Thermal and geometric errors made in the calculations of the chimney exhaust threaten problems in the operation of thermal power equipment caused by low draft. In this case, such a heating source will not be easy, and sometimes even impossible, to melt. A dangerous consequence of incorrect design calculations is the process of swirling in the flue ducts, as a result of which flue gases can enter the room, causing carbon monoxide poisoning in households. Before proceeding with the construction of the gas duct, it is necessary to perform calculations of the main construction parameters. The height of the chimney and its diameter directly affect the creation of draft in the combustion space.

Chimney requirements

A correctly calculated and installed chimney helps to comply with the maximum permissible concentration of harmful substances in the atmosphere. Without installing a chimney, it is impossible to divert fuel combustion products to the street so that they do not mix with the indoor air. The smoke exhaust system ensures safe and efficient operation of boilers by creating the necessary draft. Thanks to the chimney, people do not inhale toxic combustion products.

Only professionals know how to calculate a chimney, what technical nuances and rules for its construction must be observed. Therefore, when creating such a design, one almost never does without the help of specialists. After all, they will take into account all the requirements, which will guarantee the installation of a safe system that will operate effectively throughout the entire period of operation.

A properly constructed chimney will provide good draft. Its operation will not be negatively affected by:

- high temperatures during heating;

- settling condensate;

- aggressive substances, including soot, nitrogen oxides, sulfuric acid.

Effective smoke removal ensures comfortable and safe operation of boiler equipment Source userapi.com

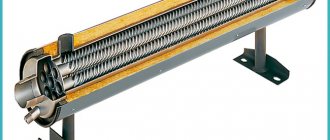

When installing boiler rooms in private homes, cylindrical smoke exhaust ducts are often used. Pipes with smooth walls are installed, which reduces the likelihood of soot accumulation. Therefore, they need to be cleaned less often compared to brick chimneys, in which local turbulence contributes to blockages.

Important! Modern chimneys for domestic boiler houses consist of separate ready-made elements. To properly configure the system, it is better to use the help of specialists. These may be employees of the design and installation organization or equipment suppliers.

The chimney installation is carried out in accordance with building codes. Therefore, the following requirements are met:

- The cross-section of the smoke exhaust pipe cannot be less than the same size of the boiler pipe.

- According to the regulations, it is allowed to create a chimney with only 3 turns. In this case, the radius of curvature of each of them cannot exceed the diameter of the chimney.

According to regulations, it is allowed to create a chimney with only three turns Source sense-life.com

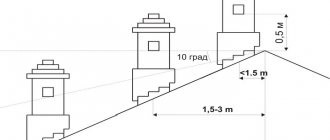

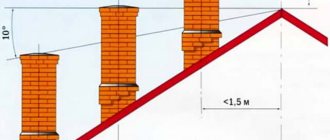

- When calculating the smoke exhaust duct, the height of the roof in relation to the height of the house and the rules for installing combustion product exhaust systems are taken into account.

- The manufacture of a metal chimney is made of alloy steel with a minimum thickness of 1 mm. In this case, only anti-corrosion metal is used.

- Be sure to create special pockets at the base of the smoke exhaust duct with a minimum depth of 250 mm. Soot accumulates in them. It is periodically removed during operation of boiler equipment.

Compliance with the basic requirements will ensure reliable operation of the chimney. By following the rules, there will be good traction in the channel.

Elastic penetration

Most often in private construction they are faced with the installation of round metal pipes. To ensure the tightness of the passage, a special device is used - an elastic penetration. This is a product made of high-strength silicone or rubber, shaped like a funnel with a wide flange in the form of a square or circle, called an apron. Thanks to its properties, the elastic penetration takes any shape, adapting to the angle of inclination of the slope. It can withstand extremely high or low temperatures, exposure to aggressive chemicals and comes in a wide range.

Installation diagram of elastic penetration

Elastic penetration on a metal chain

When purchasing an elastic penetration, they are guided by the diameter of the pipe and the color of the roofing material. Universal models, in the form of a stepped pyramid, are suitable for any size; adjustment is carried out by trimming the penetration to the desired level. Installing an elastic apron on the roof is very simple, you need to place it on the chimney passage, apply a metal circle with holes for fasteners, treat the joint with fire-resistant sealant and secure it with a screwdriver. For roofs with steep slopes, a special type of plastic penetrations with a specified flange mounting angle is used.

Selection of the optimal chimney

The optimal chimney option is usually selected at the house design stage during the development of the heating system. It is often also necessary to select a chimney after the construction of a building is completed. In any case, the construction parameters are taken into account. Be sure to take into account, for example, the height of a one-story house with a roof in the form of an attic or non-residential attic space.

When calculating a chimney, the height of the house is always taken into account Source myhome.ru

Chimneys for boiler rooms of private houses are made from the following materials:

- stainless steel;

- bricks;

- ceramics.

Each of the materials can withstand high temperatures and is resistant to aggressive environments and moisture. In addition, boilers in private homes can also be connected to concrete and even glass ducts to remove smoke. However, the latter option is still very rarely used. Although it is absolutely corrosion resistant. Asbestos-cement pipes are often installed. After all, this is a fireproof and environmentally friendly option.

When choosing a chimney, the personal preferences of the homeowner and the architectural style of the building are taken into account. In this case, you always have to first calculate the height of the roof ridge in order to determine the appropriate size of the chimney. In addition, they focus on the type and characteristics of boiler equipment. The following must be taken into account:

- pipe pressure;

- smoke temperature;

- presence of condensation;

- resistance of the chimney material to spontaneous combustion of soot;

- amount of combustion products;

- the height of the ridge of a gable roof or the standard distance from a flat roof.

Standard minimum chimney height Source genrealtor.ru

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

Previously, brick was widely used for the construction of chimneys. Now this is also a popular material. Moreover, many manufacturers offer brick and mortar. In addition, there are a large number of companies where you can order professional chimney laying. By choosing this option, the homeowner will receive a guarantee of quality. He does not have to worry about the integrity of the masonry, foundation and safety of the house.

A brick chimney is installed when installing a solid fuel boiler. If the masonry is done well, the channel can easily withstand high temperatures. It will not even suffer significant damage if the soot ignites. However, brick chimneys are not installed if the boiler runs on gas or liquid fuel. After all, the combustion temperature of such fuel is lower, and this contributes to the formation of condensation, which negatively affects the integrity of the masonry.

On a note! When installing a gas boiler instead of solid fuel equipment, a brick chimney can be upgraded to a new type of fuel. To do this, a steel pipe is inserted into the existing channel. The homeowner can carry out the adaptation at minimal cost.

Options for installing a chimney from a gas boiler Source in4o.ru

Ceramic and sandwich chimneys are also available today due to the presence of a large number of manufacturers on the market. When choosing smoke exhaust ducts from such materials, attention is paid to their quality and methods of fastening structures. At the same time, installation should be trusted only to professionals.

When installing gas, liquid, pyrolysis and pellet boilers, a ceramic chimney has recently been increasingly installed. This option is characterized by high strength, corrosion resistance and durability. It is no worse than a steel pipe.

A ceramic chimney is a multilayer structure. Inside it is a ceramic pipe. It is insulated with mineral wool. On top, the thermal insulation material is protected by a casing made of stainless steel or even foam concrete. Ceramic chimneys are more expensive and durable compared to other similar structures. Installation is carried out according to the manufacturer's instructions. Some ceramic chimneys require a reinforced base.

Construction of a ceramic chimney Source tildacdn.com

Important! Sandwich pipes for removing combustion products cost an order of magnitude less compared to ceramic chimneys.

Metal feedthrough

In hardware stores you can find another type of penetration for round pipes - a metal feedthrough. It is used to pass a chimney through a roof that does not have a relief. Finished alloy steel pipes have a standard roof angle, which is adjusted to the roof slope. To perform installation, you must:

Installation diagram of the passage pipe

Cut a hole of a suitable shape in the roof. To do this, markings are applied to the roof surface using a marker. Depending on the roofing material, cutting is performed with a grinder or sharp scissors, retreating 1-2 cm inside the circle.

- Remove the waterproofing and thermal insulation material from the hole made, freeing the passage for the chimney. If necessary, remove the sheathing elements by carefully sawing them off.

- On the underside of the roof, secure a sheet of fire-resistant material with a hole of the required diameter of such an area that there is a margin of 15-20 cm on each side of the chimney.

- Insert the pipe module into the hole, connect it to the laid chimney, tightening the connection with a clamp.

- Place the outlet pipe onto the pipe, securing it to the surface of the slope with fire-resistant sealant and self-tapping screws with a rubber cap.

- Add new segments to the pipe so that the height of the chimney exceeds the level of the ridge by 0.5-1.5 m.

Roof passage made of corrugated sheets

Some craftsmen prefer to use a different method - they solder a chimney pipe into the passage pipe in advance, line it with thermal insulating material, for example stone wool, and only then install this structure into the passage.

Calculation of the required chimney height

When choosing a chimney, its height is taken into account. To determine this parameter, a simplified calculation scheme is often used. However, before calculating the height of the chimney, you need to accurately determine the power of the boiler installation. Therefore, a boiler selection is always carried out first.

The combustion process in a furnace largely depends on draft. It also affects the efficiency of smoke removal. In this case, draft will be present in the pipe only with a constant supply of air to the boiler unit. Its entry into the equipment is carried out forcibly using a special pump or naturally.

Installation of the outlet box

The roof structure consists of layers of several materials, the fire-resistant qualities of which are expressed in different ways. While most roofing materials do not burn or support combustion, a rafter system traditionally made from wood does not have such properties. In order to safely remove the chimney pipe through any material, install a passage box:

Output box installation diagram

Exiting the pipe through an asbestos outlet box

- The first step is to purchase or make a box from a fire-resistant material, for example, metal or asbestos. The size of the box is selected in accordance with the cross-section of the pipe, so that there is at least 15 cm between their walls.

- After making the hole, a box is installed in it, the upper edge is aligned with the level of the roof slope.

- Exit the chimney through the hole in the passage box. The edges of the waterproofing film and vapor barrier are glued to the pipe using fire-resistant sealant and reinforced tape.

- Expanded clay is poured inside the box or stone wool is laid to thermally insulate the chimney. Thermal insulating materials are placed taking into account that they should not impede air circulation.

- The outside of the chimney pipe, depending on the shape and roofing material, is finished using an elastic penetration, a decorative apron or a metal pipe.

A high-quality chimney outlet does not spoil the appearance of the roof, does not allow moisture to pass through, and is safe from the point of view of fire safety standards. Follow the correct technology for passing tubes through ceilings to protect yourself and your property.

Video description

What traction is is described in detail in the video:

Calculation of chimney height for gravity drafting

Natural normal draft is created when there is a balance between its force and the resistance that arises when smoke moves both through the chimney and through the gas-water boiler channels. Therefore, gravity is formed at a relatively low chimney height. After all, only in this case will a slight gas resistance be created.

Important! When determining the height of a pipe, specialists use SNiP 41-01-2003.

Why are solid fuel devices considered?

It's simple - there are always more problems with them in these matters compared to gas ones. Let's explain why:

- First of all, gas heating appliances are almost always factory-made products. That is, they must have a pipe of a certain cross-section for connection to the chimney. The cross-sectional area of the channel is also specified in the technical documentation of the model. That is, everything is quite simple - it is not allowed to narrow the channel in any of the sections of the upward chimney.

Factory-assembled boilers or stoves always have a pipe for connecting the chimney. That is, there is no longer a problem with the cross-section of the chimney - it should be no less than that specified in the technical documentation.

- The temperature of the gas combustion products leaving the chimney is disproportionately lower than that generated during the combustion of wood or other solid fuel.

- It is also difficult to compare the volumes of gas mixtures formed during the combustion of “blue” and solid fuels. The difference here is quite significant!

But solid fuel heating devices, stoves or boilers, are very often created independently. Or they are “inherited” from the former owners of the house. And here it is never superfluous to check the parameters of the chimney connected to such a device.

However, what concerns the height of the pipe and checking draft can probably be fully attributed to gas heating equipment. The cross section is known, but it wouldn’t hurt to check the rest.

But let's start with the section.

Briefly about the main thing

Before calculating the height of the chimney, determine the material from which it will be made. They create a smoke exhaust system from bricks and sandwich chimneys; ceramic pipes with lightweight casings. In this case, the smoke channel is equipped subject to specific requirements:

- maximum 3 turns;

- diameter is not less than the boiler pipe;

- only alloy steel and at least 1 mm thick;

- presence of pockets for soot.

Typically, the height of the pipe is calculated using a simplified scheme, taking into account the distance from the smoke exhaust duct to the roof ridge. The chimney can be located above, below or level with it.

Ratings 0

A couple of tips

When the house has alternative heating, it also requires a chimney. But it is unprofitable to produce different smoke exhaust systems. It is easier to combine them into one, which will connect all the channels made taking into account such parameters as equipment power, amount of smoke and type of fuel. Such structures have a number of advantageous qualities:

- they save living space;

- all systems work stably;

- time, money and labor are saved.

But only specialists can calculate such structures.

Head design rules

What functions are attributed to this device:

- protecting the chimney from rain, snow, leaves and foreign objects, reducing the impact of strong gusts of wind;

- thanks to protection from moisture and wind, increased draft in the smoke channel;

- roof decoration.

If the roof serves for the outlet of several pipes , then identical heads will serve as a decorative detail and combine all the outlets into one ensemble. There are various designs of caps; they are intended for ventilation ducts and chimneys, but their protective functions are necessary for the normal operation of the heating system.