A visit to a modern bathhouse or steam room is not just a desire for cleanliness or a tribute to fashion. A bathhouse with healing steam and heat from the stove promotes health, beauty of body and spirit, good mood, and restoration of vitality. However, this is possible with a sufficient amount of fresh air and the absence of microorganisms that can cause disease. A well-equipped hood in the bath as an element of the ventilation system of the room.

Is a ventilation system needed in a bathhouse?

Breathing is a reflex process that our lungs perform to take the required amount of oxygen from the environment. Normal air consumption is not noticed until a person enters a room where the air is stale or insufficient. Baths and steam rooms are precisely such risky places; they should always be hot, fresh, and clean. The question of whether ventilation is needed in the bathhouse and steam room is not even discussed. According to sanitary standards, owners must provide an air exchange system in the project and apply step-by-step guidance during the construction phase.

During the ventilation process, conditions are created under which the proliferation of bacteria and fungi becomes impossible, which means that mold and mucus will not grow in the corners and crevices of the structure.

Conclusion

So, these days, ventilation in the bathhouse is becoming more and more popular. In most projects of bath complexes, ventilation is already included by the designers. Ventilation can be done either with your own hands or ordered from specialized companies. When choosing a ventilation system, everything depends primarily on the type of structure and on what kind of steam room the owner of the future bathhouse wants to get.

It is important to remember that the type of future bath will also depend on the selected ventilation. If you decide to do the ventilation yourself, be sure to follow all safety requirements and be extremely careful when making calculations. Remember that a design mistake can ruin all the sensations you wanted to get from your future bathhouse.

The principle of operation of the ventilation system in the bathhouse

ventilation is conventionally divided into constant (includes wall, roof and foundation) and ventilation, which operates periodically, when the bathhouse is in operation, the stove is heated. Both are included in a single ventilation system, which is designed together with the construction of the bathhouse.

The principle of operation is to displace exhaust air with clean, fresh air. For this purpose, through holes are installed, at least two, which operate depending on the direction of flow and only when there is a difference in temperature indoors and outdoors.

A few more rules, if you follow them when arranging ventilation in a bathhouse with your own hands , the principle of operation will not be violated:

- When the bathhouse warms up, close the vents in the foundation and the dampers in the steam room.

- During procedures, windows are opened as needed.

- After steaming, the sauna is completely ventilated.

The supply and exhaust supply and exhaust air in the volume that the dampers on them allow. Calculating the size of the window is simple: for every cubic meter of room you need 24 cm2 of holes. And one more thing: the windows cannot be placed opposite each other.

Additional Tips

In order for ventilation to function normally, vents are made in the foundation.

To ensure normal air circulation in the bathhouse, adhere to the following recommendations.

- Under no circumstances should you plug the vents with rags or fill them with foam for the winter. In this case, the ability to remove steam disappears completely and moisture accumulates inside the bath. Vents must be left open.

- To create vents in the foundation, it is better to use asbestos-cement or plastic pipes rather than wooden blocks. Removing the pipes is much easier.

- Ventilation holes located low above the ground are covered with durable grilles to prevent rodents from entering the bathhouse.

- It is better to install vents in the room after decorative finishing.

Ventilation in the bathhouse guarantees an optimal microclimate and a long service life of the building. Insufficient ventilation is the cause of moisture accumulation, wood rotting, mold, and destruction of finishing materials.

Proper ventilation in the sauna steam room

To provide for all the subtleties of installing ventilation in a bath means to protect yourself from dampness, rapid cooling of walls and furniture, cold floors and the accumulation of carbon monoxide. In addition to freshness, ventilation should not create drafts, cool the floor, or provoke sudden temperature changes.

The essence of ventilation is air flow at two ends: inflow and outflow. You need at least 2 holes, installed according to the rule - outflow above, inlet below. It is best if a ventilation device is included in the bathhouse design before construction. The shafts and the diameter for the holes are indicated. There are 3 basic solutions for choosing openings that provide not only air exchange, but also safety:

| Type of bath | Inflow, mm | Hood, mm |

| Russian | 100 | 100 |

| Finnish | 130 | 100 |

| Swedish | 100 | 80 |

It is prohibited to make the exhaust opening smaller than the supply opening. Also, according to the rules, ventilation openings must have valves that ensure tightness during the moment of kindling and warming up the steam room. In winter, the valves are closed halfway, because the greater the temperature difference, the stronger the air circulates.

The need for ventilation in a bath structure

Without ventilation, when using a bathhouse, you may encounter dampness, bad odor and lack of clean indoor air. High-quality ventilation in a steam room is a criterion not only for a favorable atmosphere, but also for the safety of visitors. If ventilation is not arranged correctly, the following negative consequences may occur:

- Wooden parts, even with proper ventilation, are subject to significant stress and last a maximum of 20 years. Lack of ventilation can reduce this period several times. Therefore, it is recommended to take care of the ventilation system in advance so that you do not have to carry out major repairs at unplanned times.

- The air will stagnate in the bathhouse, which will cause the wooden parts to rot. This may cause discomfort to visitors.

- If stagnant air is not removed from the room in a timely manner, the use of such a building can cause harm to the human body. The steam room will accumulate gases that people exhale and emit from a functioning stove, as well as the odors of progressive fungi and mold.

If there is insufficient ventilation, fungi and mold begin to appear in bath rooms.

Another important function of ventilation is to provide heat exchange. Humid air practically does not allow heat to pass through, so without recirculating the air flow, the stove will only heat the surface around itself. For this reason, the ventilation inlet is often located at the rear of the stove at a low height from the floor. This will allow the air to warm up and distribute heat throughout the building. Otherwise, cool air will be supplied to the room, and therefore the temperature regime will be disrupted. From this we can conclude that not a single bathhouse building can do without proper ventilation.

Bath ventilation device, diagrams

Natural ventilation operates thanks to air convection, which occurs in the event of temperature changes in and outside the building. Hot air will always rise to the top, and cool air will always descend to the floor base.

Air circulation in the bath occurs due to the displacement of hot air by colder air entering through channels specially made for this purpose.

The main task of ventilation is to ensure the supply of the required amount of cool air and replace the hot air with it. Therefore, the outlet should be placed on the wall opposite to the air inlet channel. Otherwise, the mechanism will not function correctly.

Quite often, novice craftsmen make the mistake of placing the ventilation slots at the same level: they will form a closed flow that will not affect most of the room, so it will always be cool in the lower part, and stuffy and hot in the upper part. If everything is done correctly, the warm air will rise and move outside through the hood. A vacuum will be created in the building, and fresh air will be drawn in through the inflow near the floor base. After some time, it will begin to heat up, rise and displace some of the hot air through the hood. This method provides constant convection and natural ventilation, without requiring human intervention.

Inlet and outlet ventilation openings should be located on opposite walls and at different levels

As an exhaust device in a bathhouse you can use:

- products;

- stove chimney;

- windows.

Air supply can be provided through:

- open doors;

- vents for ventilation;

- crowns of walls (relevant for log baths).

Each vent required for the ventilation mechanism must be equipped with a shutter and an adjustable grille. This will control air exchange and eliminate drafts.

To correctly build a ventilation mechanism in a bathhouse, you need to familiarize yourself with the principle of its structure.

Warmer and humid air rises up and is removed through the hood, and in its place comes fresh air, heated by the furnace body.

There are several methods of natural ventilation. Each has advantages, special functions and certain restrictions on use.

Burst ventilation

In a small Russian bathhouse, burst ventilation is often used. This method consists of ordinary ventilation, which is performed after procedures or between trips to the steam room. Such ventilation allows you to immediately change the air and dry the surface of the steam room.

Burst ventilation allows you to quickly dry the internal surfaces of walls, ceilings and shelves

In burst ventilation, the role of ventilation slots is performed by a transom and a door, which are located on opposite walls. To change the air, they will need to be opened for a short period after the procedures. Air can move towards the doors or in the opposite direction. It depends on which direction the pressure difference will act. Such ventilation is needed to freshen the air, but not to cool the walls. Therefore, you need to ventilate for no more than 2 minutes.

The possibility of such ventilation should be provided in any bathhouse. This will allow you to quickly dry the internal bases of walls, ceilings and shelves, as well as extend the service life of the bathhouse elements.

Ventilation with outflow through the chimney pipe

For ventilation, you can use a stove-heater with a chimney pipe. During the combustion process, hot air will be drawn into the ash pit and exit through the chimney pipe. To allow inflow of cold air, you will need to make a gap of about 6–8 mm at the bottom of the door. Another option is to loosely close it when taking procedures. In the log-house bathhouse, during the heating process, air from the street can be drawn in through the lower rims. To do this, they need to be adjusted, leaving a gap of several millimeters.

When fuel burns in the stove, a vacuum occurs, air from the steam room is drawn in, passes through the chimney and is thrown out.

Ventilation by venting air through a chimney can only be done while maintaining a fire in the stove. If the fuel does not burn, the air will stop circulating. A more advanced ventilation mechanism will be needed.

Ventilation through vents

Air exchange, which is carried out through special openings, is a universal ventilation mechanism. It makes it possible to gradually replace the air in the steam room several times during the procedure (about 6-7 times in 60 minutes). If you plan such ventilation correctly, there will be no draft and no drop in temperature.

The air outlet hole is mainly located under the ceiling structure, above the top shelf. The optimal size is 16–20 cm. It can be made in the shape of a circle or square. The hood will need to be closed with a removable plug or a sliding door, with the help of which it will be possible to change the dimensions of the hood and the level of air exchange.

When designing a ventilation system in a bathhouse, you must choose one of the vent layouts

When installing vents, it is important to consider some rules:

- It is not recommended to place the slots at the same level. The cool air that enters the steam room will immediately fly out into the exhaust slot. Accordingly, it will not be able to fully recirculate, but a draft will form.

- The linear dimensions of the hood should not be less than the dimensions of the inlet recess. Otherwise, fresh air will not be able to penetrate into the bathhouse.

- If it is necessary to increase the outflow of hot air, the dimensions of the hood are increased relative to the supply opening. Another option is to arrange 2 hoods for 1 entrance slot.

The entrance slot should be located at a height of approximately 0.2–0.4 m from the floor covering. It can be placed on the same wall as the hood, or on the opposite side. The advantage would be to place it next to the stove so that the penetrating air has time to warm up and enters the steaming zone already hot. The inlet hole must be covered with a metal grill so that the air is drawn into the building in streams and not as a solid stream.

Forced ventilation

A mechanical ventilation system is needed if:

- the total area of the building is quite large;

- the structure is made of bricks, blocks or stones;

- the steam room is large in size;

- ventilation pipes cannot be placed correctly;

- The oven is designed for high power.

To implement such a system, you should use:

- valve for air flow;

- deflector;

- fan.

Forced ventilation in the bathhouse is suitable for large rooms

You need to purchase a heat-resistant fan designed for baths, with a degree of protection against dust and moisture at IP 44 or higher.

Fresh air will flow naturally, through the lower opening. The extraction of heated air will be ensured by mechanical devices.

Video: ventilation device in the bathhouse

Types of ventilation

There are several ways to remove exhaust air and replace it with fresh air. It all depends on the configuration, area, and functionality of the room. The most suitable way to properly ventilate a bathhouse is selected taking into account:

- number and location of rooms;

- type of walls;

- type of heating: wood and electric appliances are part of the ventilation system of the bathhouse.

When building baths, natural and forced ventilation are used.

Natural

The operating principle is based on temperature differences and atmospheric pressure changes inside and outside the building. The advantage of natural ventilation is autonomous operation without power supply and the use of other factors that encourage air flows to move. It is easy to install, does not break, and does not require large expenses. To regulate ventilation and limit the access of frosty air, valves or vent covers are purchased.

Forced

Here air flows are created or strengthened forcibly. Fans are used for this. The system allows you to supply or displace air stably and continuously, its operation does not depend on weather conditions. Human intervention is minimized, and the ability to control and make fan operation settings via a smartphone makes this method of maintaining comfort even more convenient.

Combined

Buildings made of stone, frame-panel, lined and insulated in different ways require different approaches to the arrangement of ventilation systems. In addition, the designs of modern baths are not limited to only the dressing room and washing room: steam room , locker room, bathroom, rest room - in each of these rooms one or more types of ventilation are installed and used depending on the situation, before, during the procedure or after her.

How to properly make ventilation in a bathhouse with your own hands

Modern manufacturers offer a wide range of ready-made kits for ventilation of rooms. You can take advantage of these suggestions or make the system yourself. There are three options for organizing air exchange:

| Option | Description |

| Natural | It works thanks to the difference in pressure inside and outside the room. The supply duct is located near the floor, the exhaust duct is located near the ceiling. Does not require any special equipment, but may cause drafts. With such a system, it is important to carefully seal and insulate the room. |

| Combined | Fans are used to speed up air exchange. Such systems performed especially well in the steam room. To install, you will need to buy special equipment and connect it to a power source. |

| Mechanical | Highly productive systems using sensors and controllers for control. They require regular maintenance and are more expensive than others. |

The choice between these three types of air exchange depends not only on the financial capabilities of the bathhouse owner, but also on the type of structure. Proper ventilation in a bathhouse takes into account the materials of the walls and floors, the location of heating devices, and the placement of the bathhouse relative to other buildings on the site.

Frame bath

Ventilation in a frame bath should be arranged in such a way as not to disturb the multi-layer structure of the walls. Frame buildings are completely sealed, so it is important to organize adequate air exchange to avoid the appearance of mustiness and dampness. In this case, the installation of combined or mechanical ventilation is justified.

Frame baths are quickly erected and have good heat retention

Important! The installation locations for air ducts should be determined at the design stage.

The location of the ventilation ducts in a frame bath is traditional: at the bottom there is a supply flow, in the opposite corner there is an exhaust.

Wooden sauna

Wood is an environmentally friendly material that “breathes” on its own. The spaces between the logs also contribute to natural ventilation in a log bathhouse. But it should be taken into account that a bathhouse is a room with special operating conditions, so you cannot limit yourself to natural air exchange conditions.

For good atmospheric circulation, hoods are installed in the log house

Expert opinion

Andrey Pavlenkov

HVAC design engineer (heating, ventilation and air conditioning) ASP North-West LLC

Ask a specialist

“The opinion that it is necessary to install windows of non-standard, small sizes in wooden baths is erroneous. Double-glazed windows must be of high quality and conserve heat - this is the only requirement.”

Natural ventilation in a wooden bath can be slightly improved by using forced air supply into the steam room. Otherwise, the log house itself will cope well with the task.

Brick and stone bathhouse

Brick and stone buildings are durable. The walls themselves are resistant to moisture, but usually the inside is lined with natural lining, and this material needs protection. If there is no good ventilation in a brick bathhouse, the lining material will inevitably become moldy and deformed. To avoid this, it is necessary to distribute the air flows so that they penetrate under the sheathing material. For this purpose, the finishing material is fixed to the sheathing and holes are left for air flow. Small fans are used to force air into the ventilation slots. This technique guarantees the absence of mustiness and dampness.

Ventilation ducts should be laid at the stage of wall construction

Important! The tightness of the brickwork forces the use of ventilation ducts of a larger diameter, approximately 20 centimeters.

Where to place the cold air vent

The lower vent is responsible for the influx and supply of cold air. A pipe is laid under it during construction or a shaft is left. Bottom hole installation options:

- In the wall, opposite the stove.

- Under the sun loungers, you can’t see it there, and there are no drafts. However, to adjust the position of the damper, you have to bend down under the shelf, which is inconvenient. The situation is corrected by opening the upper outflow, and after the procedures both outflows are opened - both the upper and the lower.

- Behind the stove, if the stove is not installed in a wall and there is access to it. The cold stream immediately warms up, causing the coals to burn hotter.

Outflows are made either in the wall or in the ceiling, providing a place for them in the project.

General principles

Can you relax in a stale steam room, where there is little oxygen and the steam is tiring? The question is rhetorical. Fortunately, ventilation in a bathhouse can be done easily and without much expense.

There are several reasons why you should pay special attention to ventilation: firstly, a wet space requires a draft to dry it well between working periods.

Secondly, during procedures, good ventilation increases the pleasure of the steam, since it is saturated with oxygen, and cold, sweaty air is removed in time.

Modern building elements and materials have increased the tightness of premises by an order of magnitude. This is the answer to the question why our grandfathers did not bother with special ventilation in their bathhouses. The hole under the ceiling for drying was and remains its only element. The flow of fresh air was not ensured by the density of the log house itself, the floor, doors, or windows.

Before you start ventilation in a new or reconstructed bathhouse, you need to take into account such factors.

Spatial orientation

Prevailing winds have a significant effect on exhaust air removal. The inflow should always be organized on the pressure side of the air masses, the outlet on the opposite side.

The logic is simple: the structure creates an obstacle to the wind, behind which a vacuum zone is formed, which enhances natural ventilation and helps the exhaust air leave the steam room faster. Of course, the free exit should not be hampered by the roof slope or other obstacles.

Ability to heat up

The ventilation system will not work if the bathhouse does not warm up well.

Causes:

- The power of the stove does not correspond to the size of the room.

- Ventilation produces increased air exchange.

- Ceilings too high.

- Poor thermal insulation, especially on the floor.

- Unsuitable interior finishing materials.

Incomplete drying of the space and materials under the shelf will also require additional heat to warm it up. Doors and windows must be heat-saving. Ceramic tiles on the floor and walls will always be cold to the touch and condense steam.

Normative base

There is no need to figure out how to properly ventilate a bathhouse: everything was invented a long time ago. Section 6 “Methodological recommendations for the design of baths dated December 30, 1993” talks (with reference to the relevant SNiPs) about ventilation.

Data on the air exchange rate are provided. This is the starting point for correctly calculating the diameters of the air ducts. It is also worth providing the initial data for thermal calculations at which the ventilation works correctly.

Ventilation of various auxiliary rooms

Ventilation in the bathhouse is on the list of mandatory construction measures. Understanding the importance of sufficient air exchange has led to the development and application of various step-by-step schemes for each individual room.

Steam room

If some of the air in a confined space is not removed, then new, fresh air will not be able to enter the steam room. The diagram and device of the steam room ventilation is as follows:

- An influx of fresh air is provided. To do this, a hole is made in the wall below near the floor next to the stove.

- The exhaust hole for natural ventilation is installed on the opposite wall from the stove under the ceiling, and is closed at the time when people are busy with procedures.

- The air entering the steam room immediately heats up and rises upward using convection.

- Up above, under the ceiling, in the Russian bathhouse it begins to become saturated with moisture. Humid air is heavier, so the steam gradually cools in the corner farthest from the stove and falls down.

View this post on Instagram

Post from I’m building a bathhouse as best I can (@banpartal)

It is at the regiment level, at the time of taking bath procedures, that this air must be taken in and removed so that it does not evaporate again. To do this, an exhaust ventilation hole is made on the opposite wall from the stove under the shelves, into which a fan is installed. Damp cooled air comes out, and at the top, where people are steaming, there is good steam and heat.

After the procedures, you need to quickly empty the steam room of warm and humid air. Ventilation in the steam room occurs using a diffuser installed using a tee.

Is it possible not to install such ventilation in the steam room of a bathhouse ? Perhaps a window will suffice? Experts are categorical - the window serves for rapid ventilation of the steam room and rapid removal of air. It is not suitable for maintaining comfort during procedures.

Attic

The attic space should not simply be ventilated using a window. Steam reaching the rafters leads to the beginning of destructive processes. Solution: inflow under the roof canopy, outflow at the ridge. The two-way natural movement of flows occurs from bottom to top.

The space between the roofing material and the membrane is ventilated forcibly or naturally, but only with aerators and soffits. Aerators are placed on the roof area or on the ridge and extract air. Soffits allow air flow.

Washing

Most often, air exchange is forced. The outflow is directed towards the vestibule. In the corner, under the floor, there is a ventilation riser. It can be made from an asbestos-cement pipe, which draws air out due to the difference in pressure in the room and the end of the pipe leading to the roof.

Ground floor

Arranging a bathhouse in the basement places increased demands on the waterproofing of floor panels and walls. The ventilation system is only forced in all rooms.

Shower room

Refreshment in the shower and toilet occurs through the projection of air from fans in the ceiling or at the top of the wall . Installing exhaust ventilation in the hole closest to the shower will speed up drying.

Waiting room

The proximity to the steam room causes condensation on the walls and temperature changes. A window is installed in the dressing room and forced ventilation is provided.

Accessories for ventilation construction

To create favorable conditions in the steam room of the bathhouse and in all additional rooms, it is necessary to properly arrange the ventilation system. Otherwise, there can be no talk of any comfort.

The components used for the ventilation device are as follows:

- ventilation valve;

- valve;

- lattice;

- anti-mosquito/protective net;

- ventilation duct;

- galvanized or corrugated air duct;

- fan;

- hygrometer, thermometer;

- metal tape, clamp, polyurethane foam, sealant, fasteners and other consumables for installation and design of inlet and outlet openings.

Ventilation valves for ventilation in the bathhouse are placed on the supply and exhaust openings. They come in different sizes, shapes and materials. Therefore, it will not be difficult to choose a valve that perfectly matches the color.

Valves for ventilation, which are unscrewed/screwed, are the most convenient to use, allowing you to leave very small gaps for the passage of micro portions of air

Gate valves are also available in various designs. They are needed to open/close holes if necessary. Often, home craftsmen make a homemade design that copes just as well with the function of removing/influxing air masses from the premises.

Image gallery

Photo from

Installing a corner diffuser

Smooth air flow adjustment

Anemostat for ventilation and air conditioning systems

Connecting the anemostat to the air duct with a coupling

The grille and mesh are needed to protect the ventilation hole from rodents, moths, mosquitoes and other living creatures getting inside. The gratings are chosen from wood, heat-resistant plastic, and the mesh is most often made of metal.

It is not advisable to place a grille made of soft material over the inlet openings - rodents can damage it. It is better to choose metal options

The ventilation duct is installed in a wall niche or, if conditions do not allow, laid on top, for example, if aerated concrete is used as the wall material. The box can be made from scrap materials or a corrugated or galvanized pipe can be used as an air duct. Plastic analogues are not suitable for a steam room - you need to take into account the temperature to which the room will heat up.

The fan in the bathhouse is used for both supply and exhaust. It is considered optimal to use it in only one direction - for the influx or removal of air masses.

You need to buy a heat-resistant device, specifically designed for baths and saunas with IP 44 and above. Do not forget about the specifics of the room - there is a lot of steam and high temperature.

If there is a swimming pool in the bathhouse, then you cannot do without forced ventilation. The pool is an additional room where water evaporates around the clock. But the tree doesn't like it

Consumables are used during installation for fastening air ducts, arranging ventilation ducts and installing valves and fans. A hygrometer and thermometer are needed to effectively use the ventilation system.

If mechanical ventilation is installed using climate technology, then there is a built-in temperature sensor and a humidity level regulator. Based on the actual indicators of the devices, the system starts the exhaust fan or opens the supply valve.

The installation of ventilated floors is planned at the construction stage. They implement this type of ventilation together with the construction of a rough and then a finished floor, choosing for themselves the most acceptable option for the price

Properly equipped ventilation will ensure a comfortable stay in all rooms of the bathhouse, unclouded by extraneous odors and drops of water flowing down the walls and falling down the collar from the ceiling.

Another important condition for a long service life is timely and complete drying after use. It is on the implementation of this point that it depends on how long the bathhouse will last and whether rotten boards will need to be replaced with new ones in the next 3-5 years.

When there is no ventilation, and the owner of the bathhouse tightly closes the doors and windows after use, fungus, mold, and rot can be detected within a year

The need for ventilation in modern baths

The ventilation of the bathhouse carries out the influx of cold air into the steam room, heating and removing the air that is already humid and cooled after heating. What does a good exhaust system provide:

- quickly removes moist air from the room;

- promotes rapid drying of wooden structures, extends their service life;

- removes carbon dioxide, keeping its concentration at an acceptable level;

- regulates temperature efficiently;

- supports the combustion process in baths with gas and solid fuel stoves, providing air flow.

In a bathhouse with proper ventilation you will never encounter a musty, stagnant, unpleasant odor.

View this post on Instagram

Publication from ATELIER SAUNA - the best for a bath! (@ateliesaun)

System design features

When arranging floor ventilation, it is necessary to take into account a number of specific conditions. The efficiency and comfort of the system is determined by the fulfillment of the following requirements:

- preventing the floor from cooling during the bath procedure, it is especially important to ensure that there are no drafts (should not pull on the legs);

- the volume of air mass must be sufficient to complete the assigned tasks;

- fast, optimal drying should be ensured, especially in the presence of wooden floors, when dampness is unacceptable, but excessive drying, which can cause cracking of the wood, is also bad;

- Ventilation should be installed at the bathhouse construction stage, when vents of the required shape and size are created, pipes are laid, and distribution channels (gaps) are formed.

When providing fresh air ventilation through the floor, it is necessary that cold air does not flow along the floor.

The quality and characteristics of ventilation depend, first of all, on the location of the vents. When choosing a location for them, it is necessary to take into account climatic conditions (humidity and air temperature), wind conditions (“wind rose”), the landscape of the site, the presence of polluting sources, as well as internal factors - the type and location of the stove, the design of the doors, the presence of windows and vents.

Diagram of a ventilation device through the floor into a bath oven

Most often, the inlet for floor ventilation is located in the following places, at 3 different levels:

- lowest level: in the foundation or under the floor covering;

- directly under the stove or at the level of its base;

- in the wall at a height of 35-45 cm from the floor (best behind the stove).

Floor ventilation device

To ensure that the bathhouse boards do not rot and serve for a long time, it is necessary to install vents under the floorboards. Ventilation of the floor in the bathhouse with vents occurs even during procedures. The boards dry when ventilated from the outside, and when the hood is running, from the inside. Proper drainage of water from the steam room, away from the floor covering , will prevent deterioration and help the wood dry quickly with the help of ventilation.

Another method of forced air exhaust is through the underground of combined adjacent rooms. Suitable for washing rooms and steam rooms, in which the boardwalk lies on a concrete base, where natural ventilation cannot provide exhaust air.

A hole is provided in the foundation for the exhaust duct. It is made under the floor and equipped with a fan. The inlet opening is located close to the stove. The incoming air immediately begins to heat up and rise. If you make openings in adjacent rooms, heat will flow into the adjacent rooms.

Ventilation device for floorboards in a steam room

Wooden floorboards are most susceptible to rotting in a steam room. This is due to the fact that moisture accumulates from below, coming from the foundation and from above, settling in the form of steam.

Vents are best installed under floorboards. First of all, with this method of ventilation there is no draft, which means they can be used directly during the vaping process. Due to the fact that ventilation passes under the floorboards, the lower part of the floor covering is perfectly dried.

To facilitate ventilation, it is also recommended to move the sewer drain aside. This will help minimize the amount of moisture under the floorboards.

Methods of natural ventilation

The peculiarity of bath air exchange is that the flow of fresh air does not displace heat, but directs the flow heated by the stove in the desired direction, creating a special microclimate in the room. To know how to make inflow and exhaust , let’s remember the principle of operation of the system, which is based on simple laws of physics:

- in any room with any type of heating, the air moves - dense and heavy cold air goes down, warm air rises up;

- Without an influx of oxygen, this movement is ineffective: oxygen is used up, it becomes less abundant, and at the same time the concentration of carbon dioxide increases.

Breathing air that moves without renewal is not only difficult, but also life-threatening. When the temperature outside is lower than in the room, air enters through the hole in the lower part of the wall, and through the upper part it is removed from the building under the influence of draft , performing natural ventilation. One of the methods of natural ventilation in a bathhouse is ventilation by opening windows or doors. Fresh air comes in, which is good, but condensation quickly settles on the walls of the premises, and stable microclimate parameters cannot be achieved. Therefore, opening ventilation can be done before bath procedures, but not during or after them. And for more efficient air circulation, you should use other methods for ventilation in a bathhouse .

Ventilation through the chimney

A steam room equipped with a stove with a chimney will always have a comfortable temperature for receiving procedures, because the stove has a vent. draft occurs during combustion . The fume extraction process occurs only when air from outside flows into the room. A few simple ways to ensure inflow:

- A hole is made in the wall opposite the stove at a height of 20-30 cm from the floor.

- Periodically the door is closed and opened briefly.

- A 1 cm gap is made at the bottom of the door, or an opening is left between the floor and the door.

- If the log house of the bathhouse is not sheathed, a gap is left between the first crowns below the floor level if the boards do not fit tightly.

Penetrating into the room, the cold flow moves towards the heat source, the heated air is forced upward. Circulating up and down, the warm flow gradually cools, descends and is drawn in by the ash. Together with combustion products, it goes outside through the chimney.

Note! Ventilation through the chimney duct occurs only when the stove . In the absence of fire, air exchange does not take place.

Ventilation through vents

In case the stove is not heated, but ventilation is needed, air flow is made through special holes. To do this, before constructing and installing the stove, you need to provide a diagram of how to properly make a hood in a bathhouse :

- The exhaust hole is planned where the heated air accumulates - under the ceiling of the bathhouse.

- The inflow is provided low above the floor on the wall opposite the hood, choosing the place closest to the stove. It is best if the inlet is located immediately behind the stove.

The vertical distance between the vents is 1.5 - 2 m. The exhaust hole is larger in cross-section than the exhaust hole.

Cold air entering the room immediately begins to heat up. It displaces warmer air upward, which rises upward towards the exhaust hood. In a steam room with this type of ventilation, there are no noticeable cold flows and levels with different temperatures.

Important! There must be a difference in height between levels. Being at the same level, the vents create a straight-line air flow, without circulation, which is known as a “draft”, which is dangerous to health, especially for a heated and wet body.

Features of the ventilation system design

A big role in choosing the optimal ventilation scheme is played by the material of the bathhouse, its location, whether it is free-standing or not. All this helps to make the right decision when installing a venous system.

One of the effective methods of ventilation is burst ventilation - when you need to quickly ventilate everything, all doors and windows are opened. Of course, this can be implemented if there are windows.

With burst ventilation, the bulk of the moisture leaves in a matter of minutes, preventing the wooden finishing of the bathhouse premises from getting wet

Participating in the ventilation of the bath are:

- window;

- vents in the foundation;

- special holes in the wall/ceiling;

- doors and the gap under them.

The solution to installing a window in the steam room is very good, but another thing is that it is not always possible to implement it. It is in such cases that it is necessary to choose another option for organizing the ventilation of the room.

Image gallery

Photo from

Supply air vent

Exhaust vent with access to the attic

Hatch in the ceiling for ventilation

Fabric valve for exhaust outlet

It is also not often possible to use vents in the foundation. Especially if the owner decided to allocate one of the rooms of the house for a steam room, the foundation of which is not equipped with special holes. This is where forced ventilation comes to the rescue with a carefully selected arrangement of supply and exhaust openings.

No matter how much you would like to protect the room from steam leakage by carefully covering it with vapor-proof materials and tightly fitting the doors, you should not do this. Under the door to the steam room you should definitely leave a gap of 2-3 cm and nothing else.

The gap under the steam room door will ensure a more uniform flow of air, which will have a beneficial effect on people steaming.

For air flow, it is advisable to make holes in the lower part of the room, connecting to the street. After all, the room needs clean and fresh air, especially if the bathhouse is located outside the city near a coniferous or deciduous forest.

Holes designed to remove exhaust air are located in the upper part of the walls opposite the walls with supply valves. Moreover, their height depends on the chosen ventilation scheme and starts from 80 cm from the floor level or more. It is also possible to install an exhaust valve in the ceiling with the ventilation duct leading to the roof.

The inlet openings are closed with valves and gate valves so that they can be conveniently controlled during bathing procedures.

Methods for installing forced ventilation

Modern baths can be located in a house, be attached and have common walls with the main structure. In such rooms it is difficult to ensure natural ventilation, especially if the bathhouse has many functional rooms.

Ventilation in the steam room of a Russian bath is forced; for this purpose, exhaust or supply type fans are used. The devices create artificial air currents and make them move quickly. Forced ventilation is:

- Supply and exhaust, when equipment of both exhaust and supply types is used.

- Exhaust: A fan pulls air outside, creating a rarefied effect in the room. The deficiency is compensated by the natural supply of air from the street, which occupies the freed-up volume.

- Supply air, when a fan blows air from the street, creating excess gases in the room. Under the created pressure, the exhaust air is pushed out.

When choosing what type of ventilation to install in a Russian steam room , the needs are taken into account. Supply and exhaust equipment creates intensive air exchange; this is not required in small baths. When using one supply ventilation, the air does not have time to warm up to the required temperature. Most often, baths and steam rooms are equipped with exhaust .

Forced ventilation schemes

In a steam room that has only one outer wall, it is possible to install vents only on it. In this case, as well as when you need to refresh several rooms at once, you will have to force air displacement. To prevent incoming fresh air from immediately escaping into the exhaust vent, one of the following schemes is used:

- The stove is placed opposite the “inlet”. The hood is mounted as high as possible from the floor, or in the ceiling. If the attic is residential, make an air vent and bring it to the roof. How it works: cold air entering the room immediately moves to the heating device. As it heats up, it rises, giving way to the next portion of cold mass from the street. Warm air rises to the top, is sucked in by a fan, and comes out.

- The second option is suitable for a steam room that has a common wall with a room without a firebox. The exhaust vent is not mounted under the ceiling, but below, on the opposite wall from the supply vent. The channel through which the hot air escapes is hidden in the wall; it simultaneously heats the adjacent room. This room is provided with its own individual, possibly natural, ventilation.

View this post on Instagram

Publication from Ideas for home and garden. Lifehacks (@asbocem)

Both methods of forced ventilation have a drawback - cold air, which rushes from the supply opening to the stove, crosses the room and cools the floor. Therefore, air exchange is carried out when there are no people in the steam room, and the rest of the time the hole is closed with a valve.

Fan selection

Equipment for premises with special conditions must meet safety requirements. Therefore, they choose devices that can withstand heat, high humidity, and temperature fluctuations. Where to begin:

- Select a fan from among the devices for baths and saunas. Made of glass-filled polyamide, the sauna can withstand temperatures up to 180°, while maintaining functionality. The motor has special moisture protection, as well as bearings that provide 30,000 hours of operation.

- You need to know the area of the room to calculate power . The area is calculated using the formula S = l * b * h (length*width*height). The resulting number is multiplied by 5 (air exchange coefficient recommended for baths). For example, the area of a room is 12 m2. 12*5=60 m3/h. Choosing a fan with excess power is wrong; it is dangerous in bathhouses. In addition, the fan must be used according to the instructions .

- A device with a timer will help make ventilation easier. The option periodically turns the fan and regulates power.

- Built-in humidity and temperature sensors in auto mode turn on the fan only when the settings reach certain values.

Depending on the system, the fan is installed directly into the hood opening or on the wall behind it.

How does high-quality ventilation work in a bathhouse: diagram and design, features of different rooms

Ventilation system design

The top pictures explain how the supply and exhaust openings can be installed differently. Each option has certain advantages and disadvantages. It is easier to study them using a specific example, which is given at the bottom.

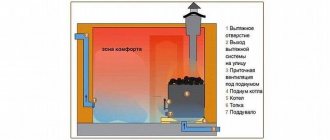

This is a typical exhaust hood in a bathhouse. The steam room has a wood-burning stove, which is filled with fuel from outside. Also, from another room, air is supplied to the firebox through the ash pan. This solution simplifies technical operations and prevents debris from entering the clean area.

Air initially enters the steam room through a hole in the foundation, underground space and ceiling. The inflow is located directly next to the furnace. After cooling, the air falls down and is discharged outside through the intake slit of the hood.

This ventilation scheme in the bathhouse helps solve the issues outlined above. A special intake path preheats the air. Wooden flooring is effectively ventilated, which prevents the development of mold and other biological damage. Manual valves can be used to precisely adjust the system's performance based on current weather and other conditions.

The type of bath is essential

This picture schematically shows the features of different technologies. In practice they use:

- contact and radiant thermal effects;

- certain temperature ranges;

- creating steam using hot stones, aromatization;

- plunge pools, separate cabins.

Each option has special ventilation requirements that should be studied specifically.

To narrow the scope of the study, this article examines typical Russian baths, which differ from this scheme only in small details

For your information! Nowadays, natural, forced and combined ventilation systems are used. But below is information only about relatively simple designs. The most complex sets of equipment use temperature and humidity sensors, filters, and air conditioning units. Such projects are difficult to implement without high costs and the help of specialized specialists.

Floor ventilation device in the bathhouse

To extend the service life of building structures, it is necessary to initially select suitable materials. However, moisture-resistant concrete and ceramic coatings are not popular. But the wood in this room cannot be protected with chemical impregnations, which will worsen the condition of the atmosphere.

This problem is solved by using ventilation under the floor in the bathhouse.

In the simplest version, support logs are installed at a height of 20-30 cm from ground level. Boards with slots (5-10 mm) are mounted on them. Flowing water will be absorbed into the soil, so it is recommended to make a suitable backfill from sand or other granular materials. This inexpensive solution does not need to be explained in detail. Its main disadvantage is the accumulation of contaminants at the bottom, which, together with the fumes, will penetrate inside the steam room.

This floor ventilation scheme in a bathhouse is more complicated, but it allows drainage from two rooms to be removed into the drainage

The photo shows that to access the drain hole, one board is not firmly fixed. It can be quickly removed for inspection or cleaning.

When creating an insulated floor, ventilation of this power part of the structure is not necessary. It is made airtight.

Load-resistant materials are carefully selected

A screed is poured over the insulating layer at a slope towards the drain. On top - a flooring made of boards is installed.

It can be installed according to the standard scheme discussed above, on strong beams, with spaces between the individual elements

Interesting solution. It ensures rapid removal of moisture from wood with heated air

Extending the life of a building: foundation ventilation

For this part of the system, it is necessary to provide for the installation of embedded parts at the stage of pouring the mortar. Appropriately sized pipes are suitable, which are subsequently removed.

The photo shows the ventilation channels of the foundation in the bathhouse. Please note that they create a free path for air to flow under all rooms of the building

To create complex routes, you can use plastic pipes that are not damaged by corrosion. Use such material correctly, excluding exposure of products to excessively high (low) temperatures.

The entrance openings are covered with decorative and protective grilles. They prevent rodents from entering.

Homemade valve to regulate the flow of fresh air. Such devices must be freely accessible.

Functioning of high-quality ventilation in a bathhouse in a steam room

Such a design can be created at minimal cost

This simple ventilation diagram in a steam room of a bathhouse explains well the erroneous actions:

- The grille in the door supplies air from the adjacent room, which does not exclude the possibility of increased humidity levels and the entry of foreign odors.

- The wide inlet is not adjustable. It is installed far from the stove, so a cold draft will be felt.

- One of the holes (above the stove) is running idle. This reduces the efficiency of using fuel resources.

- There is no provision for ventilation of the floor covering. The importance of this procedure is discussed in detail in the previous sections.

Proper ventilation in the steam room

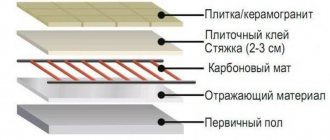

The author of this project (a typical Finnish sauna with electric heating elements) installed an inlet (1) next to the heater. A small part of the fresh air passes through the lower route (2). It does not disturb users and ventilates the floor covering and the surface under the shelves. The heated air rises into the “working zone”. After cooling, it falls down and enters the inlet (4). The ventilation duct (5) creates the draft necessary for the efficient operation of the system without fans.

A ventilation scheme in a Russian steam bath can be created based on the same principles. But we must take into account that this technology, unlike the Finnish one, is accompanied by a large amount of steam. This increases the system performance requirements.

If the classic method is used, “in black”, install a stove without a chimney. To prevent carbon monoxide poisoning, after warming up the bath, remove the coals and ventilate the premises well.

Features of washing machine equipment

There is a very high level of humidity here, so structural elements are selected taking this factor into account. To ensure sufficient ventilation in the washing bath, a fan can be used.

Purchase a model that is designed for operation at high concentrations of moisture in the room atmosphere

For electrical wiring, an appropriate cable is used, which ensures reliable insulation even when immersed in liquid. The switch is installed in the rest room, or in another room with a normal level of humidity.

For ventilation in the bathhouse sink, you can use a small window or a special channel. In any case, you need to configure the system in such a way as to eliminate drafts. You can combine the air supply parts here and in the steam room to increase the air temperature and ensure ventilation of wooden floor coverings.

Ventilation design in the dressing room

In this room, the organization of access to fresh air does not differ from a similar system in a regular living room. Natural and forced ventilation are available in various combinations. We must remember that hypothermia provokes the occurrence of colds and other diseases.

This is where a vestibule comes in handy to prevent drafts.

For your information! Log houses have special capabilities. They create comfortable temperature conditions in rooms without special technical means due to natural micro-ventilation of the walls. For intensive ventilation, you can open doors and windows.

Related article:

Bathhouse projects with a relaxation room and a terrace. In a separate publication you will learn about the most successful layouts of bathhouses with an extension in the form of a veranda or terrace.

Ventilation of walls in a steam frame bath

The constant humidity that is present in the bathhouse leads to the risk of moisture accumulation. In order not to shorten the service life of the premises, they make the correct design for moisture and wind insulation of the panels, and also equip the building with sufficient ventilation. The “pie” is formed as follows: a wind-hydroprotective membrane is laid on the frame posts, a sheathing block is sewn onto it, on which decorative siding or other facing material is mounted. If a large amount of moisture potentially enters the plane of the wall from the inside, the membrane freely releases this moisture using a ventilation gap.

To better protect the insulation from the inside of the bath, it is covered with foil material, and all joints are sealed with an airtight film. Additionally, slats are mounted after the foil, creating an air space between them. Elements of interior decoration are screwed onto the slats.

The absence of an exhaust hood “kills” the building in 2-3 years. Walls and floors damaged by fungus cannot be repaired. Installing ventilation in a bathhouse does not require significant funds, and openings for natural air circulation are completely costless. You just need to know how to make ventilation in the steam room , where to place it, and what cannot be used specifically in this room.

Is ventilation needed in a bathhouse and what are its basic principles?

Even the ancient architects knew that without access to fresh air, a house or bathhouse would quickly collapse under the influence of dampness and mold. It was for air exchange that they left gaps between the upper logs. Now such simple technology has been replaced by more efficient systems. They take some time to set up and plan. There is a temptation to give up on this issue altogether, but what are the consequences of this:

- after just a couple of years, the materials of the building, especially if it is made using frame technology, will become unusable due to constant dampness;

- There will be a constant musty smell in the room. It will be especially noticeable when heating the bath, and this will negate all the pleasure from the process;

- Staying in such a bathhouse will not only become unpleasant, but also dangerous to health. In addition to the accumulation of carbon monoxide and carbon dioxide, there will be a large number of mold spores in the air, which can cause severe lung and skin diseases.

Mold can penetrate deep into wood and is almost impossible to get rid of.

Obviously, it is worth investing time and money for your own safety. Before you get to work, study the basic principles of arranging ventilation for a bathhouse:

| Principle | Description |

| Correct air flow distribution | According to the basic laws of physics, hot air rises, and cold air, accordingly, falls down. The flow should be distributed so that the sunbeds have the optimal temperature and your feet do not freeze in the steam room. |

| Maintaining room temperature | Air exchange should not disrupt the vaping process, that is, air flows should not cool the steam room. |

| Use of materials resistant to high temperature and humidity | To organize forced ventilation in the room, systems with mechanical air supply can be used. All elements of the system are made of materials that are resistant to high-temperature steam conditions and high air humidity. |

And now how to make ventilation in a bathhouse in such a way as not to lose precious steam and at the same time preserve materials and health?

Features of the underfloor system

Ventilation installed under the floor of the bathhouse has a number of advantages. In addition to the fact that it helps eliminate condensation and ensure drying of the floor covering, the air flow hidden below cannot cause drafts, which means the system can also be used during the bath procedure.

For effective operation of underfloor ventilation, it is important to properly arrange the drainage system, i.e. constantly remove wastewater outside the bathhouse. Ventilation is ensured by installing 2 holes in the foundation. They are located on opposite walls, but not directly opposite each other. In general, the optimal option is when the air flow passes along a complex path, covering the maximum possible area. The vents are equipped with valves that allow you to regulate the fresh air supply time and flow rate. It is worth highlighting one of the types of outlet vent - a vertical hole through the entire thickness of the foundation to the ground. This channel also ensures moisture drainage.

The ventilation duct under the floor is formed by jumpers (logs), which are usually used as timber measuring 6-8 x 10-15 cm. These logs are mounted on a concrete screed, made with a slope to drain the drainage. The plank flooring is laid on top of the joists, and the boards are attached with a gap, which ensures the free flow of water. The valves on the vents open taking into account the outside air temperature. In summer they can be open constantly, but in winter active ventilation should be carried out only when there are no people in the steam room.