Construction of a bathhouse is a task whose importance is not disputed by any owner of a private or country house.

The main and most important part of the work is the creation of a reliable and high-quality foundation.

The choice of foundation type is determined by the size and material of the future building.

Most owners opt for a strip foundation, the most common and popular type among all available options.

Let's consider its features and construction order.

Why you should choose a strip foundation for a bathhouse

A strip foundation is a continuous strip of concrete located under all load-bearing walls of the building.

It occupies a leading position among alternative methods of building a foundation for a number of reasons.:

- First of all, it has a high load-bearing capacity with relatively low consumption of building material. If we consider the comparative need for materials of different types of base, the tape type represents the “golden mean”, optimally combining costs and results.

- The strip base has several options for creation and allows the use of various building materials. During construction, both monolithic concrete casting and ready-made blocks (FBS), brick or stone strips, and other methods are used.

- The depth of immersion in the soil can be either lower or higher than the winter freezing level, which allows you to choose the best option depending on the hydrogeological conditions of the site.

- The properties and features of a strip foundation have been studied better than other types of foundation; the design allows, if necessary, to carry out repair work, waterproofing or other repair and restoration work.

The design of the strip base is simple and understandable to all users. All these features together determine the primacy of the tape over other methods of creating a foundation .

Beginning of work

The first stage of any construction is always very interesting and enjoyable, since it does not involve hard work. At the very initial stage, you should just calmly walk around your own area and decide for yourself where you would like to see your cozy bathhouse. During this walk you will have to answer the following questions for yourself:

- What view would you like to see from the windows of the bathhouse?

- Where should the door from the bathhouse go?

- If in the future it is planned to build a swimming pool, how will it be connected to the bathhouse?

- If the bathhouse has a veranda, which side will it be located on?

- Depending on where your sewage system is located, you will need to remove wastewater from the bathhouse.

- If you plan to heat the bathhouse with wood, then immediately mark where the firewood box will be located.

Proper layout of the site is the key to your comfort

Advantages and disadvantages

The advantages of a strip base include:

- The cost of materials and labor is relatively low.

- The speed of work production distinguishes the tape from other types of monolithic base.

- The design of the tape is simple and can be created even by novice builders.

- The load-bearing capacity allows the construction of buildings of several floors.

- It is possible to build on different, even problematic types of soil.

There are also disadvantages:

- When calculating the depth, it is necessary to take into account the type of soil, which is best done in consultation with specialists.

- Construction will require preparation and considerable excavation work.

- After pouring, you will need to wait a certain time for the concrete to completely harden.

The disadvantages of a strip foundation are determined by its design and construction technology, therefore they are treated as construction features.

They do not create any fundamental difficulties, and the beneficial qualities of the foundation significantly exceed some of the negative aspects.

Areas of application of tape-type bases

Strip foundation diagram

Strip foundations have successfully proven themselves in the following works:

- construction of relatively light (frame, log) and heavy (cinder block, brick, concrete, stone, etc.) buildings;

- construction of buildings with a basement, underground garage and other similar premises;

- construction of bathhouses and houses with attic floors;

- performing construction work on sites with heterogeneous soil.

The base under consideration is almost completely universal - a concrete strip cannot be installed except on a peat bog or subsiding soil. Be sure to take this point into account when arranging your own supporting structure and familiarize yourself with the key requirements for strip foundations.

File for download: SNiP 2.02.01-83. Foundations of buildings and structures

General installation diagram

The use of wood is a traditional way of building a Russian bathhouse (6x6 or 6x4). The timber allows you to get strong and warm walls that do not have much weight and do not create excessive loads on the base.

This allows the use of a shallow version of a strip foundation, which requires less excavation and does not require a large amount of building material .

The only external condition for choice remains the hydrogeological situation on the site, soil composition and other conditions.

The configuration of the tape in plan follows the contours of the load-bearing walls of the bathhouse, as well as the internal walls that strengthen the structure and take on most of the loads.

The foundation for the furnace is built separately and is not mechanically connected to the common base.

To create the foundation you will need to perform a number of works:

- Site preparation. The top fertile layer of soil is removed and the site is leveled.

- Marking with pegs.

- Digging a trench.

- Preparatory work before installing the tape (so-called concrete footing).

- Installation of formwork.

- Creation of a reinforcing frame.

- Filling the tape.

- Exposure, removal of formwork.

IMPORTANT!

All work is carried out in the specified sequence and requires care and compliance with technological requirements. Any deviation or negligence leads to a decrease in the load-bearing capacity of the tape, fraught with destruction of the building.

Design

After determining the depth and type of foundation, design begins. This stage is not difficult, but you need to treat it responsibly, since the service life and quality of operation of the structure will depend on the selected values and methods.

Tape width

Determined by the following formula:

1.3x(sum of all possible loads)/base perimeter/soil resistance coefficient

The sum of all possible loads consists of:

- The so-called dead load is the total weight of the building.

- Payload – the weight of people, furniture, etc.

- Snow and wind.

- 1.3 – safety factor

Unknown average load values and soil resistance coefficient can be obtained from SP 20.13330.2010

In general, the width of the foundation strip for a bathhouse usually does not exceed 0.4 m.

Laying depth

It was determined above that the default basis for a bathhouse is a shallow foundation, the depth of which does not exceed 0.5 m . MZLF is used on such types of soil as sandy and clayey.

Reinforcement

When calculating, it is assumed that the reinforcement frame will have a three-dimensional structure, since the foundation experiences not only compressive loads from the weight of the building. Tensile forces due to soil deformation in winter are also possible.

Periodic profile products with a diameter of 8 to 12 mm are used as longitudinal reinforcement. Transverse reinforcement has a smaller diameter - from 6 to 8 mm. Can be smooth or periodic profile.

Reinforcement of corners and junctions should be done not just by overlapping, but according to special schemes, of which there are several options, but we will give one of the most popular:

Reinforcement of corners.

Reinforcement of T-shapes.

This stage of construction will be described in more detail in a separate chapter.

Concrete grade

Since a bathhouse is often a light-weight structure, it is not at all necessary to opt for the highest grades of concrete. The best option would be a mixture of the M250-M300 brand. The numbers in the article show the maximum weight in kilograms that can press on a conventional square centimeter of the base without causing deformation or destruction.

This is interesting! The higher the grade of concrete, the lower the ratio of the proportion of cement to the proportion of other components. For example, in M200 grade concrete the weight ratio (kg) is cement/sand/crushed stone=1/2.8/4.8. The M450 brand has a completely different ratio - 1/1.1/2.5. Accordingly, the more of the most expensive component - cement - in concrete, the higher the cost of the mixture itself.

Foundation for the stove

The installation of this element is carried out simultaneously with the manufacturing process of the strip base. The upper edge of a separate foundation, as a rule, is made “flush” with the plane of the tape. However, in some cases, at the discretion of the owner, the level may be higher or lower than the basic one. The size must exceed the geometric dimensions of the furnace itself by at least 150 mm on each side. The foundation for the furnace is separated from the main concrete mass by an expansion joint at least 50 mm wide, which is filled with sand. It is impossible to tie the stove base with the base of the bathhouse itself, because with a high probability they will settle at different rates.

Excavation

The first stage of excavation work is the removal of the top layer with simultaneous leveling (leveling) of the site. For this purpose, it is best to use a bulldozer, although for small buildings located on a flat area, manual preparation is also allowed.

The prepared area is carefully marked using wooden pegs. They are stuck at corner and intermediate points that define the contours of the future trench . After marking is completed, a trench is dug to the calculated depth.

The excavated soil is transported off-site or stored nearby for later use.

What influences the choice of foundation

This is not an idle question, because the foundation determines the load-bearing capacity of the entire structure. Therefore, it must be resolved before construction begins, because after the completion of construction work, adjusting something will be a big problem.

It is necessary to add the fact that the foundation structure allows the entire building to shift under the influence of various loads without violating the integrity of the structure. Therefore, before placing a foundation for a bathhouse, you need to choose its type and the materials from which the structure will be built. But this is just a consequence, and the reasons for the choice are:

- type of soil at the construction site;

- soil freezing level;

- ground water level.

To be more precise, these are three pillars that are taken into account when choosing a foundation. But there are a number of other minor factors that need to be taken into account. We'll talk about this below.

Types of soils for construction Source stroyfora.ru

Pillow under the foundation

After completing the excavation work, it is necessary to create a bulk cushion (concrete footing) that performs a drainage function. The pillow usually consists of two materials - river sand and crushed stone. First, a layer of sand is poured, the thickness of which is determined by the hydrogeological conditions of the site and the depth of the trench (usually 20-30 cm).

It is carefully compacted with water. A layer of crushed stone of the same thickness is poured on top and compacted as thoroughly as possible.

A leveling sand layer of about 5 cm is poured over the crushed stone, spilled with water and compacted again with maximum care..

CAREFULLY!

Poor compaction of the footing layer can result in subsidence of the backfill layer, sagging and destruction of the concrete strip.

Do-it-yourself strip shallow foundation for a 4x6 bathhouse

The main stage of building a foundation for a bathhouse is the calculation of materials and strength characteristics of the structure. And if it is quite difficult to calculate the strength, such calculations are carried out by professionals taking into account the density and humidity of the soil, climatic and other conditions, then it is quite possible to calculate the amount of necessary materials yourself.

Calculation of the quantity of materials

To do this, you need to decide in advance on the dimensions of the future structure, and then calculate the volume of the foundation using the formula from the school textbook.

When the volume is known, calculating the required amount of materials to produce the required amount of concrete mixture is not difficult, since there are many online calculators on the Internet that offer such services and with their help it is very easy to calculate a shallow strip foundation.

The next stage after the calculation is preparation for the work.

Preparatory stage

At this stage, it is necessary to clear the area for construction and prepare the tools. To make a strip foundation for a bathhouse with your own hands, you will need to have:

- Tape measure to measure the required distance;

- Construction level, to control the installation of formwork and leveling the foundation plane;

- Chainsaw, for sawing boards and making formwork;

- Screwdriver, for installation of formwork;

- Shovels for sampling soil and preparing batches;

- Electric or mechanical concrete mixer;

- The necessary materials - sand, cement, crushed stone and rubble stone - must also be prepared in advance.

Marking the foundation for a bathhouse

Marking the location of the foundation is one of the important stages in the process of constructing a foundation for a bathhouse.

To carry it out, you will need to prepare a sufficient number of wooden pegs that will mark the corners of the building. After the pegs are prepared, you can proceed directly to marking. First you need to determine the position of the foundation relative to other buildings located on the site. Then the first side of the building is marked and pegs are installed to mark its boundaries. Next, a distance equal to the second side is set aside from the pegs. This distance must be temporarily marked by placing pegs by hand so that they can be easily removed and moved.

Now that the distance of both sides is known, you need to align the diagonals. To do this, the diagonals are measured one by one and the stakes are transferred. After the diagonals are aligned, you need to once again check the length of each side.

Important: in no case should you neglect the equality of the diagonals, because if this requirement is neglected, the foundation will have the shape of a rhombus, therefore, the angles of the building will not be 90°. In the future, such structural irregularities will be reflected when laying the frame and building the roof.

After the external marking is completed, it is necessary to carry out the internal marking. To do this, a distance equal to the width of the future foundation is measured from each side and the string is pulled.

Soil sampling

To organize a shallow foundation, it is not necessary to select soil to a great depth. The planting depth is not important; the main thing is to equip a sand cushion under it to compensate for heaving of the soil, and also to arrange a warm blind area around the foundation. The width of the blind area should be equal to the depth of soil freezing in the place where construction is being carried out.

sand cushion

To make a cushion, sand is poured onto the bottom of the trench, after which it must be leveled and compacted. The layer of sand should be at least 15 cm. For better compaction, the sand in the trench should be poured generously with water and compacted again.

Installation of formwork

Before pouring the foundation for the bathhouse, it is necessary to set up the formwork. For a shallow foundation, it can be made from edged planks. To do this, it is cut into pieces of the required length, equal to the length of each side. Then, using a hammer and nails, shields are knocked together from identical sections of boards. It is convenient to use short pieces of plank as jumpers for panels.

It is necessary to prepare shields both on the outside and on the inside. Once they are ready, you can install the formwork according to the dimensions indicated by stakes . First, the outer side is exposed and secured with wooden stakes and spacers, then the inner side. To fix the width, both sides of the formwork are fixed to each other at a certain distance using a transverse strip and self-tapping screws. This must be done in several places.

The last stage of preparing the formwork is the upper level of concrete pouring using a string stretched along the entire length of the formwork . Of course, many people ignore this process due to the fact that the load on the foundation is small. But the technology involves strengthening the foundation with reinforcement in order to reduce loads and increase the strength of the structure.

Read how to knit reinforcement correctly here.

Preparing concrete and pouring strip foundations

As a rule, depending on the required strength of concrete, the proportion of the mixture of sand, crushed stone and cement can vary significantly. To select the strength and, accordingly, the grade of concrete, it is necessary to calculate the weight of the future building. The weight of a wooden bathhouse is small - concrete grade M100 is suitable (the marking of concrete means the weight that it can withstand per square centimeter in kilograms).

The proportion for preparing concrete M100 is as follows: 1 kg of cement, 5 kg of sand and 7 kg of crushed stone. For the convenience of preparing the solution, you can weigh one shovel of each component in advance and convert the proportion into the number of shovels. This will allow you to make batches much faster.

To prepare the mixture, it is advisable to use a concrete mixer and prepare the mixture according to the following algorithm:

- The required amount of water is poured into the concrete mixer;

- Cement is poured and mixed;

- Next you can add sand and crushed stone.

This order allows you to mix the solution well and avoid cement sticking to the walls of the concrete mixer. It is better to use a construction trolley to transport and pour the mortar into the formwork. Pour the solution directly into it and then spread it over the formwork. Concrete must be poured as carefully as possible, trying to avoid crushing the formwork.

To save material, rubble stone can be added to concrete as a filler.

You can fill the foundation in parts , the main thing is to adhere to several rules: Fill the next part with a break of no more than 8 hours in winter, 4 hours in spring or autumn, 3 hours in summer. If you do not have time at this time, then wait until the concrete has completely set, this is at least 3 days. It is advisable to cast in layers using good vertical reinforcement. If you have not calculated the amount of concrete, leave a 45 degree bevel to increase the bonding area. The next steps will be waterproofing and insulating the foundation.

How to correctly calculate the depth and width

A complete foundation calculation is a complex engineering task, accessible only to a trained specialist.

It is required to perform a comprehensive study of the soil, calculate the weight of the bathhouse without and with a foundation, and take into account a large number of special quantities, coefficients and indicators.

For outsiders who do not have the appropriate education and experience, such a calculation will not be possible.

The solution to the problem will be to contact specialists who professionally deal with such calculations. This option is optimal, but will require certain financial investments.

Another possible way is to use online calculators, of which there are many on the Internet . The results obtained using this method must be duplicated on other resources in order to be able to check the data obtained and select the most reliable values.

Wooden log bathhouse: pros and cons

A log bathhouse is a classic Russian version; such buildings are being built in all regions of our vast country. The popularity of wooden baths partly depends on the fairly economical material, which is not in short supply throughout Russia.

The advantages of wooden baths include environmental safety, quick heating of the washing and steam compartments; efficiency and speed of construction (a log bathhouse is easy to build with your own hands).

There are also plenty of disadvantages to wooden baths: the log house has significant weight, there is a high risk of fire and the occurrence of foci of biological damage (rot, mold and fungus can render a wooden building (log bathhouse) unusable in a very short time).

In order for a bathhouse built from logs with your own hands to serve for many years, it is necessary to carefully construct a support base that can withstand the loads from the weight of the bathhouse, the water boiler, the weight of human bodies, snow loads in winter and other factors affecting the foundation.

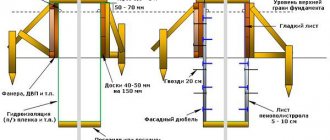

Installation of formwork

To create formwork with your own hands, edged boards with a thickness of 25-40 mm are used.

There are other materials, but wood is more accessible, cheaper and easier to work with . In addition, after completion of the work, the boards can be used for other purposes.

The thickness of the boards directly depends on the height of the tape.

The formwork is assembled in stages:

- Assembly of shields. The height is 5-10 cm greater than the height of the tape; the length of the boards is determined by the length of the walls or the size of the boards.

- Installation of shields in the trench. They are fastened together by support strips that determine the thickness of the future tape. On the outside, the shields are reinforced with supports that prevent the mass of concrete from pushing the walls of the formwork outward.

- If the boards are low (up to 20 cm), supports can be omitted, securing the walls from the outside with pegs.

NOTE!

When assembling the boards, gaps between the boards should not be larger than 3 mm (ideally, there should be no gaps at all). If gaps appear, they are filled with tow or slats.

The installed formwork is a structure whose interior is the exact shape of a concrete strip. After assembly, all dimensions should be checked to eliminate the possibility of errors.

Nothing can be corrected subsequently, so the assembly process must be monitored with the utmost care.

How to make a foundation for a bathhouse from timber

The construction of a shallow strip foundation is associated with certain time and financial costs. A large volume of concrete mixture is required to form a belt with suitable overall dimensions.

As an alternative, we can consider a columnar base consisting of concreted asbestos pipes with a diameter of 25–30 cm. The supports are placed in the ground to a depth below the freezing level of the soil. Usually 2 meters. This prevents damage to the mounted frame and foundation due to soil heaving.

Installation work is carried out in the following sequence:

- The site is being marked. Mark the points where the supports will be located;

- Wells are formed for the subsequent installation of support elements. For this purpose, a hand-held drilling tool is used;

- Pipes are inserted into the prepared wells;

- Reinforcement is being done. To do this, at least four 10 mm thick rods are inserted in the center of the pipe;

- M300 concrete mixture is poured. Without waiting for the composition to completely harden, a steel pin is installed in the center. The latter is made from a rod with a diameter of 40–50 cm, on which a thread is cut. This is necessary for subsequent fastening of the grillage. The stud should protrude above the surface by the thickness of the grillage. The part located in concrete must have a length of at least 20 cm;

- The prepared supports are tied with a grillage, for the formation of which a beam with a cross section of 150 by 200 cm is used. Before installation, the beam is cut to size. Groove joints are formed at the joints. Through holes are formed for the pin;

- The strapping is laid on supports, ensuring alignment of the pin and the prepared holes. A nut is used to secure the grillage.

Selecting reinforcement and its diameter

Selecting fittings is a procedure that in any case will have to be done independently. If concrete or other material can be purchased ready-made, the frame of the tape is made on site, so you need to choose the best option.

There are two types of reinforcing bar:

- Traditional metal rod with fins.

- Composite reinforcement made of fiberglass or other similar material.

Composite reinforcement is 9 times lighter than metal. In addition, it is approximately 20% cheaper, which gives it a significant advantage. But metal rods are capable of bending, which fiberglass does not allow.

In addition, the coefficient of adhesion of fiberglass to concrete is lower than that of metal. If you plan to assemble the frame using a welded method, it is possible to use only the metal type.

The consumption of reinforcing bars for foundations is high, so the opportunity to save is seen as a big advantage. If you plan to assemble the frame using the knitting method, and there is no need to bend the rods, the best option would be to use a fiberglass rod.

For a bathhouse, the recommended diameter is 10 mm, if the structure is large - 12 mm.

Installation of formwork

Regardless of what type of foundation you choose, you will need to install wooden formwork. The only exception to this rule can be the installation of concrete piles - they can be installed directly into the hole and filled with concrete. But if you choose, for example, the strip method, you will have to purchase boards and nails to create formwork panels. If you have old strong boards on the site, then they can be used for this work.

The formwork should be made smooth and neat

It is necessary to put together shields of such width that they go the entire depth of the trench and rise above it at a sufficient distance. To do this, you need to calculate this width as follows:

Add 25-30 cm to the depth of the trench or hole - it will be approximately 60-70 cm.

This width is quite enough to get a reliable and high-quality foundation that will be suitable for any bathhouse. It is better to do this option right away, because during the construction process you may want to add a second floor or attic to the bathhouse, and this foundation will withstand such a load. After the shields are ready, they must be carefully installed in the trenches and special wooden blocks must be secured between them so that the shields stand perfectly level. When laying, it is necessary to ensure that there are no large gaps in the structure.

The neater your foundation is, the better the quality of the entire structure will be.

Foundation reinforcement and reinforcement tying

The reinforcement cage is designed to compensate for the tensile forces that the tape experiences under bending load. Concrete can easily withstand high pressure, but it cannot work in tension, so installing reinforcement is a necessary procedure.

The frame design is a spatial lattice, the main elements of which are longitudinal rods. They are held in position by vertical rods of smaller diameter with a smooth surface . They are needed only to support the main rods until pouring.

The frame is connected by welding or by knitting with annealed steel wire. Welding is not always available, but knitting provides some elasticity to the structure, which allows it to maintain its integrity with small movements.

The knitting process is not complicated and does not require much time, but it does require some skill..

Preparatory stage

First you need to decide where the bathhouse will be located. You should study the landscape and choose the future type of sewer system. For example, a cesspool and a septic tank should be located away from water intake points, water sources and neighboring properties. If the bathhouse drain is connected to a centralized sewerage system, the bathhouse can be built in any area of the site. If there is a river, pond or pool nearby, then the distance from it should be about 30 meters.

It is recommended to decide at the preparatory stage how you can hide the area around the bathhouse from prying eyes. If a fence is installed, you need to make preparatory markings. The same should be done if trees or shrubs are planted.

At this stage, you will additionally need to remove the top layer of soil and level the area. Most likely, this will require special equipment.

Pouring the foundation

A sand-cement mortar is used for pouring. You can make it yourself, but most builders prefer to use ready-made mortar delivered directly to the site in a mixer.

It is necessary to use concrete grades M 200 or M 300. The best option is to pour the entire strip at once, which makes it possible to obtain a monolithic foundation with the same properties along the entire length.

You cannot pour material into one place, expecting it to spread along the entire length of the tape. It is necessary to pour at several equidistant points, this will speed up the work and ensure a uniform structure of the concrete.

If pouring concrete for any reason was interrupted for more than a day, it can be continued only after the previous portion of the material has completely hardened.

The surface of the poured tape must be leveled with a rule or a spatula . Drying must be done under a layer of polyethylene, with watering every 4 hours for the first 3 days. Then, for 7 days, watering is carried out 3 times a day.

The formwork can be removed after 10 days, and complete drying is considered completed after 28 days.

Screw pile foundation

If the building site has weak soils, a high level of groundwater and deep freezing of the soil in winter, it is best to build a pile foundation of screw support elements under the log house of the bathhouse.

The foundation on screw piles is excellent for heaving soils

The helical support is a hollow metal rod with welded (or cast) blades and a pointed end.

The piles are easily screwed into the ground with your own hands using a special device threaded into a hole in the upper part of the rod, so this foundation for a bathhouse can be built without the involvement of expensive installation equipment and qualified specialists.

A log house for a bathhouse can be erected on a site with difficult terrain, immersing the screw supports to a considerable depth. The core of screw piles can be easily extended to the required length, so the support can be easily screwed deep enough so that the ends of the piles rest against soil with a high load-bearing capacity.

The use of piles in wet soils is also possible, but in this case, the supports should be treated with anti-corrosion compounds before screwing in, because any scratch on the metal can cause rapid corrosion.

A pile field of screw supports for a bathhouse frame is erected in a fairly short period of time.

Technology for constructing a foundation from screw piles

Before you start screwing the screw supports into the ground, you should clear the area of debris, uproot trees and shrubs, carefully selecting the roots. It is very important that the trees growing next to the building do not damage the root system of the piles immersed in the soil. Uprooting trees and shrubs is usually easy to do with your own hands.

Proper marking is one of the keys to the reliability of the foundation

Then they begin to mark the places for screwing in the piles, for which the perimeter of the future bathhouse is marked on the site, for which pegs are driven into the corners of the building, along which the cords are pulled. It is absolutely not difficult to do this work with your own hands.

After marking the pile field (screw supports are installed under external and internal load-bearing walls, under stoves, boilers and hearths that have significant weight, it is worth installing separate foundations), they begin to screw in the piles. Two people drive the pile into the ground by rotating the device in the eye clockwise.

To more accurately hit the center of the marking, it is best to first dig pits, the depth of which can be up to 0.5 m. The vertical position of the support is determined by the third worker, carrying out the necessary control using a level.

The piles are screwed: what to do next

When all the piles are immersed to certain marks, supports of different heights with eyelets remain above the ground. It is necessary to cut all piles to the same height, monitoring this process using measuring instruments. Hollow supports can be easily cut with your own hands using a specialized power tool.

The internal cavity of the screw piles is filled with concrete mortar, which must harden within a few days. Until the mortar inside the rod gains strength, it is best to suspend other work on the foundation supports.

After the concrete has completely hardened, you can begin installing the headers, which are welded to the top of the supports; they serve to protect the metal rods from moisture penetration. The piles are tied with timber or a channel - the grillage combines the supports into a single foundation belt, which guarantees a more even distribution of the load on the ground.

A log bathhouse on a pile foundation can be used for up to 50 years.

Watch the video to see what a log house on a screw base looks like.

Waterproofing

There are many ways to waterproof a strip foundation. The most popular and simplest option is to apply hot bitumen or ready-made bitumen mastic, which does not require preheating.

The material is applied in at least two layers. Additional waterproofing is often used using roofing felt, densely distributed along the internal walls of the formwork before pouring . The main task is to ensure complete tightness of the waterproofing layer, continuity and uniformity of application of the material to the surface of the foundation.

Briefly about the main thing

More often, a strip foundation is erected under a bathhouse. Moreover, it can have a completely monolithic, prefabricated or prefabricated-monolithic structure and differ in its depth.

Often a strip shallow foundation is created for a wooden bathhouse. Any type of such base is distinguished by good load-bearing capacity, quick installation, and low price. The type of strip base is selected for the specific soil.

The creation of a foundation is accompanied by excavation work, backfilling of crushed stone and sand, creation of formwork, installation of reinforcement, and pouring of concrete. Finally, waterproofing and backfilling are carried out.

Ratings 0

Foundation height

This indicator is determined from the planning level of the ground on the site where the building is located. The minimum height of the strip foundation of a bathhouse, the walls of which are made of wooden beams, must be more than 250 mm. This is necessary to protect the enclosing structures from moisture. Knowledge of this parameter in combination with the laying depth will allow you to accurately calculate the strip foundation of the bathhouse and establish the required amount of materials.

For heated premises, the height of the base must be sufficient to ensure comfortable conditions for people, eliminating the possibility of drafts. The floor level in a bathhouse with a strip foundation is set along the upper edge of the supporting structure or plinth, if there is one. A higher base height will reduce the influence of the ground and make the room warmer.

Creating formwork

Formwork can be made from panels, boards, slate, fiberboard and other similar materials. It is worth noting that plastic and steel panels can be rented, which to some extent will simplify the work of constructing the formwork. It is best to wrap the selected material in polyethylene so that it can be used again when constructing other objects.

The formwork is installed inside the trenches, the outer part of which is supported with polymaterial and stakes. Transverse struts made of wood and metal studs are inserted into the spaces between the walls of the formwork in increments of 50 centimeters. This is done so that due to the mass of the solution that will be poured, the shields do not move apart. The shields need to be fastened to the ground; 20-centimeter nails are suitable for this; they can be fastened together with self-tapping screws or a stapler.

Holes for sewer pipes and other communications in the panels must be made in advance, otherwise after the concrete hardens it will be necessary to drill it, which will have a bad effect on the strength of the foundation.

It is worth noting that if you do not use film to protect the wooden formwork, use glassine and attach it with a stapler. It will not allow moisture from liquid concrete to quickly absorb into the wood, thus preventing the finished foundation from cracking.

Holding the foundation for settlement

The time required for concrete to completely harden is at least 24 hours. During the construction of a strip foundation for a bathhouse, it is necessary to take into account that the structure must be maintained for a certain period. The drying time depends greatly on the ambient temperature and the presence of winds. The mixture gains brand strength in about four weeks at 20 °C.

To protect concrete from drying out, it is recommended to cover it with sawdust and moisten it with water. Once the foundation is ready, the formwork is removed and the foundation is backfilled with soil to the planning level. To receive professional advice on how to properly install a bathhouse on a strip foundation, you should contact the specialists of our company.