- Technological regulations

The location and height of the chimney pipe relative to the roof ridge directly affects the efficiency and safety of using the heating system. If mistakes are made during construction, comfortable operation of the house is simply impossible. That is why it is extremely important to determine the exact value before repair and construction work begins.

General requirements

Today, construction companies offer a huge number of architectural roof solutions. Naturally, all of them are carried out taking into account individual characteristics and prescribed standards. But when determining what height the chimney should be, there are conditions that are met regardless of which project is chosen.

Optimal length and diameter

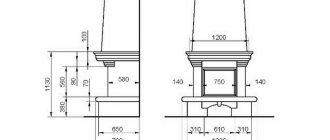

The chord of the smoke exhaust pipe must be greater than or equal to the Ø of the heating device pipe. Typically, this information is indicated by the manufacturer in the instructions that are attached to other documentation when purchasing a heating device. SNiP identifies the total length of the chimney as 5 meters and its elevation above the upper horizontal rib as 50 centimeters.

These requirements for the minimum height of the chimney pipe above the roof ridge must be observed. Otherwise, the use of the structure will be unsafe.

The smallest value does not have to be the real one. During construction this figure may be increased. In this case, operation is permitted and does not affect the reliability of the pipes, but at the same time the efficiency of the heating system decreases. The difference as a result can change by 20 or even 30%. The indicator is too high to simply ignore it, so during construction it is better to calculate everything in advance or stop at the rise recommended by the manufacturer.

Height above the ridge of a pitched roof

This type of roof requires a particularly careful approach to determining the correct size of the chimney. The fact is that the upper horizontal rib can become an obstacle to the free movement of air masses. Having encountered it, the wind will change its natural direction. As a result, the gas rising from the furnace will not be drawn out. On the contrary, it will return to the room, filling it. To avoid this, it is necessary to be guided by existing regulatory documents.

Diagram for determining the roof slope angle.

SNiP, in turn, prescribe the use of the following rules:

- If the gap between the chimney outlet point and the ridge is no more than 1.5 m in a straight line, then the height of the chimney above the roof should be 0.5 m.

- If the distance is in the range from 1.5 to 3 m, then the maximum point of the pipeline may coincide with the ridge.

- If the interval is more than 3 m, a special calculation is required. It is carried out individually by masters.

Correct sizing will allow you to use the heating system efficiently without creating additional problems.

Influence on the length of the furnace stroke of nearby high-rise buildings

As mentioned earlier, pitched ceilings themselves can become the strongest obstacle to the normal operation of the smoke duct. But besides them, tall buildings located near the house can become such a barrier. They also change the movement of air masses, making it difficult for the smoke to escape normally.

Calculation of the height of the chimney pipe above the roof should be carried out taking into account the surrounding architecture. For this purpose, specially developed schemes are used. It is better to turn to the experts for help. After taking measurements, they will prepare important recommendations.

Where it is not recommended to make a channel for smoke exit

To ensure comfortable and safe use of chimney structures, you should consider some general rules about where it is better not to install them. Among other things, architects advise avoiding installation in the following locations:

- In close proximity to the skylights. These structures themselves are complex and require the use of special fasteners during installation. The chimney can damage them, not to mention the fact that even a weak wind can blow gas waste towards the glass unit. Naturally, in such conditions you will not want to open them.

- On the inner corners of the roof. These areas of the roof are considered the most dangerous and short-lived, and repairs near the chimney are difficult and costly.

- When using several heating systems inside the house at once, it is not recommended to separate their chimneys. It is much more convenient and practical to remove waste through separate channels into a single wide opening. In this case, it is calculated according to an individual project.

Installation of the structure requires careful calculation. It is not always possible to do the work yourself, so it is better to get advice at the design stage.

Rules and nuances of planning

Calculations and construction alone are not enough to create a flawless project. After all, the vertical chimney channel crosses the interior spaces, which means it influences the layout.

Despite the desire to install it closer to the ridge, it is not always possible to implement the plan. It often happens that it has to be located at a considerable distance.

The location of the chimney inside the room and, as a result, the height of the outer section of the chimney is influenced by the following factors:

- Internal layout of the equipped box.

- Chimney type.

- Number of floors.

- Ease of installation of the smoke channel.

- Providing access for maintenance.

- A type of material used in the construction of walls and rafter structures.

- Number of units connected to one smoke channel.

Note that according to the rules for installing heating systems in private houses, a single unit must be connected to one chimney. Only in exceptional cases is it permissible to collect flue gases from two furnaces in one pipe. However, in such situations, for the proper operation of the combustion product removal system, a cut is made inside.

The stoves of two or three-story houses are located one above the other. Their chimneys are built so that they exit through one shaft. Naturally, only the stove pipe on the top floor can be perfectly straight. All the rest are performed by withdrawals. The slip slope is 60º, its maximum length is allowed to be no more than 1 m.

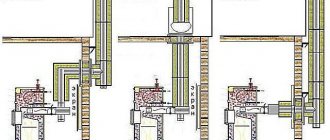

According to their structural type, chimneys are divided into:

- Wall. The most economical, easy to construct and operate option, installed in permanent internal walls. They are used in brick and stone buildings - where it is possible to lay a channel in a load-bearing wall.

- Indigenous. A variety constructed in the form of risers separate from the furnace. A more expensive design, but in some cases the only possible one. They are constructed if there are no technical prerequisites for constructing a wall channel. They are mainly used in the construction of chimneys in stacks folded with timber or logs.

- Mounted. The type of chimneys is placed directly on the ceiling - a reinforced concrete slab installed on the ceiling of the stove. They are used in small-sized buildings that dictate the need to save usable space.

Designers give priority to wall smoke ducts - risers, because... their construction is carried out during the laying of walls and allows saving an impressive amount of building materials. True, it is impossible to arrange them in a box without an internal main wall. But if there are prerequisites for construction, the wall smoke channel will be as close as possible to the ridge girder.

The wall chimney is laid using a buoy template, which is simply covered with brick around the perimeter. This is a kind of wooden box with a cross-section in plan equivalent to the cross-section of the smoke duct. Having reached the upper edge of the template during the laying process, it is moved higher and covered again. So until the construction of the load-bearing wall is completed.

Wall brick pipes are located mainly in internal main walls. This heats the house better and reduces heating costs. There are situations when wall risers are laid in external walls, but this solution is uneconomical and difficult to operate. When installing a chimney in an external wall, its thickness increases.

Naturally, the construction of a pipe in an external wall will force you to calculate the height of the chimney relative to the ridge using the methods described above. The height of the outer section of the chimney constructed during the construction of the internal main wall, according to standard rules, is half a meter.

It is important to remember that smoke channels in walls made of foam concrete blocks or sand-lime bricks are laid out only from ordinary solid red brick. This is subject to fire safety requirements. The same standards indicate the distances between chimneys and combustible structures.

You should retreat from an unprotected wooden ridge girder and rafter legs by 0.5 m, from protected analogues by 0.38 m. Metal pipes should be removed from flammable structures at a distance of 0.7 m or more. Fire regulations must be observed when determining the distance between the chimney and the wooden components of the rafter system.

There are no equally strict rules in the design of main and casing pipes. Their location is more focused on architectural and planning specifics, ease of installation and future maintenance. The location of the chimney relative to the ridge can be whatever the owner of the house prefers, but taking into account the requirements of firefighters.

The part of the chimney that rises above the roofing should be plastered with a cement composition. The thickness of the plaster layer should be 2-3 cm. Within the attic space, the chimney must be whitewashed so that the location of the gas leak can be quickly determined and the dangerous area can be repaired.

Channel requirements

The location of the chimney relative to the ridge is not the only issue during construction. It is important to take into account the recommendations and pay attention to the following:

- The material is selected depending on the fuel the boiler runs on. For a gas, stove or solid fuel unit, a stainless steel pipeline would be a good option.

- The number of heating devices should not exceed two per chimney. Otherwise, there is a high risk of incorrect diameter calculation. When using two heating devices, one type of fuel must be used, and the diameter of the pipes can be no larger than the chord of the chimney itself.

- It is preferable to construct a cylindrical or round pipe. This design allows you to create ideal draft, preventing smoke from returning to the room.

By following these simple rules, you can achieve efficient operation of your heating system.

More powerful means more

The productivity of a boiler or heating unit used for domestic purposes and heating is typically taken to be up to 7 kW. The throughput area of the chimney depends on the performance of the heating unit:

- heat generator up to 3.5 kW

–14×14 cm; - heat generator from 3.5 to 5.2 kW

– 14×20 cm; - heat generator from 5.2 to 7 kW

– 14×27 cm.

Smoke exhaust ducts are installed vertically. With no steps, no narrowings, made of solid annealed brick, with a wall of 12 cm. Also, this design is made of heat-resistant concrete with a wall of 6 cm, with the arrangement of technological niches, closed with doors 25 cm deep, which are needed for cleaning the pipe during operation.

The clearance of a round chimney should not be inferior to the throughput of the corresponding rectangular flue. Approximate ratios of internal dimensions to diameter are as follows:

- 140×140

mm – ∅ 160 mm; - 140×200

mm – ∅ 200 mm; - 140×250

mm – ∅ 220 mm;

Chimney Source idachi.ru

It is permissible to install smoke exhaust ducts from chrysalite-cement pipes, with a permissible internal temperature of up to 300˚ C. Prefabricated structures made of industrially produced stainless steel are also used. Metal chimneys are operated up to 400˚ C.

The use of asbestos-cement and stainless steel products in smoke exhaust lines for coal-fired stoves is strictly prohibited.

In multi-storey residential buildings, the installation of solid fuel heat generators is permitted. The heat generating unit must be connected to the chimney.

The internal clearance of the industrial smoke exhaust communication path for heat generators is taken to be at least 8 square meters. see 1 kW device.

Distance of the chimney from the ridge

To ensure sufficient draft, it is necessary to correctly calculate where to install the chimney duct. This takes into account the type of roof and the surrounding buildings. The flow of wind passing over the roof is of great importance.

Technological regulations

All rules and requirements for heating are specified in building codes. In particular, specialists are required to:

- The total length of the pipe was at least 5 meters from the grate to the outlet, with the exception of houses with a roofless structure. Otherwise, sufficient traction will not be provided.

- The height of the chimney above the flat roof was at least half a meter.

- The chimney outlet must be located no lower than the line of the top point of the ridge. In this case, it is necessary to maintain an inclination of 10 degrees relative to the horizon.

Graphic and mathematical methods

The most complex calculation option involves the use of this technique. It is usually used when the distance from the pipe to the ridge exceeds 3 m, although other situations also occur.

General provisions

The instantaneous throughput of the chimney determines how high the chimney pipe should be above the roof. Household heating units with a power of up to 7 kW are operated only at a height from the grate to the edge of the top of more than 5.0 m.

Communication smoke exhaust ducts are made without scuffing and gas-tight, from structural components that are resistant to mechanical loads, temperature changes, and resistant to the corrosive action of combustion products.

Insulation of chimneys where the operating conditions exceed 105 C is made from heat-resistant insulation. Source sl.aviarydecor.com

See also: Catalog of companies that specialize in roof design and repair.

The parameters of the cuts and offsets of the chimneys of heating units are used in accordance with the manufacturer’s technical regulations.

It is advisable to install smoke vents inside walls and partitions from non-combustible components. External walls made of non-combustible components are allowed to be used only when insulated to prevent condensation.

If it is impossible to arrange communication ducts for smoke exhaust in the walls, mounted and root pipes are used.

Root pipes are structures with their own foundation located not far from the heating unit.

Mounted pipes are installed on top of the heater. It is necessary to take into account the pressure created by the chimney. In earthquake-prone areas, the construction of mounted gas ducts is prohibited.

The gap between the chimney and the rafters, lathing and other parts of the roof made of flammable components is taken to be at least 13 cm, to uninsulated ceramic flues - 25 cm, and when insulated with heat-resistant or poorly flammable components - 13 cm.

The gap between chimneys and roof structures made of non-combustible and poorly combustible components is equipped with heat-resistant roofing materials Source skvb-nn.com

It is important to protect the chimney head from atmospheric influences. The protection must allow combustion products to pass freely.

The chimneys of units using wood and peat, on buildings with roofs made of flammable components, are covered with spark arresters made of metal mesh with a size of no more than 5 × 5 mm.

If the flue length is more than 1.5 meters from the roof plane, the chimney must be equipped with additional guys to resist wind.

Calculation of the parameter taking into account the wind support zone

This is the name given to an area where the air pressure is increased compared to the rest. The air masses here encounter an obstacle, which reduces the traction force of the chimney. In the worst case scenario, the treated gases begin to flow back into the room.

If such a situation arises, calculations must be carried out according to a different scheme. To begin with, a sketch is drawn that takes into account the height of both buildings. Next, the angle between them is determined.

What it is

During normal operation of the smoke exhaust system, gas generated as a result of fuel combustion is discharged outside. If the operating mode is incorrect, you may observe the opposite situation. The smoke does not go straight up through the pipeline, as it should, but down, it does not go out into the street, instead it pours into the house - that’s what reverse draft is. And it is not just an unpleasant, but a truly dangerous phenomenon, which, if neglected, leads to a fire hazard in the house, or even to severe carbon monoxide poisoning.

Pipe section

This design parameter is critical to ensuring the efficiency of the heating system. It is determined primarily by the shape of the chimney.

When using a classic cylindrical or round channel, it is enough to follow a simple rule: the cross-section of the pipeline should be proportional to the combustion chamber in the amount of 1 to 10. If a square shape is used during construction, the proportions should be 1 to 1.5.

If the requirements are met, the heat output will be sufficiently effective to ensure proper operation of the stove heating. In this case, the boiler itself will not be overloaded, working at 100%, but without wear.

Calculations of strength and stability of the structure

The regulations for gas boilers differ depending on the type of burner. The following standards and regulations apply to chimney systems installed on open-type boilers:

- the pipe has no more than 3 bends (45-90°);

- only non-flammable material is used;

- pipes must be protected with thermal insulation;

- a hole with a damper is provided through which the chimney is cleaned;

- the height and cross-sectional parameters of the chimney comply with the requirements recommended by the boiler manufacturer;

- there is another hole in the pipe to collect condensate;

- To protect the chimney from dirt, leaves, etc., a special umbrella is provided.

Requirements for chimneys on boilers with closed air exchange:

- the diameter of the outlet pipe is less than the diameter of the pipe itself;

- the minimum distance of the horizontal chimney from the ground surface is 2 m;

- the chimney pipe is located at least 2 meters from windows, doors, ventilation holes;

- the minimum vertical distance from the pipe to the window openings is 1 m;

- there should be no walls, fences or other obstacles closer than 1.5 m near the pipe;

- When installing, you should maintain a pipe inclination angle of 6-12° for natural removal of condensate.

It may be useful for many to know the requirements regarding chimneys for solid fuel boilers:

- it is allowed to use one outlet channel for two heating devices if the distance between them is at least 750 mm;

- pipes must be completely sealed;

- the optimal type of section is round;

- perfectly smooth inner walls (finished with galvanized or stainless steel).

Sandwich chimney installation diagram.

The draft is affected not only by the height, but also by the diameter of the chimney of the boiler room, the size of which depends on the amount of fuel burned per unit of time.

Depending on the dimensions of the smoke exhaust structure, the foundation is calculated, namely, it is determined:

- its design;

- required depth;

- sufficient sole area, etc.

The range of diameters of chimneys constructed of brick and reinforced concrete varies from 1.2 m to 9.6 m. It should be noted that the minimum diameter of reinforced concrete pipes is 3.6 m.

Important nuances of calculating a chimney

Even with the help of a seemingly simple formula, it is not always possible to achieve the desired result. During construction, it is necessary to take into account several more important details. One of them concerns the diameter of the outlet. If you select it correctly, you can achieve additional advantages:

- Reduce fuel consumption.

- Regulate the operation of the heating system.

- Ensure absolute safety.

When making calculations, it is necessary to take into account the material used and existing ventilation. It depends on them how well the exhaust gas will be removed.

How to calculate the height of the ridge of a gable roof

The height of the ridge of a gable roof is calculated in two ways: schematic and mathematical. The accuracy of the results obtained is approximately the same, since they are based on similar principles of trigonometry.

Both methods assume that the height of the ridge is determined by the known angles of the slopes and the length of the roof span.

Mathematical calculation is carried out using the formula c = a × tan b, where:

- C is the length of the ridge;

- a is half the span length;

- b is the angle of inclination of the roof.

The use of this formula is determined by the fact that the design of a gable roof is an isosceles triangle, which is divided by its height into two rectangular ones.

A schematic calculation involves constructing a triangle with a shape similar to the shape of the roof on a strictly maintained scale. The most convenient scale for drawings is 1:100, where 1 centimeter in graphical terms corresponds to 1 meter of real indicators.

First you need to draw a roof span line, which will be the base of the triangle. Then its middle is found, and the axis of symmetry is drawn from it. Using a protractor, the set slope angle is laid off from the ends of this line. In accordance with the marked angle, you need to draw a line. The point at which it intersects with the axis of symmetry will become the approximate location of the ridge.

NOTE!

The thickness of the ridge board and other additional elements installed in the upper part of the structure is added to the obtained indicators.

The distance from the base to the point of intersection of the axis of symmetry with the line of the slope is measured and converted in accordance with scaling into the actual height of the ridge.

Despite the possible errors associated with the inaccuracy of the completed drawings, the graphical method allows one to obtain good results.

Calculation of ridge height

Criteria for determining the height of the chimney above the ridge with a table

There are many conditions that must be taken into account in order to calculate the length of the chimney. Some of them are more important, others less. Here's what you should pay close attention to first:

- Where will the chimney be located relative to the ridge fin?

- What wind rose is typical for the area in which the house is built, how intense the gusts are at different times of the year.

- How much precipitation falls in the region and what form is dominant. Snow, or more precisely, the thickness of its coverage in winter, is of great importance.

- What angle of inclination of the ceiling is planned to be arranged.

- Are there any obstacles near the roof that could change the strength and direction of air flow?

All of these factors should be correlated with the type of fuel that is planned to be used for stove heating and other construction features.

| Distance of the chimney from the vault | Height of the pipe in relation to the roof |

| 150-300 cm | equal to |

| less than 150 cm | 50 cm higher |

| more than 300 cm | is a horizontal line drawn from the ridge and a straight line connecting it to the chimney, forming an angle of 10˚ |

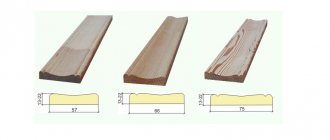

Types of pipes for stoves and fireplaces

The following types of chimneys are distinguished:

- Brick mounted pipes are massive objects resting on the stove masonry; they must be laid out at least half a brick thick.

- Root pipes are free-standing structures in the form of risers; they should be made from an asbestos-cement pipe with a diameter of 15-20 cm.

- Precast pipes are individual blocks made of heat-resistant concrete.

- Wall pipes are structures mounted in a solid load-bearing wall, which saves space in the room.

Obtaining high efficiency from a furnace with this type of pipe is not possible. If no other method of locating the wall chimney is provided, appropriate types of work are carried out to arrange a pilaster with a protrusion extending into the room. Installation is carried out with maintaining the required distances from the chimney to the outer wall:

- 2.5 bricks (from 20 to 30 - 650 mm);

- 2.0 bricks (from 20 and above - 510 mm);

- 1.5 bricks (from 20 and below - 380 mm).

The location of the chimney is determined strictly vertically without any indentations inside. If there is a bend in the structure, its dimensions should not be more than 1 m. A brick pipe often has an internal cross-section of at least 140x140 mm. Normal chimney draft is achieved due to a pipe height of at least 5 m. If it is less than 5 m, draft is provided using a deflector-diffuser.

Having equipped your house with stove and fireplace heating, you should install 2 chimneys. Different drafts of one of the sources can lead to smoke. In a wooden house, in places where there is an adjacent brick chimney, a thickening of 1-1.5 bricks is provided. A flammable structure near the chimney must be protected from it with asbestos-cement or metal sheets.

What is prohibited to do when assembling a chimney

Some actions when calculating the height and subsequent arrangement of the chimney above the roof are not recommended, so as not to create additional problems or emergency situations.

It is also not allowed to fix the chimney pipe to the rafters. The static position of the pipe is too easy to disturb, for example, when exposed to an intense gust of wind. If the chimney damages the rafters themselves, expensive and extremely difficult repairs will not be avoided. In the worst case, they will be completely destroyed, making it impossible to operate the house.

Supply and exhaust ventilation system

Technical documentation regulates the height of ventilation pipes above the roof of the building. SNiP and SP states: if the hood height is not regulated by the project, then the ventilation communication ducts are arranged in the same way as chimneys.

The height of the exhaust pipe above the roof located near the chimney is set at the same level with it Source dimari.stroimdom.com.ua

It is prohibited in houses with stove heating:

- use of forced

exhaust ventilation, without inflow compensation in the same way; - gas removal of combustion products into communication

ducts and the use of smoke removal systems for ventilation;

Height and cross-section - is there a connection?

The length of the channel and its diameter are directly related. It is their correct ratio that allows you to create sufficient draft to remove gas waste. A smaller chimney helps lower the air temperature, which means the draft force is reduced. On the other hand, a pipe that is too wide also contributes to the rapid cooling of the air flow.

The result of incorrect determination of parameters can be reduced draft, condensation on the surface and the impossibility of normal heating of the room, simultaneously with the removal of harmful substances. Consequently, much more fuel will be consumed in the heating process, and costs will increase significantly.

What is traction and what does it depend on?

The removal of combustion gases is carried out using the draft created in the pipe. Due to the constant movement of air, gases hazardous to human health are drawn out.

The draft force is directly dependent on the height of the chimney and the temperature difference in the pipe channel and in the open air. In the chimney, when the stove burns, a temperature of 200-250 degrees is formed. Due to the cooling of gases due to contact with the metal surfaces of the connecting pipe, the temperature in the draft stabilizer becomes slightly lower, and therefore a constant stabilized draft appears.

It must be remembered that vapor condensation should not collect in the chimney against the background of high flue gas temperatures. Moisture entering the pipe leads to destruction of its surface. This happens especially often in winter, when there is a significant drop in temperature. As a result of these processes, cravings decrease. The air leakage that occurs in the draft stabilizer helps reduce humidity.

With high humidity in the environment, as well as as a result of precipitation getting inside the chimney channel, the draft also decreases. An umbrella installed on top will help protect the chimney from them.

The chimney on the roof must be covered with an umbrella

You can determine the traction force using an ordinary match, brought to an open firebox, with the vent open and half-open. A flame drawn inward indicates good draft. When the flame deviates towards the room, there is a reverse draft. In such conditions, lighting the stove is strictly prohibited, as smoke and carbon monoxide will escape into the room.

This situation often occurs when the chimney is dirty or damaged, so regular cleaning, inspection and repair are required.

Chimney

When building a chimney, it is very important to correctly calculate all dimensions and select the right material. All these parameters directly depend on the fuel that will be used for heating.

A chimney made of brick is suitable for heating with solid fuel and gas. The height, its diameter and cross-section also need to be correctly calculated - this is the key to the normal and safe functioning of the heating system.

If the dimensions are chosen incorrectly, the efficiency of the heating device (appliance) will be reduced or the necessary draft will be absent, which can lead to undesirable or even tragic consequences for the residents of the house.

All these criteria are very important if smoke from not one, but two heating devices is installed into one chimney. In such a case, it is better to contact specialists to calculate the data, since you can make a mistake in one direction or the other.

According to the rules, one chimney can serve no more than two heating devices, provided that the size of the internal cross-section in total allows their simultaneous operation. The cutting channel should be about 70-80 cm high.

If the parameters are greater than required, the efficiency of the entire heating system will decrease. If they are not large enough, the draft will be small and carbon monoxide may begin to enter the premises, which can lead to irreversible consequences.

Which chimney is better

The best shape for a chimney is considered to be a cylinder. That is why even in brick structures, metal or asbestos-cement pipes are often built in, having the diameters required by calculations.

the ideal chimney shape is a cylinder (pipe)

Hot combustion products tend to move upward in a spiral path, and the cylinder is the optimal shape for this. Maximum thrust is generated precisely in such conditions.

Modern boilers operating on the “stop-start” principle cannot do without such a pipe. The main thing in them is to quickly warm up the system to the set temperature and switch it to standby mode, this is what saves the operation of the boilers.

In a pipe that has corners (rectangular or square), turbulence is created and draft activity is reduced. For fireplaces and wood-burning stoves - this form is acceptable and even gives certain “preferences” - it helps to slow down the heat output and increase the efficiency of the devices.

Thrust calculation

Any ventilation system will not be able to function normally without good draft, which is created by the difference in pressure inside and outside the room.

To calculate the draft of a chimney, you need to multiply the height of the channel by the difference in the density of the internal and external air.

The calculation is carried out using the following formula:

F= A(pв - pд)h,

- F – thrust;

- A – coefficient;

- pв – density of outside air;

- pd – density of flue gases;

- h – pipe height.

Example

When fuel burns in the firebox, heated gases are removed. Natural draft occurs due to the difference in temperatures inside and outside the room.

Air density and temperature are directly related

When calculating, dynamic pressure is not taken into account, since the process speeds are very low

All data is substituted into the famous Bernoulli equation. Next, the pressure loss values are found, then they are compared with the thrust parameter.

If the same indicators are obtained, further calculation does not make sense. The system will work normally, combustion products will begin to be completely removed.

If equality is not maintained, you need to increase the level of traction or reduce the number of losses. To implement the first method, you can:

- lengthen the chimney pipe;

- increase the temperature difference.

To reduce pressure loss, it is recommended to use the following methods:

- make the canal walls smoother;

- reduce the path of removed gases;

- reduce the number of turns;

- increase the cross section.

Using the same method, natural ventilation indoors is calculated.

Types of chimneys

The chimney is another functional element of the building, the location and height of which is regulated by building codes.

There are several ways to classify chimneys.

Chimneys are distinguished by location:

- wall (located inside the main walls);

- indigenous (not connected to the wall and located at a distance from it in the interior of the building);

- external (pass through the facade of the building).

The main method of classification is to distinguish types of chimneys according to the material of manufacture:

- Brick. They are fireproof and have high heat capacity, but their maintenance requires a lot of time and effort, and the draft of a brick chimney is relatively low.

- Steel single-circuit. Inexpensive and easy to maintain, but wear out quickly and require additional fire safety.

- Sandwiches. A more advanced and expensive version of single-circuit chimneys, where there is a layer of non-combustible material between the layers of steel.

- Ceramic. Fire-resistant, durable, easy to install and maintain, but very expensive.

- Asbestos-cement. The cheapest variation, but its performance indicators are low: asbestos-cement chimneys quickly become clogged with soot and burn out. To avoid a house fire due to soot ignition, you need to constantly clean your pipes.

- Polymer. Inexpensive, but not fire-resistant chimneys.

Types of chimneys

What should be the height

The height of the chimney above the roof requires special attention, since this is where combustion products pass from a closed and safe environment to the outside. If this height is not sufficient to safely cool the gases and mix them with air, a dangerous situation of combustion poisoning or even a fire may occur.

Design parameters for the location of the chimney on the roof

Another issue that deserves attention is the physics of the process of the emergence of natural draft. The fact is that, being in the chimney pipe, heavy air tends to rise upward, forming the physical phenomenon of draft

The more warm air, the more draft is created. The volume inside the pipe is affected by two indicators: internal volume and height.

Here it is worth achieving the “golden mean” indicator. Natural draft can lead to a significant increase in heat loss, since the exhaust will not have time to exchange heat with the internal volume. This is very critical for fireplaces and stoves that burn solid fuel.

Let's say you have a chimney about 4 meters high. Based on the above, the higher the chimney, the greater the draft, but it turns out that there is also a downside to this process - cooling. A tall pipe will cool faster and create an air lock with heavy cool gas, which will interfere with draft. The second negative phenomenon caused by abuse of the chimney height will be condensation.

Specialists calculate the height and cross-section of chimneys using special software products that are based on thermodynamic data.

Chimney size for gas boiler

Gas boilers come with open and closed combustion chambers. Units with a closed combustion chamber are equipped with coaxial chimneys. The rules for placing them are quite simple:

- The chimney rotates 90 degrees and ideally should immediately exit horizontally behind the wall

- The outlet should be made at a slight slope towards the street so that condensate does not enter the boiler.

- If the pipe is mounted vertically, then a condensate drain must be provided.

- The height of the chimney for a gas boiler with a closed chamber is regulated by each manufacturer in its own way, because the power of the smoke exhauster into the boiler may vary. Therefore, please read the instructions before installation.

- There is no need to install a chimney above the roof and ridge.

For boilers with an open combustion chamber, the height of the chimney is calculated similarly to the method described above.

Main types of chimneys

Common types of chimneys:

- Brick. As a rule, an asbestos pipe is installed in a brick shaft. The key disadvantage of a brick chimney is the need to install a foundation for it. In addition, this design impairs traction and also promotes the formation of debris and condensation products. This destroys the system and makes the room damp. The advantages are high heat capacity and fire safety.

- Ceramic. The most expensive and high-quality option. Made from fire-resistant ceramics. A layer of thermal insulation of non-combustible material is required. Pros: they do not require frequent cleaning, have smooth walls and a round cross-section (provides good traction), have high sealing and thermal insulation rates, are heat-resistant, durable, and easy to install. Disadvantages: the foundation is required and the high price.

- Modular made of steel. They are assembled from tees, adapters, elbows, etc. Stainless steel structures are often installed with brick channels (the aforementioned sleeve). However, you can install such a chimney separately. Stainless steel must be resistant to acids and be heat-resistant so that corrosion does not appear in the chimney (wall thickness is from 0.6 to 1 mm). Galvanized steel is not suitable because zinc quickly burns out at high temperatures. Disadvantages of steel structures - increased thermal conductivity leads to rapid cooling of gases, a large volume of condensate is formed, the service life does not exceed 15 years. The advantages are good traction due to the rounded shape, no separate foundation is needed, and no soot accumulation occurs.

- Corrugated steel. They are a flexible pipe made of metal tape. Used for lining brick structures with curves. Easy to install, but do not last long.

- Sandwich structures made of steel. They are two pipes inserted into each other. The area between them is filled with special non-flammable insulation. Cons: high cost. Pros: reduced thermal conductivity and slow cooling of gases, rapid smoke passage, minimum condensation, ease of installation.

- Asbestos-cement. Suitable if the resulting heating gases are not hotter than 300 degrees. Not suitable for standard ovens due to poor heat resistance. Disadvantages - fragility, lack of thermal insulation and unsatisfactory heat resistance, porosity, the need for frequent cleaning, weak rubber connection. Pros: lightweight, round cross-section, low cost and easy installation.

- Polymer. Manufactured from composite polymers. Used for lining channels made of brick or concrete. Due to poor heat resistance, it is not suitable for hot gases with temperatures above 250 degrees (furnaces). Only for geysers or boilers with increased efficiency. Disadvantages: instability to high temperatures, fragility, lack of thermal insulation. Pros: flexibility and light weight, low cost, long service life.

We hope the material was useful to you. As you understand, calculating the height of the chimney is quite simple. Apply these solutions and your home will always be warm.

Prevention and testing methods

We told you why there is backdraft in the stove and what to do to eliminate it, and now we want to share the secret of how to prevent its occurrence. There is no secret in this, you just need:

- clean the chimney in a timely manner;

- regularly heat the system so that it does not stand idle;

- eliminate sources of drafts in residential premises;

- monitor the condition of devices installed on the pipe.

We have already described the testing methods in the section on identifying the problem, so here we will mention cases in which it is worth carrying out tests with a candle, paper or an anemometer. This should be done when the house has not been heated for a long time, when there is (or has recently been) bad weather outside - heavy rain, blizzard, gusty wind, thick fog - and you want, for example, to light a fireplace. This is also true when the rooms are cold, despite the kindling, and when you suspect a malfunction.

And as a conclusion to the review of backdraft in the chimney and what to do when it appears, we offer a video - watch a useful video on this topic:

Types of chimneys

- strength;

- high heat capacity;

- safety.

- construction requires a long time and money;

- the clay used, due to its porous structure, is capable of accumulating condensate during operation, which subsequently leads to the destruction of the chimney;

- with careless bricklaying (the clay inside is not smoothed), the accumulation of soot accelerates;

- rectangular cross-section makes it difficult for smoke to pass through;

- difficulty in maintenance and repair.

Asbestos-cement

Such chimneys can be used at gas temperatures not exceeding 300 degrees. Advantages:

- cheapness;

- ease of installation;

- round section;

- relatively light weight.

- material porosity;

- not heat resistant;

- no insulation;

- it is difficult to make turning elements;

- needs to be cleaned frequently to remove soot.

Steel single-circuit

The best material for such chimneys is acid-resistant and heat-resistant stainless steel with a thickness of 0.6-1 mm. In reality, ordinary stainless steel and even galvanization are often used. The last one is the worst solution. Advantages:

- relatively low cost;

- ease of installation;

- round cross-section and smooth surface;

- light weight;

- ease of repair.

- there is no thermal insulation, which leads to rapid cooling and condensation;

- when passing through flammable materials, such as wooden floors, a large diameter indentation and insulation with asbestos fiber or other non-combustible material are required;

- relatively short service life (10-15 years).

Steel double-circuit

Double-circuit chimneys differ from single-circuit chimneys in that they are made of two pipes, between which there is a non-combustible insulation. Advantages:

- maintain temperature, the rate of gas passage is higher;

- requirements for internal installation are underestimated;

- Little condensation is formed.

very high cost.

Ceramic

The product on the market is relatively young, but has already gained popularity. It consists of three components: fire-resistant ceramics, non-flammable thermal insulation and a lightweight concrete protective box. Advantages:

- very high temperature resistance (withstands up to 1200˚C);

- round cross-section and smooth inner surface;

- tightness and thermal insulation at a high level;

- installation is quite simple;

- durability (ceramic pipe will last about 30 years).

Features of the chimney

Removal of gases through the channel will occur effectively only if the pipe is constructed according to standard dimensions and made of the correct material. These pipe characteristics are selected depending on the type of fuel; the material for the chimney is:

- refractory ceramic bricks;

- asbestos pipes;

- stainless steel;

- sandwich pipes with an inner layer of insulation.

Brick channels are made in the case of a stationary chimney. providing gas removal when heating with wood and coal

To determine the diameter and internal size, the boiler power and the dimensions of the firebox are taken into account. If the calculation is incorrect, reverse draft results or the useful effect of the furnace is significantly reduced.

For gas boilers, it is effective to use pipes with two walls. between which insulation is laid. The problem with a chimney for a gas fuel boiler is internal condensation, so insulation will help avoid significant temperature differences.

It is allowed to install one chimney for two operating heating units. if the internal size of the chimney, raised to the required height above the roof ridge, allows combustion products to be easily removed from both stoves. The cutting section pipe is about 0.8 m high.

A feature of the functioning of the chimney is that all overall, internal dimensions and height must be made with maximum accuracy. A wide and tall chimney, folded to a large height, with a low power of the heating unit, will reduce the efficiency. Insufficient dimensions will lead to smoke being sucked into the room, creating backdraft, and leaking dangerous carbon monoxide.

The warmth in the house depends on a well-designed heating system. But not a single stove or boiler will be able to cope with the task of supplying heat unless a technically competent chimney is made, raised to the required height above the roof ridge.

Dependence of draft on pipe height

The importance of the chimney in the heating system cannot be overestimated. Attempts to save on an extra meter of pipe will lead to cold walls during the heating season and excessive waste of fuel

The danger of carbon monoxide is that it is invisible and undetectable, but can be fatal.

Thrust occurs when heated smoke and gas with low density, in accordance with the laws of physics, rises upward. The result is a pressure difference at the beginning and end of the channel, that is, draft occurs. To ensure that the process is constantly repeated, cold oxygen is supplied through the blower. The greater the temperature difference, the stronger the thrust will be.

A narrow chimney of great height relative to the ridge will accelerate the smoke masses, thus reducing heat transfer. To maintain the desired temperature in the room, you will have to add fuel in excess of the norm. A wide channel of small height will allow smoke and gases to rotate arbitrarily in the pipe, their movement will slow down, and most likely a reverse flow of gases will result. Most often this happens in autumn or spring, when the temperature difference between outside and inside decreases and smoke, without overcoming resistance, is drawn into the room through the firebox.

Chimney location and height

To correctly select the height of the chimney relative to the roof ridge, you need to take into account the location of nearby structures. For an outdoor home, the draft indicators will be good, since there is constant blowing and pick-up of smoke masses. If we talk about a small building surrounded by high-rise buildings, then the length of the pipe should be increased. The height of the chimney depends on several factors:

- slope of the roof plane;

- location of the channel on the roof plan relative to the ridge;

- the location of surrounding buildings and trees;

- estimated thickness of snow cover in a specific area.

When installing a chimney, you should determine:

- elevation of the pipe relative to the roof ridge;

- the total length of the smoke channel from the stove;

- type and dimensions of the head;

- the height of the chimney relative to ventilation and windows of neighboring buildings.

The norms and rules for the construction of a chimney are prescribed in documents SNiP 41.01.03 and in building regulations under number 7.13130.09.