Foam plastic began to be used as insulation in the mid-20th century. The foam consists of expanded polystyrene. When foaming, air bubbles form. Due to the large number of air bubbles, polystyrene foam is considered an excellent thermal insulator. But is it possible to insulate a bathhouse with foam plastic? Let's figure it out together.

Is it possible to insulate polystyrene foam and a bathhouse?

Materials for thermal protection of frame baths

When choosing insulation for a frame bath, it is necessary to take into account not only the thermal insulation characteristics of a particular material, but also its ability to withstand significant temperatures at a constant high level of humidity.

In addition, the insulation for a sauna building, when heating the room, should not emit toxic compounds that negatively affect the health of people receiving the procedures.

In order to improve the thermal insulation parameters, insulation of a frame bath, such as in the photo, can be done using the following materials:

- Mineral wool . Its slabs consist of thin fibers, which are obtained by melting rocks or waste from metallurgical enterprises. In the process of weaving a large number of these fibers, air is retained between them, due to which the products have excellent thermal insulation qualities. As a result of the peculiarities of mineral wool production, the material can withstand very intense heating while its performance characteristics do not change. Such slabs retain heat-saving properties in conditions of high humidity and do not collapse.

- Reed slabs . They are natural and environmentally friendly heat insulators. Their thickness is 15 centimeters and this parameter is very convenient when building frame structures.

- Insulation made from sawdust-gypsum mixture . To make it, you need to mix 10 parts of dried small sawdust with 1 part of cement (gypsum). Insulating a frame bathhouse from the inside using this mixture has a significant advantage - affordable cost and excellent thermal insulation (read: “How and with what to insulate a bathhouse inside - tips from a master”).

- Foamed synthetic products - polyurethane foam, polystyrene foam, etc. They have a number of advantages, including low price, immunity to moisture, ease of installation, low weight, and low thermal conductivity. But these synthetic insulation materials cannot be installed on elements of a bathhouse building, where exposure to high temperatures is possible, so they are used to insulate walls located away from the stove. They are placed in the dressing room, rest areas or washing area.

Types of insulation

There are various types of insulation materials on the modern building materials market. And before you make a choice in favor of any particular one, remember that obtaining a healing effect will directly depend on the material you choose.

A fairly low hygroscopicity and thermal conductivity is an important requirement for finishing, because the lower it is, the less heat the material transmits through itself. All insulation materials available on the construction market are divided into several groups. All insulation materials available on the construction market are divided into several groups

All insulation materials available on the construction market are divided into several groups.

Organic

They have been known since ancient times. Our grandfathers and great-grandfathers also used this material at hand to preserve and retain heat in the bathhouse.

In the production of organic insulation, natural raw materials are used:

- regular flax or resin-treated tow;

- moss;

- sawdust from wood processing;

- felt or jute.

Their undeniable advantage is that they are all of natural origin, but the disadvantage is a high level of moisture absorption, fire hazard, difficulty in use and vulnerability to rodents and harmful microorganisms.

Semi-organic

In the production of this material, natural raw materials are used, but adhesives are used during the technological process. This insulation is not suitable for finishing steam rooms. These include chipboard and peat boards.

Synthetic

They are divided into several types.

Polymer, which includes polystyrene foam, polystyrene foam, penofol, polyurethane foam. It is strictly forbidden to use such materials when sealing a steam room or near a stove, because they can easily catch fire and emit harmful gases when burned. But when used in adjacent rooms, they are very suitable. In steam rooms, only penofol is allowed, which is covered with a layer of aluminum foil and prevents heat from escaping.

Currently, leading manufacturers of thermal insulation materials have found a suitable option for insulating baths and steam rooms. Now special mineral wool based on stone or fiberglass is produced. It is used for insulating surfaces made of any material. This product is produced using modern technology and is made from broken glass and sand.

In the production of stone wool, rocks similar to the gabbro-basalt group are used. This raw material is melted at high temperature and fibers are obtained from the liquid mass, which are then formed into slabs of various sizes. The resulting product does not smolder, there is no smoke, no toxic substances are released and it prevents the spread of fire.

Mineral wool, produced on the basis of glass fiber, has elastic and horizontally located fibers, due to which the product is firm and elastic. It is easily mounted in a structure and is able to fill all areas of empty space. The service life of this product is at least 50 years, but over time it shrinks. This happens due to poor quality work performed. Stone wool does not lend itself to deformation; with proper installation, it can last 50 years, and some types up to 100.

Currently, fiberglass mats from such manufacturers as Ursa, Isover, Knauf and stone wool insulation materials Rockwool and Technonikol are widely used on the Russian market.

When insulating steam rooms, the material must withstand high temperatures and not be affected by fire, so it is better to use foil plates. The surface on which the layer of aluminum foil is applied must be directed indoors. It will insulate the material, reflect heat and prevent the material from getting wet. When installing it, there is no need to use a vapor barrier.

It is worth noting that today bathhouses made from blocks are most often insulated with mineral wool, penoplex, foam glass and ecowool. You can choose the option that suits you best.

Arrangement of vapor barrier

Before you start work, you need to know how to properly insulate a frame bath in order to do it efficiently. Regardless of which material was chosen as insulation, when laying it in the cells of the frame, it is necessary to ensure reliable vapor barrier (for more details: “Vapor barrier of a bathhouse - selection of material and its installation”).

If you do not cut off the insulation from the bathhouse atmosphere with its high humidity, it will absorb water as the steam cools, which will certainly lead to the most undesirable consequences:

- a wet thermal insulator will significantly increase its own thermal conductivity and heat will quickly move from the room to the environment;

- the porous structure will not allow the material to dry quickly, which means mold may appear and the frame of the building will begin to rot.

Thus, when a frame bath is made, the walls are insulated using high-quality vapor barrier.

To do this, experts recommend using one of the following materials:

- aluminum foil will not only protect the insulation from moisture, but will also reflect thermal energy;

- polyethylene film;

- glassine is environmentally friendly and inexpensive.

It is undesirable to use roofing felt, as it begins to smell unpleasant when heated. When installing a vapor barrier, you should not allow even the slightest gaps to remain between pieces of material. The tightness of the joints is ensured using metallized tape, or by overlapping adjacent sheets.

Pros and cons of the material

Polystyrene foam is nothing more than foamed polymers that form gas capsules at high temperatures and retain their shape when cooled.

As a substance formed with the help of gas, polystyrene foam has a number of excellent insulation properties :

- ease;

- moisture resistance;

- durability;

- sound insulation;

- resistance to shrinkage.

In addition, in price lists, foam plastic consistently occupies a position among the cheapest building materials. Just what you need for economical and quick insulation.

However, don’t get too fascinated and think that polystyrene foam is perfect. Of course, it also has disadvantages, but whether or not to pay attention to the disadvantages of this insulation is your choice.

The disadvantages of polystyrene foam are::

- flammability (due to the nature of its formation - using gas);

- not too long service life, which may be further shortened due to violation of installation technology;

- unsuitability for insulation of wooden premises. In practice this is possible, but only if there is high-quality ventilation;

- fragility;

- release of toxic substances during combustion that can cause paralysis of the respiratory tract;

- poor quality of some brands of polystyrene foam produced in artisanal conditions.

Insulation of frame building walls

They begin to equip the thermal protection of a frame bathhouse building simultaneously with the construction of its walls. The fact is that the use of this technology assumes that the heat insulator is also a structural material. When building a panel bathhouse from insulation with your own hands, its layers are laid out between the load-bearing elements of the frame. A vapor barrier is installed on top of it.

At the end of the insulation work, you get something like a pie, in the center of which there is a heat-insulating material, lined with a vapor barrier on the inside, and waterproofing on the outside.

The outer layer of the cake will be represented by decorative finishing inside the bathhouses, and on the outside - by facade cladding. Both of these layers will not only provide additional thermal protection, but will also serve as a structural element that will enhance the strength of the entire building.

Among professionals, the best option is considered to be laying two layers of heat-insulating material into the bath frame. In this case, it is advisable to make the first of them from tile insulation, and the second from roll insulation. As a result, such a thickness of the walls of a frame bath can reliably protect the premises from heat loss.

In the process of laying insulation, special attention should be paid to the fact that most materials have different sides - external and internal. To distinguish them, pay attention to the recommendations of product manufacturers.

Preparatory calculations

A bathhouse is a wonderful place to relax the body and soul, but its proper functioning is impossible without insulation. Click on photo to enlarge.

- calculation of the total area of the structure;

- the approximate number of people who will visit the steam room at a single point in time;

- the number of different rooms, from the dressing room or vestibule to the steam room or locker room;

- additional rooms - this can accommodate, for example, a swimming pool or a small hall with various exercise equipment.

Which parts of the bathhouse are advantageous to insulate with foam plastic?

Since polystyrene foam is not only a good heat insulator, but can additionally protect the surface from moisture, it is often used to insulate the foundation of a bathhouse.

How to insulate the foundation of a bathhouse?

Polystyrene foam is excellent for foundation insulation. But we must not forget that the insulation crumbles and is afraid of mechanical damage. To protect it from the outside, it is necessary to make a protective partition from boards or bricks. Foam plastic is optimal for insulating the foundation. It does not allow water to pass through and the foundation will be reliably protected.

Technology

No matter how good the material is, failure to adhere to the accuracy of the installation technology can, over time, negatively affect the quality of heat conservation.

Therefore, having prepared the necessary material, carefully study the step-by-step instructions .

Frame installation

Required:

- foam sheets;

- metal profile or wooden blocks 50x50;

- film for vapor barrier.

Stages:

- Clean the ceiling from dirt and dust, eliminate unevenness, if any. Treat the surface with an antiseptic.

- Remove electrical wiring. To do this, use a special protective corrugation.

- Attach beams or a profile to the ceiling at a distance of 50 cm. Make sure that the shape of the attached beams takes on the appearance of a large cage, each cell of which should correspond in size to the foam sheet.

- Install foam plastic using dowels or glue.

- Treat joints and cracks with polyurethane foam.

- Attach a vapor barrier layer to the insulation.

- Finally, start installing drywall, wood or other material that matches the overall interior.

Adhesive mounting option

Required:

- sheets of foam plastic in an amount corresponding to the total area of the ceiling;

- adhesive composition.

Stages:

- Clean the ceiling, treat it with an antiseptic and prime it for a better bond between the glue and the surface.

- Prepare an adhesive composition or use a ready-made one.

- Apply glue to the foam sheet (in continuous lines along the edge and in splashes in the center of the board). Press the foam sheet as firmly as possible against the ceiling and hold for a few seconds.

- If you are insulating the ceiling using polystyrene foam, then all the sheets should be prepared in advance: scratch with an iron brush along the working side (the one on which you will apply the adhesive).

- Start gluing the sheets from the middle of the ceiling in a checkerboard pattern.

- For greater reliability, the foam sheets can be additionally attached with dowels after the glue has dried.

- Glue the reinforced mesh on top of the foam and putty.

Ceiling insulation in a house or apartment

Stages of ceiling insulation with foam plastic

Economical polystyrene foam will help you do the ceiling insulation of an apartment, wooden or brick house with your own hands at minimal cost. This will prevent heat loss and maintain a comfortable atmosphere in the room. The thickness of the foam sheets used for wooden bases is 40-50 mm, the thickness of panels for concrete and brick bases is up to 100 mm at 25 percent density.

Important! Before installing foam panels from inside the room, the base of the ceiling must be thoroughly cleaned of old paint, whitewash, dirt and dust. It should be leveled and primed

Insulation sheets are installed from the inside onto a special sheathing (wooden, aluminum, plastic), so the ceiling height will be slightly reduced. The profile, which is secured with dowels, gives the structure high rigidity and strength. The panels are adjusted to the dimensions of the sheathing cells and attached to the profile frame with screws or glue. The foam sheets must fit tightly together

It should be leveled and primed. Insulation sheets are installed from the inside onto a special sheathing (wooden, aluminum, plastic), so the ceiling height will be slightly reduced. The profile, which is secured with dowels, gives the structure high rigidity and strength. The panels are adjusted to the dimensions of the sheathing cells and attached to the profile frame with screws or glue. The foam sheets should fit snugly against each other.

The thermal insulation sheathing is covered with plaster and decorative paint. You can use decorative plaster. Drywall is widely used. Lamps are freely mounted on the ceiling. The master will install thermal insulating ceiling panels from the inside without damaging the interior.

How to insulate a bathhouse with foam plastic

- Internal thermal insulation of the bath

- Bathroom floor insulation with foam plastic

- Wall insulation

- Thermal insulation of ceiling and roof

Unlike other buildings, the insulation of a bathhouse consists of stages that play their role. For example, if you can save a little money in order to insulate a house or apartment, then this option is not suitable for a bathhouse. After all, if thermal protection is incorrectly equipped, the structure simply will not fulfill its tasks, and the benefits of the bathhouse will decrease several times.

Bath insulation scheme.

Preparatory work for insulating the foundation with foam plastic

The soil around the foundation is removed to the freezing depth (preferably a little lower), the walls are cleaned and primed. You can buy a primer on the market, or make it yourself: you will need molten bitumen, to which you need to add the same amount of diesel fuel or gasoline. Apply the resulting mixture to the foundation and wait until it dries (about 1 hour). A layer of waterproofing must be applied to the primed foundation. This can be liquid rubber (applied with a brush) or rolled bitumen materials (fused using a torch). Then they begin installing the foam.

Internal thermal insulation of the bath

Insulation of the bathhouse must be carried out at the construction stage, since thermal protection in the bathhouse should be done in any significant place. After construction, it is simply impossible to gain access to some areas, as a result of which insulation should be considered at the development stage.

It is necessary to begin insulating a bath structure from the foundation, then comes the supporting structure, floor, wall surfaces, ceiling and roof.

Insulation diagram of a bathhouse inside.

Almost all work is performed indoors. The choice of materials for insulation is also important in this matter.

The insulation of the foundation of a bathhouse is practically no different from the insulation of the foundation of an ordinary building. The most important thing is that it does not contain a huge number of holes and cavities. Moreover, the base should not allow cold to pass through to the floor.

Basically, the foundation for a bathhouse is thermally insulated using materials that are moisture resistant, tolerate temperature changes well and cope well with biological pests. The most suitable option is foam insulation.

Why foam plastic? At the moment, plinths, blind areas, and foundations of various structures are insulated with polystyrene foam. As for the bathhouse, the installation of foam plastic is done according to certain rules.

After the concrete strips have hardened, waterproofing must be applied to their outer part, onto which foam plastic is attached, 5 to 10 cm thick. The products are glued in a checkerboard pattern, and then they are covered with a layer of plaster, warm or regular.

Bathroom floor insulation with foam plastic

Scheme for insulating a bathhouse floor with foam plastic.

If we talk about the internal thermal insulation of a bathhouse, then we should not forget about concrete floors. The structure is based on a foundation, followed by concrete floor slabs and a layer of waterproofing. Next comes insulation, reinforced with a screed using a reinforcing mesh, then comes the turn of tiles or other floor covering.

Briefly about insulation measures

Floor. In this case, a multi-layer “pie” is usually created, which includes polystyrene foam or other heat insulator. The insulating material is protected on all sides by various waterproofing coatings and filled with concrete. Any suitable floor covering is placed on top.

We recommend using tiles. Why? Firstly, it heats up literally in a matter of minutes. Secondly, it retains heat for a long time. The floor does not remain cold. The main thing is to insulate well.

Walls. Everything is simpler here. There is no need to do any concrete pouring. It is enough to mount the insulator correctly and protect it from moisture. At the end they put a finish, which often takes on part of the functions of containing heat. An excellent solution is wooden lining. Both for wood and brick buildings.

Remember, insulating a bathhouse is impossible without creating a vapor barrier layer. Click on photo to enlarge.

Ceiling. This part is usually covered with a special frame made of wood.

Insulation materials are placed in the gaps between the guide beams. Naturally, they are also reliably insulated from moisture.

Do not forget that water, no matter how high-quality the insulation is, significantly reduces its basic characteristics.

Roof. Everything is simple here and there is nothing special to talk about.

The roof structure and other areas of the roof are thermally insulated with almost any material that suits the taste preferences of the owner of the building.

Polystyrene foam or mineral wool are most often used.

Foundation. There are no specific requirements. The work is carried out using generally accepted technology. In fact, they are not much different from insulating the foundation of a residential building.

The foundation is a universal component of buildings. Insulation is aimed at protecting the lower rooms, if any, or the basement area.

How to insulate the floor in a bathhouse with foam plastic

Usually, full-size sheets of 60x150 cm are purchased for screeding or laying in a wooden frame. Before starting work, you need to do the following:

- Using a wire thermal cutter, the sheets are pre-cut into separate sections, grooves are cut out, and the edges are adjusted;

- Joists, skull blocks, and boards are treated with fire-retardant and antifungal solutions at least 24 hours beforehand, then impregnated with oil varnish. The rough concrete floor is simply primed with waterproofing.

After the impregnations have dried and the cut panels are ready, you can pre-cut the hydro- and vapor barrier into separate panels. This will simplify your work and reduce wasted time.

Laying polystyrene foam on a wooden floor

Technically, you just need to lay down the film and lay the foam in rows between the joists. But there is one difference.

For a bathhouse on a concrete foundation, waterproofing and foam are laid as in the diagram below.

Scheme for a bathhouse on a concrete strip foundation

In this situation, the waterproofing is laid under the foam, and the vapor barrier is placed on top of the insulation. This is done in order to protect the bathhouse from groundwater evaporation. Even if air vents are made, waterproofing is still needed.

Laying foam paths

It’s another matter if the bathhouse box is installed on stilts. In this case, the bottom layer is made of vapor barrier, then foam plastic, which is covered with waterproofing and a rough plank floor, along which all the moisture in the steam room or shower is collected.

Insulation of boxes on stilts

In this case, the insulation of the bathhouse floor completely copies the thermal insulation of the walls of the house.

How to properly lay polystyrene foam on the concrete floor of a bathhouse

Installing foam plastic thermal insulation on concrete is much simpler, although it requires a lot of effort. First of all, the subfloor is poured; it must be monolithic and rest on the ground through a thick polyethylene film and a layer of polystyrene foam. In this way it is possible to reduce heat loss into the foundation.

Next, waterproofing is applied to the rough screed; this can be mastic or even sheets of roofing felt laid on the floor of the bathhouse with overlapping edges. The next layer is foam plastic, 100 mm thick. The joints between the plates must be sealed so that the solution does not get into the seams.

Filling of insulation can only be done along the guide strips

Plastic chips are placed on the foam and a fiberglass mesh with reinforcement with a diameter of 3-5 mm is placed and beacons are glued. Next, a screed with a thickness of at least 4 cm is poured.

Installation on joists

Insulation of the floor in a bathhouse on screw piles (or for a wooden structure on any foundation) is most often carried out between joists or beams. Unlike the previous method, here you can choose insulation with less strength, since the material does not take the load from furniture and people.

Expanded polystyrene is mounted between wooden floor joists or between floor beams. The floor pie for a wooden bath in this case looks like this:

- subfloor boards (or plywood, DSP, OSB);

- waterproofing;

- insulation between load-bearing wooden beams;

- vapor barrier;

- clean floor.

The insulation is simply laid between the beams. There is no need to use glue or dowels. But it is necessary to fill the gaps between polystyrene and wood with sealant or polyurethane foam.

Proper insulation of the bathhouse will ensure a comfortable microclimate and extend the service life of the building. An increase in construction costs in this case leads to savings in operation.

Instructions on how to insulate a bathhouse with foam plastic

The Russian bath is a tradition of the entire nation as a whole. It not only serves as a place for washing the body, but is also used as a place where a person rests his soul and clears himself of various thoughts. Besides, visiting a bathhouse has a great effect on human health. In order to make visiting the bathhouse as comfortable as possible, it is necessary to carefully take care of the structure of the entire structure as a whole. Moreover, special attention must be paid to the stage of insulation and waterproofing. In this article we will talk about this type of insulation, such as polystyrene foam.

The photo shows an example of insulating a bathhouse with foam plastic.

Can I use foam?

If it was decided to insulate the bathhouse with polystyrene foam, then this type of insulation should be used when installing external insulation of the walls. Only in this particular case will this type of insulation work one hundred percent. But, it is worth considering the fact that this type of insulation almost completely loses its properties due to humidity. This influences the fact that the outer side of the building is insulated with polystyrene foam, although it is also often humid outside, therefore, you will need to take care of waterproofing the material.

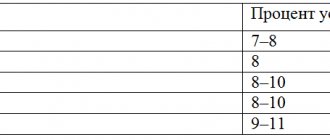

Polystyrene foam is available on the construction market in several versions:

Experts say that insulating a bathhouse with foam plastic is harmless, but only if the foam plastic is not used to insulate the steam room. When the material is exposed to high temperatures, it releases toxic substances that can have a negative impact on human health. Consequently, polystyrene foam can be used, but only as external insulation or for insulating the dressing room. Read an overview of the types of doors for wooden baths.

What to consider when buying insulation?

Having weighed all the pros and cons, it becomes clear that insulating a bathhouse with foam plastic is the best option. The amount of insulation you need to purchase will depend on several factors. Firstly, the climate zone: in a warmer climate, much less material will be required than in regions where the thermometer can drop to -20 degrees or below. The material of the walls is also an important factor: stone structures retain heat worse than wooden ones, which means they will require more insulation.

In addition to the material of the walls, the baths differ in type: in addition to the Russian “black” and “white” baths, there are the Finnish sauna, the German “Sanarium”, the Turkish “Hamam” and the Japanese “Ofuro”. Each of them has its own specifics, which must be taken into account when insulating a structure.

Regardless of the type of bathhouse, its geographical location and wall material, foam insulation must be purchased with a slight excess (10-15% of the calculated quantity), the same rule should be followed when purchasing materials for securing the insulation. This approach will allow you to avoid shortages of material in the event of defects or damage that occur during the execution of work.

After you insulate your steam room with polystyrene foam, you will be able to feel from your own experience how much the quality of the bathing procedure has improved, since it will be possible to heat the steam room to 100 degrees and higher much faster than before (the exact time depends on the area of the room). At the same time, much less fuel will be spent on kindling. Owners of bathhouses insulated with foam plastic can only wish for light steam!

So is it worth it to insulate with polystyrene foam?

And yet, there is an opinion among experts that all the disadvantages of polystyrene foam are more far-fetched than real.

The popularity of foam sheets among developers has no equal. And if we talk about insulation as a low-cost, simple and fast process, then it is hardly possible to find a better material.

Insulating the ceiling of a bathhouse with polystyrene foam can be done without any problems by a non-professional, a person who has taken up repair work for the first time.

However, when purchasing foam plastic boards, you need to be very careful not to bring a pile of small balls instead of whole sheets. Use products only from trusted manufacturers.

Insulation of a bathhouse made of foam blocks from the inside

As for the steam room, high-density foam blocks are often used to insulate it, because this type of material is less active than other insulation in this category and is more wear-resistant. In order to insulate the walls of a bathhouse with foam blocks from the inside, they should be laid between the wall panels, so that they fill most of the space inside; the distance from the beam to the material should be about 7-13 centimeters.

Attention! In any case, in order to do everything correctly, you will need to carefully waterproof all surfaces.

Useful tips

An insulated wooden floor of a bathhouse is good, but such structures have the unpleasant feature of accumulating water vapor in the underground. For foam plastic and wood, this means an increased risk of fungus and a significant deterioration in thermal insulation. Therefore, vents are installed separately from the foundation for the subfloor with foam plastic. The inlet and outlet windows are closed with pipes, the section of the first is led into the bathhouse dressing room, the outlet is led into the riser of the chimney pipe. It turns out that the stronger and more often the bathhouse is heated, the drier the floor and the better the thermal insulation of the room.