A brick bathhouse turns out to be solid, warm and durable.

But not everyone can create such a structure; the work requires a lot of effort, time and financial investment. Among all materials, brick is the best in terms of thermal conductivity, is reliable and does not pose a fire hazard, unlike a wooden frame.

Let's look at how to build brick walls in a bathhouse, what they are like, requirements for structures, and stages of work.

Wall requirements

The classic bathhouse is documented as a technical building. SNiP II-L.13-62 specifies all the requirements for this type of building. As for brick walls, they must meet the following requirements:

Build a brick bathhouse on a dry part of the site.

The material is hygroscopic and perfectly absorbs moisture, which will ultimately destroy it. To prevent this from happening, it is necessary to make high-quality waterproofing of the walls and build a bathhouse no closer than 30 meters to a pond or pool.- If the bathhouse is planned to be heated with wood, the distance of the walls to the neighboring building should not be closer than 15 meters. If the room is heated with gas or electricity, you can reduce the distance to 5-6 m.

There are 3 types of masonry load-bearing walls that have contact with the street:

- continuous masonry - two surfaces are mounted without gaps, close to each other;

- with a gap for ventilation (4-6 cm);

- with a gap for insulation - lightweight masonry.

For central Russia, the third option is often chosen, since brick does not retain heat well, and insulation is a necessary structural element.

A distance of 0.5 - 1 brick is left between the walls, the void is filled with insulation. A multi-row dressing system is used.

Internal

The walls inside the bathhouse are load-bearing and are laid with rough masonry.

Things to consider:

- The material is sensitive to steam; a vapor barrier on the internal walls of the steam room is required.

- The permitted horizontal deviation of the rows is no more than 10 mm.

- Vertical permissible deviation is +/– 15 mm.

- Deviation in laying corners is not allowed.

- The seams in adjacent rows of masonry should not coincide; an offset is created according to the selected ordering scheme. Otherwise, the structure will not have sufficient strength; the solution will not be able to support the weight of the walls, ceilings and roof.

- After the masonry is completed, it is forbidden to create openings and openings in it, otherwise the design will be disrupted and the weight of the bathhouse will not be distributed correctly.

- Openings for windows and doors are formed during the construction process.

Before starting masonry work, a concrete base for the walls is formed.

The rough masonry refers to the load-bearing part of the structure; it is placed around the perimeter of the future bathhouse. If the area exceeds 6 m2, then approximately another load-bearing wall should pass through the middle of the building, which will take on part of the load from the floors.Under it there is a part of the foundation (if it is strip) and a concrete base is formed.

- A layer of waterproofing is laid between the base of the wall and the first row of masonry. Roll materials are used (for example, roofing felt).

- Finishing and insulation must be present, since brick transmits heat well.

- Every 3-4 rows the walls are tied with reinforcing mesh, which preserves the strength of the structure.

- Internal surfaces are most often laid in 1 brick. The width is 25 cm.

- If the bathhouse is planned to have 2 floors, the thickness increases to 1.5 bricks.

- The difference in height between the walls of the first and second floors should not be more than 1.2 m.

- The thickness of the masonry joints is 10-12 mm.

- If it is known in advance where the partition will be located, flexible connections are installed in this place of the masonry or bricks are removed from the rows for subsequent connection of the walls. The distance between 4-5 rows.

The standard height of the wall is 2 m; it cannot be raised to the full height at once, otherwise the seams may come apart under the weight. Experienced builders recommend building 1 meter high walls in 1 day.

External

Cladding walls require care when working with seams to ensure a beautiful appearance of the building. The requirements for masonry are similar to the requirements for internal similar structures, but there are some differences:

- the standard width of external wall masonry for a bathhouse is 1\2 bricks (12 cm);

- vents are left in the surface so that the air circulates evenly and the moisture evaporates in time, otherwise the insulation may begin to rot or become moldy, vents are not vertical seams covered with mortar, they are assigned a place closer to the top of the wall, distributed at a distance every 1.5 -2 meters;

- The masonry is formed with jointing, i.e. with leveling the solution with a narrow spatula using a special technology;

- The brick is waterproofed, most often the injection method or impregnation is used, the seams are also covered with a waterproof mortar or paint.

Other parameters, such as the thickness of the seams, deviations, openings, adherence to order, are identical to the requirements for internal walls. In the process of creating lightweight masonry, the surfaces are connected to each other.

Near the stove

What you need to know:

The partition is laid in ¼ or ½ brick.- The wall is protected from overheating using materials such as porcelain stoneware, tiles, special protective screens, etc. The finishing is mounted on top of the brickwork; plaster is inappropriate here.

- A foundation will be required as the brick is heavy. If this point has not been thought out in advance, you need to disassemble the floor and create a base from scratch. With a solid concrete monolithic foundation, no special manipulations are needed. The foundation of the stove and the foundation of the wall are not connected.

- Be sure to maintain a distance of 20 cm from the wall to the stove.

- The minimum height of the partition is 20 cm above the stove, most often it is made up to the ceiling (a distance of 2 cm is left between the last row and the ceiling for shrinkage).

If the surface will not be covered with finishing, the partition is built with jointing. Reinforcement is done every 2-3 rows. The thickness of the joints and deviations are similar to the rest of the walls.

According to fire safety rules, the walls of a brick bathhouse cannot be located closer than 15 m from the forest, 1 m from the bushes. There are many more nuances regarding the location of a building within a garden plot.

They are regulated:

- SNiP 31-05-2003 (clause 6.3.9),

- SNiP 2.09.04-87 (clauses 2.34, 2.35, 2.36),

- SP 118.13330.2012,

- SP 53.13330.2011,

- SP 54.13330.2016,

- SP 55.13330.2016.

The layout and projects are based on SP 11.106-97, 4.13130, 60.13130.

Wooden cladding, installation of beacons

A brick bathhouse must be lined with wood from the inside. This layer performs an insulating and aesthetic function. The best way to finish a brick bath is to cover it with wooden boards, clapboard, block house or imitation timber.

If the cladding is thin, for example lining, then only moisture-resistant species are suitable, for example: aspen, linden and larch. Pine lining is not suitable for a steam room. Insulation is placed between the wooden layer and the brick.

Regardless of the type of lumber used for cladding, beacons are placed vertically. They play the role of a connecting unit between the brick and the wooden cladding board. A lighthouse is a wooden block that is attached to a brick wall, and sheathing boards are nailed to its outer side.

The lighthouse is attached to the brick using dowels and angles. In combination with the dowel, you can use various specialized fasteners. It is convenient to purchase it as a set. Calculate based on the number of beacons. On average, they are located every 0.5 m of walls.

The cross-section of the lighthouse bar is usually chosen equal to the thickness of the insulating layer.

The outer edge should be no narrower than 3 cm. Then it will be convenient to attach the sheathing to it.

In addition to its direct function, the beacon is a guide for attaching boards. It must be installed strictly plumb. This guarantees a neat appearance of the cladding.

What kind of brick is used?

For a bathhouse, only standard red brick is used; silicate brick will not withstand temperature changes. The varieties depend on the type of walls where the material is used.

Suitable for rough masonry of internal walls

- Solid brick, being the densest, is recommended to be laid in the lower part of the wall, where the maximum weight load is.

- Hollow for masonry higher, at the level of human height and under the ceiling, as it retains heat better.

- Strength grade from M150.

- The frost resistance indicator is F50, since the bathhouse warms up from time to time and in winter it is not heated.

- The size most often used is single.

It is recommended to take material for roughing and facing masonry of the same size so that the connection of the rows is uniform and convenient.

For cladding external walls use:

Moisture-resistant brick, for example clinker. It does not allow moisture to pass through and has good thermal insulation properties. In addition, it looks great, neat, smooth and almost unbreakable.- As a more budget option, use regular red ceramic facing bricks.

- For a beautiful façade that attracts attention, use hyper-pressed brick. It replicates the texture of natural stone, comes in different colors, and you can use it to create a pattern. It is stronger than analogues and tolerates frost well.

- Strength grade preferably from M 200.

- Frost resistance from F50 and above.

- Hollow brick structure retains heat inside better. But since the bathhouse is unlikely to warm up to the outer walls, you can use a solid one, it is stronger.

For the part of the bathhouse near the stove , choose:

- Solid or hollow ceramic brick. The first option transmits heat worse.

- Facing brick. Can be used as a beautiful, moisture-resistant, but expensive option.

- Brand from M100.

- Frost resistance from F50.

Peculiarities

Each bathhouse consists of at least 3 rooms:

- vestibule;

- steam room;

- washing;

Each of them has special requirements: it is forbidden to use a slippery floor in the washing room, the steam room must be saturated with persistent and hot steam circulating throughout the room evenly, and in other rooms - maintaining a hygienic microclimate and an aesthetically pleasing design.

Consequently, each of them has finishing features that need to be taken into account. When choosing the main material for interior walls, you should pay attention to brick.

This material has a number of significant advantages compared to analogues:

- high degree of heat capacity, which is a determining factor;

- harmless and environmentally friendly, even at the highest temperatures it does not release any toxins;

- durability, one of the simplest, yet durable materials;

- safety, reliability: brick is not capable of igniting or collapsing when exposed to high temperatures.

Step-by-step instructions for constructing a structure with your own hands

Before starting masonry, prepare the base for the concrete walls, its height is 20 cm. Between the first row of masonry and the concrete, roll waterproofing is laid in two layers with an overlap and sealed joints. Let's consider the process of raising each type of wall separately.

Solution

Mortar composition for external and internal walls, options:

Cement + sand, diluted with water.

Ratio 1:3, add liquid until a viscous, dense texture is obtained. The mass should not spread, but should be evenly distributed over the surface of the material using a spatula. This composition is called fatty or normal.- The finished mixture is diluted with water in the proportion indicated on the label.

The solution for the furnace partition is slightly different; a purified clay-sand mixture diluted with water is recommended; it tolerates temperature well and the masonry will be safe. Some builders add cement to the mixture for added strength.

Manufacturing procedure:

- Soak the clay in water for 24 hours so that it becomes elastic;

- strain, stir with a shovel until smooth, add water as needed;

- mix with sand, gradually, until a dense mass is obtained, the ratio is 1 liter of sand to a bucket of clay (10 liter).

For any type of wall, the connecting mixture with cement is prepared in batches, immediately before starting work, because the material hardens very quickly. When laying lightweight load-bearing walls, the outer part of the structure is laid out first.

External walls

Procedure:

- Place beacons around the perimeter of the building, highlight the places where openings will be formed. Stretch the mooring thread, check the accuracy of the angles.

- Start work from the corners, laying is carried out in ½ brick, observing the order and constantly monitoring the quality of the geometry. A multi-row masonry system is used.

- The corners are connected according to the same scheme: the first row is dry, the subsequent rows are in compliance with the order of multi-row masonry.

- Every 4 rows the masonry is reinforced with reinforcement. Several rods with anchors are laid across the row; their length should be enough to attach the inner wall.

- The seams on the front side of the masonry are formed with jointing so that the work looks attractive from the outside.

Laying partitions from the inside

For example, let’s choose a masonry of 1.5 bricks:

Place the beacons at the corners of the base, accurately measure the length, and tighten the mooring thread. Repeat the markings along the perimeter of the future building, highlight the junction of the load-bearing walls with the partitions and indicate the location of the doorways.- Check the accuracy of the corners using diagonal threads and a wooden corner.

- Start laying from the corners, the first row is formed without mortar, on a dry basis. Fasten with connecting mixture only vertically.

- The second row is placed on the mixture, the order is observed and the accuracy of the angles of each row is checked.

- Repeat the laying in rows 3 and 4, observing the order. Reinforce the seam after the 4th row with reinforcement mesh.

- The main part of the masonry is also assembled in accordance with the order, the first row is dry, reinforcement is done every 4 rows.

- Multi-row masonry is carried out, and insulation is laid at the same time.

- Reinforcing pins with anchors are laid from the outer wall to the inner wall to connect them. General cross-sectional view in the photo.

- In places where an opening is created, the wall at the ends should be made of solid brick. The top of window and door openings is reinforced with metal or concrete blocks, which are held in place by side masonry. On top of the block, masonry continues in the same way as before its appearance.

External walls are laid at a distance equal to the thickness of the insulation and anchors, which form a ventilation gap. Approximate distance 12 cm.

Around the stove

Procedure:

- Beacons are set, the mooring line is tightened. The first row is laid dry.

- The second and subsequent rows form the wall; during the work, compliance with the geometry and angle of the masonry is checked. It is necessary to follow the order.

- The connection (if any) is carried out along the bricks that were placed to create a connection on the rough masonry of the main walls of the bathhouse.

- If connections have not been made in advance, the structures are connected with mortar or attached to a steel profile. There is no need to form rigid connections, since the partition is lightweight.

- It is recommended to install floor-to-ceiling beams on both sides of the wall to guide and hold the masonry.

Strengthening

To strengthen the walls, reinforcing mesh, reinforcement pins or flexible metal plates are used . The first option is preferable, but the thickness of the masonry does not always allow it.

To strengthen the external and internal structures, the reinforcing mesh is laid inside the seam every 4-5 rows, buried in the solution. Since the wall near the stove is thinner, it is reinforced across a row.

Since the walls for construction are thin, they need to be strengthened so that the weight of the structure does not destroy the masonry.

Insulation

Insulation of a bathhouse is carried out in several stages:

Exterior walls .

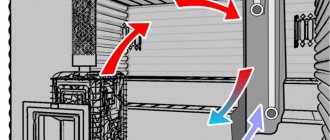

The insulation is laid inside lightweight masonry. For it, you can use sheets of expanded polystyrene, which are cut to the desired shape and filled with them into the space inside the lightweight masonry as the internal walls are built.Mineral wool is also good for these purposes. External structures must be insulated so that when warming up the bathhouse there is no need to spend money on heating the entire building. The task of a sauna stove is to warm up the air inside the room.

- Internal walls .

Here it is necessary to make a high-quality finish so that the heat does not escape into the walls. To do this, the rough masonry is waterproofed with coating materials (for example, bitumen mastic). Next, a layer of plaster is applied, a lathing is attached to it, and fiberglass is placed inside the resulting cells. A layer of thermal insulation is laid (expanded polystyrene, ecowool, basalt wool). Next, the wall is covered with a vapor barrier (for example, foil), on top of which the finishing is placed. Experts recommend using lining, which quickly warms up and will become an obstacle to the transfer of heat to the brick. - near the stove is insulated with a denser layer of heat-insulating material, according to the same principle as the internal surfaces of the bathhouse. Foil must be used as a vapor barrier, since the steam room is the wettest part of the bath and is subject to the most dramatic temperature changes.

The steam room must have high-quality ventilation so that when heated the room does not turn into a kind of thermos without air access.

It is strictly forbidden to use flammable materials and those that emit toxic substances when heated: mineral wool, polystyrene foam and the like for internal insulation.

Difficulties and possible errors during the work process

What you need to know in advance:

- The possibility and safety of using a bathhouse depends on the choice of insulation. Depending on the type of walls, the material must be of high quality and suitable for the conditions in which it will be located.

- Some builders, instead of lightweight masonry walls, use solid masonry, without an opening between the outer part of the structure and the inner one. This is done mainly for the purpose of saving, but this makes the structure much colder, the air takes longer to warm up, since some of the heat goes to the walls.

- It is necessary to strengthen the thin walls of the bathhouse so that the masonry does not crack or deform under the weight of the ceilings.

- Construction must begin and end in the warm season, at above-zero temperatures. Frost causes the mortar to cease to perform its functions and contributes to a short service life of the walls.

- There should be a ventilation gap under the finishing and between the main walls so that the air helps the penetrated moisture evaporate and the bathhouse dries out faster.

- The lack of vapor barrier and high-quality waterproofing of brick is a direct path to the rapid appearance of fungus and mold on the brick, which cannot be removed. The consequence is rotting of finishing materials.

- The ventilation system must be thoroughly thought out, otherwise the walls will be constantly wet, become damp and collapse.

- Checking the geometry of the masonry and maintaining the order are mandatory. Otherwise, the walls will deform over time, and along with them the entire bathhouse.

You can only build a brick bathhouse on stable ground. The structure is heavy and there is a high probability of subsidence after completion of construction. This point must be taken into account when calculating the height of the walls.

Determining the thickness of walls depending on the type of their construction

This parameter differs for all materials, which is due to such features as load-bearing capacity, compressive strength, bending, which are calculated at the design stage. The size of the layers of insulation, external and internal finishing, and in certain cases the air gap is added to the main thickness of the wall. The required load-bearing capacity depends on the roof material, the number of storeys of the building, and the type of external and internal finishing. The thickness of the walls is calculated at the initial stage of project development, since it directly affects the size of the foundation.

Chopped structures

For the bathhouse, mainly logs from coniferous wood are used, most often pine, which can be cut down independently, purchased at a logging enterprise or in the form of a finished log house from a construction company. Construction is carried out from rounded logs with a minimum diameter of 200 mm. We use high-quality dried wood, completely sanded and free from insects and rot. Logs must be selected as straight as possible and with the least number of knots.

The process of building a log house from glued or profiled timber is faster and less labor-intensive, since no adjustment of the material is required. According to current standards, the minimum width of walls made of it for a one-story building is 165 mm, for a two-story building - 200 mm. These values are relevant when using a bath only in the warm season.

Important! If you plan to operate a bathhouse made of timber all year round, it is necessary to insulate the walls, the layer thickness of which is calculated depending on the climatic features of the area where the facility is located.

Brickwork

The main advantage of buildings is fire safety and durability. The minimum width of a brick wall is 510 mm, rubble masonry is 750 mm. The high thermal conductivity of the material requires insulation, preferably external, as it is more effective. Otherwise, the bath heats up very slowly and cools down extremely quickly.

Advice! The thermal conductivity of walls can be reduced by using hollow bricks or making well masonry, in which gaps of up to 130 mm are provided, filled with insulation.

Block structures

The construction technology is characterized by reduced time and relative simplicity. Its peculiarity is that the masonry is carried out not with cement mortar, but with a special adhesive composition, which is caused by the high porosity of the material. As a rule, a thickness of 380 mm is sufficient to ensure sufficient load-bearing capacity of a block wall. To obtain the required heat resistance of structures, insulation is required.

To build a bathhouse, cellular blocks from:

- Gas silicate;

- Expanded clay concrete;

- Reinforced concrete;

- Slag concrete;

- Foam concrete.

Advantages and disadvantages of this structure

The brick walls of the bathhouse give the building:

- durability;

- environmental friendliness;

- fire safety;

- no rotting;

- beautiful appearance;

- rapid shrinkage period.

But there are also disadvantages that it is better to think about in advance:

- such walls take a long time to warm up;

- the material is expensive;

- high thermal conductivity (high-quality vapor barrier is needed);

- hygroscopicity of brick (solved by waterproofing);

- fragility of the material.

If the technical requirements for the construction of brick walls in a bathhouse are met, most of the material’s shortcomings will not matter.

Furnace lining

They use red ceramic brick or fireclay, but it is more expensive. The lining of the stove in the bathhouse serves as its case, which should facilitate smooth heating and have special channels for the circulation of hot air.

Sequence of actions and features:

- Laying is carried out in a vertical position, a distance of 40 - 60 mm from the stove casing, such a gap ensures the free passage of hot air;

- Cast iron doors are placed in one of the lower layers to regulate the air supply;

- The width is usually made half a brick, but not thinner, because overheating of the screen may occur;

- Experienced builders suggest using fire-resistant fireclay bricks, but this is not necessary, since the heating temperature of the brick cladding is not so high; here, rather, it plays a decorative role;

- If the stoves are heated from the next room, then special tunnels are created in the panels to provide access to the ash pit.

Prices for masonry in the Russian Federation

The cost of building brick walls depends on the complexity of the structure and the type of material. The scope of work will affect the final price offered by builders . It is not billed separately per element, but on a turnkey basis, per square meter of a brick bathhouse.

Average prices for laying bath walls by city of the Russian Federation:

| Name of works | Moscow and Moscow Region, rub/m2 | St. Petersburg and Leningrad Region, rub/m2 | Krasnodar region, rub/m2 | Kazan, rub/m2 |

| Construction of a brick bathhouse | 16000 | 13500 | 13000 | 14000 |

General rules for choosing material

- For walls, ordinary red brick, hollow brick, silicate brick is suitable (facing brick is not suitable).

- For the foundation - ordinary red, as well as batches with defects in appearance, for example, iron ore (hollow and facing are not suitable).

- For the stove - red and fireproof (silicate is not suitable due to low fire resistance).

Bathhouse bricks are purchased in bulk and delivered in one batch by truck. During storage, it must be protected from water. The general rules here are approximately the same as for timber lumber.

The delivered brick is stacked on a wooden pallet and covered with film. It is also convenient to place the stacks under a canopy. Bricklaying, especially if done by one person, takes several weeks. All this time, the brick must be stored in a dry place.