Properly supplying water to the steam room or shower room is just part of the problem; at a minimum, you will need to select a faucet for the bath. So that it looks nice and is safe and convenient to use in a sauna or steam room. The faucet for baths and saunas is usually chosen to match the interior of the room; it can be bronze or stainless steel. In any case, the device must be reliable enough not to burn your hands or scald with boiling water.

What to look for when choosing a model

It seems that when choosing a model, it doesn’t really matter how to choose and what to focus on when deciding to buy a bath faucet. But the difference still exists; experts recommend paying attention to several basic parameters of the product:

- Case material. The harder the metal, the longer the bath faucet will work;

- Availability of a protective coating if the device is planned to be used in a steam room. Simple steel and plastic structures, as well as steel-aluminum ones, are not used in bathhouse conditions;

- The reach of the faucet spout and the shape of the rotary handle. This is especially important if you plan to collect water in an awkwardly shaped container;

- Design of the faucet locking mechanism. A leaking valve in a bathhouse is a disaster;

- If you select a bath tap for hot water, then the handle of the axle box must be elongated and must be insulated with wood or ceramics.

Advice!

In addition, a faucet with a wooden handle should be, if not beautiful, then at least stylish, so that using it evokes a positive mood. The design of the device is extremely important for maintaining the interior design, especially in cases where you have to select a model for an unusual bath, for example, for a hammam, decorated in an oriental style.

In this case, you can use a simple model with ligature, like SM68 photo.

Or buy a designer faucet for the bathhouse with a dragon head.

Main characteristics

Installation of shut-off valves for hot water columns

Have you decided to decorate your bathroom and don’t know the difference between a pool faucet and a similar device intended for bathrooms? In this article we will look at the current types of mixers, the features of their operation, as well as the advantages and disadvantages. As a result, you will be able to decide on the advisability of purchasing a particular device.

A mixer for wood-burning water heaters, as well as its analogue intended for installation in a bathroom, is a type of plumbing equipment through which you can control the flow rate and temperature parameters of water. In essence, the design of the device is cold and hot water taps combined in a single housing.

It’s curious: in England, Scotland and Ireland it is customary to use separate taps, located on opposite sides of the sink.

But, despite such examples, it is the mixers that are easy to install with your own hands and provide comfort and ease of use. Moreover, for ease of use, high-tech valveless modifications that respond to movement are appearing on the market.

So, what types of faucets can be purchased on the market today?

Reliability of the valve mechanism of the faucet

First of all, you need to pay attention to the material of the case. Bathhouses are made from the most corrosion-resistant materials:

- Bronze;

- Brass;

- Stainless steel;

- Steel-aluminum alloys.

Sometimes less resistant alloys are used, but in this case the taps are necessarily coated with galvanic chromium or nickel, titanium nitride, and cadmium. They look very beautiful, but most often such a product is less suitable for a bathhouse than brass or bronze.

The best option is to use a bronze bath faucet. The alloy of tin and copper is quite hard and wear-resistant. The bronze thread inside the faucet lasts twice as long as soft brass and can withstand the load, even if one of the bathhouse visitors decides to close the valve with maximum force.

In a bathhouse, bronze darkens and becomes more beautiful, while brass blooms with a greenish “patina.” Both materials are great for hot water taps.

Types of installation of a water heating tank

Below we will talk about the two main ways to install a water heating tank.

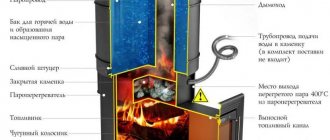

It is better to install a samovar-type tank in place of the first chimney module. The main advantage of such tanks is almost instantaneous heating of water. By the time the temperature in the steam room reaches 90°C, the water in the tank will already be heated to 70-75°C. However, it should be taken into account that with such dynamics the water can quickly boil. This is especially true during the cold season, when the room takes longer to warm up and uses a large amount of fuel. Boiling water risks supplying a large amount of raw, heavy steam to the steam room.

If the tank is connected through a heat exchanger register, then this completely solves the problem with excess wet steam. It is also worth remembering that in this case the water will take twice as long to heat up. As for the optimal installation method, the installation of a water tank connected through a register is best done in the adjacent bathhouse room.

There are drip feed fittings at the bottom of the samovar tank, which is especially convenient if the sauna stove has a high-speed steam generator in its design - in this case, the steam room is filled with light, comfortable steam much faster. In particular, the “Sahara LNZP” or “Rus-Panorama LNZP” models were designed in this way.

Installation of bath taps

The range of shut-off devices used in water pipes and on water tanks in the bathhouse is divided into three large groups:

- Valve or axle box structures;

- Single-lever valves with ball or cylindrical valves, also called single-handle devices;

- Faucets, or double tap blocks, allow you to regulate the water temperature by turning a hot and cold handle.

A damper insert is installed inside the single-lever faucet; to shut off the water, just turn the head part 90°. Such devices are easily recognized by the thickened central part of the body.

Valve devices have a massive, thick-walled body, inside of which there is a threaded insert - axle box. To turn off or open the water, you will need to turn the handle several times. The valve is easy to distinguish from other types of shut-off devices; the inlet pipe and the body spout are always located at different levels.

Specifics of spindle heads

This is an improved version of the previous type, only its stem is stationary. And the “rail” thread along which the device with the attached valve moves is cut not inside the head body, but inside the stationary rod. There is no fundamental difference with the previous type; an increase in comfort can also be argued. It’s just that the flywheel does not “move” up and down along the thread, but is stably in its place, because the rotation occurs inside a stationary rod.

In addition to the breakdowns typical of valve devices, spindle heads are not prone to breakage of spindle threads. It is believed that it is impossible to install cutting at home. This is true. However, there is a measure that allows you to temporarily postpone going to the store for a new head:

- disassemble the tap and unscrew the spindle from the stem;

- disconnect the valve from the spindle;

- We put a ring made of copper wire with a diameter of 2 mm on the upper valve stem. By installing a ring between the spindle and the valve, an additional rigid part will appear, replacing part of the worn thread. If one ring is not enough, you can make two or use thicker wire.

The work is almost like jewelry. If you don’t want to bother with repairs, it’s better to buy a new head. No thread at all, for example.

Axle box systems for hot water in the bathhouse

Valve taps are considered to be the most reliable and repairable. Even in the hot atmosphere of the bathhouse, the axle valves work without any particular complaints. If you need to choose a reliable tap for hot water supply, then a valve will be the most suitable solution.

Advantages and disadvantages of valves

Initially, axle-box valves were developed to shut off water under pressure up to 16 atm. Therefore, if hot water in the bathhouse is supplied from a centralized water supply system, then it is better to install an axle-box model.

Valve systems have two serious disadvantages. Firstly, in a bathhouse, when using hot water, the rubber seal that seals the central rod of the axlebox wears out very quickly. This leads to valve leakage and the need for further repair.

Secondly, opening the valve by rotating the head several turns is not very convenient. Especially if it is in a steam room or sauna and, accordingly, heats up to a high temperature. Usually in such situations, the handle on the valve is replaced with a wooden one or the head is wrapped with a dry cloth.

Turkish and Chinese bath models

You can find quite a large number of valve taps on the market, most often made in Turkey, China or Italy.

Italian products are very impressive, have an expressive design, often stylized as antique faucets, such as the Morelli Francoforte models, photo.

The case is cast from bronze, with a protective coating on the surface that imitates gold plating. The cost of the model is about 200 euros.

Turkish bath models are much simpler; they are made of brass casting and painted bronze.

The average cost of such a product is just over $100.

Chinese taps are pressed using powder metallurgy and cost between $30-50, but in conditions of high temperature and humidity, the baths rot in a few months.

How to get light, fine steam?

Of course, you can simply purchase a steam generator and enjoy high-quality steam without much effort. Fortunately, the choice of appropriate devices is now large. Such steam generators or steam generators are installed in the stove. They allow you to produce superheated, finely dispersed steam by supplying water to the lower stones of the heater, which are not only well heated, but extremely hot. You can see the options for steam generators on our website at the link: STEAM GENERATORS

However, the very fact of having a steam generator does not guarantee the creation of a comfortable atmosphere for vaping. At a minimum, for it to work effectively, the bathhouse must be well heated, the stones must be correctly selected and laid, and water must be supplied in the right quantity and quality, without impurities.

The general recommendations here are:

- The air temperature in the steam room should be at least 40 degrees, optimally 50-60 degrees

- The stones in the heater need to be heated to 600-800 degrees

- Water must be used clean, without impurities. This is important because any impurities, firstly, “heighten” the steam, and secondly, they quickly begin to burn on hot stones. So, if you use water from steaming a broom, make sure that there are no leaves or other debris floating in it; if you use aromatic oils, their concentration should be low.

- It is advisable to use water that is already hot. This is an important point, which for some reason even some experienced bathhouse attendants neglect when using cold water. Moreover, among them there are those who are quite seriously trying to justify the effectiveness of using cold water due to a higher temperature difference. However, let's remember physics: before water evaporates, it must heat up, and heating the water takes a certain amount of energy, given in this case by the stones. That is why the water supplied to the hot stones must be as hot as possible, this allows the stones to maintain a high temperature longer. In addition, such steam will be smaller due to the higher evaporation rate. Of course, this is almost impossible to see with the naked eye, so you'll have to take our word for it.

Single lever taps

If valve devices are installed mainly in Turkish baths and showers, then for a hot and humid steam room atmosphere, a single-handle faucet is considered a more preferable option.

The valve design with a ball valve has its advantages:

- It is very convenient to open the water, especially if the container has to be held suspended;

- Insensitive to water temperature; faucet models specifically designed for hot water use special ceramic and fluoroplastic liners that practically do not wear out;

- The single-lever faucet does not leak, even when the valve is very worn.

For your information! Systems with one lever have the ability to stick to the inner walls of the case if the device has not been used for more than a year.

Features of cone plugs

The operation of a plug valve is generally elementary, which is why it is most desirable for inclusion in the water supply system in a bathhouse. It was created on the basis of an ancient samovar design. The spindle function is performed by a cone-shaped plug with a horizontal hole for water flow. We turned the faucet handle so that the hole in the plug coincided with the pipes, and the water flowed at full strength. We returned the handle to its place, the stream does not flow. Repair the plug valve by tightening the tension nut. It didn’t help, buy a new cone plug.

According to the requirements of GOST 6127-52:

- the body of the bath faucet must be made of cast iron;

- parts of the working unit made of steel alloys, malleable cast iron or bronze;

- handle made of wood or plastic so that it does not heat up in hot bath conditions.

The standard sizes of bath taps are designed to connect to pipes of 20 mm and 25 mm, which in inches will be 3/4 inch and 1 inch, respectively.

Variety of single-lever models for baths

When choosing a suitable faucet for a sauna, you need to pay attention to the correct design of the handle, the material of the product and the shape of the drain spout. These are three fundamental points on which the reliability and comfort of using a water shut-off device depends.

The most affordable models for single-lever saunas, made in China, are made of cast brass with a chrome or oxide coating, which makes it quite durable in sauna conditions.

An aerator is installed on the body spout of the FKS-272 model, which can easily be replaced with a fitting for a hose or extension. At first glance, it’s a small thing, but if someone has had to draw water from a tank over a hot metal stove, they will appreciate the innovation. The model costs about 30-35 dollars.

Turkish bath models, as always, are produced mainly in a stylized form. Often with imitation of gilding and the use of openwork casting. Such a faucet is of little use in a sauna, primarily because of the handle.

In saunas and steam rooms, experienced lovers of strong steam traditionally use sauna taps with a wooden handle.

This is the only correct solution, since the metal handles used with ceramic or polymer inserts burn your hands no worse than metal. The FKS-03 model costs only $65, it has a convenient design, but the handle clearly needs improvement.

Of those recommended for use in baths and saunas, we can note the Turkish model Sonder 001 BW, photo.

The RG-183 model with a handle lined with a wooden attachment looks good.

Cast iron, steel or stainless steel?

Quite a lot depends on the material from which the tank is made - both the rate of heating and cooling of water, and the durability of the tank itself.

Cast iron: hot water all day long

For a long time, the tank in the bathhouse was made of heavy cast iron - the water took a long time to heat up, a lot of firewood was consumed, but it was hot until the evening and the whole family could wash all day. In addition, cast iron is not afraid of either corrosion or high temperatures. But its considerable weight is, of course, an obvious drawback.

Stainless steel sauna tanks: lightweight and durable

But today, a stainless steel sauna tank is becoming increasingly popular - there is no need to isolate moisture from it, it has excellent thermal conductivity, and the deformation coefficient due to sudden temperature fluctuations is negligible and cannot be compared with the properties of ferrous metals.

The best brands for such tanks are 8-12X18H10 (304) and 08X17 (430), which are also used for making dishes. They are resistant to even extreme temperatures, hygienic and do not corrode or deform.

Such bath tanks are made from durable and thin stainless steel sheets, into which special ball valves are installed to enter and supply water. Caring for such tanks is extremely simple.

Enameled tanks - good if handled with care

Enameled tanks will also get rid of unpleasant rust. Their only drawback is possible chips, which will lead to corrosion. But they can be treated with special heat-resistant paint - unless the tank itself is inserted into the oven.

Mixer for baths and saunas

Separately, it is worth mentioning special double blocks of two taps, in design and principle of operation, reminiscent of household faucets for bathtubs and showers.

The main purpose of the mixer is to be able to regulate and select the water temperature. Often you need to wash off the shelves, or clean the floor in the steam room; you can’t do this with boiling water or cold water, so a good bathhouse always has a twin tap.

Unlike a shower device, a sauna faucet is equipped with only a small drain fitting, with which it is convenient to draw water into a container standing on the floor of the bathhouse.

If you are looking for a universal type of bath faucet, you can use the option with axle-box taps and a drain spout, similar to those found on kitchen sinks. This model can be used in almost any bathhouse.

An exception is the mixing taps for the Turkish bath - hamam. The device is no different from the model for a shower cabin; it has a more interesting design and a distinct stylization of an antique product.

Other fittings

There are several types of fittings, the main ones:

These models have one similarity - they are used to supply water. Due to the many differences, it is recommended that you carefully study the technical characteristics of each type of fittings before making a purchase.

Shut-off valves

Using a shut-off valve, you can shut off the water and remove the pipeline or plumbing fixture during installation and repair work. In other cases, the valve is closed.

The shut-off valve may be located:

The design of the shut-off valve resembles a spindle tap for a bathhouse. In this case, the shut-off valves can be movable or fixed, and the valves themselves can be straight-through, angular, or direct-flow.

Drain taps for water supply

In order to be able to completely empty the pipeline, a drain valve is installed in the water supply system. As a rule, in the summer, water is drained only after the end of the summer season; in winter, this procedure must be carried out every time the system is not fully used.

The drain mechanism is installed:

Often, solenoid valves are used as an alternative solution to the drain valve. Such options are much more convenient, since they can be controlled remotely.