Since the bathhouse has its own specific operating conditions, the requirements for the supporting structure are special.

The article will present arguments in favor of one or another type of foundation for a bathhouse. The reader will also learn how to design and calculate the support base of a structure, what preparation for construction involves, how to build different types of foundations with your own hands and how much it will cost.

Which base is best?

A sauna measuring 4 x 6 meters in plan is one of the most popular home sauna projects. A compact budget building will fit on the smallest plot of land.

The choice of foundation type depends on factors such as the characteristics of the soil foundation, the complexity of the work and the cost of constructing the supporting structure.

On solid soils, a strip foundation would be the best option.- If the task is how to make a foundation at a lower cost, then install columnar supports.

- In order not to risk the first two options, piles are driven on loamy soils, which, after passing through weakly bearing soil layers, reach a solid soil base.

- In the case of building a bathhouse on a peat bog or swampy soil, a monolithic slab is erected, which, holding the entire structure on itself, will “float” on the surface of the earth.

In the process of designing, calculating and comparing various foundation options, the developer can make the optimal choice in favor of a certain type of basic support for the structure.

When to use a pile foundation

In most cases, a pile foundation for a bathhouse is built on a soil composition that is not capable of providing the necessary stability to the building. Such places include:

- quicksand;

- sandy soils;

- peat bogs;

- loams excessively saturated with water.

In such areas, the piles must be lowered to the level of the dense soil layer so that all the load forces created by the structure are transferred to it.

It is recommended to use a pile foundation on soils that freeze below the one and a half meter mark in winter. To fill a strip base, large volumes of excavation work will be required, while installing piles will cost much less.

The next option when it is necessary to arrange just such a foundation is if the site allocated for construction has complex terrain. To level it, you have to incur unplanned and very significant costs, and it is better to build the foundation on pile supports.

Pile foundations are also used on dense and difficult-to-cultivate soils, when digging a foundation pit is difficult and quite expensive.

Size calculations

After the type of foundation for the bathhouse has been chosen, they proceed to the calculation of its load-bearing capacity. This parameter characterizes the ability of the building’s foundation to withstand the load from the entire structure as a whole. The foundation must transfer the load from top to bottom onto the ground and not fall into it.

Using data such as the weight of the bath (T) and the resistance of the soil underneath (R), the required support area (S) is obtained.

The bearing capacity of the base of the building is ensured by the excess of the soil resistivity and the specific load from the weight of the building.

The formula for calculating the reference area will be as follows:

S = T/R

Having received this parameter, proceed to determining the depth of the foundation base. The calculation of this value is based on two facts - the depth of soil freezing and the groundwater level. The base of the foundation must be below the soil freezing line and above the groundwater level.

Soil resistance, freezing depth and groundwater level are determined by reference. Typically, this data is taken from a copy of a geological vertical survey linked to the construction site in the architecture and land management department. Otherwise, the parameters are determined experimentally. To do this, they turn to the geological service, whose workers obtain soil samples by drilling.

Knowing these two main parameters, you can calculate the dimensions for foundations of such types as strip, columnar, pile, pile-screw, monolithic slab.

Tape

A strip foundation is a closed long structure under the load-bearing walls of a building.

The tape is formed from:

- reinforced monolithic concrete;

- prefabricated reinforced concrete blocks;

- different masonry materials.

Knowing the estimated area of the bathhouse support, determine the width of the tape. To do this, the area is divided by the length of the perimeter of the building.

Since the depth of the base of the support base is already known, this completes the determination of the dimensions of the strip foundation. If the freezing point of the soil is at a depth of less than 1 meter, then a shallow foundation is erected - this is the most economical option for the foundation of a structure, which does not require much time to install formwork and reinforcement.

Carefully. Whatever the calculated width of the tape, in reality it must be at least 50 mm larger on each side of the load-bearing wall. This requirement is approved by regulatory documentation.

Columnar

The foundation is a torn strip onto free-standing supports. This achieves great savings in consumables compared to a monolithic structure. Support posts are made from a variety of materials.

It can be:

- reinforced monolithic supports;

- metal or asbestos pipes filled with concrete with reinforcement inside;

- pillars made of wild, rubble stone and even brickwork.

The number of pillars is calculated based on the estimated supporting area, the size of the horizontal plane of one support and the standard distance between pillars of 1 - 1.5 meters. Interesting options for monolithic structures with permanent formwork made of metal, asbestos sheets or roofing felt.

Pile

Piles are used when the top layer of soil is not able to withstand the load from the building.

The pile, like a needle, pierces the weak upper base, reaching solid soil. The support is the connecting link between the building and the solid ground. Piles are:

- monolithic;

- bored;

- metal;

- in the form of pointed wooden pillars wrapped in roofing felt.

Reference. Driven-in supports are usually factory-made structures. The manufacturer indicates in the accompanying documentation the load-bearing capacity of a unit of its product.

The filling of the pile field is calculated by dividing the total weight of the structure, including the snow load, by the load-bearing characteristic of one pile, thereby obtaining their total number. All that remains is to place them on the construction site plan along the entire perimeter of the load-bearing walls. The heads of the piles are tied with a grillage, on which the walls of the bathhouse are erected.

Pile-screw

Recently, developers have been actively using metal screw supports to build saunas with a plan size of 4 x 6 m. For such a structure, only 12 - 15 screw piles will be needed, based on the accepted gap between the supports.

The attractiveness of this type of pile foundation is that screw supports can be installed on almost any soil, except rocky soil. Installation is carried out within several hours manually without the use of any equipment.

The heads of screw supports of different heights are cut to one level using an angle grinder with a saw blade or gas welding. A laser level is used to control heights.

Monolithic slab

First of all, you need to calculate the degree of penetration and thickness of the slab . To do this, you need to know the type of soil, the collection of loads from the structure and the bearing capacity. In practice, the foundation in the northern regions must be buried at least 0.8–1 m from the surface of the earth. In warm latitudes, 0.3–0.4 m depth is sufficient. On stable soils, the depth can be minimal and amount to only 0.2 m.

For 4 by 6 baths made of lightweight materials, the optimal slab size is considered to be 0.2–0.3 m. In this case, you need to take into account the height of the pillow - 0.5 m (0.3 m of sand and 0.2 m of crushed stone). Insulation layer up to 0.1 m for cold regions.

With a known thickness, it is possible to calculate the need for mortar and the parameters of rolled metal for reinforcement.

Brick pillars

Piles/pillars for the foundation of a bathhouse can also be made of bricks or rubble stone, which are connected to each other using concrete mortar. Then the foundation is called columnar. The choice of location and distance between supports are similar. The manufacturing technique changes - bricks are placed on mortar.

The columnar foundation is made using the same technology. There will be more excavation work: you will have to dig a hole for each pillar

In the corners they are placed with a square section (at least 38*38 cm), the intermediate ones are made rectangular 38*25 cm. To save on bricks (rubble stone), half the depth of the pit can be filled with coarse sand. Sand is poured into layers of 10-15 centimeters, each layer is filled with water and compacted thoroughly.

Brick piles/pillars are made 30-40 cm above the ground level. The space between them is then filled with brick (thickness - brick or half a brick). These brick walls need to be buried 25-30 cm into the ground. The piles and walls are leveled using mortar and covered with a layer of roofing felt to ensure waterproofing.

Preparation for construction

Activities include preparation of the construction site and delivery of materials, connecting equipment to a power source. Regardless of the type of foundation chosen, debris is removed from the construction site and the vegetation layer is removed. Markings are made on the site with a cord and pegs, using goniometer tools and a laser level. Next, prepare the tools and materials.

Tool:

mortar mixer;- entrenching tools (shovels, picks), stretchers;

- hammer, saw and drill;

- angle grinder (UPSh);

- stapler;

- electric vibrator;

- gas welding

Materials:

- boards, timber, plywood;

- PVC film, geotextile;

- fittings, binding wire;

- cement, sand, crushed stone, gravel, water.

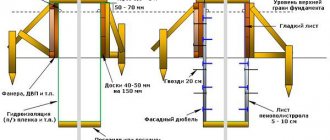

Installation of formwork

To create formwork with your own hands, edged boards with a thickness of 25-40 mm are used.

There are other materials, but wood is more accessible, cheaper and easier to work with. In addition, after completion of the work, the boards can be used for other purposes.

The thickness of the boards directly depends on the height of the tape.

The formwork is assembled in stages:

- Assembly of shields. The height is 5-10 cm greater than the height of the tape; the length of the boards is determined by the length of the walls or the size of the boards.

- Installation of shields in the trench. They are fastened together by support strips that determine the thickness of the future tape. On the outside, the shields are reinforced with supports that prevent the mass of concrete from pushing the walls of the formwork outward.

- If the boards are low (up to 20 cm), supports can be omitted, securing the walls from the outside with pegs.

NOTE! When assembling the boards, gaps between the boards should not be larger than 3 mm (ideally, there should be no gaps at all). If gaps appear, they are filled with tow or slats. The installed formwork is a structure whose internal space is the exact shape of a concrete strip

After assembly, all dimensions should be checked to eliminate the possibility of errors.

The installed formwork is a structure whose interior is the exact shape of a concrete strip. After assembly, all dimensions should be checked to eliminate the possibility of errors.

Nothing can be corrected subsequently, so the assembly process must be monitored with the utmost care.

Construction of the supporting structure

A certain type of foundation has its own installation characteristics. Therefore, brief instructions on the construction of each of them will be presented below.

Tape

To construct the tape, you should follow the following instructions:

- Using the markings, trenches are dug with shovels according to the foundation plan.

- On both sides of the ditches, formwork made of boards, timber, and plywood is installed.

- The bottom is covered with crushed stone, then with sand, accompanied by a layer-by-layer tamper.

- The formwork panels are covered with PVC film, secured with a stapler. Geotextiles are laid on the bottom.

- The trenches are filled with frames made from pieces of reinforcement connected with wire.

- A cement-sand mortar is prepared in a mortar mixer, which is delivered to the formwork on a stretcher.

- When placing the solution in the trenches, it is compacted with an electric vibrator or a handy tool.

- The surface of the poured concrete is covered with a film, protecting it from drying out in hot weather and from waterlogging during rains.

- After 30 days, the formwork is dismantled and the construction of the walls of the bathhouse begins.

From the video you will learn how to install formwork and pour the foundation for a 6x4 bathhouse:

Columnar

Instructions for installing column supports:

- Following the markings, they dig holes of the given dimensions in plan and depth.

- The sides of the pits are covered with sheet material (asbestos, metal, plywood or simply roofing felt).

- The bottom is covered with crushed stone and sand, compacting them in layers.

- Reinforced frames are lowered into the pits with the reinforcement outlets facing up.

- Then they are poured with concrete, compacting them layer by layer with a vibrator.

- After 30 days, when the concrete has gained operational strength, a grillage made of a metal profile is laid on top of the pillars, welding the above-mentioned reinforcement outlets to it.

Peculiarities. When creating point supports from rubble or brickwork, reinforcement is not needed. The masonry material has a high load-bearing capacity and does not require reinforcement.

Pile

The piles are driven manually with a hammer or a pile driving machine (pilfer). Practice shows that supports up to 1500 mm long can be driven by hand.

A level or laser level is installed in the center of the pile field. On the ground part of the piles, mark the height of the smallest support. All supports are shortened to this mark.- The pile heads are tied with a grillage and construction of the walls of the bathhouse begins. The same applies to screw piles.

Slab

The area with formwork around the perimeter for the bathhouse is filled with concrete. Such a base for a sauna is installed in places with peaty, loamy and swampy soils.

Due to its large area, a monolithic slab significantly reduces the specific load, and the foundation seems to float above the surface of the earth.

- A sand-crushed stone cushion is placed around the perimeter of the future bathhouse, which is compacted layer by layer. The pillow should protrude beyond the perimeter of the bathhouse by the width of the blind area.

- They place formwork panels, strengthening them with spacers.

- Geotextile or PVC film is laid on the pillow.

- A reinforcement frame is formed from pieces of reinforcement using a knitting wire.

- Concrete is poured using a mortar mixer and a stretcher.

- Until the concrete hardens completely, the slab is covered with film.

Find out how to pour piles for a 6 by 4 bathhouse from the video below:

Prices for screw piles for baths

89 mm Category 2 (wall thickness 3 mm)

| Name | Blade diameter mm. | Barrel length mm. | Retail, pcs. | Installation cost. rub. per piece | ||

| SVSN3-89-1500 | 250 | 1500 | 1710 rub. | 800 | ||

| SVSN3-89-2000 | 250 | 2000 | 2030 rub. | 800 | ||

| SVSN3-89-2500 | 250 | 2500 | 2350 rub. | 800 | ||

| SVSN3-89-3000 | 250 | 3000 | 2820 rub. | 900 | ||

| SVSN3-89-3500 | 250 | 3500 | 3140 rub. | 1090 | ||

| SVSN3-89-4000 | 250 | 4000 | 3630 rub. | 1130 | ||

| SVSN3-89-4500 | 250 | 4500 | 3980 rub. | 1220 | ||

| SVSN3-89-5000 | 250 | 5000 | 4260 rub. | 1310 | ||

| SVSN3-89-5500 | 250 | 5500 | 4770 rub. | 1380 | ||

| SVSN3-89-6000 | 250 | 6000 | 5240 rub. | 1470 | ||

| SVSN3-89-6500 | 250 | 6500 | On request | 1740 | ||

| SVSN3-89-7000 | 250 | 7000 | On request | 1940 | ||

| 89 mm Category 1 (wall thickness 3.5 mm) | ||||||

| SVSN-89-1500 | 250 | 1500 | 1840 rub. | 800 | ||

| SVSN-89-2000 | 250 | 2000 | 2270 rub. | 800 | ||

| SVSN-89-2500 | 250 | 2500 | 2680 rub. | 800 | ||

| SVSN-89-3000 | 250 | 3000 | 3150 rub. | 900 | ||

| SVSN-89-3500 | 250 | 3500 | 3650 rub. | 1090 | ||

| SVSN-89-4000 | 250 | 4000 | 4110 rub. | 1130 | ||

| SVSN-89-4500 | 250 | 4500 | 4490 rub. | 1220 | ||

| SVSN-89-5000 | 250 | 5000 | 4930 rub. | 1310 | ||

| SVSN-89-5500 | 250 | 5500 | 5350 rub. | 1380 | ||

| SVSN-89-6000 | 250 | 6000 | 5700 rub. | 1470 | ||

| SVSN-89-6500 | 250 | 6500 | On request | 1740 | ||

| SVSN-89-7000 | 250 | 7000 | On request | 1940 | ||

The number of piles and strapping beams for the frame of a bathhouse or house with a veranda

| Foundation for a log house on screw piles. The diameter of the piles is 108 mm, the length of the pile is 2500 mm. | |||||||||

| Log size , m. | 4x3+2 | 5x3+2 | 4x4+2 | 6x3+2 | 5x4+2 | 6x4+2 | 5x5+2 | 6x5+2 | 6x6+2 |

| Number of piles , pcs. | 10 | 10 | 12 | 12 — 13 | 12 | 12 — 16 | 12 | 12 — 16 | 15 — 20 |

| Strapping beam for screw piles, 250x150 or 300x150 mm. | |||||||||

| Quantity of timber , pcs. | 5 | 5 | 6 | 6 | 6 | 6,5 | 7 | 7 | 8 |

Kinds

To create the supporting structure of the bathhouse, the following types of piles can be used:

- Hammers. To immerse into the ground, special equipment is used to install supports by driving them into the ground. Work near existing buildings can cause undesirable changes in the condition of the foundation, causing subsidence or movement of the foundation. Ready-made piles are used, the speed of work is usually high, the process takes one day.

- Bored. They are made directly on the construction site by pouring concrete into a reinforced well. There is an opportunity to do everything yourself. At the same time, complex soils may not hold the well due to the walls crumbling or the cavity filling with water. In addition, it is necessary to wait about a month until the concrete gains structural strength, during which no work can be done.

- Screw. They are purchased ready-made and immersed in the ground either using special equipment or manually. They do not pose a threat to buildings located nearby and can be installed close to them. They allow you to build a bathhouse on slopes and folds of the foundation without preliminary preparation of the site. The disadvantages of screw piles are the inevitable corrosion of metal in the ground and a lot of hand-made supports that do not meet existing requirements.

IMPORTANT! There are also columnar supports, which many try to classify as pile foundations. They are not immersed in the ground, so they are simply a budget-friendly and quick solution to the issue for the construction of auxiliary buildings. They are rarely used on difficult soils, as they do not provide stability in the event of seasonal movements or flooding.