Wood is the most traditional material for a bathhouse. And if walls are made from it, then why shouldn’t doors be made from it? We agree that wooden doors for a bathhouse are a good choice, but we must make it clear: each room has its own characteristics, for which the type of wood, design and thickness of the door . Therefore, we will not lump everything together, but will analyze each case separately.

Design requirements

Like any other, a bath door serves as a barrier, protecting the interior space and helping to maintain the microclimate. But, unlike a standard door, a door for a bath (or sauna) has the following properties:

- Improved tightness. The design must reliably retain internal heat and protect from external low temperatures and drafts. Thermal insulation is ensured by a layer of properly selected insulation and a tight fit.

- Moisture resistance. High humidity is a suitable environment for mold to grow, and it is important for the door structure not to become an attractive place for uninvited guests.

- Increased heat resistance. The bathhouse is characterized by regular temperature fluctuations, which should not cause damage to the structure.

- Requirements for safety and service life. The door must withstand intensive use, be resistant to random mechanical loads, and meet fire safety requirements. All together will ensure a long service life.

Design with reinforced fabric Source aviarydecor.com

Accessories

For interior spaces, it is worth choosing doors with 3 canopies that can withstand at least 30 kg. Fulfillment of these conditions is especially important for glass doors, the leaf of which has considerable weight - with a thickness of 7 mm it can weigh up to 25 kg. Canopies should be easy to replace when necessary. The hinges are made of stainless steel or other material that is resistant to corrosion in conditions of high temperature and high humidity.

For safety reasons, the latch should open easily. It can be ball or magnetic from 3-4 elements. The second option is preferable since the ball latch may jam.

Another safety requirement is that the handle on the inside of the steam room door must be made of wood, regardless of whether it is glass or wood. If it is mounted on glass, a silicone gasket is installed between the surfaces for greater reliability of fastening.

Handles for bath doors should be comfortable and located at a suitable height.

Types of door leaves

Wooden doors have long been installed in bathhouses; they were traditional both at the entrance and in the steam room. This was a justified decision, because they fully met all the requirements. In modern buildings, they sometimes favor plastic or metal (for the entrance); glass models have been developed for steam rooms.

Entrance door (from the street)

The design of the entrance door to the bathhouse is determined by the heating method. If the sauna is heated “white”, choose a single-leaf panel with the following characteristics:

- To minimize heat loss, install a narrow, low door. The height does not exceed 1.6-1.7 m, the width is within 0.6-0.7 m.

- It is advisable that there is a threshold 0.1-0.15 m high at the entrance. It will protect against drafts and help retain heat.

- For proper design, not only insulation and the presence of a reliable lock are important. Fire safety rules stipulate easy movement of the canvas.

If the sauna is heated “black”, it is preferable to have a double leaf with a horizontal arrangement of the sashes. Such a device is more secure; you can open the top flap to let out the smoke.

Entrance wooden door with decorative elements Source pinimg.com

The main requirement for an entrance door is the ability to retain internal heat efficiently; the material itself fades into the background. The box, regardless of the material used, is necessarily massive, holding the geometry from deformation. The canvas is made from the following materials:

- From the array. The most popular, classic option. The easiest way to make it is to use tongue-and-groove floor boards. The lumber is treated with protective impregnations (antiseptic, fire retardant), and a layer of moisture-resistant thermal insulation is provided.

- Made of metal. A metal structure (usually a sheet of metal) is less problematic than a wooden one: it does not rot under the influence of moisture, is not subject to deformation, and is resistant to mechanical stress. Reinforced with an additional heat-insulating layer, it prevents heat from dissipating into space.

A good option is a solid solid door Source par-torg.com

- Made of plastic. A plastic door to a bathhouse is an ideal candidate for decorating an entrance area. Plastic does not react in any way to humidity and temperature fluctuations, it is resistant to deformation, and thanks to the thermal insulation layer, it retains heat no worse than its wooden counterpart. The plastic sheet successfully imitates the texture of wood, so there will be no dissonance with the appearance of the building.

- Panel design. Budget options are made in the form of a frame structure. The upper and lower beams are responsible for rigidity, the transverse beam serves for reinforcement. The shield is made of boards knocked down in one layer, MDF or chipboard. Wooden parts are treated with protective impregnations; insulation is often absent.

It’s easy to make a non-insulated model with your own hands Source na-dache.pro

- Frame design. The frames are made and thin timber is assembled with screws. In the simplest version, the covering is hardboard (moisture resistant is chosen). A layer of heat-insulating material is laid between the frames.

- Combined model. Sometimes owners want to have additional lighting in the dressing room. A structure consisting of a wooden frame complemented by a canvas with tempered glass inserts will help solve the problem.

Double-leaf structure in a log bath Source par-torg.com

To the steam room

The door to the steam room performs an important task: it retains heat and steam inside the room. Therefore, it is expected to be particularly tight and meet the following requirements:

- A design and material that is resistant to deformation in extremely humid and hot air is selected.

- In a traditional Russian bathhouse, the entrance to the steam room is low and narrow. Therefore, the canvas rarely exceeds 1.7 m in height and 0.75 m in width. A threshold of up to 0.2 m in height will not be superfluous.

- If no other ventilation is provided in the steam room, a gap (at least 5 cm) is left at the bottom of the sheet for forced air exchange.

- A gap must be left in the sauna, regardless of other ventilation methods. The gap above the floor helps the steam to be distributed evenly.

- In a room with high temperatures, the door should not cause burns or injury. It should also open outward so that the visitor can use it without thinking.

Canvas with decorative trim made from lining Source dveri365.house

- Products made of wood, glass or combinations of wood and glazing meet the requirements. Products made from chipboard and MDF, which are not suitable for extreme conditions, are not recommended for the steam room. The metal sheet does not meet safety standards.

See also: Catalog of companies that specialize in the design and construction of baths of any complexity

To the washroom

If the plan includes a washing room, you need to choose the right door for it. The conditions in the washing room are milder than in the steam room: the humidity remains high, but the temperature changes are smaller. For a washing room, choose a door made of hygienic materials that are indifferent to the constant exposure to water and household chemicals. A model made of frosted glass or plastic would be an appropriate option.

In interior spaces, they are limited to products made of wood, glass or plastic. A budget option would be a frame structure made of boards with a layer of insulation inside, complemented by lining made of clapboard.

Entrance to the washing room through a wooden door Source pechiexpert.ru

Combined type windows

The combined type of windows involves the use of several materials in different combinations, in particular:

- wood with plastic;

- wood and aluminum;

- plastic with aluminum;

- aluminum with wood and plastic.

The combination of several materials can improve the thermal insulation properties of windows. And most often the first two combinations of materials are used.

You can combine materials in windows in this way:

- The inside of the frame is lined with wooden planks, and the partitions and the entire frame are made of plastic. Such windows appear to be made of wood from the inside. For protection and additional decoration, the wood is coated with several layers of varnish.

- The entire frame is made from laminated veneer lumber, and aluminum or plastic strips are placed on the outside using clamps to allow the wood to “breathe.”

- First, two independent frames are made - the inner one is made of wood, and the outer one is made of plastic or metal. Along the perimeter, the frames are connected to each other with special brackets, and the glazing is done with ordinary glass, and not with bags. If desired, any of the frames can be removed.

Subtleties of choice: wood and other materials

When solving the problem of how to make a door to a bathhouse, you first need to decide on the material. If you are attracted to a high level of thermal insulation combined with environmental friendliness, easy maintenance and a stylish appearance, then most likely you will choose a wooden structure.

Wood is a natural material that is sensitive to temperature fluctuations and can absorb moisture. But these properties manifest themselves differently in different breeds, which allows you to choose the most suitable material. The following breeds will perform optimally:

- Oak. Oak canvas is not afraid of moisture, it lasts a long time and does not cause problems in maintenance. The downside is the high cost of wood and its tendency to crack when exposed to high temperatures.

- Larch. Wood is known for its special resistance to moisture and antiseptic effect. It does not rot and extremely rarely becomes a haven for wood-boring beetles.

- Pine. Budget-friendly, durable and resistant to any impact material. Plus - a pleasant pine smell, minus (not critical) - the resin melts out of the resin pockets under the influence of high temperatures.

Types of wood suitable for baths Source vasha-banya.com

- Spruce. Good wood, but capable of deformation and absorbs moisture well. Therefore, you should not choose it for the door to the steam room, and in other cases you will need to thoroughly dry the surface after bath procedures.

- Aspen. The wood is soft, easy to process, does not deform or crack when dry. The material is relatively light and wear-resistant.

- Linden. A fairly stable species, the linden canvas does not swell with intensive use. But under the influence of humidity it darkens, despite treatment with antiseptics or wax.

Glass

A glass door is a modern sign of a sauna or hammam; in a Russian bath it can be placed in the steam room and washing room. Glass is chosen for some interior solutions when a steam room needs passive lighting.

Glass products have many advantages. They are resistant to the action of moist hot steam, aesthetically pleasing and easy to use, and do not emit toxic substances when heated.

A big plus for a steam room or sauna is that the glass product does not change its geometry. Over time, you can update the fittings, and the door will return to its original appearance.

Glass sheet is more common in saunas Source baniexpert.ru

However, a glass door is not easy to make on your own; It’s easier to purchase as a kit and install using fittings. For its manufacture, special tempered glass is used, and this raw material has a very high cost, as do the components. There is a construction nuance in the form of a technical gap under the canvas. A gap 3 cm high can result in unpleasant drafts.

Decor

Decorating bath doors is an important point in the design of a building. After all, not all decorative methods are suitable for rooms with high humidity. For example, wallpaper or vinyl stickers would be inappropriate here, because after a short period of time they will simply peel off.

Iron and glass structures do not need additional decoration, as they themselves look very aesthetically pleasing. And it’s difficult to decorate metal or glass without special equipment.

It is possible to make carved canvas at home. Two methods can be used for this: overhead and on the surface of the tree itself.

The applied method uses carved elements that are attached to the canvas using glue. This method is good because it does not require removing the product from its loops, and the patterns themselves can be purchased ready-made.

Carving a door leaf is a complex and painstaking job. You can use blind and slotted threads. Carved doors, as a rule, are installed at the entrance of a building to add a luxurious and solid appearance to it.

Antique structures will look very organic in a bath structure. This design will create a rustic atmosphere of past centuries, which will allow city visitors to feel like real villagers. You can age wood yourself. This may require staining or brushing technology.

Often, owners of a sauna building think about whether it is necessary to paint wooden door panels, because inside the building there is constant high humidity, which can damage the paint. Designers advise painting wood with a paint and varnish that can withstand any external influences.

Installation technology for a simple wooden door (without insulation)

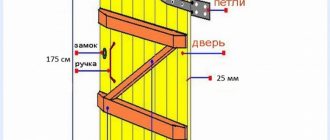

In terms of design, the best option would be a single-leaf continuous leaf. For proper installation, a drawing with prescribed dimensions is drawn up, taking into account the following points:

- Made from suitable wood, the leaf should open outwards and, when closed, fit snugly against the door frame.

- Modern heating equipment is replacing the conventional metal heater. Such devices require a constant flow of air, which may affect the design of the opening (you may have to abandon the threshold and leave a gap).

- There are some restrictions that must be taken into account when drawing up a drawing. For example, the distance between the ceiling and the box should not be less than 40 cm.

Before making a door for a bathhouse, prepare tools and materials. For this work you will need a saw (or hacksaw), a screwdriver, a level, and a plane. To cut grooves and process edges, you need a router (hand-held woodworking power tool). It is convenient to take measurements using a tape measure and pencil.

Markings for a door without a threshold Source aviarydecor.com

It is also necessary to prepare screws for wood and wood glue; at the final stage you will need a set of hinges, a latch, and handles. The minimum set of materials is as follows:

- For tight. Tongue-and-groove board (with tongue-and-groove fastening), length 2.1 m, width 0.2 m. The number of boards depends on the width of the future door.

- For strapping. Beam 3x3 cm.

- To strengthen the fabric. Beam section 3x2 cm.

- For the box. Beam 11x6 cm.

Self-production

We will do this option:

The task of making a wooden bathhouse door with your own hands is quite realistic, you just need a certain tool . Below is a list that gives a simple/mechanized attachment:

- saw / jigsaw;

- planer/thicknesser;

- screwdriver/screwdriver;

- quarter plane/milling machine attachment;

- sandpaper/belt sander;

- chisel or chisel;

- hammer;

- roulette;

- level;

- square;

- pencil.

If you prefer ready-made tongue and groove floor boards , then some tools will not be needed. Otherwise, you need to adjust the geometry of the boards to one standard, and then cut quarters on both sides in a mirror-like symmetrical manner:

An alternative to laying boards overlapping can be a tongue-and-groove connection (otherwise known as tongue-and-groove), but this requires a milling machine (or a finished board with tongue and groove).

The quarters are cut either with a plane (with the mentioned attachment) or with a milling machine.

Finished boards can be glued together with PVA. To compress the joints, a wedge or its equivalent is used: a frame or two stops, between which our canvas is wedged. After 12 hours the canvas is ready.

The resulting shield still needs to be secured with wedges . To do this, you need a beam, which is given a trapezoidal shape in profile, and which slightly narrows from one edge to the other. The length of the beam is 20-30 cm greater than the width of the door. There should be two such wedges.

A dovetail groove is cut under each wedge on the door . You can do this with a router and then select it with a chisel. If the wedge is not trapezoidal in profile, then the groove may not be widened. Then you can cut it with a jigsaw.

The wedges are driven into the grooves, after which a through hole is drilled at the beginning and end of the wedge for a wooden dowel - 4 dowels in total. They are hammered and trimmed. The wedges are also cut to the width of the door.

It is customary to install an oblique spacer (brace) between the wedges, which is necessary so that the door does not subsequently become deformed.

Finally, the canvas is sanded.

All that remains is to make a door frame and hang the panel on hinges or awnings. The easiest way to make a box is from ready-made box timber , where a quarter has already been selected. Or from ordinary timber, but you will have to cut a quarter yourself.

The box for connecting the planks is either edged at 45 degrees, or a tongue-and-groove design is made, or, in the most primitive case, it is simply attached end-to-end with self-tapping screws. (The ends at 45 degrees are fastened obliquely)

IMPORTANT! The sauna uses self-tapping screws only with anti-corrosion coating.

When choosing hinges, take stainless ones , preferably brass . Suitable designs include overhead and mortise. For more information about hinges, see the article about door fittings.

Useful video

Video instructions for making a traditional door:

Video description

About installing the frame and glass door in the steam room in the following video:

Canvas

The boards are laid on a flat surface and cut to size; in this case, the tenon is immediately cut off from the end board so that the end is even. The boards are joined into a single sheet (it is reinforced with PVA glue), left for two to three days to dry, and then sanded with a plane.

Four blanks are cut from the strapping beam (based on the size of the door). They are assembled into a single structure using wood glue, dried and fastened with self-tapping screws to the end parts of the door. Then the structure is reinforced with beams (they act as stiffeners). If the door is assembled for entry from the street, the reinforcement is placed outside; if it is intended for a steam room, then it is made from the side of the room.

Self-tapping screws are used to secure the hinges Source simplemost.com

At the final stage, the box is installed in the doorway, and the places for the hinges are marked. Then the door leaf is installed. Hinges are first hung on it, handles and a latch are installed.

After installing the door, the door leaf and jambs are finished. To protect wood, antiseptic compounds or paste-like oil-wax of deep penetration are used. Paint is not used in the bathhouse.

Chemical-free impregnations are chosen for processing Source goconqr.com

Useful tips

The very first piece of advice from experienced craftsmen is not to take on too complex projects or door designs. If you don’t have confidence in your abilities or lack experience, it is better to choose a simpler and more reliable door design option.

You cannot work with unprepared material. This applies to wood. Fresh pine can dry out and reduce the transverse size by 10%. This means that gaps up to 1 cm wide may appear in the door, which is unacceptable. It is necessary to properly dry and condition the boards.

During work, safety precautions should be observed. Power tools are dangerous, especially when working with wood. It is necessary to use personal protective equipment, glasses, and sleeves should not hang down. Gloves should not be used, especially when performing machine work (for example, when cutting wood on a circular saw). Hands can slip, which often leads to injury.

It is necessary to work with a sharp, well-threaded tool. High quality processing cannot be achieved using unprepared equipment. It is recommended to have sandpaper on hand so that you can sharpen the cutting edges at any time.

Briefly about the main thing

The bathhouse is a specific place with sharply changing microclimate conditions, therefore special requirements are imposed on the characteristics of the premises and doors. The minimum design of a bathhouse includes two doors - the entrance door and the one to the steam room. Despite their close location, they are used in different conditions and cannot be manufactured in the same way.

The best materials are considered to be wood, glass, and plastic; metal is only suitable for entrance from the street. The door leaf must close tightly, resist moisture, and have an aesthetic appearance. The simplest version of a door is made from tongue-and-groove boards and timber.

Ratings 0

We insert a door made of impact-resistant fireproof glass into the bathhouse

Glass doors are quite specific, so making them yourself is very difficult, since this requires certain skills. Therefore, they will have to be ordered from the workshop. But you can install them yourself.

Glass selection

There are several types of glass doors. Modern convenient pendulum designs can open in two directions. Usually a magnetic closer is installed on such a door, which helps the structure close more smoothly.

Fireproof glass doors in the steam room

Traditional swing doors open only in a certain direction, and installation is carried out in a wooden frame using durable hinges.

The canopies are made only of stainless, anti-corrosion metal, and the handles (brackets, coupes or knobs) and the box are made of non-coniferous wood.

Stainless steel hinges for glass door

The thickness of impact-resistant glass should not be less than 7–8 mm, since the temperature in the steam room is quite high, which the glass sheet must withstand.

If necessary, the transparent canvas can be made matte using a special sandblasting machine. In a specialized workshop such work will be carried out in the shortest possible time.

Frosted glass doors with a pattern

Glass doors must be installed only before the walls are finished, and the tighter they fit to the frame, the less heat loss there will be in the steam room.

When choosing a glass sheet, it is necessary to take into account the future conditions of its operation. Fireproof impact-resistant glass can be of three categories: A1, A2 and A3.

The best option would be doors measuring 1900x700 mm, category A3. They can withstand an impact of 3382 kgf/m and a fall of a human body from a height of about 10 meters. Such characteristics are achieved thanks to a special hardening process, in which the glass mass is softened, changing the state of the crystal lattice. During its subsequent cooling, residual stress is formed on the surface of the glass, which increases the heat resistance and mechanical strength of the product.

Material calculation

To install a glass door, you must prepare all the necessary materials.

- Cloth made of impact-resistant fire-resistant glass.

- Linden timber - 42x80 mm.

- Stainless steel hinges.

- Wooden fittings.

- Closer.

- Silicone seals.

- Platbands.

- Fasteners.

- Thermal insulating and water-repellent material.

- Impregnation for wooden elements.

Step-by-step instructions for making a glass door

- We assemble a wooden box without a threshold, so that there is a gap of about 5–7 mm between the floor and the canvas. This is necessary so that the door can move easily.

- We install the door frame, observing the exact geometry so that the glass sheet can fit into it accurately. We level it and fasten it to the wall with special anchors. In order to subsequently align the box, its dimensions should be slightly smaller than the door opening.

- We fill all the gaps with foam, and when it dries, we cut off any excess with a knife.

- We place silicone insulation in the grooves of the box.

- We mount metal hinges on the glass sheet in holes specially made for this purpose. We place silicone gaskets under the hinges.

- We expose the canvas and screw the hinges to the jamb.

- Then we attach the handles with silicone gaskets to the holes provided by the manufacturer.

- We close all the gaps between the opening and the frame with platbands.

- We treat the box with special impregnations, and then cover it with waterproof varnish.