The foundation for a log bath is a fairly common building element. The question of how to place a log bathhouse on a foundation has interested people since ancient times, and was solved in different ways.

The bath house itself has a long history; the construction of such baths remains popular in our time, and modern technologies make it possible to successfully solve the problem of which foundation is best to place the bath house on. The construction of the foundation of a building is a rather complex undertaking, but it can be done on your own if certain conditions are met.

Selection and technology of building a foundation for a bathhouse.

A modern bathhouse is a lightweight structure made of logs or timber that can stand on any type of foundation.

When choosing a foundation, you need to take into account the characteristics of the soil on the site and economic feasibility - extremely reliable foundations made of a monolithic slab or reinforced concrete piles for a small bathhouse with an area of up to 6x6 m will simply be unnecessary. Installation of a log bathhouse on the foundation.

Bathhouse on a strip foundation.

In this article we will look at the optimal types of foundations for a bathhouse, give recommendations on their calculation and DIY technology. Strip, columnar, screw and slab foundations, as well as cheap tire foundations, will be examined in detail.

Calculation instructions

To determine the size of the base of the bathhouse, it is important to take into account the weight of the future structure and the distinctive features of the soil. For calculations you will need to use three formulas:

For calculations you will need to use three formulas:

Depth H = h * kT * kL h – standard for soil freezing in the region; kT – coefficient of soil heating during active heating of the steam room (0.7 - 1); kL – coefficient value of frequency of use. Base size A = B (C * D) A – base width; B – weight of the structure, taking into account the roof, stove and number of visitors; C – soil resistance. D – base length; Number of pillars or pile supports X = B (C * Z) X – number of piles; B – weight of the structure; C – soil resistance; Z is the cross-sectional area of the pile.

Choosing a foundation for a bathhouse.

When choosing which foundation is best for a bathhouse, you need to consider three factors:

- weight and size characteristics of the structure;

- geological conditions on the site - presence of a slope, type of soil and its bearing capacity, freezing depth and groundwater level;

- budget allocated for construction.

In most cases, the best option would be a strip foundation for a bathhouse . The different depths of the strip foundation allow you to build in any soil conditions - on stable soil it is rational to construct a shallow strip (deepened by 30-80 cm), in heaving soil - deep strips (the support base is 20-30 cm below the depth of soil freezing).

However, the arrangement of a buried foundation is accompanied by serious costs for materials, and in order to save money, it is better to give preference to screw or columnar foundations.

The screw foundation for a log bathhouse consists of steel piles tied with a grillage, the blades of which open the surface layer of soil and rest on solid deep soil. The advantages of this option are low cost, quick installation time (installing a foundation for a bathhouse takes 2-3 days) and reliability.

Foundation for a log bathhouse.

Shallow strip foundation for a bathhouse.

A good analogue for the construction of light buildings (log house, frame panels - area from 3x3 to 6x6 m) is a bathhouse on a columnar foundation. To install a log bathhouse on poles, the soil on the site must not be prone to horizontal shifts, otherwise there is a high risk of the supports overturning. The pillars can be monolithic (concreted asbestos pipes) or prefabricated (from FBS blocks).

In complex soils - mobile, heaving and low-density - a foundation slab is needed. This is a monolithic structure made of reinforced concrete 30-50 cm thick, the dimensions of which correspond to the area of the building. The slab is a reliable and durable foundation for a frame bathhouse or log house, but its cost is higher than other analogues.

A simple foundation for a bathhouse, suitable for light frame buildings measuring 3x3 and 3x4 m - a base made of car tires. It is possible to erect a building on such a foundation in stable soil that is not prone to heaving. A bathhouse without a foundation can only be built on rocky soils.

Collection of characteristics and calculation of the foundation.

Before building a foundation for a bathhouse with your own hands, you need to calculate the foundation and find out whether it will withstand the building in specific soil conditions. You need to determine the type of soil on the site (sandy, clayey, sandy loam) and, using standard tables, find out the value of its resistance per 1 cm 2.

Next, you need to calculate the loads that will be transmitted by the foundation to the soil. Load calculations are performed using the following algorithm:

- Calculation of the mass of a building - the weight of the roof, floors and walls is separately calculated and summed up by multiplying their area by the specific weight of the building material (tabular data).

- Calculation of snow loads - multiply the roof area by the weight of m 2 of snow cover in your region.

- Calculation of operational loads (furniture, stove, wall cladding) - multiply the area of the basement floor by the average load of 100 kg.

- Calculation of total loads - we summarize the obtained data and add a safety margin by multiplying the amount by 1.2.

It remains to determine the supporting area of the foundation, multiplying its perimeter by its width, and calculate the load per 1 cm 2 of soil.

For example: the standard width of the tape for log walls is 30 cm, for a bathhouse with an area of 6 × 6 m (perimeter 24 m), its supporting area will be - 240 * 30 = 7200 cm 2. for a 3 × 3 building - 3600 cm 2. for 3x4 bath - 4200 cm 2. and so on. Now you need to divide the total loads by the supporting area and compare the resulting value with the resistance of 1 cm 2 of soil; if the result exceeds the bearing capacity, you will need to increase the area where the foundation rests on the ground by adding the width of the tape or the diameter of the pillars.

Depending on the bearing capacity of the soil

This indicator is considered the main one and depends on the composition and size of soil particles, the degree of its compaction and moisture saturation.

Soils with high bearing capacities (coarse and medium sands, dense gruss, gravel and rocky soils) are suitable for the construction of any type of foundation for a bathhouse, including budget columnar and prefabricated strips of concrete blocks. If there are small and weak particles in the soil (water-saturated sandy loams, plastic clays, fine sand, peat), the foundation under buildings swells and moves during periods of freezing and thawing. The requirements for the stability of the foundation for a timber bathhouse in such cases increase significantly. In particular:

Of particular danger are quicksand soils consisting of a mixture of flakes of plastic clay and fine suspended matter. Due to the strong risks of horizontal soil shifts in such areas, the construction of residential and commercial buildings is not recommended in principle. The problem can only be solved by a stable pile-screw foundation with a support length of at least 3 m or a complete replacement of the soil in the pit.

Do-it-yourself foundation construction technology.

When considering the question of how to make a foundation for a bathhouse, we focus on the fact that the floor slab of the bathhouse must be equipped with a drain, which is installed at the stage of pouring the foundation.

In the wall of the strip foundation it is necessary to provide a hole for the drainage pipe, and the floor of the bathhouse itself - a concrete screed or a joist floor, should be made with a slope towards the central part, in which a drain hole covered with a metal mesh is placed. The water is discharged through a pipe into a storage well located outside the bathhouse at a distance of 2-3 meters.

Strip foundation.

Foundation for a bathhouse made of logs.

A shallow strip foundation is the optimal solution for building a log bathhouse with an area of 4×6 to 6×6 m. The supporting part of the MLF is placed at a depth of 30-50 cm, and 20-30 cm of strip is also formed above the ground level, which is used as a base.

Let's look at how to properly pour the foundation for a bathhouse:

Which foundation is better for a log bathhouse?

Strip foundation diagram.

- The foundation is marked - its design contours are transferred to the site using reinforcement pegs and twine.

- Using shovels, a trench is dug to the depth of the tape plus 20 cm under the compacting bedding;

- A layer of sand 10 cm thick is formed at the bottom of the trench, and on top of it is a layer of crushed stone of similar thickness. The bedding is carefully compacted by compaction.

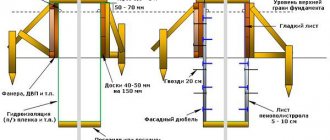

- Outside the trench, formwork is installed from boards 1-2 cm thick, which will form the ground part of the tape. The structure is strengthened with stakes and spacers. The trench and formwork walls are covered with waterproofing material.

- The foundation is reinforced with a double-circuit frame made of reinforcement with a diameter of 12-16 mm. The upper and lower belts of the foundation are connected by vertical jumpers in increments of 40 cm. Proper reinforcement of the corners of the tape - the frame should not be connected by a cross joint, but by rods curved at right angles.

- After the reinforcement is completed and the assembled frame is installed in the formwork, the shallow foundation is concreted with concrete grade M200-M300.

The formwork is dismantled 2 weeks after pouring, after which the floor can be laid out and the walls of the log house can be raised. The floor will need to be insulated to prevent heat loss from the bath through the ceiling. If you are making a joist floor, insulation (mineral wool, polystyrene foam or EPS) is laid between the joists and covered with facing boards.

Waterproofing the insulation is important - it needs to be covered on both sides with a PVC membrane that prevents the material from rotting under the influence of high air humidity. Waterproofing is also laid along the upper contour of the tape on which the basement of the bathhouse is placed.

Construction of a strip foundation (video).

Columnar foundation.

It is rational to make a columnar foundation for a bathhouse with your own hands from concreted asbestos pipes, deepened below the freezing level of the soil - in this case, the log house will be protected from heaving. The pillars are tied with a grillage made of timber or channel.

Let's look at how to pour a foundation for a bathhouse:

- The contours of the foundation are marked on the site and the installation points of the supports are indicated.

- Using hand-held drilling tools, wells are developed for the installation of pillars (the optimal diameter of asbestos pipes is 25-30 cm, the depth of the foundation is 2 m).

- The pipes are installed in the well, they are reinforced with 4 reinforcement bars of 10th diameter (the rods are stuck into the ground).

- M300 concrete is poured into the pipes, until the mixture has hardened, a steel pin (a rod 40-50 cm long with a threaded thread) is inserted into the central part of the column to secure the grillage. The stud should protrude to the thickness of the grillage and penetrate into the concrete by at least 20 cm.

- The post is tied with a grillage made of timber with a cross-section of 15×20 cm. The beam is cut to size, groove joints are cut out in the joining parts, after which the strapping is laid on the supports. At the points of connection with the posts, a through hole is drilled in the timber for the pin and a seat for the fixing nut (using a feather drill).

How to put a log bathhouse on the foundation.

Foundation made of tires for a bathhouse.

Before laying the grillage, the pillars must be waterproofed - roofing material or glass insulation is placed on their end part under the timber.

Tire foundation.

The technology for arranging a budget foundation made of tires for a small log house or a light frame bathhouse is extremely simple to implement—neither reinforcement nor waterproofing is required. To work, you need 10-15 tires from a passenger car ( diameter 60-70 cm ).

The distribution of tires is as follows - one at a time in the corners of the log house and evenly, in increments of 1 m, along the perimeter of its walls. Initially, you need to make a pit for the entire area of the bathhouse with a depth of 15-20 cm, fill it with crushed stone, level it and compact the bedding tightly.

Next, mark the contours of the log house and use pegs to indicate the placement of the tires. Having centered the tires on the pegs, cover their bottom with geotextile and fill with crushed stone, not reaching 5 cm to the top. The crushed stone is compacted and the remaining space is filled with cement-sand mortar.

To prevent the tires from being destroyed during operation due to the scorching sun, they need to be covered with glass insulation, after which you can begin laying the bottom frame timber and raising the walls.

Step-by-step instruction

A step-by-step plan will help you understand the sequence and technology of work on arranging the foundation.

1.Preparation of the site. On the selected site for construction, markings should be made according to the project. The technical description of the object must contain information about the orientation of the bathhouse relative to the cardinal directions (or the object is tied relative to the buildings already existing on the site).

Pegs are installed along the perimeter of the building area, a layer of fertile soil is removed from the marked area, and the surface is leveled.

2. Preparation of trenches. Trenches are marked and dug according to the design. Make sure that the depth corresponds to the calculated one, taking into account the thickness of the “cushion”, and the width exceeds the width of the tape by approximately 30 cm - this gap is necessary for installing the formwork. A properly prepared trench has vertical walls and a horizontal bottom, this is checked by level.

3. Laying the “pillow”. A layer of coarse sand 200 mm high makes it possible to absorb and evenly distribute the loads that act on the foundation strip from below due to soil movements. If the soil on the site is prone to heaving, it is recommended to use fine crushed stone or a mixture of crushed stone and sand instead of sand.

Guidelines for the construction of underground foundations require careful attention to the creation of a “pillow”. Sand or crushed stone is poured onto the bottom, moistened, leveled and compacted tightly by hand. A high-quality “pillow” has a horizontal, flat surface and does not leave marks on it from an average-weight adult.

4. Formwork. The materials for its installation are low-grade or used boards and plywood panels. With the help of wedges and supports, as well as metal internal struts, the verticality of the walls and the rigidity of the structure are ensured - it should not burst when concrete is supplied.

The inside of the formwork is lined with plastic film or roofing felt so that the “dishes” for the concrete mixture are airtight. Otherwise, the cement “milk” will leak out and the concrete will not gain the required strength.

5. Reinforcement. The metal frame in reinforced concrete takes on the loads of expansion and compression. The reinforcement structure is fastened in such a way that there is at least 5 cm of concrete on all sides of the rods. This will prevent moisture from getting on the metal and corrosion of the frame.

For reinforcement, ribbed rods with a diameter of 14 mm are used, which are fastened together with knitting wire or plastic clamps. It is not recommended to use welding - such joints are characterized by increased fragility due to overheating of the metal. For a shallow foundation this is critical.

6.Filling. The concrete mixture is ordered ready-made (in a mixer) or prepared independently in a large container using an attachment on an electric drill for stirring. A household concrete mixer will help simplify and speed up the work.

Concrete is fed into the formwork in different places, pouring layers 25 cm thick. Immediately pierce the concrete with a rebar to expel any air bubbles. Pouring must not be interrupted until the formwork is full.

7. Strengthening. After removing air bubbles, the filled formwork is covered with film. In hot weather, hardening concrete is regularly moistened. It will take about a month to completely dry and gain strength.

Building a strip foundation for a bathhouse with your own hands is a feasible task for a person with construction skills.

Which foundation is better for a log bathhouse?

The foundation of a log bathhouse with your own hands.

To build a bathhouse on a site outside the city, various materials can be used. First of all, this is a log house, rounded logs and other natural building materials. Saunas made of logs and logs are in demand, first of all, because they have excellent thermal conductivity characteristics.

Before you start installing a bathhouse, you should decide which foundation is best. In order not to make a mistake with your choice, you should not only accurately determine the location of the upcoming construction, but also carefully examine the soil on which the work will be carried out.

Metal and concrete screw piles

On weak, wet, uneven and prone to crumbling soils, the only correct solution is to lay a pile-type foundation under a timber bath. Such work is carried out using special equipment (in case of high soil density and long supports) or independently using devices for screwing metal piles or hand drills for preparing holes for concrete pillars. The technology for constructing a foundation from screw piles is recognized as the most effective and fastest. When implementing it, a simple algorithm of actions is carried out:

1. The pile field is marked according to a pre-drawn diagram, with pegs driven in in the right places and the level checked using a cord and a laser pointer. Supports are laid in the corners and under all load-bearing structures of a wooden bathhouse, including stove foundations, in increments of no more than 2 m. If the bathhouse is heavy and the soil has low load-bearing capacity, the piles are screwed in not only around the perimeter, but also under the building itself, followed by tying it with metal or timber .

2. In the marked places, pits up to 50 cm deep are prepared. After this, piles are screwed into them using a screw device placed on the top of the metal support. Thanks to special blades or pointed ends, problems with twisting metal piles under a bathhouse do not arise; the need to use special equipment arises only in extreme cases (the presence of large debris in the ground or construction on peat bogs).

3. After screwing in and checking the evenness, the piles are cut to a height of 20-40 cm and filled with concrete. At the same stage, threaded rods with a cross-section of at least 15 mm are installed in their upper part to hold the timber frame, or metal caps are welded for subsequent fastening of the channel.

An alternative to metal piles are driven or vibrating supports made of reinforced concrete. This option is considered reliable, but expensive due to the need to use special equipment.

When constructing on wet soils, supports need enhanced protection from corrosion or the aggressive effects of groundwater. Under such conditions, metal piles are pre-treated on the outside with protective compounds, while concrete piles have a higher water resistance grade or are coated with bitumen.

Screw piles bath

Columnar foundation.

Heaving soil.

A columnar foundation for a bathhouse is pillars buried in the soil below the fertile layer. Installation of these pillars is carried out at the intersection of partitions with the internal walls of the bathhouse, in corner parts and on straight sections of the base in increments of 1-2 meters. The sufficiently large depth of installation of the pillars makes the columnar foundation the optimal solution for the construction of a log bathhouse on soils with high heaving rates, as well as in climatic zones where the depth of soil freezing is especially high. To fill the foundation of such a plan, materials such as concrete, red hardened brick, stone, asbestos pipes filled with concrete, and wood pillars treated with antiseptics are most often used.

Base materials

Having chosen a certain type of foundation, you need to find out what the bathhouse building will be made of, because this will also affect the foundation. If the bathhouse will be built from piece material, for example, blocks or bricks, and will also be of a frame type, then this is an excellent prerequisite for using a strip base. And if the bathhouse is made of timber or logs, then a columnar type of base will also be good.

For example, if we have a bathhouse made of wooden beams, a columnar base will be required for its construction, especially if the soil mostly consists of coarse sandstone. Also in our example, the earth has a different structure in different zones, and the frost line is located at a depth of seventy centimeters. Such conditions will be ideal for constructing a columnar foundation with pillars buried to a meter depth. The depth of the base of a structure such as a bathhouse must be correctly calculated and strictly observed. After all, if the parameters of the foundation were thought out incorrectly, then the consequences could be a breakdown of the foundation in the future and an immediate need for repairs.

The columnar foundation is made on the basis of asbestos cement pipes with a diameter of 200 mm. Construction experience suggests that the pillars will be required for installation in the space under each of the log corners, as well as at a distance of no more than 1.5 meters from each other, if we are talking about the space that lies under the partitions of the capital structure that exist in the structure of the bathhouse. This also needs to be done if the pillars according to the plan are supports for load-bearing walls.

to contents

Pile foundation.

The pile foundation is perfect for a log house for a bathhouse. This option turns out to be much better than all the others if you plan to do all the work on laying the foundation without involving specialists yourself. Especially often, the installation of a pile foundation is carried out on weak, unstable, and also heaving soils. For this type of foundation, wooden, concrete, and steel types of piles are used.

There is a fairly significant difference between steel and all other types of piles. Steel piles are usually produced in a screw design. Unlike the others, they are not driven in, but screwed into the ground.

How to make a foundation for a bathhouse from a log house.

In some cases, piles can be used as an element of a strip foundation for a log bathhouse . the depth of which requires increasing.

The main advantages of a properly laid pile foundation include:

- the relatively low price of such a foundation for a log bathhouse;

- quick installation of a foundation for a log bath;

- shallow depth, allowing all work to be carried out without the involvement of professionals.

Safety

Safety for a bathhouse is a paramount issue.

Wood, stoves, constant exposure to high temperatures often lead to fires. The main reasons are contact of the chimney with wood and improperly installed electrical wiring. To avoid contact, it is recommended to tile the stove. The wiring must be used with asbestos insulation and run along the surface of the wall. Switches and sockets are not installed in the steam room; the lamps are protected by special shades. Sockets in dressing rooms are equipped with special covers. If we take into account all the mistakes traditionally made by builders, the bathhouse will last a long time and safely.

Strip foundation.

The installation of a strip foundation is justified if the bathhouse building has a very large area (in order to evenly distribute pressure on the ground). Among the different types of foundations, the strip foundation is the most expensive. But it is practically irreplaceable if it is necessary to install a bathhouse on unstable soils.

There are four main types of strip foundations:

- monolithic;

- made;

- buried below the soil freezing level;

- shallow.

Which specific strip foundation should be installed for the construction of a bathhouse made of timber is decided individually.

conclusions

In each individual case, it is very important to take into account the characteristics of the soil, the size of the structure, the quality of the materials used, as well as other factors that significantly affect the reliability and durability of the object. The width also affects the strength of the foundation. In any case, taking into account such characteristics, you can easily and confidently make one or another type of foundation with your own hands, as a result of which you will get a truly beautiful and reliable bathhouse and enjoy your vacation

In any case, taking into account such characteristics, you can easily and confidently make one or another type of foundation with your own hands, as a result of which you will get a truly beautiful and reliable bathhouse and enjoy your vacation.

Attention! If you are not confident in your abilities, it is recommended to turn to specialists with experience who will carefully analyze what kind of soil is on the territory and choose exactly the type of base that is most suitable for you.

Slab foundation.

What kind of foundation is needed for a log bathhouse?

Since building a bathhouse from a log house requires a high-quality and reliable foundation, the question of which option is better to choose is often decided in favor of a slab foundation. First of all, it is needed when constructing buildings on problematic soils. In this case, it is important to choose the right slab, which will serve as a kind of stabilizer for the building and reliably protect it from subsidence. At the same time, any material can be used to build a bathhouse: log house, logs, etc.

It should be borne in mind that in order to make a slab foundation for a bathhouse from materials such as logs or logs, it will take quite a lot of time.

The process is quite expensive from a material point of view, and therefore they decide to lay a slab foundation only if any other options turn out to be unacceptable.

Stage 1. Preparation of round timber

The construction of a log bathhouse is a labor-intensive and responsible process that is carried out in stages. The initial stage is preparing the bathhouse project. A typical project includes:

- choosing a suitable location for development;

- layout of the number of floors and interior spaces of the bathhouse;

- layout of the location of window and door openings;

- selection of heating, ventilation equipment and lighting devices;

- selection of construction and finishing materials;

- development of premises design;

- calculation of construction costs.

Finished projects are presented in the public domain, but to receive an individual sketch, you should contact the design office.

Preparing the log

Round timber must be harvested at sub-zero temperatures, that is, in winter. It is at this time that the amount of moisture in the wood is minimized, therefore, during drying the material will deform and crack less.

Harvesting logs for a log house

Butt logs

The same applies to diameter. For example, the diameter of the base of the log is 35 cm, while the top is 25 cm or less. Such round timber is categorically not recommended for use in construction.

Logs for a log house

Perform further actions in accordance with the previously drawn up project. You can create such a project yourself, find it on the Internet, or order it from specialists. It is with the help of this document that you can calculate the required amount of consumables, determine the area and shape of the base.

To work you will need the following equipment:

- chisel; Chisel

- carpenter's axe; Carpenter's Ax

- medium power chainsaw;

- plumb line; Plumb

- level; Laser level

- electric drill; Cordless drill/driver

- mallet; Wooden mallet

- "trait". Trait (tool)

We will pay special attention to the last tool - the “line”. For production you will need steel wire with sharply sharpened ends.

Bend the wire in half so that it takes the shape of a compass; you can additionally secure the handle. This tool will be needed when marking logs.