A bathhouse in a summer cottage or next to the house is what many people dream about. Having your own bathhouse has many advantages, including the opportunity to experience the healing properties of steam procedures at any time. Going to the bathhouse is an expensive pleasure that will cost a decent amount. You can visit your own bathhouse for free whenever you want. This is why many people prefer to build a bathhouse on their site.

Any construction begins with drawing up a project. But which option should you choose? First you need to decide on the size. The most popular and optimal option is the 6x4 bathhouse project.

A bathhouse of this size has sufficient area to accommodate all the necessary rooms. It does not occupy a large area, but has good capacity.

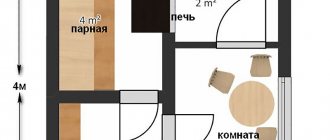

Bathhouse layout 6x4

Any bathhouse consists of several required rooms:

- steam room;

- shower;

- dressing room;

- restroom.

According to the layout, this structure can be one-story or two-story. If desired, you can complement the bathhouse with a terrace or balcony.

One-story bath complexes are more traditional. They are comfortable for people of all ages. For example, if the family has elderly people or small children who will use the bathhouse, it is better to build a one-story building without an internal staircase.

Two-story baths are ideal for owners who like to invite large groups of guests. Even if you have a small space on the site, you can build a compact bathhouse with a spacious seating area on the second floor. If you build a complex with a balcony on the upper level, you will get an almost full-fledged guest house with a steam room.

Instead of a full two floors, a bathhouse with an attic is often built Source nl.decorexpro.com

On large plots, bathhouses with a terrace are usually built. In this way, the territory of the bath complex is expanding. In summer, you can equip the terrace with garden furniture and use it instead of a relaxation room.

Peculiarities

The layout for a family holiday will differ from the commercial option at a tourist base. But families are also different - some like to gather with a noisy group of friends, others seek solitude. Some wash with the whole family at once, others wash separately. If all requirements are taken into account, internal volume distribution will not be a problem.

For a family of 3-4 people to visit the bathhouse at the same time, large premises are not required. This allows you to include additional blocks in the layout - a bathroom and vestibule at the entrance from the street, for example. If 2-3 people go to the bathhouse separately, there is space to organize a small pool, a plunge pool or a place for pouring cold water.

A bathhouse at a tourist base should be designed to accommodate a larger number of guests at the same time. Such places are often chosen by groups of friends (colleagues) to celebrate a personal or corporate holiday. Understanding this, you should not split the internal volume into several small rooms. It is better to limit yourself to the minimum required number, giving priority to the area of each.

Important!

Conversations at the table require more time to visit, so a bathroom in a bathhouse at a recreation center is not an additional option, but a prerequisite. For the same reason, it is worthwhile to provide a way to control and change the temperature in the steam room without staff intruding into the personal space of guests.

If the stove is wood-burning, you need to provide access to the firebox from a separate room or from the street. If the stove uses gas or electricity as fuel, the temperature control machines must be moved to a separate room or outside with limited access to them.

Features of the layout of a bathhouse made of 6x4 timber

The design of a 4x6 bathhouse must be carefully thought out. Despite the fact that smaller complexes are often built, every square meter still needs to be distributed with maximum benefit.

The layout of a 6x4 bathhouse may differ in the size of the rooms. The area of the steam room can be increased due to the relaxation room. You can do the opposite - plan a more spacious living room, but reduce the area of the steam room or dressing room. In some cases, owners consider it mandatory to have a separate dressing room; for other owners, it is more important to have a large, comfortable shower. There can be many nuances of planning, it all depends on how the owners see their ideal bathhouse.

What should the foundation be?

The main data needed to select the type of foundation are the characteristics of the soil and climate. In Russia, heaving soil predominates with varying degrees of freezing, which is what you should focus on. If you are going to build a bathhouse yourself, then it would be better to choose a strip foundation, since it is considered the most versatile and reliable.

A strip foundation can be laid without the professional skills of a builder; its only drawback is high labor costs. However, when finance plays a significant role, this will not be an obstacle to the implementation of the project.

Materials for building a bathhouse

For the construction of a modern wooden bath, advanced materials are used, which are manufactured industrially and have improved characteristics.

A modern bathhouse looks very impressive on the site Source sarlbethart.com

See also: Catalog of bathhouse projects presented at the “Low-Rise Country” exhibition.

A structure made of timber or logs is constructed very quickly, does not require a long time for shrinkage, does not deform due to temperature changes and does not collapse under the influence of high humidity. But there are significant differences between logs and beams, and they must be taken into account in order to correctly determine the material.

timber

This is a wood wall material with a square cross-section. For the construction of a bathhouse, glued laminated timber is usually used, which has more attractive characteristics than ordinary rounded timber or logs.

The advantages of laminated veneer lumber are obvious. Firstly, a 4x6 bathhouse made of timber does not require additional exterior finishing. Secondly, all elements fit perfectly together, and the walls are obtained with excellent thermal insulation and sound insulation characteristics. Thirdly, any structures made of laminated veneer lumber are very quickly and easily assembled. In addition, this material does not crack, does not rot and gives minimal shrinkage - from 2 to 10%.

Glued laminated timber also has its drawbacks - price and reduced environmental friendliness of the material due to the use of glue. However, it should be noted here that the price is fully justified by the durability and quality of timber buildings.

Bathhouse 6x4 made of timber with a terrace Source doma-medved.ru

See also: Catalog of companies that specialize in the construction of baths.

At the same time, any wooden materials are treated with chemical compounds to protect them from moisture and harmful insects, and from fire. Absolutely environmentally friendly wood is a difficult-to-use and very short-lived material that is practically not used in modern construction.

Log

A rounded log has a rounded shape in the cut, and therefore buildings made from it have the appearance of classic log houses. The advantages of logs include such qualities as easy installation, good sound insulation, tight fit of elements without cracks or gaps.

The characteristics of a rounded log directly depend on its manufacturing technology, which includes the stages of harvesting, drying, and processing. Unscrupulous manufacturers supply logs to the construction market that become deformed and crack over time. Therefore, such material must be selected with extreme caution.

A correctly manufactured rounded log is still inferior to laminated veneer lumber in some respects. It gives a more noticeable shrinkage - up to 13%, and the shrinkage process lasts from six months to a year. But the log costs less.

Construction of a bathhouse from chopped logs Source bashecostroy.ru

More details about the premises

The classic 6x4 sauna has three rooms.

Rest room, steam room and shower

Waiting room

Here guests undress, coal or firewood for the stove are stored in drawers, and brooms are on the shelves.

To save space, the dressing room is often combined with the guest room, placing furniture here, installing a TV and other appliances, and setting the table.

Its ideal area is 1.3 sq.m per person + space for storing bath accessories and things.

Important! The rest room should have a window.

Steam room

There is a stove in the room - natural, gas or electric. Shelves are attached to the walls. Here the requirements are different - at least 1 meter for each + stove + distance from the stove to the walls and passages.

The ideal height is 2-2.1 meters. If the ceilings are higher, the steam will take up extra, unused space. If it is lower, accumulating, the hot air will need an outlet, and it will evaporate into the ventilation. The width of the shelves is 40-90 cm.

Important! The door should open not into the steam room, but from it, that is, into the relaxation room. Otherwise, there will be high temperature and humidity in the waiting room.

How guests and hosts can steam in a steam room is shown in the diagram below.

How to steam properly

Shower room

Depending on the size of the room, you can install a shower stall, a toilet, or mount a shower into the wall.

The shower room can be heated by the same stove as the steam room (if they have an adjacent wall).

Having chosen a layout taking into account the necessary premises in the bathhouse and their size, you need to decide on the material from which the complex will be built.

Bathhouse location

When choosing a place where a bathhouse will be built, it is necessary to take into account the requirements of SNiP, environmental regulations, and the features of the landscape design of the site. A 4x6 wooden bathhouse will become a significant and expressive element of your home. It is better to position it so that it is clearly visible to the person entering the site.

It is recommended to fill the distance from the house to the bath complex with such decorative details that will stylistically combine a modern cottage and a wooden log house.

Construction works

In order for the service life of the bath to be long, the norms and requirements must be observed during construction. The whole process consists of several stages:

- Selecting a location and marking the site.

- Purchase of building materials.

- Construction of the foundation.

- Walling.

- Installation of doors and windows.

- Roof and roof installation.

- Finishing facilities.

Choosing the location of the bath

The ease of use and service life of the steam room depend on the correct choice of place for construction. There are several features:

- A bathhouse with your own hands should be built on a hill. If it is not there, then it is recommended to erect an artificial hill. In this case, it takes a year for the soil to settle.

- Water pipes. The best option for quickly drawing water into the steam room is a well.

- Delivery and storage of fuel materials. Storage space should be selected at the planning stage.

Selecting materials for the foundation, walls and roof

The foundation should be arranged taking into account the building material chosen for the walls:

- For log, timber and frame buildings, a pile or columnar foundation is suitable.

- For heavier buildings made of bricks and blocks, a strip is required.

Corrugated sheets or metal tiles can be used as roofing material.

Marking and foundation

When the bathhouse diagram according to the drawings is ready, you can begin marking the site. To do this, in strict accordance with the project, pegs with a taut rope are installed in the corners. If you plan to install a pile or columnar foundation, then in this case it is necessary to install pegs in all places where the supports will stand.

In the case of a strip foundation, a trench is dug taking into account the depth of soil freezing. To prevent swelling, the bottom of the trench is filled 10 cm with a “cushion” of gravel and sand.

After installing the formwork, the trench is filled with concrete and reinforcement elements.

Professionals warn: with such dimensions, the baths with a relaxation room are a five-wall structure. For this reason, the partition is laid at the foundation stage.

Walling. Windows and doors

The first stage of brickwork, foam blocks or crown (when erecting a building from logs and timber) is considered extremely important. The entire further course of work depends on the correctness of its implementation. After finishing the laying of the first row, it is worth checking it using a level. If there is a distortion, it is better to redo it right away. The second row begins to be laid from the corner.

Already at this stage, the location of windows and doorways is noted. You need to remember: frames and doors can only be installed in a finished building. These elements for steam rooms are best made of wood.

Roof of the bathhouse

After the walls are erected, the roof must be installed. This work can also be done without the involvement of specialists:

- After the walls are built, ceiling beams are laid and covered with boards.

- The next stage is the installation of the rafter system and sheathing.

- The roof can be represented by corrugated sheets or tiles.

- The final stage of installation includes installing a drain.

Floors

Floors in a Russian bathhouse are installed in several stages:

- Rough floor.

- Waterproofing layer. With its help, they block moisture from entering from below.

- Insulation. This layer is required in all rooms except the washing room and steam room. Mineral wool can be used for this purpose.

- Another layer of hydro- and vapor barrier is laid on top of the thermal insulation.

- The final stage is laying the finished floor.

Buy or build

Building a high-quality bathhouse that holds the temperature well, has the required level of humidity, is properly ventilated and has other necessary qualities is not an easy task. For an experienced builder, building a real bathhouse on your own site will not be difficult. But you shouldn’t take on this without special skills, especially since today you can inexpensively order a bathhouse from professionals.

It is better to contact well-known construction companies with an impeccable reputation and a full range of services. Such organizations enter into contracts with their clients and are responsible for the quality of work performed. Professional builders will first approve the finished plan for a 6x4 bathhouse, and after that they will assemble the log house in accordance with all the rules of technology. Beautiful and successful bathhouse designs

Having your own bathhouse next to the cottage is an opportunity to fully relax with the whole family or with friends. In addition, the bath is good for health. Another advantage is that it decorates the site and gives any home a respectable and luxurious look.

Bathhouse layout options can be any Source banya-ili-sauna.ru

External and internal finishing

The choice of material for finishing work depends on financial capabilities and taste preferences. Usually, the outside walls are simply plastered in 2 layers with a total thickness of 10–15 mm and covered with siding or simply painted with water-repellent paint, having previously been puttied and covered with a primer. We recommend material about projects of a bathhouse with a swimming pool.

From the inside, lining made from non-coniferous wood looks like a good option. You can also use pine lining, but at high temperatures it will “cry”. They attach it to a pre-made frame with finishing galvanized nails or clamps, leaving a gap of several millimeters between the insulation (penofol and vapor barrier) and the lining itself. But what projects there are for bathhouses made of timber are detailed in this material.

How to decorate the inside of a bathhouse:

Sometimes the inside of a foam block bathhouse is also plastered and covered with facing tiles. But this is a more expensive and not entirely aesthetically advantageous method, and it is also quite labor-intensive. Check out our article about cladding panels.

A foam concrete bathhouse is a compromise option when finances and space on the site for the construction of a full-fledged structure made of logs or timber are not enough, but the desire to steam in your own sauna is great.

Advantages and disadvantages of a frame bath

Each building material has its own advantages and disadvantages that must be taken into account. Recently, frame baths have begun to become popular, so it makes sense to find out why they are better than structures made from other materials.

The advantages of such a bath:

- There is no need to make a capital foundation. The structure is lightweight, so it can be installed on a lightweight base.

The foundation for the frame structure can be lightweight

- Low cost. They are preferred by those who want to get a high-quality design for a low price.

- Possibility of production in the shortest possible time. Together with finishing and insulation work, production will take 1–2 weeks. The structure is assembled 3 times faster than stone or timber.

- Heat retention. According to these indicators, a frame building is not inferior to a log or timber structure.

- Environmental friendliness. This bathhouse is made from natural materials that are not capable of harming human health.

- Possibility of production at any time of the year. The structure can be manufactured even at a temperature of -15°C.

- Comfortable microclimate. Walls can breathe as the material will absorb and return air.

- Seismic resistance. Thanks to this quality, the bath can be made even in an earthquake-prone region. It can withstand fluctuations of up to 8 points.

However, it is important to know that a frame bath has significant disadvantages:

- Costs for insulation and finishing materials. The frame building itself is cheaper than a stone or timber steam room, but the cost increases several times during finishing and insulation work. Panels for decoration and plastering are required.

- Shrinkage. The process takes at least 2 years, and the building may sag by 10 cm. This may lead to deformation of the finishing layer. To reduce the effects of shrinkage, it is recommended to use chamber-drying materials during the construction process.

- The difficulty of choosing high-quality material for insulation. If you use budget mineral wool, the bathhouse will not be able to fully cope with its functions. The use of budget polystyrene foam is also not allowed, since the material is easily flammable.

Arrangement

In a classic Russian bathhouse there are usually 3 rooms at once - a washing room, a dressing room and a steam room. But most owners of country houses want to complement such a set with a recreation room, a vestibule, a swimming pool or even an attic. Regardless of the set, the dimensions of the room should be sufficient for a pleasant stay. The length of the bathhouse façade of 4*6 meters makes it possible to comply with this requirement. But you cannot skimp on thermal insulation, and even if you are at the dacha only in the summer, your bathhouse still needs excellent thermal insulation. This allows the bath to quickly warm up and retain heat for a long time. When building walls, you need to mark in advance where doors and windows will be placed. At the same time, it is important not to saw a log or a whole beam, and you can try on the leftovers that are available.

How to make a project yourself

When drawing up a project, every little detail must be taken into account . You will need to accurately calculate the location of the building - the building must be located on a natural or artificial elevation. It is equally important to consider the size of each room, since the functionality and quality characteristics of the bathhouse directly depend on this. 6x4 bathhouse projects must include an accurate calculation of the materials required for construction and all components. So, the building without finishing consists of the following:

- Foundation.

- Five-walled log house measuring 6x4.

- Windows, doors.

- Ruberoid and roof covering.

- Floor covering.

If you wish, you can include additional details in the project:

- windows in the frame and gables;

- additional wall.

It is worth considering when drawing up a project that by increasing the steam room you will maximize the functionality of the building as a whole. It is worth making wide shelves in the steam room so that several people can enjoy the steam at the same time. When choosing a location for a stove or boiler, pay attention to safety - it is important that there is no possibility of touching a hot heating device, even by accident. This will allow you to avoid burns and spend time as positively and safely as possible.

Before starting construction, it is necessary to think through the project down to the smallest detail . Only in this case will you get a truly high-quality structure that can last for years. Good luck to you and enjoy your steam!

Calculation of materials and list of tools

As an example, we will consider the calculation for a frame bath of the most common sizes. The frame is made of timber, the size of the structure is 5x4 m. The base will be reinforced columnar.

For the frame structure, you can use a lightweight foundation made of asbestos-cement pipes

Coniferous wood lining is used to decorate the walls inside and outside. The roof will be gable, the covering will be metal tiles.

A pressing issue is the choice of wood. The material must be dried. Linden, larch or aspen are most suitable. These rocks have low thermal conductivity; they are capable of maintaining their original structure for a long period of time. The walls are erected from boards 2-3 cm thick. Larch or pine slats are suitable for external cladding.

In terms of cost and reliability, a columnar reinforced base is the best option for frame construction.

Columnar reinforced foundation is suitable for the construction of frame baths in most regions

It can be used in most regions. You will need to prepare materials in the following quantities:

- concrete - 2 m3;

- edged boards for the frame - 0.3 m3;

- reinforcing bars - 80 linear meters

The frame can be made from boards, pieces of plywood sheets or OSB. If the soil on the construction site is clayey, then formwork is not necessary.

The most complex and financially expensive part of the bathhouse is the frame. The purchase of materials at this stage must be approached carefully. List of required materials:

- timber 120x120 mm - 5.3 m3;

- mineral wool 10 cm thick - 36 m2;

- vapor barrier material - 40 m2;

- wooden lining - 70 m2;

- material for waterproofing - 40 m2.

To save money, instead of bars you can purchase 50x100 mm boards.

To save money, you can use 50x100 mm edged boards during the frame manufacturing process

The timber must be of the second grade and lower, the board can only be of the first grade. The cladding of the walls on the outside can be done not with wooden lining, but with plastic sheets or corrugated sheets.

The floor is made of edged veneer boards. The ceiling should be covered with clapboard. If you want to save money, you can use mineral wool for thermal insulation. List of materials:

- edged boards - 1.8 m3;

- boards 150x50 mm - 0.2 m3;

- plinth - 20 linear meters;

- mineral wool - 20 m2;

- wooden lining - 20 m2.

You can save money on attic flooring. If you do not plan to use it, then the mineral wool can be covered with unedged boards or pieces of slabs.

The roof is gable, the attic can be used to store tools.

The best option for a frame structure is a gable roof.

There is no need to insulate the roof. The rafters will be hanging. You will need the following materials:

- drainage system - 1 set;

- slats for rafters - 0.2 m3;

- lathing strips - 0.1 m3;

- cornice slats - 0.1 m3;

- metal tiles - 20 m2.

In a bathhouse, quite often, instead of a drain, a blind area around the perimeter is installed using a cement-sand mortar.

List of materials that will also be needed:

- asbestos pipes;

- self-tapping screws;

- nails;

- staples;

- cement;

- gravel or sand.

You will need the following tools:

- square;

- building level;

- roulette;

- electric drill;

- Screwdriver Set;

- hammer;

- pliers.

It is important to think through all architectural and construction tasks, which include:

- internal lining of the bathhouse building;

- selection of optimal materials for construction work;

- actions that are required to ensure the safe use of the structure.

After preparing the tools and materials, you can proceed to construction work.