If you initially plan to install a good stove in the bathhouse, then you do not need to think about purchasing a boiler for heating water. The heating unit already has a heat exchanger that acts as a heater, from which the liquid enters the tank intended for its accumulation. A rational design solution for such a furnace involves constantly filling the tank with hot water. If the bathing liquid is no longer needed, you can simply drain it. Thus, the functionality of a sauna stove with a similar apparatus is determined by the need to create heat for the entire sauna room and provide hot water to people who wash themselves.

Varieties

There are several types of heat exchangers for equipping sauna stoves.

Depending on the design features, the following types of devices are distinguished:

- Coil , which is a fairly simple option. Both ends of the heat exchanger are removed from the tank to take in cold water and release hot water.

- Connection of two metal containers : a cylinder and a parallelepiped. When heated, the liquid from such a heat exchanger flows through pipes to its destination.

The second version of the device is considered the most common, because with its help not only the water becomes hot, but also all the rooms of the bathhouse are heated. This saves fuel and, accordingly, money.

Depending on their location, heat exchangers are divided into the following two types:

- hinged , that is, located on the chimney;

- built into the furnace design.

The first type of unit receives the necessary heat not from the stove itself, but from the smoke duct due to the heating of the emitted gases. The spacious box helps to quickly heat the liquid in the tank. It remains hot throughout the entire heating time of the sauna. One of the disadvantages of the device is its massiveness. Sometimes, when installing a chimney, a so-called samovar-type heat exchanger is first installed, and then a chimney pipe.

When assembling a water circulation system, you should stop using plastic products in the steam room. The high temperature of such a room affects the plastic, as a result of which this material begins to release substances that negatively affect human health.

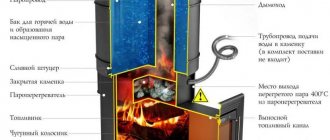

The heat exchanger built into the furnace design has the form of a sealed flat tank with a capacity of up to 5 liters. Two pipes with threads cut at their ends are welded into this tank. They are connected to water pipes leading to a large volume remote tank (up to 100 l).

In the furnace, the heat exchanger is allocated a place between the convector casing and the device for burning flammable substances. In this case, the device does not come into contact with fire at all.

Before starting to fire the stove, it is necessary to fill the system with water, since the heated dry heat exchanger, under the influence of cold liquid, loses its tightness and begins to leak. In order to prevent the appearance of air pockets in the system, water must be pumped from below using a pump.

Heat exchangers for stoves deserve a lot of attention because of their ability to save on fuel, because their normal functioning requires heat accumulated from the combustion of wood. Thus, a built-in type device is heated by the energy used to heat the steam room and stones. The device, placed on the chimney, is powered by heat, which is directed into the pipe. Its efficiency and heating speed are increased due to the larger capacity of the device. In this case, the tank into which hot water is drained can be placed at a significant distance from the heating device.

Installation of a boiler for water heating of a bath and pipe routing

The cast iron structure must be placed behind the firebox chamber. It will be heated not by the flame, but by the gas. To install the equipment correctly, we follow this procedure:

- We place the radiator on pre-made corners, maintaining a distance to the walls of about 5-6 mm. The gap will compensate for the thermal expansion of the structure.

- If the selected pipes for connection to the boiler have seams, then additionally weld them before installation.

- We connect the inch water supply and return pipes diagonally. In a place with a right-hand thread, simply screw in the product. On the left, we use a coupling with a squeegee and a nipple for fixation.

- We install the water supply pipe perpendicular to the floor at the top point, and install the return pipe in the underground space and connect it from below. This is necessary for improved circulation.

- We close the two extra holes of the product with a plug.

- When welding pipes together, we remove the chamfer along the cut contour to ensure that the weld seam fills the entire thickness with a high-quality weld and securely fixes the parts. If the steam room warms up infrequently in winter, you can add antifreeze to the system instead of water.

Advantages of sauna stoves with a heat exchanger

The unit is used both for heating water and for creating high temperature, as well as generating steam in the bath. Let's list some advantages of the device:

- Long service life (25 years).

- Significant space savings due to the ideal combination of heating device and heat exchanger.

- The water in the device heats up faster than the air in the room.

- The storage tank can be installed in the washing room at some distance from the stove.

Bath heating circuit

Pipe heating consists of the fact that the coolant (usually water), heated in a heat exchanger, circulates through the pipes and heats the room. It is worth saying that the bath tap for hot water can also be connected to this circuit.

Sauna stoves with a water circuit for heating are divided into two types:

- A circuit in which water circulates by gravity, without the use of additional forces - a pump. The movement is carried out due to the property of the liquid to move upward when the temperature rises - this is facilitated by pipes of sufficient diameter, welded into a closed system with a certain slope that ensures water circulation.

- A heating system where water circulation in pipes is achieved by a pump. Forced movement of the coolant is used when the system is long or the pipe cross-section is small.

The classic water heating circuit consists of the following components:

- Heat exchanger - a water tank or coil (tube system) located inside the firebox or outside the stove;

- Pipes connecting the system components;

- Radiators - placed on the walls, often under the window;

- Storage tank;

- Circulation pump (if necessary).

Features of the device

As mentioned above, a built-in heat exchanger is located between the convector casing and the firebox. In this case, exposure to open fire is excluded. The device with a capacity of 5 liters is capable of quickly filling a tank with a volume of up to 120 liters. The efficiency and correct operation of the device is ensured by the preliminary entry of water into the tank. After this, you can start lighting the stove. Failure to comply with the basic condition over time leads to the loss of tightness of the coolant and, as a consequence, its failure.

Installation requirements

The thickness of the water layer in the heat exchanger should exceed 4 cm, since with a smaller thickness the water will boil.

The walls of the coil must be at least 5 mm, and if coal is used, even thicker. Failure to comply with the thickness can lead to burning of the walls.

Furnace construction process

Under no circumstances should the heat exchanger be mounted close to the firebox wall. Leave at least 2 cm. This space is necessary for thermal expansion of the coil.

Particular attention must be paid to the fire safety of the system. There must certainly be air gaps between the stove and the wooden partitions, since overheating of wooden structures is the first cause of fires

It is best to line it with brick or other fire-resistant materials.

How to calculate the heat exchanger area

It is not uncommon for home craftsmen to undertake making such a device with their own hands. To do this, they should learn to calculate the necessary parameters related to providing the bath room with sufficient heat and the volume of hot water for washing.

When calculating the dimensions of the device, rounding is allowed. So, when installing a heating system with a power of 5 kW, you will need a device whose useful area is defined as 1 m². This example is quite approximate, since a device with similar parameters will also be provided with heat using a stove with a power of 9 kW. In this case, it is still better to calculate the size of the area, leaving some margin. During cooling of the unit, the power is significantly reduced, and the reserve allows you to maintain the temperature in the room until the next heating of the stove.

When choosing a heat exchanger, the last thing you should pay attention to is the shape of the device. There are no special requirements for this parameter, so you can safely rely on your imagination. Often, heat exchangers, like the pipe system, are made of stainless steel. This is a fairly durable and efficient material. The only negative is that some difficulties arise when performing welding work.

Several alternative options

Despite the fact that the options described above are the most popular and considered optimal, I decided to briefly mention some alternatives. In fact, they are varieties of stove heating, but have their own characteristics.

For example, if you have such capabilities, then you can install a diesel fuel boiler in your bathhouse. But this option requires a separate room (diesel fuel does not smell much), and you need to think about fuel storage.

There are also pyrolysis heating boilers. The undoubted advantage of such a boiler can be considered a very long, almost complete combustion of fuel. The disadvantage is the high cost and difficulty of operation (for example, raw wood does not burn in it).

It is also possible to use long-term combustion boilers, capable of burning a separate batch of fuel for up to 5 days, maintaining the desired temperature. There are even options for high-quality graded coal. But this is rather an “industrial” option, which is not suitable for a good traditional bath.

Ready-made devices with heat exchanger on sale

Traditional models of sauna stoves made of brick are gradually being replaced by more modern metal structures, characterized by an affordable price, high quality, compactness and perfect design. When choosing a worthy model, the consumer must know the volume of the steam room and water tank, as well as the power of the stove. We suggest considering the most popular models of heating devices for baths, equipped with a heat exchanger.

Furnace with heat exchanger “Vesuvius Skif 16 VChT”

This unit has sufficient power to provide high temperatures in the bath, the volume of which reaches 18 m³. A heat exchanger is built into the furnace body, which quickly heats the water in a tank located in the room adjacent to the steam room. Depending on the features of installing the stove in the bathhouse, the buyer himself chooses a unit with a left-sided or right-sided placement of the heat exchanger. This representative of the Vesuvius stove range is notable for the fact that stones are placed around its body in a special casing, creating the effect of brickwork. Almost all models are equipped with a heater installed on top of the unit.

The furnace firebox is made of high-strength high-quality steel, the thickness of which is 8 mm. Such material retains its characteristics and proportions of the device even at the highest temperatures.

The distribution of prices for Vesuvius Skif stoves can be seen in the table:

Unit "Tornado 20M2"

Thanks to its power, a model with a cast iron door is capable of heating a steam room with a volume of 20 m³. The distinctive features of the stove are the following:

- impressive dimensions and weight;

- heat exchanger built into the housing;

- powerful firebox;

- Large capacity side casing for storing 240 kg of stones.

The last structural element on the list performs two functions at once: it protects the sauna stove with a heat exchanger from overheating and effectively heats the filling of the side heater.

Due to the fact that the weight of the unit is 125 kg, which is a fairly significant indicator, before carrying out installation work it is necessary to lay the foundation, having previously calculated its required strength.

The cost of devices of this brand varies between 22-38 thousand rubles.

Harvia 20SL Boiler

The Harvia 20 SL Boiler stove-heater is a development by Finnish manufacturers of heating units for baths and saunas. The 75 kg model is perfect for heating a steam room with a volume of up to 20 m³. The optimal temperature in the room is also created due to uniform heating and smooth heat transfer from 40 kg of stones. A wood-burning heater is very popular among consumers, mainly due to the modern technologies incorporated into its design.

Bottom line

To provide heating for a home, several options are usually considered. Popular gas or electric equipment runs on expensive energy resources. The most economical type is heating and cooking furnaces with a water circuit. They are easy to build yourself, which results in noticeable financial savings. This type of heating involves a combination of traditional brick construction and modern technology. As a result, the home receives the necessary warmth and comfort. In addition to brick ones, they often make metal stoves with a water circuit with their own hands. By ensuring proper maintenance of your heating system, you can guarantee a suitable microclimate in your home for many years.

Installation of a sauna stove with a heat exchanger

- The unit is installed on a foundation previously sunk into the ground (40 cm). The constructed base should not protrude above the floor level.

- Around the stove, brickwork is made using clay mortar.

- The heat exchanger for the heating device is installed in the room adjacent to the steam room.

- A hole is made in the wall of the bathhouse to remove the firebox.

- Liquid is poured into the system, which is supplied through pipes wrapped with thermal insulation into a storage tank.

- A smoke channel is installed, the upper end of which passes through a hole in the ceiling and a metal sheet attached to it.

- The opening and all joints are thoroughly sealed.

Making a potbelly stove

Initially, it is necessary to draw up a drawing diagram indicating all the dimensions of the parts and prepare the necessary tools for performing metal work (welding, grinder, pliers) and materials.

After cutting the metal, the following actions are performed:

The main elements are welded at right angles: the bottom and walls. Except for the front.

It is important to know! It is recommended to install the bottom of the heating structure at a distance of at least 30 cm from the floor level. Installed metal legs will help reduce the strong temperature effect on the floor covering

The furnace space is subject to zoning, namely, a grate or a sheet of metal is welded between the firebox and the ash pit, in which backlashes are drilled to remove ash.

- It is necessary to make an opening on the front wall to mount the doors. Now the front part can be welded to the remaining elements.

- Hinged hinges are added to the sides, after which the doors can be installed according to the location diagram.

A chimney pipe must be welded at the top of the stove structure. After completion of the work, all seams are cleaned and checked for defects. The next stage is the installation of the water jacket.

Handmade production

To create a heat exchanger with your own hands, you need to stock up on metal sheets with a thickness of 2.5 mm or more. To equip a sauna stove with such a device, you will need the following set:

- tank built into the unit;

- water tank;

- pipes for connecting containers.

It follows that the heat exchanger for a heating device consists of two parts: an upper cylinder and a lower rectangle.

Having previously cut the metal blanks, they are welded. In this case, you need to try to connect the parts with the smallest gap. After the tanks are manufactured, the system is assembled. The choice of pipe diameter depends on the area of the room that will be heated. The length of the connection elements is no less important. The shorter the pipes, the higher the efficiency of the heat exchanger for a sauna stove.

Final assembly involves the following steps:

- A pipe is welded to the bottom of the apparatus.

- Through its hole, water is poured into a tank built into the stove.

- The rolled metal product is welded to the top of the heat exchanger.

The device is ready. The quality of all welding work can be checked using high pressure. To do this, you need a source of compressed air connected to the constructed system. If no leaks occur, then everything was done correctly. Otherwise, you will have to get rid of defects made during manufacturing.

A heat exchanger is a device that can be put into operation if it only heats water in a bathhouse. In the case of a full introduction of the unit into the heating system, it is necessary to take care of high-quality insulation of the room.

Making a steel stove-stove

The construction of a homemade sauna stove with a built-in heater and water tank is shown in the drawing. The design is quite simple - the body of the heat generator, made of an iron pipe, is divided into 4 compartments - an ash chamber, a firebox, a heater and a water heating tank. At the bottom of the firebox there are grates, between the remaining sections there are metal partitions crossed by a chimney.

The following materials will be used to manufacture the heater:

- pipe with a diameter of 400-500 mm;

- sheet metal 3 and 5 mm thick for partitions;

- fittings or corners for the grate;

- pipe Ø10-15 cm for the chimney.

Advice. For the body, it is advisable to find a thin-walled pipe (3-5 mm), since standard rolled metal with a wall thickness of 8-10 mm will be too heavy. The height of the stove can be adjusted due to the size of the heater, tank and firebox.

The procedure for assembling a heat generator with an integrated tank:

- Align the ends of the pipe with a grinder, cut openings for loading hatches and doors. Treat sharp edges.

- Place the cut pieces of metal on the doors - clean the edges, weld the handles and hinges.

- Make round partitions with holes for the flue. Make the firebox vault from 5 mm thick steel, the remaining covers from 3 mm sheets.

- Weld the grates from reinforcement Ø12-18 mm or angles No. 4-4.5.

- Mount all workpieces according to the drawing. Clean the welding seams and check for permeability using kerosene.

Equip the tank located on top with a convenient lid, cut a fitting into the bottom of the container and install a drain valve. It is better to reinforce the junction of the chimney and the firebox roof with stiffening ribs made of metal triangles, since this place burns out first. How to properly make such a stove, see the latest video:

What you need to know about using the device

An equally important task is choosing a stove equipped with a similar device. When considering different models, you need to be extremely careful not to miss the smallest nuances. We invite you to familiarize yourself with the basic rules that determine the safe operation of devices:

- Fastening due to movable joints compensates for temperature deformation and changes in the dimensions of the apparatus components during their heating.

- Net power is an important indicator that must be taken into account when making all necessary calculations.

- It is desirable that the dimensions of the heat exchanger correspond to the characteristics of the furnace. Only a tenth of the total heat generated in the heating unit should be allocated to perform the functions of the device.

- It is necessary that the remote tank contains as much water as can be heated in just two hours from the moment the stove is lit.

- All seals installed at the joints of system elements must be made of materials that are resistant to high temperatures.

There are few basic requirements, but compliance with them is mandatory when installing and operating the device. This contributes to a significant increase in the durability of the device.