During the “black baths”, the problem of hot water supply was easily solved. A copper vat was installed on the hearth, in which water was heated by contact with the flame. There were no more frills. After all, both the steam room and the washing department were combined in one functional area. Centuries have passed and the idea of a sauna tank being built into a stove has not lost its relevance. Is everything ingenious simple?

Rating of the best water tanks

There are several models of quality tanks available.

No. 5. Horizontal

The container is made of AISI 439 stainless steel. Its purpose is to store hot and cold water in baths and housing. At the top of the tank there is a filler hole, at the bottom and on the sides there are G3/4 pipes for supplying and draining liquid. The tank is hung on the wall using the mount included in the kit.

Horizontal

pros

- tightness;

- resistance to chemical and temperature influences;

- low deformation coefficient.

Minuses

There are no downsides to this model.

No. 4. Volcano

The rectangular tank is installed vertically. It is made of AISI 439 steel. Its purpose is to use it in conjunction with a heat exchanger, from which hot water flows into the container through natural circulation.

Volcano

pros

- good workmanship;

- budget cost.

Minuses

No. 3. MetalStroy

The tank is suitable for storing drinking water, organizing an autonomous hot water supply or installing a summer shower. The tank is made of AISI-430 steel with a thickness of 1 mm.

MetalStroy

pros

- high strength;

- hygiene;

- thick steel;

- light weight.

Minuses

The absence of nickel in steel makes it less resistant to corrosion, which shortens the service life of the product.

No. 2. Ferrum

A triangular-shaped container is mounted on the chimney. For connection it is equipped with elbows DU-115. Laser welding technology is used in manufacturing, which ensures the reliability of the seam.

Ferrum

pros

- excellent build quality;

- attractive design.

Minuses

high price.

No. 1. Teplodar Parus

The water in the tank built into the chimney (DN 115) heats up to 70...75 degrees. You can fill it through the hatch in the upper part. Steel thickness – 0.8 mm.

Teplodar Parus

pros

- long service life;

- high-quality performance.

Minuses

quite high price.

Table. Comparison of water tank models.

| Tank brand | Volume, l | Dimensions, cm | price, rub. |

| Horizontal | 60 | 48 x 30.5 x 48 | 2880 |

| Volcano | 60 | 33 x 50 x 50 | 3050 |

| Ferrus | 55 | 40 x 78 x 41 | 5120 |

| Teplodar Parus | 60 | 39 x 95 x 23 | 6500 |

| MetalStroy | 60 | 44 x 31 x 44 | 3400 |

Purpose

To obtain hot water in the wash room of your bath complex, several types of structures have been developed that operate on different types of fuel. But the most inexpensive is installing a heating tank on the heater and obtaining hot water together with heating the steam room.

The advantages of such a device are due not only to the reduction in the cost of hot water when heated with gas or electricity. This design avoids the risk of fire and electric shock when using these types of fuel.

Autonomous water heating systems are especially in demand for summer cottages and households in places with no natural gas supply. In this case, such tanks can be used for heating water and for household needs. The main thing is to choose the right tank for the volume and type of installation and install it correctly.

Types of tanks

Water tanks of different configurations are installed. The method of heating water may also differ. When choosing a container, you should take into account all the nuances.

The purpose of the hot water tank in the bathhouse

Capacity

The volume of the installed tank depends on the number of people who can simultaneously be in the bathhouse and use hot water. On average, 10...20 liters of boiling water should be provided for each person (with a small reserve). Today, tanks with a volume of 50...100 liters are produced. As a rule, it is not advisable to install a tank with a capacity exceeding 100 liters.

The shape of the container can be any

Material

When choosing a container, you need to consider that it must be able to withstand high temperatures (up to 250 degrees) for a long time.

Metal tank for water in the bath

You should not try to save money and install tanks made of ferrous metals. This approach cannot be justified not from an aesthetic point of view, but mainly from practical reasons. Due to constant exposure to high temperatures, the metal will deform over time and traces of corrosion will appear on it. This significantly reduces the service life of the tanks and the quality of the water in them.

The most common tank option is stainless steel construction. The demand for such tanks is explained by their attractive appearance, durability, resistance to various types of external influences, high heating rate, ability to retain heat for a long time, relatively low weight, hygiene, high durability and ease of maintenance. The tank configuration may vary. But high-quality stainless steel costs a lot. And you need to take into account that today there are many counterfeit products on offer, which will soon rust.

Not so often, but there are tanks made of cast iron. They are not afraid of rust. However, it must be borne in mind that, despite the fact that the water in such structures will not cool quickly, it takes more time to heat it up. Due to the bulkiness of the tanks, you need to carefully consider their location. Today, not many companies produce cast iron tanks, and they are not very cheap.

Enameled containers can be used, but they are not the best option. Of course, such material does not corrode and is very hygienic.

But low resistance to mechanical damage over time will inevitably lead to the fact that the metal with a fairly thin coating will become chipped (as a result of not very careful handling) and these areas will rust. It will no longer be possible to fix the problem.

Location and design

Three methods are used to place the tank: traditional (directly near the firebox), on the chimney, and remotely. What is the difference?

Bath stove with tank

Tank built into the oven

The reservoir can be located on the side or above the firebox. The water in it heats up quite quickly (exposed to open fire). To drain it, a ball valve is installed. Of course, this design does not involve pipeline laying work, which saves labor and material resources. However, using such a container is not very convenient; usually a tank of not very large capacity is installed, and its installation takes up useful space in the steam room, which usually is not very much. The best solution in small-sized baths is the top location of the tank. Since the metal will be in direct contact with the fire, the thickness of the tank walls must be at least 8 mm.

Water tank next to metal firebox

Reservoir on a pipe

If the ceiling height allows, you can install the tank on the chimney. Water is heated by hot gases passing through it. To simplify the installation process, it is possible to purchase a container with built-in chimney elbows. This tank can be fixed without much effort. By laying a pipeline from the tank, you can carry water to any point in the bathhouse, for which a pipe is connected to the bottom of the tank, ensuring the flow of liquid, for example, into the shower. Filling a tank installed in this way is not very easy due to the high location of the filler hole. It is best to use a hose lowered into a container for these purposes.

Reservoir on a pipe

Remote design

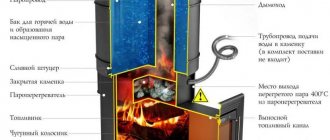

Thanks to the installation of a heat exchanger on the heater (on the chimney or directly on the stove) and natural convection, it is possible to place the tank in the washing compartment.

Water tank over brick firebox

The heat exchanger can be integrated into the oven (removable or non-removable), but you can easily install it yourself. It is a coil or container with a volume of several liters with pipes to create a circuit.

Pros and cons of different designs

Depending on the circumstances, individual advantages may outweigh the disadvantages. It is clear that if the tank is located on the stove or attached to the side, then three unpleasant things follow from this:

- Constant heating of water will lead to the formation of steam, but it will not be the steam heated over 100 degrees, which is called light - it is obtained only from overheated stones. And the usual heavy steam will pour out of the container, which makes it difficult to stay in the steam room.

- Using heated water for washing is problematic if the steam room is not combined with a steam room. You will have to carry hot water to the washroom and wash the way your ancestors washed).

- In tanks built on the side of the stove, heating occurs the worst, because the walls of the stove do not heat up as much as the top or chimney. Plus, over time, the wall of the tank itself will lose thermal conductivity due to scale, and the wall of the furnace will lose its thermal conductivity due to scale. Therefore, the water does not warm up well, remains cold at the bottom, and must be stirred manually.

However, such structures also have advantages - they are easy to fill with water precisely because the container is not located high. But this is if there is no cold water supply either. Otherwise, the plus is leveled out.

By the way! The larger the contact area between the container with water and the oven, the faster the heating. But this is not always worth striving for - why do you need clouds of heavy steam in an unheated bathhouse?

Of course, you still have the opportunity to set up a shower from any tank. And, although stove makers do not recommend using a pump, the forced circulation of liquid in the system will calmly take water from either the manual or the attached tank. The main thing is not to forget to add more.

We ourselves consider the optimal system to be one in which the tank is mounted on the chimney. Whether it will be a large tank or a heat exchanger depends on how you are more accustomed or comfortable to wash. Well, or whether there is a pump in the system or not.

Photo: samovar-type heat exchanger

However, the optimal system also has its drawbacks. In particular, traders admit that the connection between the tank and the pipe at the inlet below can suffer greatly from overheating, for example, in a situation where water is poured after the stove has been lit. Then the seam splits and needs to be welded. Another drawback is that the pipe burns out when the furnace heats up too much.

Pay attention to the size of the filler hole. For some tanks it is large, it even has a hinged lid, while for others it is small round

Still, you will have to fill tens of liters, and also wash the inside of the tank from time to time!

On a note! The stove should not be heated to the limit of its capabilities. This shortens the service life of the metal, which inevitably oxidizes and turns into scale, and then it crumbles and holes remain. The bottom piece of the chimney will also burn out if you heat it like this. If you don't want this, insert a piece of black structural steel pipe of the required diameter inside. It will take away some of the heat and add strength to the structure.

Useful video

This video explains in more detail about strengthening the chimney with pipe cutting:

You can learn more about the disadvantages of a hinged and chimney-mounted tank from the following videos:

https://www.youtube.com/watch?v=S5TRvRjgmLs

DIY making

If you can’t buy a tank in a store, you can assemble it yourself. To do this, you need to prepare consumables and tools:

- grinder with discs;

- file, hammer, pliers;

- welding machine;

- shut-off valve with the ability to adjust the flow;

- stainless steel sheets;

- metal pipes.

Build process:

- Mark the main parts of the container body on the metal sheets. It's better to make it rectangular.

- Cut out parts of the body using a grinder.

- Connect the main parts and weld them.

- Cut a hole in the top through which fresh water will be poured.

- Make a hole in the bottom and secure the drain tap.

All that remains is to make hanging hooks on one of the walls of the stove, and labels for hanging on the tank itself.

Let's talk about the rules of installation and operation

System calculation

If you decide to install the system yourself, you will have to make certain calculations. It will be difficult to absolutely accurately calculate the dimensions and volume of the system, and there is no urgent need for this.

For example, 5 kW is enough to heat a medium-sized room. This power can be provided by a heat exchanger with an area of 1 m². But the temperature in the furnace constantly fluctuates; when fully heated, 1 m² provides up to 9 kW, and when the furnace goes out, the power begins to drop rapidly and can drop by 5 to 10 times. Therefore, the area of the unit is taken with a significant margin, which makes it possible to equalize the heating of the liquid.

The configuration of the heat exchanger itself can be different; there is no consensus among experts. Some argue that stainless steel pipes are the best option, others prefer plates or manifolds consisting of 2 mating channels.

Connecting the system to the shower stall.

Tips for installation

If you decide to assemble the system yourself, then you should take into account several mandatory requirements.

- Tanks should be welded from metal with a thickness of at least 2.5 mm. The requirements for the upper, large tank are minimal; the main thing is that it does not rust or leak.

- The requirements for piping and the heat exchanger itself are somewhat higher; in the past, the most popular material for a heat exchanger was cast iron. Indeed, the material is very durable, does not corrode and holds the temperature for a long time. But cast iron also has serious disadvantages; it is heavy, which requires serious fastenings. And cast iron takes a long time to heat up.

- At this time, most experts prefer to assemble a system from stainless steel; its price is of course higher than that of cast iron or conventional steel grades that are susceptible to corrosion, but the savings here will cost more in the future. For the heat exchanger, stainless steel grades 08X17 (430) will be the most optimal; or 8-12Х18Н10 (304) they have optimal heat transfer parameters and meet all hygienic standards.

- As for the connecting pipes, naturally they should also be made of stainless steel. The drive pipe with cold water must initially, when leaving the large tank, fall slightly below the level of the heat exchanger; a drain valve is mounted at the lowest point and then rises at an angle of 2˚ to 5˚ to the entrance to the heat exchanger.

- The outlet pipe, through which hot water will flow into a large tank for a heated bath, must exit the heat exchanger, pass through the wall at an angle of at least 30˚ and connect to the tank.

Selecting the boiler power

It is important to take care of the installation of an RCD (residual current device). This will prevent accidental electric shock to bathhouse visitors.

This will prevent accidental electric shock to bathhouse visitors.

Based on the design features and range of water heaters, we can state the following:

- If you don’t have gas, then the heaters and boilers using this fuel will “pass” by your bathhouse. If you are the happy owner of a gas bath, then you can no longer consider other options.

- Electric water heaters are expensive, but there are no problems with installing the device. It is cut into the water supply and plugged into an outlet. And that’s it – you can use it. Moreover, an electric boiler is a “one-time” device - this device will prepare the next portion of hot water after 3-4 hours. In addition, instantaneous and electric storage water heaters are afraid of excessive humidity in the bathhouse “atmosphere”.

- If you are a supporter of budget solutions and want to have a supply of hot water until the heater goes out, then you will undoubtedly like wood-burning water heaters. In this case, the water in the tank is heated by the stove itself, which imposes some restrictions on the process of installing such water heaters. They are installed during the construction of the heater. But if you haven’t missed the moment, then you won’t find anything better.

Well, now let's talk about volume:

- Large companies need an appropriate amount of water. Therefore, for a company of 4-5 people, you need either an instantaneous water heater or a boiler with a capacity of 100-150 liters.

- One or two people or a company of three people will get by with a 50-80 liter boiler.

- The bathhouse for one “user” is equipped with a 30-liter boiler.

water heaters “Success”,

which are tanks with a capacity of 40 to 250 liters, heated by heating elements at 1.5-2 kW.

Water heater “Success” 125 l

The tank is made of sheet steel, at least a millimeter thick, and the heating element is equipped not only with a thermostat, but also with a mechanical temperature regulator.

Less sociable bathhouse owners will be interested in

model GARANTERM ER 150 V

Water heater GARANTERM ER 150 V

electric boiler for 150 liters, boiling water heating element for 1.5 kW. This dressing can serve a company of 3-4 people, who can not only rinse off in front of the steam room, but also take a full-fledged hot shower. Moreover, the heater body, as well as the outlet fittings, are made of stainless steel, and moisture-resistant polyurethane foam is used as a heat insulator.

The cost of the heater is 10-11 thousand rubles.

model Ermak KVS-10-2-90

Water heater model Ermak KVS-10-2-90

wood-burning storage water heater made of stainless steel with a capacity of 90 liters. This boiler boils water using both wood and heating elements with a power of up to 2.5 kW. Moreover, this boiler has relatively modest dimensions - the wood-burning firebox is built directly into the storage tank of the heater.

The cost of a stainless steel model is 15,000 rubles.

Material for container

In the old days, the most popular material was cast iron. Of course, it will take a little longer to heat up, but the temperature will be maintained better. An important factor is the resistance of cast iron to corrosion and its long service life. But cast iron is a heavy material and such a container will need powerful support.

Cast iron stove with tank.

Ferrous metal is now practically not used for these purposes due to its tendency to corrosion and the high probability of deformation due to sudden temperature changes.

Stainless steel is deservedly considered a universal material. This metal is not afraid of corrosion and is relatively lightweight. In order to weld a large-capacity tank, a sheet 1.5 - 2 mm thick is enough. During temperature changes, such containers do not deform.

The video in this article shows the opinion of a specialist.

Assortment of tanks.

How to make a stove for a bath of a suitable size with a coupling of 400, 500, 530 mm

The choice of a homemade device depends on the dimensions of the paired compartment and the priorities of the owner. The manufacture of any type of structure is regulated by the standards PPB 01–93 and SNiP 41–01-2003. Regardless of whether the oven is horizontal or vertical, a number of general rules apply:

- For a heater you will need a sheet of 30x35 cm. The distance from the top of the heater to the bottom of the tank is at least ten centimeters.

- The back wall is completely welded, and a door is mounted on the facade.

- A coupling made of steel strip with a thickness of 400, 500 or 530 mm is attached to the top. Its width is approximately 5 cm. Half is welded to the body, and the protruding part is used for assembly.

- When installing the chimney, leave a third of the top area of the tank unsealed so that you can fill in water. A door with a handle is attached to the bay opening.

- A tap with a valve is welded at the bottom of the tank.

Important! The heater is filled with cobblestones only to half the space. You can equip the entrance hole with an iron rod to prevent cobblestones from falling out

Vertical homemade device

In a design built on a vertical principle, the grate is located above the heater.

The diameter of the stove will depend on the caliber of the selected pipe.

When installing a vertical sauna stove with your own hands, adhere to the following algorithm:

- Cut off a piece of pipe approximately 0.8 m long.

- Clean the cut edges.

- The bottom is welded from below - a circle of the same diameter as the pipe itself.

- Cut out the vent opening at the bottom.

- The grate bars are installed. They are located slightly above the blower hole.

- A slit for the combustion compartment is cut above the grate.

A hole is made on top of the stove for the chimney. All openings are equipped with doors adjusted to size. After the work is done, the stove is sanded and coated with paint.

Do-it-yourself horizontal design: photo

A distinctive feature of this type of device is that the firebox is moved from the steam room to the dressing room, which makes ignition easier and faster. But horizontal ovens require much more space.

Photo 2. A horizontal stove with a brick lining, located in the dressing room, requiring a fairly large space for installation.

To manufacture the device, a piece of pipe measuring 0.8 m is taken and the openings are sanded. A grate is installed below. A metal sheet sufficient to cut out a rectangle of the required size is suitable for it. The middle is cut out of the material, while the edges are left not too narrow. Then the metal rods are welded. The finished grate is mounted to the body.

Photo 3. Homemade horizontal sauna stove with a water tank and a compartment for stones.

For the rear section of the device, a metal rectangle slightly larger than the diameter of the pipe is suitable. If you plan to install a heater, you need to take this into account when cutting and add a larger allowance.

The sheet for the facade will be approximately the same size. Holes for the firebox and air vent are cut out in it. The mold is then welded to the front of the pipe. A square hole of approximately 12x12 cm is cut out from the top of the body. This will be the chimney. Next, the doors are hung.

Photo 4. Small metal sauna stove with a firebox and blower, with a hole for the chimney.

Before painting, the unit is thoroughly cleaned of plaque and rust. As a finish, you can line the structure with brick.

Attention! If you are painting the stove, at the end of the procedure, heat it outside!

Hot water tank for a bathhouse - how to choose?

Everyone understands perfectly well the importance of hot water in a bathhouse. Without it, you can’t wash yourself or use the heater. A technological solution would be to install a heating boiler. But why take up extra space, for example, in a small bathhouse, if you can organize water heating in a regular tank using stove heating? And all you need to do is choose the right container for this.

To begin with, we note that all tanks differ in shape and capacity.

Design options

The sizes are clear. Now let's talk about the method of heating water. It depends on the design features of the containers and the method of their location. The main options include the following types:

- classic tanks built into the oven;

- containers on the pipe;

- remote tanks.

Built-in containers

The first option is considered a classic. The container is located on the side or above the stove. Heating occurs as it heats up, and there is a ball valve on the tank for draining. On the one hand, they are quite convenient and do not require additional work to remove pipes or arrange places for fastening. But stoves with such tanks are large in size, and in some bathhouses that do not stand out in size, their installation will involve the loss of precious meters. In such cases, it is necessary to choose a sauna stove with a tank located on top. In this design, it will not block the passage.

Remote structures

Such tanks are more often used in saunas,

What should the tank be made of?

Of course, the most common option in all forms is stainless steel. There is several indisputable evidence for this: they are not subject to corrosion, the water in them warms up faster, and due to the special properties of the metal, it cools down more slowly. Stainless steel does not deform from high temperatures, is lightweight and always looks attractive, complementing the design of the interior space.

To save money, many people still use metal tanks. But they are impractical neither from an aesthetic point of view nor from a practical point of view. And if the unsightly appearance can be hidden behind the brickwork, then it is impossible to cope with the rust that appears over the years inside the container. And constant heating deforms the metal. And if people who have had such tanks for a relatively long time can still be understood, then it is impossible to understand the complexity of the thinking of those who install metal tanks in a newly built bathhouse. Moreover, many do not even try to hide them with partitions, leaving them outside for everyone to see.

You can also find cast iron tanks on sale. Thick metal that has a certain structure does not rust, but the water in it takes a long time to warm up, but also cools down slowly. Cast iron tanks are heavy; it is better not to place them on a small stove, but to place them on the side.

In addition to capacity, you also need to choose a tank based on its design features. Conventional stainless steel containers, powered by furnace heating, are produced in rectangular, square and semicircular shapes. Depending on the free space and taking into account whether the foundation will be poured under the stove, the type of tank is selected. Also, do not forget about the free space. They need to be positioned in such a way that they do not restrict the space. So that when washing you do not get scalded by accidentally touching it.

In winter, after washing is completed, the tanks are completely emptied. Once frozen, water will tear apart any metal. Do not fire stoves with an empty tank. High temperatures deform the container, and all protection will peel off from the enamel surface.

proekt-banya.ru>

Installing a cold water tank

An individual water supply system with a storage tank is convenient to use and simple to install. Water is pumped from the well or it is filled in manually. But the latter option is considered “Spartan” and modern technologies make it possible to move away from this method of collecting water, especially since pumps are relatively inexpensive, and water is pumped into storage tanks.

A little about pumps

Submersible pump for water intake.

The work usually uses silent submersible pumps or installations with a hydraulic tank. It would be good if there is a small space in the bathhouse for installing such a station. This could be a basement, a shed built on the side, or a place in the bathhouse separated by a partition. In some options, you can even refuse to install a tank if the pumping station reservoir has a sufficient supply.

By type, pumps are distinguished by their power characteristics and noise ranges. It is clear that the quieter it works, the more complex the mechanism and the more expensive the device itself. But for a bath these are not regulatory indicators. For one-time water intake, the cheapest pump is suitable. But such devices only pump water from wells located nearby, with a high surface of water in them. The main thing is that the height between the level in the reservoir and the installation site of the water tank does not exceed 7 meters, but in reality this rarely occurs. If only the bathhouse is made on two floors.

Methods for installing storage tanks

The complexity of the water supply wiring depends on the location of the water tank in the bathhouse. It needs to be chosen so that you don’t have to pull the supply from one end of the room to the other. In any case, a bathhouse is a low-rise building, so you will have to choose the storage location from two options: lower and upper.

Bottom position of the tank

Such tanks are installed in the basement.

They already have a built-in water supply system. In this scheme, it is installed at the level of the bathhouse foundation. The tank is buried in the ground, and water is collected by installing an additional pump. Year-round use of the bathhouse requires insulation of the tank and laying it at a level below freezing of the soil. In the summer version, it is installed in the basement at a distance of 0.5 meters from the ground.

This arrangement of the tank also works on a pneumatic water supply circuit. The pump forces liquid into the reservoir, displacing air. When the balance is exceeded in favor of the liquid, due to its physical properties, the latter will begin to displace water to the outlet: taps and watering cans. But such a scheme is rarely resorted to, due to the unreliability of its operation. Typically, additional units are used to supply water: pumps and blowers. But this also entails increased costs, not to mention the installation, connection and supply work.

Upper diagram

An example of a top drive location. This is not recommended. It is better to secure it on a more stable platform.

Due to simpler installation, no need for central water supply to the bathhouse and installation of additional devices, the option with an overhead tank is used more often. According to the name, the tank is mounted at the maximum height, from the point of supply: watering cans and taps. This could be a roof, a special overpass, or a place inside the bathhouse. The water supply is carried out due to the difference in height. That is, by placing the tank in the attic, there is no need for any blowers, the water will flow by gravity to the taps. Like the lower installation option, this arrangement requires insulation if the bathhouse is used all year round.

The disadvantage of this method is considered to be low pressure, but to rinse after a steam room, you do not need high pressure. Raising it a little will allow the tank to be positioned. Increasing the pressure is achieved by setting it at a higher point. For example, for 0.1 atmospheres, a height above the level of the taps of 1 meter is sufficient, and for 0.5 atmospheres, the storage tank is installed at a height of 3–5 m. This is quite sufficient for bath procedures and technically feasible. Also, when installing a roofing system for a bathhouse, a place for the tank is provided in advance.

How to install a simple drive

As it turned out, these include tanks mounted at the top point. This means that first we select a container or make it from stainless metal according to the required dimensions. The tank installation process is as follows:

- In the intended location, the floor beams are first strengthened;

- the tank is installed and attached to the base in any way convenient for you;

- The valve and all outlets are installed.

How to install the valve?

An example of an installed storage unit in the wash compartment.

This process needs to be described in more detail. It is necessary to mark a point from the top edge of the tank, 7–8 cm away from it. A hole is cut here to fit the size of the valve. The tail part with a plastic float is inserted inside and secured to the tank with a bolted connection. To prevent water from escaping at the valve entry point, rubber gaskets are made on both sides, and the connection point is coated

adhesives and sealants. The seat is tightened, and a supply pipe of the appropriate diameter is connected to the shank. It is better to lay it to the tank in the ceiling space of the bathhouse, so that there are no pipes in the attic that interfere with movement. Now, when water is drawn in, the float will block the inlet, thereby stopping the flow until space is freed up.

Next we do the overflow. It is placed 2–3 cm below the valve entry point. A hole is drilled and the pipe is fixed in this place, similar to the installation of the valve. The outlet is discharged into the sewer. The outlet location is made at a level above 3 cm, from the bottom of the tank. So that water is not completely taken out of it. All outlets are sealed with gaskets and treated with hermetic compounds.

Plastic container for storage. Very convenient containers. The outlet and inlet valve are already installed in this model.

The tank is installed. If necessary, it is insulated by covering it with a special box. If possible, all protruding sections of pipes are fixed on the walls so that there is not a single freely hanging hose. The operation of the system is checked by starting the water. If any shortcomings are identified, it is better to eliminate them at the stage of installing the drive.

The upper location of the water tank is convenient when planning the construction of a bathhouse roof with a veranda. You can set aside a small space in advance and securely hide the drive, making all the necessary connections.

proekt-banya.ru>

How to install and connect correctly?

During the process of installing and connecting a tank in a bathhouse, one of the main priorities is deciding how the water in the tank will be heated. The water in the tank can be heated either from the heat of the stove in the steam room, or using a heating element. The main factor here is the number of people visiting the steam room and their need for hot water. The thickness of the tank will also affect the rate at which the water heats up.

Connection diagrams for the water tank may vary. If there is running water in the premises, it is necessary to use a closed water supply system. For this purpose, it is most advisable to use a stove that has a coil, which, in turn, will be connected to a water reservoir and heat the liquid. The container itself can be mounted on the wall. Sometimes tanks are mounted directly above the furnaces, but with this installation option it is best to use lighter and smaller structures. For containers that have a water circuit, stainless steel or galvanized sheet is often used.

You need to connect according to the following instructions:

- The tank itself should be installed in the steam room and connected to the pipes using a coil.

- To achieve good circulation, it is worth connecting the upper part of the tank with the upper outlet of the coil, and the lower part of the tank, respectively, with the lower one. For this reason, cold water will enter from below, and hot water will be discharged from above.

- At the point where cold water will enter the tank, a safety and check valve is used.

- Then you need to set the threshold pressure for the valves at which they will operate. The drawings are presented below.

Thanks to this principle of operation, the liquid in the container will be heated using a coil. And after it is used, the tank will be filled with cold water again.

Water bath containers: how not to make a mistake when choosing

The main elements of a bathhouse, if you intend to get maximum pleasure from the process, are a stove and a water tank. To ensure that everything related to the water tank in the bathhouse is done correctly, we will dwell on the main issues that may arise when setting up a steam room yourself.

The main questions that arise when choosing an element such as a tank for a bath are:

- Its parameters

- Which type should I choose: remote, built into the oven, on a pipe?

- What should it be made of: steel, stainless steel, cast iron?

Tank parameters

If you are used to doing everything with your own hands, then, of course, you will try to make a sauna tank yourself.

However, you should first think about what type of container is suitable for your steam room, what principle of water heating will be used, what material to make the tank from, so that later you do not have to invest money in re-equipment again. So, you must decide whether you will heat the stove in a sauna or simply heat the water using the heating element built into the tank. And in order to understand what is more profitable for you, heating a stove or using an electrically heated container, estimate how many people will steam at the same time. Another important factor is the volume of water that needs to be heated and the allowable time for heating to the required temperature.

Let’s say that if you want to steam alone, a person is unlikely to need more than fifty liters of hot water. But to please the whole family or group of friends, you need to install a water heating tank with a capacity of seventy or more liters.

Also pay attention to the thickness of the tank wall. It is this parameter that determines how evenly the water in it will be heated and how long its temperature will remain. But remember that the thickness of the tank wall directly affects its price and weight.

In any case, a stainless steel bath tank with a volume of up to fifty liters should have a wall thickness of 0.8-1 mm. For containers of larger volume, a wall thickness of 1.5 mm is desirable.

Advice from the master!

And do not forget that no matter what material the tank in the bathhouse is made of, you need to equip it with the optimal number of outlets and make an inlet for water. When choosing a tank in a store, ordering it in a workshop, or preparing to brew a canister for a sauna yourself, take into account all the parameters mentioned, and the process of washing in a sauna will be a complete pleasure for you.

Return to content

Remote with heat exchanger

Heating water in a bathhouse using a heat exchanger is highly efficient. This method is used in boiler houses of any size. The heat exchanger is located in the furnace flame. Water circulates through it; this heating of water is the most effective of all possible. The only thing that limits the use of this system for baths is its complexity and the resulting high cost.

Advantages

A remote tank for hot water in a bathhouse is placed in any convenient place. Heat is transferred to it through circulation pipes if a stove or boiler is used. Remote tanks are also ideal for electric heaters.

Compared to a tank directly on the stove, heat is transferred to a remote tank in a more complex way. The length of the pipes can be several meters. Of course, this causes additional heat loss, but also provides many advantages:

- If the tank is remote, then a highly efficient heat exchanger is necessarily used to heat the water;

- The installation location can be any; large volume containers can be installed;

- It is convenient to install at a height, for example, in the attic of a bathhouse for a ceiling shower.

Types of heat exchangers for sauna stoves

Structurally, the heat exchanger can be a coil or a tank with a maximum volume of 5 liters and two pipes for connecting a water tank/radiator.

According to the mounting method, heat exchangers are divided into two types:

- internal. Such products are fixed on one of the side walls of the furnace or mounted on its bottom. It is also possible to install a water jacket, which literally encircles the fuel chamber from the inside or is located in the space between the stove casing and the walls of the firebox;

- external. Heat exchangers of this type are fixed to the chimney or attached to the wall of the furnace.

Prices for different types of heat exchangers

heat exchanger

Internal type heat exchangers have the best heat saving indicators. The water in them will heat up until the stove cools down completely down to its last brick or stone.

The fastest heating of water is provided by internal heat exchangers and external ones installed on the chimney. At the same time, the first products often imply the need to make design changes/additions to the sauna stove, while the second cannot be called a decoration for the steam room (a wide tank does not fit well into the interior).

Example of an internal steel heat exchanger in a brick kiln

Why stainless steel: key advantages of the material

The modern market offers a wide range of water tanks made of cast iron, stainless steel and enameled material. As practice shows, stainless steel is the most popular among bathhouse owners, which is due to the competent and acceptable ratio of operational and technical characteristics and cost indicators.

Stainless steel is characterized by excellent thermal conductivity, withstands temperature changes and objectively lasts longer than various ferrous metals.

Examples of stainless steel tanks

Stainless Steel Oven Mounting Tank

Stainless steel tank

Stainless steel containers

A logical question arises here: which of the existing brands of stainless steel is better suited for the manufacture of the container in question, intended for use in a bathhouse? Firstly, this is brand 08Х17 (430), secondly, 8-12Х18Н10 (304). The mentioned materials, among other things, are used for the production of tableware and are characterized by high resistance to high temperatures, are completely hygienic, do not rust or deform during use. In addition, such materials are unpretentious and extremely easy to maintain.

Composition and mechanical properties of different grades of stainless steel

To summarize the above, we can highlight 3 main advantages of water tanks made of stainless steel:

- the products do not require additional protection from high air humidity and can easily withstand operation in conditions typical for a steam room;

- Stainless steel has high thermal conductivity, which makes it possible to obtain hot water in the shortest possible time;

- Stainless steel tanks do not deform due to sudden temperature changes, or these deformations are insignificant.

Anti-corrosion treatment

For metal tanks, corrosion is the main problem. The key solution is stainless steel, but for now, the price for it remains 10 times higher than usual (in terms of weight). In reality, a stainless steel tank costs not 10 times more than a regular steel tank, but much less. This happens because the thickness of the walls of the stainless steel tank is made smaller. There is no reserve required for thinning due to corrosion.

Anti-corrosion treatment of tanks is carried out in the factory. Technologies in this area do not stand still and are constantly being improved. Zinc has the strongest adhesion to steel. Various protective layers are applied on top of it.

There are two popular options for anti-corrosion protection. This is either paint for a hot water tank in a bathhouse, or glassy enamel, which is applied at high temperature. Enameled tanks are better protected from corrosion and high temperatures than painted ones.

The general technology for their manufacture is the same as for conventional enamel cookware. Glass-based food grade enamel is used for tanks and utensils, without the addition of lead.

Information. In some cases, they carry out independent anti-corrosion treatment of tanks. All homemade structures need it (with the exception of stainless steel). You need to use only specially developed compounds and apply them to a clean and grease-free surface.

Mounted

This design option is hung on a standard metal sauna stove.

The presence of metal walls of the furnace is mandatory, since heat is transferred through one of them to the water in the tank. This design is not widely used due to low efficiency, but its main advantage is maximum simplicity. A hanging tank for a bathhouse is usually made of thin stainless steel. It is placed outside the stove and located in a visible place in the bathhouse. Stainless steel is not only an ideal material for water tanks, but also has a beautiful appearance.

When you need the simplest tank for hot water in a bathhouse, wall-mounted installation is best. With it, you don’t even need to do pipe routing. The tank is delivered completely ready.

The bath tap for hot water is also included with the tank upon purchase. The spigot is located at the center of the lowest point, and the bottom is usually flat or has a conical stamping.

The inconvenience of this location of the tap is the small distance from the floor. In addition, the stove is often placed in the corner of the bathhouse. One side of it is occupied by the door, and the other by the tank. Thus, it turns out that the tap is in a very inconvenient place. This problem is solved by installing a pump.

Information. For a wall-mounted tank, the sauna stove should be standard. This is either a ready-made structure, or a home-made one, but having at least one flat metal wall of the appropriate size for the tank.

Wall-mounted tanks have either a removable lid or a filler neck with a diameter of at least 10 cm. A filler neck is much more common. It makes cleaning and processing the internal space somewhat more difficult, but makes the structure more durable.

The cheapest designs of hanging tanks are welded from sheet steel and galvanized. The service life of such structures is short. Stainless steel thin-walled structures are gaining popularity.

Due to their small wall thickness, they are affordable. Steel enameled tanks are rarely used as hinged tanks on the stove.

What designs can be used

You can place the tank in the bathhouse in different ways. The main types used are:

Built-in design. In this case, the chimney pipe runs inside the tank. This structure is considered stationary, non-removable and is installed during the manufacture of the chimney. The tank can be made in the form of a pipe (cylindrical version) or have a rectangular cross-section

It is important to securely seal the bottom entrance of the pipe to prevent water from leaking out of the tank. To use water, outlets are made from the tank directly into the shower stall or intermediate tank

Given the elevated location of such a tank, water flows by gravity.

The device of a heater with a tank on the chimney

- Hanging structure. Such a system is removable, i.e. installed on an existing chimney. The tank is placed close to the chimney pipe and securely attached to the column. Such containers can be purchased or made by yourself. This design is typical when a gutter is formed on the back wall, repeating the shape and diameter of the chimney, which makes it possible to bring the surfaces as close as possible and ensure high-quality heating.

Design of a hanging tank for a bath

- Remote design. In principle, the water container itself can be placed in any convenient place (for example, in a shower). In this case, the energy of the chimney heats the coolant, which is sent to heat the water container. When such a heat exchanger is mounted on a bath pipe, the installation height of the tank must be selected so as to ensure gravity flow of the coolant according to the laws of physics, i.e. the warm flow rushes upward, and the cooled flow – downward. This design provides for the presence of additional elements in the form of a heat exchanger, but it also allows you to place the tank itself in the right place.

Water circulation diagram with a remote design of the tank and stove in the bathhouse

Depending on the design, the tank can be placed at different height levels. 3 options can be implemented:

- At the stove level: the base of the tank is placed on the top of the stove, which means no additional brackets are required. The main disadvantage is that the height does not allow gravity flow of water for showering. In this case, it is scooped by hand.

Tanks at furnace level

- On the chimney column. This design is located at a certain height, which eliminates the previous drawback. Mounting the tank requires special brackets, and the weight of the structure is limited.

- Attic level. Here there is a reliable support for the tank in the form of a ceiling. The problem arises in a cold attic, where you will have to think about external thermal insulation.

Diagram of installing a water tank on a chimney at the attic level

When calculating the parameter, they usually proceed from the following requirement: 10 liters per person for a bath procedure and 5 liters per person when taking a shower. In addition, a reserve should be created for unforeseen circumstances.

There are various forms of water tanks for a bath on a chimney

The dimensions of the container also depend on the design and dimensions of the chimney. The most common type is a sauna tank with a 115 mm pipe. Naturally, a bath tank for a 150 mm pipe is made of a larger diameter, regardless of the need.

The choice of volume of a metal water tank depends on the number of family members

Formula for determining the volume of a cylindrical tank

Popular stove-heater

click to enlarge

Heater stoves differ in the way the stones are placed. Stoves with closed and open heaters are common.

A heater stove with a water tank located at the top becomes a universal option. This is the most popular design of a stove of this type, allowing the stove to be placed in small rooms.

The combustion chamber is covered with a cast-iron stove, smoke circulation is arranged at the bottom of the rear part, and the stove is laid on top using the method of protruding bricks - this ensures ideal heat transfer. A special steel lid is made for the water tank, which is located at the top.

Built-in tank, remote tank or tank on a pipe?

Bath tanks come in various types. The most famous are built-in, remote and on a pipe. Each of them has its own advantages and disadvantages. Compare and evaluate which one is right for your bath.

Advantages of a tank that is built into the oven

Once upon a time, water tanks for the bath were always built into the stove - so that the entire lower part of the boiler was in the upper part of the firebox - the hottest. In this case, the bottom of the tank is in direct contact with the stove fire. Water from this container can either be drawn directly or removed through a special built-in tap.

Remote sauna tank: main advantages and disadvantages

Thanks to the excellent ability to install a special heat exchanger in the oven, the tank does not need to be tied to a specific place - it can even be installed in a washing room. According to all known laws of physics, cold water will fall into the heat exchanger, and hot water will rise back.

Sauna tank on a pipe

Of course, it also happens that the sauna is used not for a couple of hours at all, but for the whole day - for example, when washing, but time has already passed since the fire. Then the best option is a sauna tank on a pipe, where the water will be constantly heated to the required temperature. This is on the pipe through which smoke comes out of the furnace - and its temperature can reach 500 degrees. Such tanks can be quite large, since the heating area of the pipe is very large, and the water will heat up evenly and quickly.

There is also another advantage of this design - in this bathhouse, smoke leakage through a crack in the pipe is absolutely impossible, since the tank in this case serves as a full-fledged fuse.

Types of tanks

All tanks are divided into types according to two criteria: installation method and material of manufacture. According to the installation method, tanks are:

- built-in;

- remote;

- samovar type (mounted on a chimney).

According to the material of manufacture:

- cast iron;

- stainless steel;

- made of enameled steel.

Each type has models that differ in shape, volume, and wall thickness. Most containers are equipped with standard taps and have shower outlets, but there are also those from which water is drawn through the top using a ladle. In order not to make a mistake when choosing, you should familiarize yourself in detail with the advantages and disadvantages of all these types.

Built-in tanks

Built-in tanks

The most economical and convenient option. The tank is installed during the laying of the furnace. Its lower part is located inside the firebox, due to which the water is heated directly by the flame. Hot water is drawn through the top using a ladle or using a built-in tap.

Brick oven with water tank

Due to direct contact with fire, the walls and bottom of the container must be as thick as possible, therefore the most preferred material for such a tank is cast iron with a thickness of 5 mm. Stainless steel tanks with wall thicknesses of 1 and 1.5 mm are considered no less popular. Enameled steel containers are not suitable for this installation method. Cast iron tanks are bowl shaped, stainless steel tanks are usually cube or cylinder shaped.

Cast iron water tanks

Advantages of built-in tanks:

- water heats up quickly;

- the water temperature is maintained for a long time;

- free space is saved since the tank does not protrude beyond the stove;

- easy installation.

Flaws:

- the heat transfer of the furnace decreases, since the main part of the heat is spent on heating water;

- the dimensions of the tank are limited by the size of the furnace;

- the tank must have thick walls, which increases its weight and cost.

Metal tanks for sauna stoves

This method is convenient in cases where no more than 4 people are steaming in the bathhouse at the same time, or people wash separately. For example, if 3-4 people take turns steaming in a bathhouse, this takes quite a lot of time, and accordingly, it will take longer to maintain the water temperature by adding firewood. The built-in tank allows you to save on fuel while remaining hot for a very long time. But for large companies, this option is not the most optimal, since it does not provide the required amount of water.

Remote tanks

Remote tanks

The remote tank is located at a distance from the firebox and is connected by pipes to a heat exchanger built into the furnace. Without this, its operation is impossible. Most often, such a tank is installed in a washing room or mounted on the wall of a steam room next to the stove, if its dimensions are larger than the area of the firebox. When choosing a location for a container, it is necessary to take into account that the length of the pipes should not exceed 2.5-3 m. Remote tanks can be made of stainless steel or enameled, cylindrical, rectangular or even triangular in shape - for installation in the corner of the room.

Triangular shaped water tank

Advantages:

- the tank is installed where it is more convenient;

- Large containers can be used;

- there is no direct contact with fire, so the tank can be enameled and with thinner walls.

If 6-8 people regularly steam in a sauna, a remote tank is an excellent option.

Flaws:

- without maintaining a fire in the firebox, the water quickly cools;

- the oven cannot be used without water in the circuit;

- more complex installation compared to a built-in tank.

Remote tank connection diagram

Tank on a pipe or “Samovar” design

This option involves installing a tank around a chimney, and in some models the pipe is located outside the tank, in others - inside.

Hot water tank on a pipe

Design option for a water tank on a pipe

In height, the tank can occupy the space from the stove to the ceiling, partially extend into the attic, or be attached only to a small section of the chimney above the stove. The most convenient container shape is cylindrical, but there are many models with rectangular, triangular and oval sections. Heating of water is carried out using smoke passing through a pipe, which has a very high temperature.

Oval shaped water tank

Advantages:

- fast and uniform heating of water;

- does not reduce the heat output of the furnace;

- space saving;

- you can install a container of any volume;

- the water stays hot for a long time.

This tank is suitable for any bathhouse and any number of people. It all depends on the size of the container.

Stoves with water tanks on a pipe

Flaws:

- installation complexity;

- increased soot deposition on the walls of the chimney.

When installing the tank, it is necessary to select the correct fastening elements in order to securely fix the tank in a vertical position. In addition, you will need to install pipes for supplying cold water and discharging hot water, and install a faucet.

Samovar type tank

All the details and nuances

Depending on the purposes for which you will use the room, how many people will relax there, the choice of construction method will vary. If you plan to build an entire complex, then most likely you will have to be patient.

Building a sauna tank with your own hands or calling a construction company for help is a matter of your choice, but its presence will significantly simplify some processes.

Previously, the container was placed directly in the stove or above it. Since the slab itself is made of brick, stone or metal, the structure is truly strong and durable. Today there are many options for replacement. As an alternative to this, you may be offered:

- Remote

- Mounted

- Heated by heat exchanger

Those structures and tanks that have the ability to be transported are much more practical and can be easily moved to other rooms.

Recently, the production of this type of product has become more in demand. The latest generation technologies allow you to choose from a number of tanks with any parameters and efficiency, at a price that suits you.

The main purpose of such tanks is for greater release of light and soft steam, as well as water supply in the shower or other amenities. The volume of the container and its dimensions will depend on how great the need for water is. For 3 people, 50 liters is quite enough, 80 liters or more for noisy companies, or if the bathhouse is heated several times a day.

Good functioning is also influenced by factors such as the density or thickness of the metal. A stainless steel water container is very practical and maintains optimal temperature conditions well. It’s not worth saving on such a device, and you need to understand that high-quality material will cost much more.

The choice of tank plays a big role; during the combustion process, the temperature reaches 400 degrees; if the installation is attached to a chimney, then this level of steam goes beyond such a building and can be called a classic option, since it has become widely used in the last ten years. Choose a manufacturer responsibly and try to purchase only high-quality certified products.

Other methods of heating water

Important! The use of gas boilers requires strict adherence to safety regulations. Installation and operation of equipment with a power of more than 50 kW involves the mandatory receipt of additional technical conditions and permits. Electric water heaters are available in two types:

Electric water heaters are available in two types:

- Flow type with optimal performance of 2.5 l/s. The equipment heats the water as it moves, consuming the greatest amount of electricity.

- Capacitive water heaters with an optimal volume of 100 l. They consume significantly less electricity. The water is heated for 3-4 hours, after which its temperature is maintained constant.

In order to save energy and ensure the ability to use the shower in the washing room at any time, a combined system is used. It consists of a furnace and an electric water heater, which can work simultaneously to quickly heat a large volume of water or separately, depending on the current need.

Even today, the bathhouse has not lost its relevance: the purpose of building a bathhouse or purchasing ready-made structures is the desire to improve one’s health in the most accessible and enjoyable way.

When installing a bath these days, stoves with a remote tank have gained particular popularity.

Materials

When choosing a tank for a bathhouse or when making it yourself, an unmistakable choice of the material for its manufacture is extremely important. The heating time of the liquid, the period of its cooling and the duration of operation of the device itself will depend on this. Among the most widely used materials, cast iron, stainless steel and enameled steel are widely used.

Previously, only cast iron tanks were used for hot water tanks. Cast iron containers have been tested by time and have a number of positive aspects. In particular, a cast iron tank will keep the water hot for a long time. There is no corrosion on them and the water in this tank will always be clean. This material is very resistant to temperature changes. And finally, the shelf life of a cast iron tank is very long, since this material is not susceptible to corrosion. Currently, not many manufacturers are engaged in the manufacture of cast iron tanks. But it is quite possible to buy a used tank at a lower price. In this case, you will need to process it and give it a pleasant appearance.

One of the disadvantages is the rather long time it takes to heat the water in the tank. Cast iron tanks are heavy and sometimes need to be installed on a special foundation. If the tank is located above the stove, its fastening requires additional reinforcement. Making such a tank yourself will also be a very problematic undertaking.

Stainless steel containers are now used quite often. This material replaced cast iron tanks. The owners of the baths appreciated their high positive qualities. Such tanks do not require additional protection from high humidity. The water in a stainless steel tank heats up in an extremely short period of time. Stainless steel has good resistance to sudden temperature changes and, accordingly, does not rust, as its name already implies. The only downside that can be noted is that the water in it cools down quickly.

Tanks made of enameled steel are also a popular option for this design. A special enamel coating on such tanks reliably protects them from corrosion. The main thing is to prevent damage to the enamel, otherwise the tank may begin to rust. Although damaging the enamel layer is quite problematic, since such a coating is resistant to various types of damage. If necessary, a tank made of this material can be very easily cleaned. Enamel of various colors is available on the market.

For cold water, separate tanks are now rarely used, since it most often enters the room through the water supply. But if there is a need to install a container for cold water, then there is much less hassle with it than with a tank for hot water, since there are no particularly strict requirements for it. You can even use wooden containers, such as an oak barrel. Plastic containers for cold water are also popular. But such containers cannot be placed in a steam room, much less near a stove, because plastic is sensitive to high temperatures and can become deformed when heated. You can also make such a tank yourself.

Advantages and disadvantages of samovar systems

The photo shows the structure of a samovar tank at the attic level; a cold water supply is connected to it.

A sauna tank on a pipe is called a samovar. It is an integral part of the chimney pipe elbow. Its location is very convenient, the water heating process occurs much faster and more uniformly than with other locations. The design itself is very compact.

The negative aspects of samovar systems include the fact that filling the tank with water is not very convenient. But this issue is easily resolved if the top of the tank is in the attic and a water tap is connected to it.

Important. It is very dangerous to make miscalculations in designing the volume of the container, as this can result in very frequent boiling of water.

The material for making samovar containers is usually stainless steel. The possibility of corrosion over time when using other materials is detrimental to the normal operation of the bathhouse, therefore the decision to install a stainless steel container is the right decision.

Among other things, the high thermal conductivity of stainless steel guarantees fairly rapid heating of the water in the samovar tank, and the strength of this material allows you not to be afraid of deformation of the device due to temperature changes.