more expressive under varnish. Since larch is a coniferous plant, it produces phytoncides that kill harmful microorganisms and bacteria.

- Oak. Expensive, durable, weighs a lot, looks solid. Suitable if you want to impress guests. The only negative is that it cracks when overheated, which makes wood an unsuitable option for a steam room.

Wood is used for entrances to interior rooms. An array is taken - this reduces the likelihood of the slightest cracks and joints appearing. It is recommended to use durum varieties. Choose a water-based, non-toxic varnish.

Plastic

Plastic doors are often used at the entrance. They retain heat well, do not deform from cold, and fungus does not form on them.

Plastic is a poor material for rooms. This is an artificial material that, when exposed to heat, releases toxic substances and becomes deformed.

Metal

Metal doors are ideal as entrance doors. There is no need to care for them - the metal is not subject to mechanical damage and is resistant to mold and mildew. Thanks to the thermal insulation lining, it does not release heat and does not allow cold to penetrate inside.

Metal bath doors are not used for rooms because they have high thermal conductivity, heat up quickly, and are easy to get burned on. Also, when humidity is high, condensation forms, so the metal rusts.

Glass

A very stylish option - 8 mm thick tempered glass. The main advantages are appearance, heat resistance (withstands up to 300˚C), variety of decor. There are frosted glass designs, glossy, patterned, transparent, of any color. Glass is easy to clean, safe, and has low thermal conductivity.

The lower part of the glass sheet is shorter according to manufacturing standards, allowing air to circulate

Combined type windows

The combined type of windows involves the use of several materials in different combinations, in particular:

- wood with plastic;

- wood and aluminum;

- plastic with aluminum;

- aluminum with wood and plastic.

The combination of several materials can improve the thermal insulation properties of windows. And most often the first two combinations of materials are used.

You can combine materials in windows in this way:

- The inside of the frame is lined with wooden planks, and the partitions and the entire frame are made of plastic. Such windows appear to be made of wood from the inside. For protection and additional decoration, the wood is coated with several layers of varnish.

- The entire frame is made from laminated veneer lumber, and aluminum or plastic strips are placed on the outside using clamps to allow the wood to “breathe.”

- First, two independent frames are made - the inner one is made of wood, and the outer one is made of plastic or metal. Along the perimeter, the frames are connected to each other with special brackets, and the glazing is done with ordinary glass, and not with bags. If desired, any of the frames can be removed.

Pros and cons of bath doors

The main advantages of doors for bath rooms:

- Energy saving - they prevent the removal of heat from the steam room or washing room, thereby significantly saving fuel and electricity costs.

- They have excellent hydro- and vapor barrier. Door structures for the washroom and steam room are designed in such a way that dampness and steam do not penetrate into the dressing room.

- They are distinguished by a variety of shapes, structures and textures.

- They can be very ordinary, or they can become a bright decoration of the interior.

Each room needs its own door with certain standards made from specific materials.

The only disadvantages of bath doors include low-quality raw materials and improper use.

Adviсe

Experts have prepared several useful recommendations.

To ensure maximum comfort in your bath room, you should pay attention to some recommendations from experienced professionals. For example, it is better to install a sauna on the south side, since in winter, when you sometimes want to take a steam bath, it will be easier to get to the entrance due to the fastest snow melting on the side closer to the south

In addition, it will be preferable if the windows face west, since in the evening the room will be illuminated by rays for much longer. Also, for constant air circulation and excellent heat maintenance, it is recommended to build a bathhouse from wooden logs.

Types of doors to the bathhouse

If you look at the photo of the entrance doors to the bathhouse, you can see that they are made of different materials. There are several options for doors that are suitable for a bath: wooden, plastic and metal.

Wooden entrance door to the bathhouse

Most baths are built of wood. Our ancestors also used this material for construction, so those who want to create a rustic atmosphere in a bathhouse and feel unity with nature give preference to this material.

A wooden entrance door is perfect for a log bathhouse. Its main advantage is its naturalness. Wood is an environmentally friendly material that does not contain chemical impurities or toxic additives; it is absolutely safe for use.

A wooden door looks beautiful and cozy, and when exposed to heat, it emits a pleasant and relaxing woody aroma. By the way, you can additionally decorate the door using carvings; it will help complement the interior and make it more comfortable.

An important advantage is that a wooden door has low thermal conductivity, which helps retain heat in the bathhouse.

A wooden door will cost less than a plastic or metal one, so this option is the most budget-friendly.

Despite the variety of advantages, wood, like any other material, has its disadvantages. The main one is low resistance to moisture. In a humid environment, wood can become deformed, causing cracks and, consequently, drafts.

Wood cannot be called a hygienic material; it is an excellent breeding ground for insects and mold. This can be corrected if you first carefully treat the door with a special compound.

Caring for wooden doors is more difficult than, for example, plastic ones. Not all products are suitable for cleaning wooden surfaces.

Different types of wood can be used to make an entrance door.

A popular option is linden. It has high performance properties, in particular, it tolerates temperature changes and high humidity well. At the same time, its price is low.

Larch is distinguished by its strength and reliability. It also tolerates temperature fluctuations and moisture well.

An oak door is strength and durability. It has an original appearance due to its unique structure. The disadvantage of an oak door is its high price.

Other wood species are also used to make doors: aspen, alder, cedar, etc.

Plastic entrance door for a bathhouse

Plastic doors cannot be called a popular option for baths. Many people do not like not only the fact that the material is artificial, but also the feeling that breaking such a door will not be difficult.

In fact, it is easy to break down an interior plastic door, but an entrance door is a completely different matter; it is made with a reinforced profile: a closed steel loop 2 mm thick is inserted into the door leaf. This design ensures the safety of the door and prevents it from sagging.

Plastic is an artificial material, due to which it has a number of advantages:

- tightness. Thanks to this, there is no need to protect the bathhouse from drafts;

- hygiene. Plastic does not harbor mold, mildew, or insects;

- color variety. There are thousands of shades of plastic, so you can choose an option to suit any interior; the collection of shades even includes ones that imitate wood and other materials;

- moisture resistance. Plastic is not at all afraid of exposure to water, it does not deform or swell;

- ease of care. This material is unpretentious and can be cleaned with various abrasives.

The disadvantage is the high price. Of course, you can buy a cheap plastic door without a metal profile, but this option will not be durable. High-quality and reliable doors made of plastic are quite expensive.

Metal entrance door to the bathhouse

The metal door has good performance characteristics. Such doors are installed not only in bathhouses, but in apartments and private houses. Metal doors are highly stable and durable. They, like wooden ones, are environmentally friendly and do not emit harmful toxic substances.

Doors to the bathhouse: which material is better?

Let's briefly go through the pros and cons of each material.

Tree

The material is the most sauna, the most environmentally friendly and the most preferred today. There are fewer sophisticated bathhouses than simple ones, so wooden doors predominate, and they are installed in all rooms.

Advantages of wood:

- low thermal conductivity - you won’t get burned like you would with any other bath material;

- relative cheapness - can be replaced if it fails;

- does not emit harmful substances when heated.

Flaws:

- takes on water and increases in size, causing the doors to stop closing;

- warps - bends or twists, in general, the correctness of the geometry suffers;

- cracks when dried incorrectly, forming cracks and crevices that damage the thermal insulation;

- susceptible to fungi, insects, and rodents.

Plastic

We can say that it is the least desirable in a bathhouse, although it can be used in certain rooms. If you're going to put it in, do it in the washroom.

ADVICE! Do not use plastic in the steam room - neither in the decoration, nor in the form of doors or windows. It will not withstand high temperatures and will warp. And along the way, it will poison the air, releasing volatile organic matter, most of whose compounds are carcinogenic!

Advantages:

- does not change properties under the influence of moisture;

- not afraid of mold, insects, uninteresting to rodents;

- cheap material, although this may not apply to doors.

Flaws:

- flammable, when burned it releases even more poisons;

- under the influence of relatively high temperatures it warps or melts;

- brittle.

Metal

The only metal in the bathhouse may be the stove and the front door. There will be more on little things, but these two are the main ones.

Advantages:

If we talk about the front door, then a metal one is good because it scares away unwanted visitors. Even if it is made of the thinnest and cheapest steel, it still looks more impressive than simple wood.

Flaws:

Metal has high thermal conductivity, so in an atmosphere of high humidity, condensation will inevitably appear on it. And where there is condensation, there is rusting of the metal. This means that the iron door will need additional protection or the installation of a second door.

Glass

Glass doors in the bathhouse appeared thanks to the spread of saunas. Glass looks very attractive and is installed not only in Finnish, but also in Russian bathhouses. Place the glass sheet in the steam room and in the washing room.

Advantages:

- beautiful, fashionable, modern, comfortable;

- transmits light;

- not subject to rotting;

- is not spoiled by insects or rodents;

- does not deform;

- does not change appearance over time;

- does not emit substances harmful to health.

Flaws:

- beats;

- has greater thermal conductivity than a wooden door;

- not very desirable in a Russian steam room.

+++

Well, we’ve looked at all the possible doors to the bathhouse: which ones are better is up to you to decide. One should proceed not only from whether the material is suitable for a particular room, but also from stylistic uniformity, as well as from the choice of door hardware: handles and hinges.

Useful tips

When installing a door structure in a bathhouse, you should remember some nuances:

- It should be taken into account that the door will shrink after some time: a frame made of raw wood shrinks by approximately 8%, and a frame made of dry wood - by 2%.

- It is not recommended to install locks or latches on door structures leading to the steam room. This is done for safety purposes, so that it is convenient to get into the premises in case of accidents or emergency situations. In addition, at high temperatures, metal fittings heat up, and when exposed to steam, they quickly become unusable and can jam at any moment, which is very dangerous.

- It is strictly forbidden to treat the door leaf leading to the steam room with paints and varnishes.

- A threshold of 15-20 cm is always installed under the entrance door. Under the door structure leading to the steam room, a threshold is not installed, but a gap of 3 cm is made.

- The doors always open only outwards, and the hinges are mounted on the opposite side from the wet room.

Whatever doors to the bathhouse are chosen, it is important that they consist of moisture-resistant and sealed materials that can withstand constant pressure.

It doesn’t matter at all whether the door structure is made independently, in production, or purchased from an expensive, prestigious showroom. The main thing is how comfortable, reliable, aesthetically pleasing and easy to use it is.

We insert a door made of impact-resistant fireproof glass into the bathhouse

Glass doors are quite specific, so making them yourself is very difficult, since this requires certain skills. Therefore, they will have to be ordered from the workshop. But you can install them yourself.

Glass selection

There are several types of glass doors. Modern convenient pendulum designs can open in two directions. Usually a magnetic closer is installed on such a door, which helps the structure close more smoothly.

Fireproof glass doors in the steam room

Traditional swing doors open only in a certain direction, and installation is carried out in a wooden frame using durable hinges.

The canopies are made only of stainless, anti-corrosion metal, and the handles (brackets, coupes or knobs) and the box are made of non-coniferous wood.

Stainless steel hinges for glass door

The thickness of impact-resistant glass should not be less than 7–8 mm, since the temperature in the steam room is quite high, which the glass sheet must withstand.

If necessary, the transparent canvas can be made matte using a special sandblasting machine. In a specialized workshop such work will be carried out in the shortest possible time.

Frosted glass doors with a pattern

Glass doors must be installed only before the walls are finished, and the tighter they fit to the frame, the less heat loss there will be in the steam room.

When choosing a glass sheet, it is necessary to take into account the future conditions of its operation. Fireproof impact-resistant glass can be of three categories: A1, A2 and A3.

The best option would be doors measuring 1900x700 mm, category A3. They can withstand an impact of 3382 kgf/m and a fall of a human body from a height of about 10 meters. Such characteristics are achieved thanks to a special hardening process, in which the glass mass is softened, changing the state of the crystal lattice. During its subsequent cooling, residual stress is formed on the surface of the glass, which increases the heat resistance and mechanical strength of the product.

Material calculation

To install a glass door, you must prepare all the necessary materials.

- Cloth made of impact-resistant fire-resistant glass.

- Linden timber - 42x80 mm.

- Stainless steel hinges.

- Wooden fittings.

- Closer.

- Silicone seals.

- Platbands.

- Fasteners.

- Thermal insulating and water-repellent material.

- Impregnation for wooden elements.

Step-by-step instructions for making a glass door

- We assemble a wooden box without a threshold, so that there is a gap of about 5–7 mm between the floor and the canvas. This is necessary so that the door can move easily.

- We install the door frame, observing the exact geometry so that the glass sheet can fit into it accurately. We level it and fasten it to the wall with special anchors. In order to subsequently align the box, its dimensions should be slightly smaller than the door opening.

- We fill all the gaps with foam, and when it dries, we cut off any excess with a knife.

- We place silicone insulation in the grooves of the box.

- We mount metal hinges on the glass sheet in holes specially made for this purpose. We place silicone gaskets under the hinges.

- We expose the canvas and screw the hinges to the jamb.

- Then we attach the handles with silicone gaskets to the holes provided by the manufacturer.

- We close all the gaps between the opening and the frame with platbands.

- We treat the box with special impregnations, and then cover it with waterproof varnish.