Features of drying the bath

Proper and timely ventilation of the steam room is necessary to prevent the unpleasant smell of dampness, the appearance of mold and mildew, and damage to wood. Please note that you need to thoroughly dry not only the steam room, but also the washing compartment.

There are several ways to dry a bathhouse after washing:

- Equipment for supply and exhaust ventilation openings.

- Turning on the heating fan with a spiral (method suitable for use in the wash compartment).

- Opening the windows and the vent with simultaneous heating.

- Creating drafts and opening all doors in bathhouses with a brick oven.

It is necessary to think over the vents in the bathhouse at the stage of wall construction.

Signs of improperly functioning ventilation

The operation of ventilation in the steam room must be monitored and sometimes they will check how correctly it is functioning. You can tell that the air is circulating correctly by how you feel: easy breathing and uniform heating of the body, comfortable temperature and humidity.

Mold in the bath

If the installation of ventilation in the steam room was carried out incorrectly or over time the system stopped working correctly, the following signs will appear:

- A large amount of condensation will begin to accumulate on the walls.

- Mold will appear in the corners.

- A characteristic smell of rotting wood will appear in the room.

- The air will warm up unevenly.

- A draft will appear.

- The room will heat up slowly, and the heat will disappear quickly.

- It will be uncomfortable to breathe.

Any of these signs should already serve as a signal that something is wrong with the ventilation. Most likely, if everything was fine before, it will be necessary to clean the ventilation ducts and check the operation of the fan.

Equipment for the ventilation system in the steam room of the bathhouse

To prevent the formation of condensation and ensure high-quality ventilation, you need to take care not only of insulation and vapor barrier, but also of creating holes for the inflow and outflow of air.

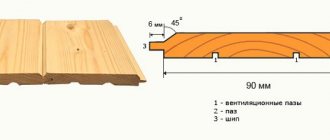

Despite the fact that wood itself breathes, you should consider some details during construction:

- We install lower crowns with special openings to ensure moderate air ingress from the street.

- When installing the stove, we arrange the vent in such a way that air is vented out through it.

- A steam room in a log house must border the street with at least one wall to allow natural air exchange.

- It is advisable to equip a wooden steam room with an opening window. The pressure and temperature in the bathhouse and outside are different.

Due to this, the ventilation system with windows works effectively, which is equipped in several ways:

- We place the supply window at a height of 25-35 cm from the floor next to the stove and equip it with movable blinds, which will act as a regulator of the direction of the air flow. We make an exit hole on the opposite wall, at a height of 15-25 cm from the ceiling. We build a fan into it.

- If there is one external wall, then we will equip one window at the bottom at a height of 30 cm from the floor, and the second at the top at 30 cm from the ceiling. In this case, the heat source should be placed opposite, and a fan should be mounted in the upper hole.

- If the flooring is leaking, we place the lower window near the stove at a height of 30 cm from the floor, and the exhaust hole is in the next room. In this case, the heated air passes through the cracks in the floor, dries it well and enters through the built-in ventilation pipe to the hood.

- We install the inflow under the shelf. The vent serves as a hood. However, this method only works when the oven is running.

- We make the entrance window behind the stove at a height of 0.5 meters, and the hood on the opposite wall, 30 cm from the floor. We install a fan in the last one.

- We make an inlet hole behind the stove 20 cm from the floor, and an outflow hole at the same height opposite.

The calculation of the hole area is carried out according to the principle: 24 cm2 per 1 m3 of room. It is important to follow the recommended sizes and heights of the windows, since only in this case will the air circulate correctly, which means the room will dry out as quickly as possible.

Brief analysis of frequently encountered statements

Having opened two or three items at random in the top lines of the search results, a novice bathhouse owner is likely to encounter such statements.

I don’t dry anything (I don’t ventilate), and everything is fine

This statement can often be found as part of the answer to a newbie’s question about drying on third-party forums, and even in specialized bathhouses.

However, the laws of physics and biology, when combined together, are inexorable:

If a person really leaves everything after the steam room and leaves, then this may mean that:

Hence the conclusion: it is necessary to dry the bathhouse, and for this you need to know how to organize everything.

Just open the doors and that's it

What is attractive about this method is its simplicity. But here, too, not everything is clear. Opening the door to the steam room will actually improve air exchange. But in one bathhouse this can solve the drying issue, in another it will not be enough, and in a third it may be contraindicated to open the doors at all.

The drying method by opening the doors will be discussed in more detail below.

Use a fan heater

It would seem that the solution is incredibly simple: install an additional electrical appliance that will blow hot air into the steam room. As a precaution, it is indicated not to place the device on a wet floor (although to dry, excess moisture should be removed from the room with a rag or sponge).

In fact, a bathhouse that needs to be dried using a fan heater is the wrong bathhouse. In addition to the additional energy consumption (after all, it will take more than one hour to dry), there is an inconvenience with the power cord. Imagine that after using a robot vacuum cleaner you will have to additionally sweep away the dust with a broom into a dustpan - such an allegory suggests itself.

Drying the bath after the operating cycle should occur without the involvement of extraneous heat sources.

Rub with linseed oil

This advice wanders from one article to another.

In order to facilitate the drying process, it is recommended to thoroughly rub the wooden paneling, and especially horizontal surfaces - grates, shelves - with linseed oil. Oil will not help dry the steam room! However, impregnation has its advantages - the boards will be less susceptible to rot and mold, and will not dry out during the drying process.

Instead of linseed oil, some bathhouse owners recommend using lamp oil - it is inexpensive and has the highest degree of purification.

Rules for drying a steam room in a bathhouse using a draft

To make the wood dry faster, it is advisable to install doors and windows on the south side.

In this case, more sun and heat will penetrate into it. You can quickly ventilate the room in this way:

- We open the doors and windows, creating a through movement of air.

- To quickly and efficiently ventilate shelves, benches, walls and floors, wipe them with cotton or terry cloth to remove excess moisture.

- If the floor is equipped with a wooden ladder and the shelves are removable, then we also dry them after the procedures. To do this, we take them outside in dry weather or simply remove them and lean them against the walls.

The steam room is considered dried if the floor is dry. It is this surface that gets wet first and dries last. Flooring is most susceptible to moisture. It is the first to begin to darken and rot if not properly cared for.

How to properly dry a bathhouse after washing: quickly and easily + secrets of bathhouse attendants

We need a bathhouse not only to wash ourselves. It helps relieve stress, relax, gives vigor and strength. To maintain the longevity of the bath, you need to know how to properly dry it after washing. This is a mandatory rule so that the bathhouse pleases its owners for a long time.

Baths are often decorated with wood. It's environmentally friendly and beautiful. But, after washing, moisture accumulates on the wood, which leads to mold and mildew.

Flaxseed oil will help preserve the bath.

Treat the wooden floor in the bathhouse with linseed oil. Leave to dry for a day. After drying, you need to heat the bathhouse and remove excess oil with a rag. This will protect the wood from rotting, cracking, fungus and darkening.

If you leave the door open in winter after washing, cold air will begin to penetrate into the damp room and the floor in the bathhouse will quickly rot. In winter, after washing, close the windows and door. And the next day, open them for ventilation.

Specifics of drying a steam room in a bathhouse with an additional firebox

If the stove is a traditional brick one, then there is no point in reheating it.

Brick accumulates heat very well and is able to release it for a long time, so if the temperature is maintained, the wood in the steam room will dry out faster. If an electric heater is installed in the bathhouse, then it must be turned on after the procedures to warm up and dry the steam room, after which you can open the door and window, creating a draft.

If you know how to dry a bathhouse after washing in winter and at other times of the year, you can ensure that the aesthetic appearance and performance properties of the wood are preserved for many years.

Lighting up the oven

Those lucky people who have a brick stove can take good care of their bathhouse. A heated brick accumulates heat and stores it for a long time after the room has cooled. Soft “residual” heating of the room together with cross-ventilation helps get rid of excess moisture without any tricks. I can’t boast of such a thing, so I make do with other drying methods.

My steam room has a standard Finnish stove.

It cools down quickly.

To achieve the brick oven effect, you need to put in extra effort. After entering the steam room, I throw firewood into the stove and open the ash pan. To keep the warm, dry air “concentrated,” I close the windows and doors. You can open them after the wood has completely burned out.

Method of drying the washing compartment in a bathhouse

The temperature in this room is lower than in the steam room, and the humidity is higher.

Therefore, before drying the sink in a bathhouse, you need to take these features into account and arrange ventilation. We make an exhaust window between the finished and subfloor and equip the hole with a fan. You can use models with electric motors that will turn on simultaneously with the lighting. We bring the outflow pipe to the roof.

To install a ventilation system in the wash compartment, you can use plastic boxes, as well as moisture-resistant fans, while these products cannot be used in a steam room.

Question answer

What is burst ventilation?

This is when a significant amount of new air enters the room, but for a short time. Can be used between visits to the steam room or in the summer on an ongoing basis - for drying.

What additional steps should I take to speed up drying?

Collect excess water with a rag or sponge, remove wooden flooring and shelves and place them upright (it is better to make them removable from the beginning).

Do I need to close the doors during the final fire to dry out?

If there is good ventilation, be sure to close it. If not, then at first you need to keep the doors closed so that the heat does not escape, and then open them a few centimeters.

Should a forced exhaust fan be powered from a light switch?

Not worth it. It is better to display a separate toggle switch or key - there will be more freedom of action.

Rules for drying a bath broom

In general, it is not recommended to use one broom for a reusable parka.

It loses its healing properties. Over time, the branches become less elastic and the leaves fall off. To use it several times, you need to know how to dry a broom after a bath. To do this, rinse the product with water at room temperature and place it in a dry cotton cloth. After completely absorbing the moisture, hold the broom at a height of 40 cm above the oven for 5-10 minutes. We hang it on a thread in a well-ventilated room. We make sure that direct sunlight does not fall on it. After a few hours, put the broom under the press.

Please note that not all products are suitable for reusable use.

Brooms made from herbs and coniferous trees are immediately excluded from the list. And from deciduous ones, you can steam with oak several times. However, you will get the maximum health benefits from the parka with a fresh or dried broom. Watch a video about ventilation in a bathhouse with an air-conditioning stove: Special attention should be paid to drying the bathhouse. Only in this case the steam room will not emit an unpleasant odor, and the lining will retain its original appearance for a long time. This will significantly save money on periodic replacement of finishing. To effectively ventilate the steam room and sink, you can combine several proposed methods.

Dry the bathhouse

Page 1 of 3

1 2 3 Next >

- Registration: 07/06/10 Messages: 149 Thanks: 5

registrar

Live here

Registration: 07/06/10 Messages: 149 Thanks: 5 Address: Moscow

In the summer they installed a bathhouse, a 6 x 4 log house with an outtake. Divided into two parts. In one part, which is larger, there is a relaxation room, in the other there is a steam room combined with a sink.

The stove is homemade. It heats up quickly, but in the rest room all the walls and ceiling are covered with condensation, despite the slightly open window.

Tell me how to dry it?

- Registration: 06.24.08 Messages: 231 Thanks: 69

Tuljak1

Live here

Registration: 06/24/08 Messages: 231 Thanks: 69 Address: Tula

Dry the bathhouse.

The stove is homemade, but which one: metal or brick? How is ventilation organized besides the window?

- Registration: 02/03/11 Messages: 490 Thanks: 459

Seal

Narrator

Registration: 02/03/11 Messages: 490 Thanks: 459 Address: Rybinsk

I'm afraid it will always be like this. With a combined steam room and sink going into the boiler room, the steam always condenses on the ceiling and walls! To alleviate this phenomenon, some people make a hatch in the ceiling and steam pours out there.

- Registration: 07/06/10 Messages: 149 Thanks: 5

registrar

Live here

Registration: 07/06/10 Messages: 149 Thanks: 5 Address: Moscow

The stove is metal, there is a brick pipe leading up to the ceiling, then there is double asbestos cement.

And if you make a small vestibule between the CO and the steam room, will it help?

Ventilation was hoped for through the window. There is a hole in the foundation between the floor and the concrete pour, I hoped that the inflow would be into this hole, and the outflow would be a window and a stove hood.

Hatch in the ceiling in a KO or steam room?

- Registration: 03/03/11 Messages: 12,443 Thanks: 12,442

ZYBY

MABI

Registration: 03.03.11 Messages: 12.443 Thanks: 12.442 Address: St. Petersburg, Bolshaya Vishera, Novgorod region.

I can assure you that if you make a vestibule at the ENTRANCE to the CO (from the street) and warm the CO, the process of steam generation in the CO will be significantly reduced. Although your combination will always float in KO.

- Registration: 07/06/10 Messages: 149 Thanks: 5

registrar

Live here

Registration: 07/06/10 Messages: 149 Thanks: 5 Address: Moscow

What if we make a small vestibule between the KO and the steam room?

- Registration: 03/03/11 Messages: 12,443 Thanks: 12,442

ZYBY

MABI

Registration: 03.03.11 Messages: 12.443 Thanks: 12.442 Address: St. Petersburg, Bolshaya Vishera, Novgorod region.

Let's decide what this vestibule will solve (between the steam room and the CO). If it is organized with a serious extraction of steam from the steam room, it will help. And if not, then the steam from the steam room, when entering a cool CO, will condense on the ceiling and walls.

Therefore you need:

1. Warm KO

2. Use natural wood to decorate the KO; everything else (plastic, chipboard, etc.) will collect drops.

- Registration: 12/07/09 Messages: 71 Thanks: 21

max50

Live here

Registration: 12/07/09 Messages: 71 Thanks: 21 Address: Pestovo village

This summer I built a 6*4 bathhouse. At first I planned, like you, to heat it from the KO, but after much thought I decided to turn the stove with the firebox into the dressing room. I have a similar layout, KO - 11 m2, a sink combined with a steam room and a dressing room - the same clean dimensions 1.75 * 3 each. I plan to heat from the dressing room. I plan to put a small heating stove in the KO, in case of a winter fishing trip. Unfortunately, now I don’t have the opportunity to post the layout plan, but I’ll do it these days. Today I was in the stove store, my head was spinning, my thoughts were scattered. I have not yet decided which stoves I will buy. And I would like the stoves to have a common chimney. Therefore, I will ask for advice from members of the forum.

- Registration: 07/06/10 Messages: 149 Thanks: 5

registrar

Live here

Registration: 07/06/10 Messages: 149 Thanks: 5 Address: Moscow

Why did you abandon the idea of firebox and CO? I have a firebox made of CO, and some of the heat still goes into the CO, which is very convenient (probably) in the off-season.

I made the stove to order, and lined it with bricks, leaving a gap between the bricks and the stove, so the steam room heats up quickly enough (on Saturday they heated it for the first time) and the bricks provide a heated mass, which allows you to throw one wood stove in the morning and go steam in half an hour later . It was minus 2 outside at night.

- Registration: 07/06/10 Messages: 149 Thanks: 5

registrar

Live here

Registration: 07/06/10 Messages: 149 Thanks: 5 Address: Moscow

We came to the conclusion that we really need to heat the boiler more, we will install an electric stove.

And yet I’m thinking of making a small vestibule 70cm x 70cm between the steam room and the CO. Make the walls of the vestibule out of plastic, then all the moisture will settle on the walls, flow down and make the floor at an angle into the steam room so that the condensation flows back.

Do you think it will help?

- Registration: 09/07/11 Messages: 12,410 Thanks: 17,234

pn2

steamy spirit

Registration: 09/07/11 Messages: 12,410 Thanks: 17,234 Address: St. Petersburg

If you keep this vestibule cold, then partly yes, but why cold condensate back into the steam room?

Well, due to the small volume of the vestibule, the effect is still insignificant.

- Registration: 05/31/11 Messages: 3,510 Thanks: 3,705

I'm building for myself

Drifter

Registration: 05/31/11 Messages: 3,510 Thanks: 3,705 Address: Chelyabinsk

made of good solid wood and good ventilation, and not just a draft from the hole below to the hole at the top, but think about how to take warm air from the rest room and throw it outside without creating drafts. Moreover, if there is effective ventilation, then it will clearly not be hot in this vestibule, and here your plastic will further reduce comfort. When drying the entire bathhouse after use, think about how this vestibule will dry, otherwise you risk getting a thick layer of frost on the walls of this vestibule by your next visit. If you warm it up, you will warm it up, but the humidity will already be enormous. Get additional uncontrolled ventilation in the steam room

- Registration: 07/06/10 Messages: 149 Thanks: 5

registrar

Live here

Registration: 07/06/10 Messages: 149 Thanks: 5 Address: Moscow

As long as it’s cool in the CO, the vestibule will also be cool. And when the CO heats up, condensation will not form so much.

As for the outflow of condensate, I agree that going back into the steam room is probably not advisable. But he is especially not needed in KO. Maybe make an outflow to the street?

- Registration: 06.24.08 Messages: 231 Thanks: 69

Tuljak1

Live here

Registration: 06/24/08 Messages: 231 Thanks: 69 Address: Tula

If you make an additional vestibule, you will get additional problems in terms of heating the rest room - it will take longer to heat up. Accordingly, the walls will be even colder than now and you will get even more condensation. I believe that you need to warm up the rest room properly before vaping. How is your ceiling insulated? I can tell you how organized it is for me. I’ll say right away that there was never any condensation. So: the metal stove is lined with half a brick and is dry. About 100 kg of stones. First, I heat the stove with the door open in the KO to a temperature of about 27 degrees in the KO. Then I close the door. At the same time, all my ventilation is open. Ventilation is organized simply: a pipe with a diameter of 100 mm is laid through all the walls under the ceiling opposite each other: this creates something of a draft. And in the steam room there is an additional pipe under the shelf leading outside. And after all the procedures, I throw three logs into the stove, open all the ventilation, open the door to the CO and go home. Everything dries out overnight. In your case, it may help to leave the window and the crack on the front door open. Good luck.

- Registration: 06/23/09 Messages: 3,406 Thanks: 5,261

NickB

Natural or forced?

In order to answer the question: natural or forced ventilation for a steam room, you should look at each type.

A natural microclimate is formed independently in the presence of planned vents (openings) or cracks when the air convection processes described above are started in the building.

The advantages include: low cost of implementation, absence of extraneous noise/vibrations from operating devices and the use of natural features. Possible difficulties: errors in the placement of holes, as a result: lack of draft (the opposite - the appearance of excessive drafts); penetration of foreign (most likely unpleasant) odors from the street.

A forced ventilation system uses equipment and materials that create artificial air movement in the required direction. Regulated by special control units. This is a very expensive solution that requires competent design and further implementation. When placed correctly, it is guaranteed to ensure smooth circulation of air flow.

There are combined types for a bath: steam room ventilation, which combines both of these directions and has the pros and cons of each option.

If you decide to do ventilation yourself, it’s better to go with natural ventilation - it is more in line with the spirit of the bathhouse than the use of intricate devices. However, we do not dissuade you from using forced supply and exhaust ventilation.