Previously, wood was used in the construction of a Russian bathhouse, but today other materials (brick, aerated concrete) have begun to be used. But wood still remains a popular material that helps create a special atmosphere and recreate the true spirit of a Russian bath.

Advantages and disadvantages of log bathhouse projects

Advantages of wooden bathhouse projects:

- buildings are environmentally friendly, built without the use of toxic, artificial materials and are safe for use;

- wood has heat-retaining qualities and allows you to maintain a comfortable microclimate in the building in winter;

- the material has noise-insulating properties, while ensuring oxygen circulation in the room;

- buildings are durable and strong after treatment with antiseptic varnishes and impregnations;

- log bathhouses are original buildings, which are implemented according to original and standard designs;

- wood is easily processed, sanded, the material can be carved, engraved, painted;

- the material is aesthetic and does not require cladding with decorative panels; it is enough to insulate the cracks and joints.

The list of shortcomings:

- the material is less durable than metal and stone;

- during operation, a log bathhouse shrinks, cracks and chips may appear;

- at high humidity, wood can rot and deform; for strength, the raw materials are coated with impregnations;

- The material is fire hazardous; safety precautions must be observed during the construction and operation of wooden baths.

Features of construction and operation

A wooden bathhouse is built in several stages:

- construction of a foundation (concrete strip or pile);

- making ventilation openings around the perimeter of the base;

- construction of walls;

- building insulation;

- roof installation (single or gable);

- laying the stove structure, which is located separately from the walls and is made of special heat-resistant bricks;

- insulation of floors, wall panels, ceilings using tow, fibers, sealant;

- creating openings in the log house for installing door blocks and windows;

- installation of frames and glass;

- interior decoration using lining and polished boards.

Placement of a bathhouse on the site

When designing log baths, it is important to plan a place on the land plot. When determining a site, it is important to consider:

- construction standards, which specify the parameters for underground communications, the distances between buildings and neighboring plots;

- terrain of the territory, proximity to rivers, lakes (optimal construction is carried out at least 5 m from the reservoir);

- a log bathhouse with a veranda is a fire hazard and is located 8 m from other buildings on the site;

- purpose of the territory, it is optimal to place the bathhouse in a recreation area.

Log processing

The first thing you need to know is that a log house made of logs or timber (except laminated veneer lumber) must remain under the roof for at least 8 of the driest months. Most often, a bathhouse is installed in December, finishing work begins in August. But only if these are really dry months and they are in a hurry to start the sauna. If there is no rush, it is better to wait one and a half to two years.

The ends of the logs must be coated with a special compound

There will be enough work for the drying time. After installation, the logs must be treated with solvent-based antiseptics. For example, Tikkuril has Valti Pohjusta impregnation, and Woodex Base. They will protect the wood from fungi and blueing. To prevent them from being torn during drying, the ends of the logs are coated with another composition “Teknol JRM” from the same “Teknos” or its equivalent.

The log house itself also needs processing

After the wood dries, the log is sanded, removing the bacterial treatment. This operation opens the pores of the wood, allowing it to be painted with high quality. Oil-wax is most often used to paint a log house. These products also contain a coloring pigment that gives the wood a tint. Therefore, in addition to protective properties, they also perform a decorative function.

After shrinkage, the frame is sanded and then painted

Types of buildings

The designs of log bathhouses differ in size, design features, and style solutions. Before construction work, it is necessary to draw up a drawing, a diagram of the layout of the rooms, and perform calculations of materials.

Common buildings:

- classic;

- complemented by an attic;

- with terrace;

- large-sized.

Classical

Standard designs of log baths are made in dimensions of 6x8 m. The buildings contain a steam room, a dressing room with a dressing room and a space for relaxation. Classic buildings are one-story, suitable for small areas, quickly erected, and do not require complex calculations when preparing drawings.

Building with an attic

Buildings with an attic are suitable for compact plots of land. The dimensions of the building reach 3x3, 3x5 m. The first floor is allocated for a steam room, the second for a space for relaxation, a billiard room or a place for watching TV shows. The separation of different functional rooms helps maintain the necessary microclimate in the spaces. In some projects, it is possible to arrange a separate entrance to the attic via stairs.

With terrace

A log bathhouse with a terrace is a universal project, the dimensions of which vary depending on the tasks and area of the summer cottage. The project is used for houses with an area of 3x5, 3x6 m or for spacious buildings of 6x6 m. In the terrace area there are chairs, a small table, sun loungers, and wooden benches. The extension is an element of decoration of the building, because may be surrounded by a carved fence.

Large building

The design of a chopped bathhouse can be large in size. Calibrated timber is used in the work. Before construction, preparatory work, drawing up a drawing, and calculation of materials are necessary. The 8x8 m structure allows you to implement different planning solutions. The space can accommodate a steam room, a dressing room, storage space for bath accessories, a wash room, and a guest room. The project does not involve the construction of a 2nd floor.

A swimming pool (square, rectangular) can be installed next to the building. Typical buildings are modified to suit the characteristics of the site.

Materials

Before constructing a bathhouse, the necessary materials are indicated in the project. In addition to wood of the required quality, thickness, water resistance and strength, paints, varnishes, stains, putties, and sealants will be useful. For the durability of the building, it is necessary to select high-quality raw materials for the foundation.

Foundation

Before constructing a wooden bathhouse, raw materials for the foundation are selected, because the array shrinks over time. The optimal solution for the project is a strip-type base; it is durable, reliable, affordable, and quick and easy to implement.

Wood

For a bathhouse, you need to select high-quality building materials. The array must be of high quality, without chips, cracks, defects, or stains. Before construction, the materials must be dried. The raw materials are laid out in the yard. Then the surfaces are treated with impregnations, antiseptics, agents against fungus, inflammation, and pests. Without impregnation, wood quickly becomes deformed and damaged.

For a chopped bathhouse, damage-resistant wood varieties are required:

- pine;

- spruce;

- cedar;

- larch.

Interior

The design of a bathhouse made of solid wood is carried out in different styles. The list of popular destinations:

- Russian;

- modern;

- rustic (country);

- Provence

Russian

The classic Russian bathhouse is popular in the countryside. The interior can be made laconic or complemented with decorative carved, painted details, platbands, and railings. Walls made of chopped logs are aesthetically pleasing without additional decoration; the wood pattern can be emphasized with impregnations and varnishes. The decoration will be furniture, carpets, textiles placed in the recreation area. Items should be made in Russian style; simple benches, chairs, wooden tabletops, complemented by carvings or painted, are optimal.

In the shower or washroom, style-oriented decor is required (watering cans, massive tubs, wicker carpets). In the living room, on the table there is a tablecloth with embroidery, samovars, and sets with traditional painting. The style is also emphasized by lamps made of metal and bronze. In the recreation area you can put a classic brick stove and decorate it with paintings. Spacious buildings will accommodate a swimming pool.

Rustic

Projects of log baths with a veranda in a rustic style are distinguished by their laconicism, simplicity, and the absence of bright decor or gilding. For wooden decoration, hand-made decorations and crafts, brooms, wreaths made of medicinal herbs, and massive tubs are selected. The design will be complemented by woven carpets, napkins and other textiles made independently. Forged decorative elements are not recommended.

Modern

A bathhouse with a log attic can be made in a modern style. The logs must be carefully sanded and decorated with LEDs around the perimeter inside the rest room and shower. The traditional brick stove is being replaced with a metal structure. The furniture used is ergonomic, folding, transformable.

Planning decisions may be changed. The dressing room is used as a locker room, and the wash room is supplemented with a bathroom. Original shells, pebbles, ceramics, colored glass, and starfish are used in decoration. You can use modern household appliances in the interior.

Construction of a reliable foundation for a bathhouse

Log baths have an impressive weight, so it is necessary to build a strip or column-type foundation for them.

The strip foundation is suitable for moving soils with different levels of freezing, can withstand the maximum load of the structure, and also allows the construction of underground buildings - basements, cellars and garages.

The columnar base is more economical, practical, accessible for installation, and has high strength indicators. It is suitable for construction on soils with a high content of clay, sand, and those prone to rapid freezing. The disadvantages of the foundation include the impossibility of arranging cellars and basements, as well as the need for additional insulation of the floor base.

The construction of a strip foundation is carried out as follows:

- At the selected site for construction, a trench is dug: depth - up to 100 cm, width - up to 45 cm.

- The bottom is covered with a sand cushion, moistened and compacted. The height of the sand layer is 18 cm.

- Formwork is assembled from boards and reinforced with metal rods, the upper part of which is cut off according to the height of the foundation.

- The formwork is filled with ready-mixed concrete around the perimeter of the trench to construct a monolithic base.

- After the concrete has completely dried, a waterproofing layer is laid to prevent the base from being washed away. To do this, concrete is treated with hot bitumen and then covered with rolled roofing felt.

Exterior finishing

The external decoration of the bath should be minimal. It is important to highlight the beauty of wood; the material is coated with protective varnish, antiseptics or stain. The treatment will extend the shelf life of the building, highlight the texture and natural shade.

Experts recommend waiting some time after the construction of the log house for the logs to shrink. After 1.5-2 weeks it is allowed to install window blocks. Insulation of wood is carried out the next season after the completion of shrinkage of the structure. The finishing of a bathhouse made of rounded logs according to the project is carried out with antiseptics and impregnations, the products will emphasize the beauty of the array. Sanding and putty are used to protect wood.

During operation, you can change the design of the building by decorating the facades with panels, vinyl siding or brick. Creating an additional layer will help insulate the room. Mineral wool and expanded polystyrene can be placed under the array.

In the exterior decoration of the premises, carved beams, platbands, shutters in the Old Russian style, openwork fences, balconies and other details are used. The elements will allow you to create your own design.

Sealing cracks

It's no secret that even in a well-made log house there will be gaps: it is impossible to cut out a bowl so that it perfectly follows the shape of the log. Still, some gaps remain. Moreover, during the drying process, they increase, and cracks also appear and deepen.

All these cracks are sealed - caulked. For this purpose they use a tool similar to a small flat spatula and a hammer. Moss or tow is placed in the cracks. Using caulk, tuck the tow into the crack, compacting it by tapping on the handle.

This is how they caulk a jute bathhouse

If the frame was assembled with moss (dried moss is laid between the crowns for compaction), then its ends hang out of the cracks. To prevent birds from snatching it away, it is tucked inside immediately after installation. There is no need to compact or be zealous. The purpose of this treatment is only to remove hanging ends. The caulking itself is carried out later - after six to seven months.

If the log house is placed on a jute tape or tow, the first caulking is carried out after the initial shrinkage of the log house - after six months. After this, you can install windows and doors in the log house. Secondary caulking will be needed in about a year. It usually requires less time and materials than the first time.

In general, as they say, a log house “drives” all its life. Therefore, it needs to be inspected periodically and the cracks sealed. In addition to the fact that the old ones become wider, the tow is taken away for birds’ nests. You have to periodically update the finish. But this is the case if the outside of the log house is not finished with anything.

This is what a log house collected with moss looks like. The ends are trimmed, the remains are tucked into the cracks

For more information on how to caulk a log house, read the article “How to properly caulk a bathhouse and when to do it.”

Beautiful examples

Beautiful baths can be standard or unusual, depending on the architecture of the buildings on the site and the design decision of the designer. Color solutions vary; wood can be light or dark after being treated with stain. You can change the number of floors of the building, add functional extensions. When planning a bath complex, you can familiarize yourself with original ideas from ready-made catalogs and make the necessary changes to the project.

Building with an attic

A log bathhouse with an attic is comfortable, practical, often made of light-colored wood, complemented by a staircase and a small terrace for comfortable use. In the attic you can create a recreation area. Projects with a classic design, a small number of details, and a minimum of decor are popular. The building is suitable for a site with a brick or stone house.

Strict classic

A log bathhouse looks original in projects in a strict classical style. The building is tall and has a sloping roof. Wood of dark shades is used. It is recommended to design windows in each room. The terrace in the project is compact and can accommodate an armchair or chairs. A bathroom is being added to the building.

Light bath

The project of rounded logs with a terrace is made of light-colored materials. A high-quality, solid foundation is important for the project; the foundation can be made of stones. The roof is decorated with light-colored beams. The design is aesthetic and durable. A beautiful bathhouse accommodates a steam room, a wash room, and a guest room. There is no need to add an attic or additional floor.

Two story building

In a two-story building, you can equip a large stove structure to create a comfortable microclimate. On the ground floor there is a steam room, on the top floor there is a relaxation area, a small kitchen or a study. The constructive solution is durable, reliable, and allows you to transform the premises according to the architect’s plans.

Brick baths and their features at the design stages

A brick bathhouse has both advantages and disadvantages. Let's start with the good:

- Brick is a very durable material. The use of facing bricks eliminates finishing work;

- It has thermal insulating properties;

- Its use allows you to implement the most complex and elegant projects for a bathhouse;

- Not susceptible to rotting, swelling, damage by pests and microorganisms.

Now a few fly in the ointment:

- A bathhouse built of brick is more expensive than a wooden one;

- Requires the use of a well-thought-out ventilation system and reliable vapor barrier to avoid moisture condensation and dampening of the masonry;

- High load on the foundation;

- The appearance of a brick bathhouse is inferior to a log bathhouse in the traditional sense.

Tradition and modernity. Choosing wood for construction

When selecting building materials for a building, the diameter of the logs is taken into account, the optimal size is 18-25 cm. It is necessary to select raw materials of the same size, the discrepancy should not exceed 3 cm. The wood should be from similar climatic conditions; the most durable and moisture-resistant species are those from northern latitudes.

When selecting raw materials, the following are taken into account:

- building area;

- operating mode;

- temperature in winter;

- drying method.

Logs can be processed in the following ways:

- sanded;

- rounded;

- planed;

- scraped;

- chopped;

- with a square section.

Classics of the genre: a log house made of wild logs

A standard chopped bathhouse is built from sanded logs. The raw materials retain protective layers and are not susceptible to mold, mildew, or insect pests. Treatment with impregnations and transparent varnishes is required to preserve the structure and durability of use.

Rounded log

Bathhouse projects made from rounded logs are budget-friendly, easy to install and fix in the log house. The raw materials undergo calibration, through which the logs are given a rounded shape and precise diameter. However, during processing, the bark and the top layer (bast), which has protective characteristics, are peeled off. The building material is suitable for warm climates and non-frosting winters. The raw materials are subject to rotting and may crack.

Rustic style

Projects of one-story log baths in a rustic style are made from chopped, scraped, planed wood raw materials.

The scraped logs are ground using a special electric planer. The technology reduces material loss and the outer layer is preserved. When installing a log house, it is necessary to adjust the blocks manually.

The Norwegian fire monitor method is performed by sawing and sharpening the log. Processing ensures high-quality raw materials, the durability of materials increases after applying antiseptics and impregnations.

Scraped logs are the most durable. The processing method allows you to preserve the quality of the wood; after impregnation, the shelf life of the log house increases. However, lengthy adjustment of logs during installation work is required, because the uneven texture of the wood is preserved.

timber

A budget building material is timber with a square cross-section. The blocks are smooth, symmetrical, aesthetic. However, installation requires complex adjustment and alignment of the frame. Treatment with impregnations and antiseptics is minimal.

Construction cost: timber vs. log

There is an opinion that a log house made of logs costs less than the same one made from profiled timber (it is better processed than regular timber and has locks that reduce the risk of cracks). If you look at the cost of one cubic meter of material, then this is true. But for the same project you will need much more logs than timber. If you take a 200 mm beam, then the wall thickness will be 200 mm and the height of the crown will be 200 mm. And if you take logs with a diameter of 200 mm, then a groove 10-12 cm wide is selected in it. And the thickness of the wall at the junction of two logs will be this 10-12 cm. And the height of the crown will not be 200 mm, but 100-120 mm. This is where the difference in the required volumes when purchasing emerges. Add the labor-intensive nature of the work, and it will immediately become clear why log cabins are often built from timber. If we talk about profiled timber, then its dimensions must coincide within a few millimeters. With such material, work progresses quickly: just the bowls are cut (most often with a chain saw), the insulation is laid and a new crown is placed.

When constructing a log house, a longitudinal groove is cut out in a log to “join” it with another

Another important fact: working with timber is easier. Especially with a profiled one. It has absolutely the same dimensions (if it is made well) and folds together without problems. And with a log, if it is not rounded, there is more than enough fuss.

Log sauna projects

A bathhouse made of rounded logs (standard and custom designs) is produced in the following dimensions:

- 5x4;

- 5x5;

- 6x3;

- 6x6.

Layout of log bathhouses 6 by 6

The classic one is a 6x6 m bathhouse made of round timber. Dimensions allow you to build a building with minimal wood waste. When using timber, finishing is not required; when laying the frame with logs, cladding using lining is required. The area allows you to equip a washing room, dressing room, and steam room in the room. When operating in winter, a vestibule design will be required.

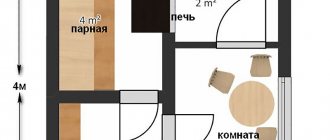

Plan of a small log house for a bathhouse

A small wooden bathhouse has dimensions of 5x4, 5x5, 6x3 m. A veranda or porch can be attached to the building. A project with a 1st floor can be supplemented with an attic if necessary. Due to the small dimensions of the building, the shower room is often made a passage between the relaxation area and the steam room.

Typical projects

The advantage of standard projects is the accuracy of dimensions, designs, and planning solutions. Projects are optimized, shortcomings are eliminated, and the client receives a reliable building. Choosing a standard drawing allows you to save on development, building materials, and the work is completed in less time.

The design solutions take into account construction standards. The list of developed projects includes compact buildings, structures with swimming pools, verandas, an attic floor, and a glazed balcony. According to the project, a bathhouse made of rounded logs 6x6 m is created with a summer kitchen, a garage block, a billiard room and a recreation area.

Choosing lumber for a bath

The log house for the bathhouse is built from coniferous wood - spruce, juniper, pine, cedar and larch. At the same time, the best lumber for the construction of wooden baths is considered to be the part of the wood from the butt (root part) to the crown. This area has a high density of wood fibers and is virtually free of flaws.

There are two types of wood on the construction market:

- dried;

- with natural humidity levels.

Important! After construction, a log house made of dried material is less susceptible to shrinkage.

In order to properly build a log bathhouse, it is important to consider the following recommendations when choosing and preparing lumber:

- The quality of the material is determined by the absence of stains, deformations, knots, cracks and wormholes on the surface.

- The permissible level of curvature of one log should not be more than 10 mm, diameter - from 25 to 35 cm.

- A wooden frame from raw material is erected immediately after its preparation for uniform drying and shrinkage of the finished structure. This will prevent possible deformation of the bath.

- Wood felling is often carried out during the cold season - in late autumn or winter.

- The sawn logs must be stable and mature for at least 30 days from the moment of felling.

- When preparing the material yourself, the logs are carefully cleaned of bark and knots with a scraper. In this case, strips up to 20 cm wide are left on the edges for natural shrinkage of the wood.

- To ensure long-term storage, cut logs are stacked in bundles or stacks, maintaining 6 cm gaps between individual elements, 1.5 cm between rows, and 15 cm from the top ground level to the bottom elements.

Important! When preparing logs, one should take into account the technical shrinkage of the trunk diameter, which should be up to 8 mm for each linear meter of wood.

Project selection criteria

When selecting a project, the following criteria are taken into account:

- dimensions;

- planning;

- number of storeys;

- communications.

The minimum dimensions of bath complexes are 3.5x3.5 m. Common standard dimensions of 5x7, 6x4, 6x6 m are optimal for installing a heater; it is not recommended to use a metal stove for use in winter. In case of non-compliance with the requirements, the author’s project is carried out taking into account the necessary structural solution, design, and layout.

The layout of the sauna should include a steam room, a dressing room and a wash room. Comfortable projects can include a terrace, swimming pool, balcony.

The building design typically includes 1-2 floors, it indicates the location of water supply, sewerage, and ventilation systems.

General layout of the bathhouse within the site

Structures must comply with key principles within the layout on the site:

- The distance from the bathhouse to the residential building must be at least 10 m. On the one hand, this is an immutable requirement of fire safety rules, on the other hand, it ensures normal smoke removal during heating of the sauna stove in various weather conditions;

- The distance from the fence to the bathhouse structure must be at least 3 m. This condition will allow fire crews to have access to the entire perimeter of the bathhouse structure during the occurrence of force majeure circumstances, in other words, a fire;

- The structure of a bathhouse located on the shore of a natural reservoir. It should be about 15 m away from it.