The bathhouse is an integral part of the Russian tradition of healing the body and spirit, an unchangeable building on a country site that many people want to own.

The issue of decorating the main structural element is discussed at the design stage. The lining of a sauna stove plays not only an aesthetic role, but also a protective one. Often, bathhouse owners don’t bother and use simple plaster, which cracks over time, and the cracks are covered up from time to time.

The modern market is pleased with the abundance of various materials for lining a bathhouse stove, which are endowed with excellent performance characteristics. The most popular among them are: metal, wood, brick, tile, stone.

Why cover with brick material?

Any work must be done thoughtfully, and before execution it is necessary to understand the reasons. The designs are easy to install, heat up quickly and are accessible to everyone due to their low price, but they have a lot of disadvantages.

In addition to the high heating rate, the surface is a source of infrared radiation, which is unpleasant for humans and burns the skin at a considerable distance.

Steel heaters dry out the air, which prevents the creation of the correct conditions in the bathhouse necessary for a comfortable procedure. When heating quickly, such a stove instantly gives off heat and has to be heated regularly, which increases the consumption of firewood and creates a lot of inconvenience.

Brickwork acts as a protective screen, allowing you to retain heat for a long time and rid you of infrared rays. Covering a sauna stove with bricks is inexpensive.

What else to consider when filling the heater

To get the maximum benefit and pleasure from bath procedures, just knowing the rules for laying stones is not enough. It is also advisable to understand their impact on health, be able to determine the required loading volume, and clean and replace them in a timely manner.

How much stone do you need?

When buying a ready-made factory furnace, they focus on the characteristics declared by the manufacturer and select equipment of the required power. As a rule, the volume of the heater in such stoves is sufficient to warm up and maintain the temperature in the steam room, the size of which the stove is selected for.

When installing a homemade brick or metal heater, the required number of stones is calculated based on the volume of the room. It is believed that for every cubic meter there should be about 40-50 kg.

Calculations for choosing a base

For the correct distribution of parameters, knowledge of the basic parameters is necessary:

- dimensions of the furnace and its weight;

- weight of stones in the heater;

- the mass of the container for heating the liquid and the volume of water (further calculations are based on the condition that a liter weighs 1 kilogram);

- the weight of the brick wall (depends on the type of stone, but standard fire brick = 4 kg).

When all the information is received, the specialist can easily carry out the necessary calculations. He will need to add up the weight of the stove, stones, brickwork, container and liquid. 20% is added to this amount to create an additional safety margin. It should be remembered that pressure is applied constantly, and if the boards do not meet the required characteristics, then sooner or later they will be pressed through.

If the resulting number does not exceed 600 kilograms, you can line a metal stove in a bathhouse with bricks without manipulating the foundation. For detailed calculations, you can use the information below.

Bath stones - theory, experience of the portal’s craftsmen

Despite the presence of a bathtub or shower, baths do not lose popularity and remain an attribute of country life. The effectiveness of bath procedures largely depends not only on the design of the room and the parameters of the stove equipment, but also on the “quality” of the steam. Therefore, for those who like to take a steam bath, the issue of filling for the heater is important, and FORUMHOUSE has specialists who can help you choose the “right” stones for the sauna.

Introduction

Bath stones are both a heat accumulator and a steam generator; they accumulate heat through direct or indirect contact with fire and transfer it to the steam room, which allows you to warm up the room faster and maintain the operating temperature longer.

To maintain optimal humidity, water is supplied to the stones, which is instantly converted into steam.

The stones can be located outside the firebox, in an open (lattice basket) or box closed on three sides, or they can be located inside the stove. There are also combined options - an internal, closed heater, with a water supply and steam outlet, and an external one, where the stone mass is loaded. The number of stones varies depending on the design and power of the stove; it can be a couple of tens of kilograms, or maybe a hundred.

The stone backfill must meet several requirements:

- increased heat resistance;

- high heat capacity;

- safety.

For many, the aesthetic side is also important, so that the stones look beautiful; for others, it is more important to get the “tasty” steam generated by special rocks, but at a minimum, the stones must withstand strong heat and retain heat for as long as possible. As for safety: the backfill should not be radioactive and should not release harmful substances or tiny particles, and should not “explode”, flying into fragments. And this is possible if you fill in rock that, in principle, is not designed for strong heating. There is a lot of information on the Internet and on various specialized resources, as well as in booklets distributed by trading companies, but it is often contradictory.

To make it easier for everyone interested in the task of choosing stones for backfilling, one of the portal participants opened the corresponding thread, but it currently contains 104 pages, and not everyone has time for painstaking study. Below we will outline the main recommendations of the topic starter and other specialists who became involved during the development of the topic.

Workshop from jadestone

Jadestone is a petrologist by training (study of rocks), and has been successfully working in the field of supplying stones for sauna stoves for many years; He has enough experience to give advice.

jadestoneFORUMHOUSE user

I already had experience communicating in this format, and I realized that competent information on this topic is quite in demand. For this reason, I decided to create a specialized topic here and, as far as possible, answer in an accessible form some common questions regarding stones for baths and saunas.

Due to their characteristics, two types of rocks are suitable for heaters - metamorphic and igneous, as meeting the requirements, although igneous rocks are more often used. Specifically: olivine, diabase, gabbro-diabase, gabbro, quartzite, dunite, peridotite, pyroxenite, jadeite, jade, basalt, basaltic porphyrite.

As for soapstone, the controversy over its use does not subside; some are completely satisfied with it, others are categorically against its use in heaters. The mineral composition of the stone is predominantly talc and chlorite in various proportions, which determines its characteristics. The main property of talc is to transform into a powdery state under mechanical influence; fluctuations caused by heating and cooling apply precisely to this.

Therefore, a characteristic “dusty” coating will form on the surface of the stones in the backfill, which, when vaporized, will be spread throughout the room. Chlorite, on the other hand, has a scaly structure, and under heater conditions, tiny particles of stone, reminiscent of mica, will be released into the air along with talc.

In addition, when heated, soapstone gradually becomes porous and brittle, which significantly reduces the service life of the backfill. But at the same time, the stone has good vaporization.

jadestone

The highest quality steam and soft heat is provided by soapstone with a high content of talc and a low content of chlorite, naturally, and there is less suspended matter from such a stone.

However, stones of this quality are rarely found on sale; they are mainly used for lining stoves, and waste and substandard materials are used under the guise of bath stones. Therefore, if you are not confident in the supplier, you should not take risks; recommendations to pre-rinse and calcine the stowage will not bring significant improvements.

But soapstone's brother, soapstone, is excellent for backfilling; instead of chlorite, it contains fireproof magnesite, which can withstand the highest temperatures without destruction. But even here there are some drawbacks - this is a rather rare breed, both in nature and in selling companies.

When the most important criterion when choosing is not the price of the issue, experts recommend jadeite, a stone with an optimal combination of physical characteristics and decorative properties. It is a refractory stone (but not intended for direct contact with fire) with a high heat capacity, which, due to its composition and structure, is capable of generating special steam. We are not talking about a comprehensive cure for all ailments, as marketers promise, but a certain effect is actually observed.

jadestone

Jadeite has a property that we can speak about with confidence, based not on speculation, but on the sensations of different people who steamed at different times and in different places. Jadeite has a clearly expressed tonic effect. A person who has experienced this effect on himself will never exchange jadeite for any other stone, if finances allow him.

And Topicstarter is not alone in this opinion.

NickB FORUMHOUSE user

Until I tried jadeite myself, I also thought that there wasn’t much difference, and what was the point of buying stones at an exorbitant price. Then I tried it and realized that the difference was significant. Jadeite produces a different vapor; it cannot be compared with gabbro, stainless steel or cast iron. I don’t know how to explain it, but it’s not a matter of self-hypnosis; there are some physical and chemical roots to this phenomenon. But whether it makes sense to pay as much for filling the heater as the heater itself costs, everyone decides for themselves.

Some portal users, for whom cost is still important, were interested in whether it makes sense to combine backfill, for example, 40 kg of diabase and 20 kg of jadeite on top. Or it is a waste and will make no difference compared to backfilling entirely with diabase.

Just a passerby FORUMHOUSE user

It will be, and it will be very large, the diabase will have cooled down by the morning, and the jadeite will be hot - you won’t be able to hold it with your hand. And when you steam, the steam is different, especially noticeable in the first days when you change the stone, the price is justified. The stone, one might say, is eternal, but there are differences between jadeite and jadeite; if the crystals are not shiny, it is not worth spending money on.

If you don’t have the finances for even part of the jadeite, gabbro or the like is quite suitable, although it has a shorter service life and will require periodic renewal of the stone mass.

jadestone

Gabbro is a very good option for a bath! Both from the point of view of physical properties and from aesthetics. It is a pity that there is significantly less of this breed on sale than the same gabbro-diabase. Personally, I would prefer gabbro, especially when it is possible to regularly replenish the backfill.

Regardless of the type of rock, the fraction and location of the stones is important; jadestone advises filling the main volume with medium and small stones, mixed with a small number of large ones to increase the density of the backfill.

The largest stones are placed in the water supply zone - they heat up more strongly and do not cool down as much after steam is generated, therefore, they are able to generate heat for a long time, even if the stove is no longer placed.

More details about choosing the optimal rock for backfill can be found in the topic on the forum; it has been “living” for four years now and does not lose its relevance. About the common variety of open and combined heaters, see the article “Cast Iron Alternative...”. The video is about the Russian steam room.

Calculation of dangerous load on floors (kg/m2)

To assess how much load your floor can support, the technician needs to know what kind of joists are used. In the table below you can see the capabilities of different types of joists to support weight in kilograms per square meter.

| Section (cm) | Beam length between supports | ||||||

| 2 m | 2.5 m | 3m | 3.5 m | 4 m | 5 m | 6 m | |

| 10×5 | 734 | 585 | 490 | 420 | 367 | 325 | 293 |

| 15×5 | 1650 | 1321 | 1101 | 942 | 827 | 733 | 665 |

| 20×5 | 2930 | 2347 | 1955 | 1675 | 1464 | 1303 | 1172 |

| 20×10 | 4867 | 4690 | 3910 | 3353 | 2933 | 2733 | 2607 |

| 20×20 | 11730 | 3987 | 7821 | 6705 | 5866 | 6215 | 4691 |

| Cylindrical shape 20 | 6912 | 5528 | 4608 | 3950 | 3456 | 3070 | 2765 |

| Cylinder. f. 22 | 9200 | 7360 | 6132 | 5256 | 4600 | 4090 | 3682 |

Let's sum it up

So, which brick is better for the stove? To build a high-quality stove, you need to choose the right brick. It should be:

- Full-bodied.

- High Quality.

- Refractory.

- Density grade 200 – 250.

- Possess high frost resistance.

- Comply with GOST.

One final piece of advice: always buy enough bricks to avoid a situation where there is not enough building materials. It is not recommended to purchase additional bricks later, since stones from different batches may differ in color and quality.

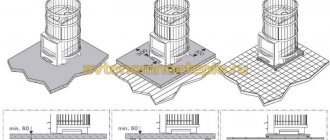

Construction on foundation

If a metal sauna stove lined with brick is not suitable for installation according to the table, then in this case it is necessary to make a foundation. This task is simplified if you have just started building a building with your own hands and you do not need to dismantle the stove and floors.

To build a foundation, a hole about half a meter deep is dug around the perimeter of the masonry and filled 3/5 with crushed stone or a mixture of gravel and sand. It must be taken into account that contact with the bathhouse foundation is unacceptable.

After laying the cushion, a cement screed and a layer of waterproofing are made, after which formwork is made, which is filled with concrete mortar. For such a product to harden properly, it must be regularly moistened with water to avoid cracks.

The next stage is the construction of brick pillars that serve as support. It is recommended to do the masonry using clay mortar. All work must be carried out taking into account the level, avoiding distortions.

When everything is ready, the metal product is installed and covered with brick.

Using plaster

Plastering is the most budget-friendly option for finishing a stove yourself. The product takes on a finished look and looks good in the interior. After plastering, you can whitewash it with a special heat-resistant compound.

This type of finishing is quite often used for brick ovens. The technology is as follows:

- It is necessary to properly prepare the surface. All traces of old finishing, incl. plaster and tiles must be removed. Each seam should be selected at 10-15 mm.

- We dilute the deep penetration primer according to the instructions. Carefully prime the surface. Do not forget that the primer must dry (at least 24 hours).

- We stretch and fix the metal mesh using dowels. Such reinforcement will significantly increase the strength of the tile fastening.

- Apply plaster to the stove. We recommend using a ready-made mixture specifically for ovens. The plaster must be allowed to dry for 48 hours.

- Now the stove needs to be whitewashed.

Floor base

If the weight of your structure does not exceed the established standards, you can place the stand directly on the surface. If the bathhouse is many years old, the technician will still have to open the floor and inspect the joists and boards for damage. You also need to remember that the brick base also has its own weight and will put pressure on the floorboards.

If the wood is not suitable for the job or is not in perfect condition, it is not necessary to replace it. It is possible to reinforce them with a metal channel or additional wooden beam. It is worth considering the distance between the beams. If they are located more than a meter apart, the specialist will need to install additional ones so that the clearance between them is about 600 mm.

To lay the base, floorboards are placed ten centimeters larger than the size of the structure with the lining. On the firebox side, it is necessary to increase this distance to avoid burning elements from hitting the wood. Then a sheet of refractory material is placed on the marked area, on which brickwork is made about 200 mm high.

It is recommended to use refractory bricks without hollow sections for these purposes. You need to use a clay mortar, to which you can add a little cement mixture. All actions must be performed using a level. After preparing the base, you can think about how to properly brick a stove in a bathhouse.

Tiles

A stove with tiles is a rather labor-intensive process. Technology has simplified things a bit. But until now, the construction of such a furnace takes 4-5 months, if you use the classic version. The laying and lining of the furnace occurs simultaneously. Although, in a simplified version, you can line a finished stove.

Expert opinion

Nikolay Davydov

Stove maker with 15 years of experience

The drawing can be anything. Usually Russian folk motifs are used. The sizes of tiles are regulated by GOST 3742-47. Permissible deviations should not exceed 1 mm in all directions. Thanks to standardization, the cladding process has been significantly simplified. The most important thing is to choose the right material.

Instructions

You should be guided by the following rules:

- Material of manufacture. Impurities in colored clay will not allow the production of high-quality tiles, so it is not used. In contrast, white clay is an ideal raw material.

- The quality of a product is determined by its ability to absorb water. The more pores in a tile and the larger they are, the less quality the product will be.

- Choose tiles made by pressing.

- The surface of the product should not have a dull appearance and there should be no cracks on it. This happens when a product undergoes only one firing.

For cladding, tiles must be sorted by shade. They will need to be laid in such a way that the transition is not noticeable. The size is adjusted using a rasp and an angle grinder on all sides. Defective tiles should not be thrown away immediately. They can be used later.

The next step is to mark. The thickness of the horizontal seam should not exceed 3 mm, vertical - 1 mm. Now let's move on to installation.

Lay out the first row.

The process is very labor-intensive, but the result is worth it. The first thing to do is to properly prepare the tiles for installation. This will ensure the best result.

The installation order is as follows:

- immerse the tiles in water, waiting until the clay absorbs water;

- the clay in the tiller will increase the heat capacity, so you need to fill it halfway;

- steel brackets allow you to correctly connect the tiles to each other;

- We connect a row of tiles to a row of the stove using wire.

Scheme for fastening the tiles: 1 – lump, 2 – pin, 3 – wire, 4 – staples.

Subsequent rows.

- drill holes in the masonry;

- We use screws and wire as a connecting element;

- We fasten the steel pins using wire;

- we place the tile on the pin and bend the last one;

- the dry solution will fill all the voids between the tiles.

Sauna stove in tiles

Construction process

If you plan to cover it with bricks on all sides, then it will be a full covering, if only some sides are partial. When completely surrounded, it is possible to control the movement of warm air masses. To do this, doors are made at the top and bottom of the screen to stop the movement of air when closed.

The model, completely covered with masonry, creates an ideal microclimate typical for a Russian bath. If at least one open wall remains, it will be more like a sauna, and the stone will protect you from burns and accumulate heat.

How often do stones need to be replaced?

The durability and heat resistance of each breed depends on its initial characteristics and on the mode of operation of the bath. Basalt has the longest service life - it can withstand up to a thousand heating and cooling cycles. There are breeds in which this figure is several times lower.

It is impossible to say exactly at what point the stone will become “dead” and lose its ability to retain heat. This becomes clear when changes occur in the operation of the steam room: it takes longer to heat up and cools down faster. In this case, the stones should be sorted and completely or partially replaced.

But it’s better not to wait until the last minute, but to regularly inspect the heater, unload stones, clean them of plaque and soot, remove broken and porous specimens - they are of little use.

Advice! You can extend the life of the stones and clean them less often if you make the bottom of the heater solid and add hot water to the steam.

Screen construction options

To determine the answer to how to line a metal sauna stove correctly and with what kind of brick, it is necessary to consider all existing classifications.

By distance:

- solid - interferes with circulation, which reduces the heating rate;

- randomly - the brick is placed with holes, this type reduces the quality of shielding;

- a screen with doors at the top and bottom is an ideal option with the ability to adjust convection.

By arrangement of bricks:

- in size - increases the heating time of stones and consumes a lot of raw materials during construction;

- half a brick - the most suitable option with a durable wall and rapid warm-up;

- in a quarter of a stone - has good heating characteristics, but the strength of the masonry is reduced.

It is worth noting that an overly unstable option can be corrected using reinforcement with a special network, but still, a thin-walled lining should not be erected without good preparation.

Steel case

Steel is also a fire-resistant material. It cannot be left untreated, as it will instantly rust in a bathhouse. When finishing the space around the stove with steel, you need to keep in mind that unlike brick, tiles and stone, steel does not insulate heat at all.

A protective portal around the stove made only of steel will be completely pointless, since it will not be able to fulfill its main task - to protect wooden walls from overheating. In order for this function to be fulfilled, it is necessary to provide a good heat-insulating layer of another material, and then cover it with a facing steel sheet.

This heat-insulating separation layer is created from mineralite. Other fire retardant insulation materials can also be used. Simple mineral wool is not suitable, since after getting wet once it shrinks in volume, and this defect cannot be corrected by anything.

The insulation near the stove should not get wet. You need to take care of its waterproofing. Moreover, this waterproofing should only be on the side of the cold wall, but not on the side of the stove.

Steel has a metallic luster. This effect can be used to greatly increase the efficiency of the portal.

If made from uncoated polished stainless steel, it will act as an infrared reflector.

A similar element can very often be seen in electric fireplaces, heating stoves and any other heating devices.

The main difficulty of this solution is the need to use only stainless steel. Compared to ordinary steel, it costs 10 times more, but the total thickness of the sheets for the reflective screen can be small.

Stainless steel perfectly withstands any humidity. It can even be placed in rooms such as a steam room in a bathhouse; the decoration around the stove will be compact and with a modern design. In a steam room, all interior elements are usually made only from wood. Stainless steel would be appropriate next to a metal stove-stove.

What kind of brick to cover a stove in a bathhouse

Before the main procedure, you must first prepare all the materials. On the modern market you will find a huge variety of bricks, varying in size, aesthetic qualities and properties.

The choice of brick must be made based on the distance from the metal to the screen being built. If it is less than 250 mm, then this will lead to strong heating of the masonry and therefore it is better to use fireclay.

The optimal is 500 mm. For such buildings, an ordinary fire-resistant red stone is perfect. If you plan to install vents from below, then this material can be used closer.

Facing brick

Kiln facing brick is a fairly heavy and expensive material. The masons who will do the façade masonry also have to pay a lot.

Before starting brick cladding, make sure that the stove has a solid reinforced foundation.

Brick cladding is perhaps the best option if it is possible to make a foundation. It's easy to do and the effect will be amazing. This is a reliable and durable design that will last for many years.

Characteristics of building materials

You can calculate the main indicators that a brick has for lining a metal or iron stove in a bathhouse using the following table:

| Options | Facing | Textured | Raised | Ceramic |

| Strength | M-250 | M-250 | M-250 | M-200 |

| Size, cm | 25×12×6,5 | 25×12×6,5 | 25×12×6,5 | 25×12×6,5 |

| Frost resistance | F35 | F35 | F35 | F75 |

| Moisture absorption,% | 8,5 | 8,5 | 8,5 | 6 |

| Weight, kg | 4 | 4 | 3,8÷4 | 4,1 |

| Thermal conductivity, W/(m×°C) | 0,61 | 0,61 | 0,61 | 0,72 |

Non-combustible wall coverings

The second option for protecting walls from fire is special sheathing, which is made from non-combustible materials. The working element of this protection, which reflects IR rays that are dangerous for flammable surfaces, is a reflective material, for example, stainless steel.

There are also decorative finishing options that preserve the aesthetic purity of your bath. One of the advantages of this method is that protecting the walls in the bathhouse from the stove will not only prevent fire, but also retain heat inside the room.

Choice of solution

The most common option for carrying out such work is clay. It is mixed with sand, adding a little cement. A cement mixture with the same clay ratio is also used. For the cementless option, make a clay mixture with twice the amount of sand, which is diluted with water to the desired consistency.

Fireclay powder is best used for refining seams, because it binds bricks less firmly.

A simpler option is to purchase a special mixture. It is inexpensive and easier to use. Thanks to a wide selection of similar products, you can easily select the optimal solution. It is worth noting that the diluted mixture must stand for some time before use so that the substances contained in it dissolve better and the solution takes on the necessary properties.

Possible difficulties

Fitting and cutting - in practice, these operations take too much time. Therefore, it is easier to calculate the length and height of the “front entrance” in order to use only whole bars, boards and other piece products.

The presence of a door at the firebox can make access difficult. If it is removable, it is better to dismantle it, carry out all the work calmly, and then install it again.

Vertical and horizontal deviations arise not only due to lack of experience, but also due to uneven floors or walls. So it is imperative to carry out constant level checks - it will help to avoid mistakes.

Fencing an iron stove in a bathhouse

Before starting construction, it is recommended to thoroughly wet the bricks with water for 12-13 hours. This will allow them to achieve the desired level of humidity. Otherwise, they will dehydrate the solution.

The quality of the mixture is checked as follows: it is applied to a new brick, and if it does not spill or crack, then the specialist has created the correct consistency.

Now you can begin the laying process itself. It is important to check each row for evenness using a level.

If you are interested in what to line a stove in a bathhouse with (except for brick), you can always find a replacement. There are special casings that are cut to suitable dimensions. They are made from different rocks, are easy to install, and you will definitely find the right option for yourself.

Step-by-step installation instructions

After calculations and design on paper, the specialized specialist begins the actual work:

- Mix the solution using cement and sand of medium or fine fraction.

- Lays bricks - sequentially, from the base, one level after another.

- Takes into account the ligation of seams when creating rows - they should go like a “ladder”, and not an even vertical line.

- Use jointing when the masonry of the portal for the sauna stove is completed to prevent surface roughness.

Afterwards, you can additionally decorate the “front entrance”, for example, with tiles, but this is not necessary, since if the work is done correctly, it already looks quite aesthetically pleasing.

Finishing

After setting, you need to make a lining so that the sauna stove, lined with brick, becomes a real decoration.

It is most convenient to remove excess solution using a drill with a special attachment. It is important to use personal protective equipment during the process. If after this procedure there are stains left on the brick, they can be removed with a brush dipped in a solution of laundry soap.

In order for the stone to retain its appearance for a long time, it is better to melt it slowly for the first time after lining, allowing the material to gradually warm up. Otherwise, the mortar may crack and the brick may lose its aesthetic qualities and properties.

Brickwork looks very beautiful regardless of the interior style. It does not require decorative finishing, and a huge selection of facing building materials will satisfy the most sophisticated tastes. All you need to do is keep it clean and protect it from damage.

Now you know how to cover an iron stove and boiler in a bathhouse with bricks. Regardless of the masonry method you choose and the materials used, you will immediately feel the pleasant comfort of the updated stove.

More about firebox rules

For your own safety, as well as for long-term, normal and problem-free operation of the heating unit and “gate”, adhere to the following recommendations:

- Splash water onto the stones carefully, without flooding them, in small portions - 50-100 ml, gradually reducing this volume.

- Use a fan to wet as much of the area as possible.

- Try to direct the liquid between the stones to obtain the hottest and dryest steam possible.

- Follow the sounds - when you hear the water hissing, you will understand that the temperature in the room is dropping.

- Pay attention to the color of the soaked stones - if they acquire a crimson glow, it means you are steaming correctly.