A visit to a modern bathhouse or steam room is not just a desire for cleanliness or a tribute to fashion. A bathhouse with healing steam and heat from the stove promotes health, beauty of body and spirit, good mood, and restoration of vitality. However, this is possible with a sufficient amount of fresh air and the absence of microorganisms that can cause disease. hood in a bathhouse can provide comfortable conditions .

Is a ventilation system needed in a bathhouse?

Breathing is a reflex process that our lungs perform to take the required amount of oxygen from the environment. Normal air consumption is not noticed until a person enters a room where the air is stale or insufficient. Baths and steam rooms are precisely such risky places; they should always be hot, fresh, and clean. The question of whether ventilation is needed in the bathhouse and steam room is not even discussed. According to sanitary standards, owners must provide an air exchange system in the project and apply step-by-step guidance during the construction phase.

During the ventilation process, conditions are created under which the proliferation of bacteria and fungi becomes impossible, which means that mold and mucus will not grow in the corners and crevices of the structure.

Conclusions and useful video on the topic

Detailed and interesting information about the principles of steam room ventilation is presented here:

Undoubtedly, ventilation in the bathhouse is necessary. Only with proper air exchange will bath procedures really bring real benefits to the health of visitors, and the owners of the building will be spared additional costs for mold control and ongoing repairs.

Do you have any questions about arranging ventilation in the sauna? Or maybe you have had the opportunity to arrange this system yourself and you can share your experience with visitors to our site? Please leave your comments in the block below.

The principle of operation of the ventilation system in the bathhouse

ventilation is conventionally divided into constant (includes wall, roof and foundation) and ventilation, which operates periodically, when the bathhouse is in operation, the stove is heated. Both are included in a single ventilation system, which is designed together with the construction of the bathhouse.

The principle of operation is to displace exhaust air with clean, fresh air. For this purpose, through holes are installed, at least two, which operate depending on the direction of flow and only when there is a difference in temperature indoors and outdoors.

A few more rules, if you follow them when arranging ventilation in a bathhouse with your own hands , the principle of operation will not be violated:

- When the bathhouse warms up, close the vents in the foundation and the dampers in the steam room.

- During procedures, windows are opened as needed.

- After steaming, the sauna is completely ventilated.

The supply and exhaust supply and exhaust air in the volume that the dampers on them allow. Calculating the size of the window is simple: for every cubic meter of room you need 24 cm2 of holes. And one more thing: the windows cannot be placed opposite each other.

How to make vents for ventilation?

Installation of ventilation in the bath is carried out as follows:

- In selected places, holes are made of such a size that the pipe or box fits freely into it.

- The space around the pipe is sealed so as not to compromise the tightness of the room.

- From the outside, the holes are covered with gratings.

- Special dampers or adjustable grilles are installed inside.

It looks simple, but there are a few things to consider. For example, ventilation holes can be made not only round, but also square or rectangular with approximately the same cross-sectional area. In wooden baths, instead of plastic or steel pipes, wooden boxes are installed.

In this case, choosing a rectangular hole looks logical, because such a box is easier to make from ordinary boards.

It is best to plan vents at the design stage so that you do not have to drill into the finished wall. Ventilation openings that open to the street should be additionally protected with insect screens. The cross-section of the supply ventilation hole in the bathhouse is calculated based on the standard: 24 sq. cm of cross-section for each cubic meter of volume of the ventilated room.

Thus, for a bath with a volume of 12 cubic meters. m. you will need a hole with an area of 284 square meters. cm. If you plan to make a round hole, then its radius is calculated using the inverse formula for the area of a circle. We divide the resulting indicator by 3.14 (the number “pi”), and extract the square root from the result.

In our example, we get a radius of approximately 9.5 cm, and its diameter is 19 cm. Exact adherence to dimensions in this case is not relevant, so a pipe with a cross-section of 200 mm is quite suitable. Or you can take two 100 mm pipes. If the ventilation cross-section is square, the approximate dimensions will be 17X17 cm.

Natural ventilation has undeniable advantages. Its installation is simple and relatively inexpensive; operation does not require electricity costs or the installation of special devices. The simple design guarantees no breakdowns and a long service life of the ventilation system.

From the inside, special grilles are installed on the ventilation holes, in which the gaps can be adjusted, this allows you to adjust the intensity of air flows

In winter, due to the significant difference in temperature inside the steam room and outside, the draft can increase noticeably. This may cause slight discomfort due to the air flowing in too quickly. In addition, odors, which are not always pleasant, can also penetrate into the bathhouse from the outside. Controlling the ventilation flow can solve this type of problem.

Proper ventilation in the sauna steam room

To provide for all the subtleties of installing ventilation in a bath means to protect yourself from dampness, rapid cooling of walls and furniture, cold floors and the accumulation of carbon monoxide. In addition to freshness, ventilation should not create drafts, cool the floor, or provoke sudden temperature changes.

The essence of ventilation is air flow at two ends: inflow and outflow. You need at least 2 holes, installed according to the rule - outflow above, inlet below. It is best if a ventilation device is included in the bathhouse design before construction. The shafts and the diameter for the holes are indicated. There are 3 basic solutions for choosing openings that provide not only air exchange, but also safety:

| Type of bath | Inflow, mm | Hood, mm |

| Russian | 100 | 100 |

| Finnish | 130 | 100 |

| Swedish | 100 | 80 |

It is prohibited to make the exhaust opening smaller than the supply opening. Also, according to the rules, ventilation openings must have valves that ensure tightness during the moment of kindling and warming up the steam room. In winter, the valves are closed halfway, because the greater the temperature difference, the stronger the air circulates.

Ventilation of a foam block building

The question of whether a hood is needed in a foam block bathhouse is always accompanied by a positive answer. Unlike wood, cellular concrete does not have such hygroscopicity and extraction is simply necessary here.

The foam block structure is characterized by tightness, so it is dried thoroughly. Concrete is susceptible to the destructive effects of moisture and high temperatures. There are types of mold that get along well on concrete surfaces. If mold or fungal colonies have appeared, removing them will create a problem.

To ventilate the foam block bath structure, vents are organized inside the foundation even at the stage of its laying. Plastic pipes filled with sand are laid inside the frame at a certain distance. This ensures the flow of fresh air under the premises and along their lower tier.

Exhaust openings are located at the top of the walls, under the ceiling. It is important to remember that ceiling ventilation openings will create a quick release of hot air flow, which will look like a constant draft, reduced temperature of the steam room. The holes should be made 30-50 cm below the ceiling.

In addition, it is necessary to take care of ventilation of the roof and attic space, where condensation will accumulate due to the temperature difference between the external and internal flows.

Types of ventilation

There are several ways to remove exhaust air and replace it with fresh air. It all depends on the configuration, area, and functionality of the room. The most suitable way to properly ventilate a bathhouse is selected taking into account:

- number and location of rooms;

- type of walls;

- type of heating: wood and electric appliances are part of the ventilation system of the bathhouse.

When building baths, natural and forced ventilation are used.

Natural

The operating principle is based on temperature differences and atmospheric pressure changes inside and outside the building. The advantage of natural ventilation is autonomous operation without power supply and the use of other factors that encourage air flows to move. It is easy to install, does not break, and does not require large expenses. To regulate ventilation and limit the access of frosty air, valves or vent covers are purchased.

Forced

Here air flows are created or strengthened forcibly. Fans are used for this. The system allows you to supply or displace air stably and continuously, its operation does not depend on weather conditions. Human intervention is minimized, and the ability to control and make fan operation settings via a smartphone makes this method of maintaining comfort even more convenient.

Combined

Buildings made of stone, frame-panel, lined and insulated in different ways require different approaches to the arrangement of ventilation systems. In addition, the designs of modern baths are not limited to only the dressing room and washing room: steam room , locker room, bathroom, rest room - in each of these rooms one or more types of ventilation are installed and used depending on the situation, before, during the procedure or after her.

Options for installing the system in different steam rooms

Baths are made from different materials using different technologies. At the same time, the difference in materials and construction technology depends on how the ventilation system for the premises will be arranged.

In frame

Frame houses and bathhouses are very popular due to their reliability and durability.

The most important thing is to make the correct calculation of the frame in order to avoid mistakes at the key stage of construction. A ventilation system must be provided at the initial stage of frame assembly. Otherwise, you will have to drill holes in the finished walls, which will lead to additional problems.

In chopped

When making a ventilation system, you need to take into account a number of nuances:

- Exhaust and supply systems are designed so that immediately after bathing procedures all excess moisture is removed from the premises.

- If a fan is installed, the wiring to it must be carried out in special non-flammable casings so that in the event of a short circuit the wood will not ignite.

- Wooden surfaces must be treated with special anti-rotting preparations.

After construction, log houses already have a natural ventilation system for the premises, but this is not enough for a bathhouse.

In a brick

Brick baths are considered the most reliable and durable. Advantages of the material:

- withstands constant temperature changes;

- not subject to rotting;

- serves for more than 100 years.

Passages in the walls for ventilation can be made using special equipment.

In buildings without a foundation

Temporary or moving baths (on wheels) have built-in ventilation systems. If the bathhouse is permanent, you need to build a foundation.

Mini sauna in the apartment

Recently, homeowners in multi-storey buildings often set up small cabins on balconies or loggias. In this case, the natural ventilation of the mini-sauna must be combined with forced elements installed in the room where it is constructed.

The inflow is organized behind the heating device, the hole is closed with a grill. The exhaust duct is installed in the middle part of the room, between the shelves. To ventilate a small “nook” after a health procedure, a ventilation valve is installed in the ceiling of the cabin.

In a log bathhouse

The log house was invented long before the laws of physics on which natural ventilation is based took shape. Nevertheless, the builders of log bathhouses actively used these laws so that the owners of the bathhouse would not suffocate during the steaming process, and the bathhouse would last for the decades it was supposed to. (Of course, the hood in a bathhouse made from a log house will not save it from fire, but from rot it may well .) In the log house, the flow of air was ensured by the lower crowns, which were deliberately laid loosely, that is, they had cracks through which fresh air was “pulled” . In addition, the door to the steam room from below did not fit tightly to the floor.

Depending on how exactly the log bathhouse was heated—“black” or “white”—it also depended on where the exhaust air went.

- In a heated “black” bathhouse, the stove does not work during the steaming process, so an open window or door was used for outflow.

- In the heated “white” bathhouse, the outflow was through the chimney. The stove was still working.

In principle, nothing prevents you from organizing the ventilation of a log house in the traditional way today. But decisions need to be made quickly, even at the construction stage. Because a more modern solution must be included in the project. Alternatively, you can punch holes (supply and exhaust) directly to the street and equip them with plugs or dampers . One is next to the furnace vent, the second is above the top shelf on the adjacent or opposite side. Or make two exhaust holes - one above, the other below the top shelf. Another option is to make blinds at the bottom of the steam room door, and an exhaust vent under the shower ceiling.

IMPORTANT! If you don’t want to go outside, you can lay air ducts, but then instead of natural ventilation you will have to install a forced ventilation system.

In a foam block bath

A foam block bathhouse is no exception to the rule that you need to think about ventilation when designing a bathhouse. It's easier than hitting ready-made walls. In order to provide a bathhouse made of cellular concrete with sufficient air circulation, which will rid the structure of excess moisture, it is necessary, at the time of pouring the foundation formwork, to lay pipe scraps, which will then become vents.

For a bathhouse that is not located in a low-lying area and is not surrounded on all sides by buildings, two vents on opposite sides are sufficient, otherwise they are made of 4. Do not forget about the ventilation gaps between the walls and the insulation.

The roof must also be ventilated, receiving inflow from the roof overhangs and releasing air through the raised ridge. In the premises, supply and exhaust openings are made according to one of the standard schemes.

If natural ventilation is insufficient, it is recommended to install fans on the hood of a bathhouse made of foam blocks.

Where to place the cold air vent

The lower vent is responsible for the influx and supply of cold air. A pipe is laid under it during construction or a shaft is left. Bottom hole installation options:

- In the wall, opposite the stove.

- Under the sun loungers, you can’t see it there, and there are no drafts. However, to adjust the position of the damper, you have to bend down under the shelf, which is inconvenient. The situation is corrected by opening the upper outflow, and after the procedures both outflows are opened - both the upper and the lower.

- Behind the stove, if the stove is not installed in a wall and there is access to it. The cold stream immediately warms up, causing the coals to burn hotter.

Outflows are made either in the wall or in the ceiling, providing a place for them in the project.

Useful tips

In winter, it is better to avoid using supply fans because they tend to draw in too cold air. If the air outside is very dirty, special filters must be used. When calculating the required power of ventilation devices, it is worth focusing on the requirement to refresh all the air in the bathhouse in a maximum of 15 minutes. Supply and exhaust devices are ideal for the steam room, but in the waiting room and relaxation room you can safely limit yourself to the natural circulation mode. When choosing locations for vents outside the building, you need to pay attention to the aesthetic qualities of the structure; the same requirement applies to pipes leading outside, to aerator fungi and valves.

If a swimming pool is equipped in the bathhouse, the air in this part should be 2-3 degrees warmer than in other parts of the room, and its humidity should not exceed 55-60%. The use of flexible air ducts is considered a much better solution than the use of rigid pipes. Taking into account all these recommendations, you can easily create a ventilation system with your own hands or have it checked by specialists.

Ventilation of various auxiliary rooms

Ventilation in the bathhouse is on the list of mandatory construction measures. Understanding the importance of sufficient air exchange has led to the development and application of various step-by-step schemes for each individual room.

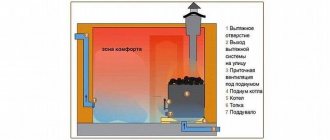

Steam room

If some of the air in a confined space is not removed, then new, fresh air will not be able to enter the steam room. The diagram and device of the steam room ventilation is as follows:

- An influx of fresh air is provided. To do this, a hole is made in the wall below near the floor next to the stove.

- The exhaust hole for natural ventilation is installed on the opposite wall from the stove under the ceiling, and is closed at the time when people are busy with procedures.

- The air entering the steam room immediately heats up and rises upward using convection.

- Up above, under the ceiling, in the Russian bathhouse it begins to become saturated with moisture. Humid air is heavier, so the steam gradually cools in the corner farthest from the stove and falls down.

View this post on Instagram

Post from I’m building a bathhouse as best I can (@banpartal)

It is at the regiment level, at the time of taking bath procedures, that this air must be taken in and removed so that it does not evaporate again. To do this, an exhaust ventilation hole is made on the opposite wall from the stove under the shelves, into which a fan is installed. Damp cooled air comes out, and at the top, where people are steaming, there is good steam and heat.

After the procedures, you need to quickly empty the steam room of warm and humid air. Ventilation in the steam room occurs using a diffuser installed using a tee.

Is it possible not to install such ventilation in the steam room of a bathhouse ? Perhaps a window will suffice? Experts are categorical - the window serves for rapid ventilation of the steam room and rapid removal of air. It is not suitable for maintaining comfort during procedures.

Attic

The attic space should not simply be ventilated using a window. Steam reaching the rafters leads to the beginning of destructive processes. Solution: inflow under the roof canopy, outflow at the ridge. The two-way natural movement of flows occurs from bottom to top.

The space between the roofing material and the membrane is ventilated forcibly or naturally, but only with aerators and soffits. Aerators are placed on the roof area or on the ridge and extract air. Soffits allow air flow.

Washing

Most often, air exchange is forced. The outflow is directed towards the vestibule. In the corner, under the floor, there is a ventilation riser. It can be made from an asbestos-cement pipe, which draws air out due to the difference in pressure in the room and the end of the pipe leading to the roof.

Ground floor

Arranging a bathhouse in the basement places increased demands on the waterproofing of floor panels and walls. The ventilation system is only forced in all rooms.

Shower room

Refreshment in the shower and toilet occurs through the projection of air from fans in the ceiling or at the top of the wall . Installing exhaust ventilation in the hole closest to the shower will speed up drying.

Waiting room

The proximity to the steam room causes condensation on the walls and temperature changes. A window is installed in the dressing room and forced ventilation is provided.

Arrangement of supply and exhaust openings

When designing a bathhouse, you must immediately provide for the location of vents in the walls or foundation. It will be easier to make them during the construction process, rather than punch them after completion. In the case of forced ventilation, their dimensions are not particularly important, since a fan of calculated power will provide the necessary air exchange.

It is easier to lay a piece of pipe when pouring it into the foundation than to drill a vent in hardened concrete Source readmehouse.ru

Another thing is how to properly make ventilation in the steam room of a bathhouse if the use of mechanisms is not provided. For good natural air exchange, the cross-section of the supply opening must be sufficient. It is calculated according to a standard that regulates the dependence of this section on the volume of the room. For each cubic meter of ventilated space it is necessary to install a vent with a cross-sectional area of 24 cm2.

If we take our example with a steam room 2x3x2.2 m, then its volume will be equal to 13.2 m3. Multiplying it by 24 we get 317 cm2. To determine the diameter of a round hole with such an area, use the converted formula for the area of a circle: divide it by Pi and take the square root from the resulting value. The radius of our hole is equal to 10 cm, so its diameter should be 20 cm.

The radius is found using the inverse formula for the area of a circle Source ds04.infourok.ru

It is even easier to find the length of the side of a square hole - it will be approximately 18 cm. The sides of the rectangle are also selected in accordance with the cross-sectional area - for example, 10x32 cm.

To arrange round vents, steel or plastic pipes of the appropriate diameter or slightly larger are used, and the channels in the rectangular wall are made in the form of wooden boxes made of boards.

The exhaust hole, as already mentioned, should be made larger than the supply hole. The gaps between the wall and the walls of the channel are filled with tow, other insulation, or foamed.

Another important point in such a matter as making an outlet in a bathhouse is protection from the outside from the penetration of insects, rodents, and debris into the channel. To do this, cover the hole from the outside with a mesh or lattice.

Ventilation grille with insect mesh Source www.video-sovety.ru

And inside, to regulate the intensity of the air flow, valves are installed, partially or completely blocking the holes when necessary. For example, in winter, the draft, due to the huge difference between the low temperature of the street air and the high temperature in the bathhouse, increases so much that the cold currents do not have time to heat up from the stove and quickly cool the room. It is reduced using a valve, leaving only a small gap or completely blocking the vent for the duration of the procedures.

The need for ventilation in modern baths

The ventilation of the bathhouse carries out the influx of cold air into the steam room, heating and removing the air that is already humid and cooled after heating. What does a good exhaust system provide:

- quickly removes moist air from the room;

- promotes rapid drying of wooden structures, extends their service life;

- removes carbon dioxide, keeping its concentration at an acceptable level;

- regulates temperature efficiently;

- supports the combustion process in baths with gas and solid fuel stoves, providing air flow.

In a bathhouse with proper ventilation you will never encounter a musty, stagnant, unpleasant odor.

View this post on Instagram

Publication from ATELIER SAUNA - the best for a bath! (@ateliesaun)

How much does it cost

When planning to make ventilation in the sauna with your own hands, you need to know that its cost will cost approximately 24-38 thousand rubles. Everything will depend on the cost of components.

- A ventilation valve can be purchased for 650-1500 rubles.

- A grill for 300-400 rubles.

- Supply and exhaust system for 18,500 rubles.

Creating a high-quality air exchange system is an important part of the operation of a sauna, so the selection of its components, as well as the installation process, must be approached thoughtfully and in a timely manner.

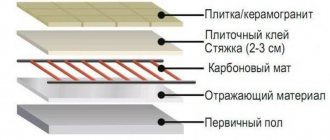

Floor ventilation device

To ensure that the bathhouse boards do not rot and serve for a long time, it is necessary to install vents under the floorboards. Ventilation of the floor in the bathhouse with vents occurs even during procedures. The boards dry when ventilated from the outside, and when the hood is running, from the inside. Proper drainage of water from the steam room, away from the floor covering , will prevent deterioration and help the wood dry quickly with the help of ventilation.

Another method of forced air exhaust is through the underground of combined adjacent rooms. Suitable for washing rooms and steam rooms, in which the boardwalk lies on a concrete base, where natural ventilation cannot provide exhaust air.

A hole is provided in the foundation for the exhaust duct. It is made under the floor and equipped with a fan. The inlet opening is located close to the stove. The incoming air immediately begins to heat up and rise. If you make openings in adjacent rooms, heat will flow into the adjacent rooms.

Errors in ventilation construction

If you take into account all the subtleties of the ventilation system design, the result will please you for decades. But often inexperienced professionals make annoying mistakes that directly affect the quality of the procedures and the mood of those relaxing in the sauna/bath.

The most common mistake is planning the layout of the air ducts after construction is completed. This is the most unpleasant thing, because such work should be done at the very beginning. Then not only will everything be convenient to install, but it will also be easy to hide communications by decorating them.

Excessive tightness of walls and floors can lead to the fact that they will soon require replacement

Secondly, excessive tightness of the room may not serve the best role. So, if there is no gap under the door of at least 2-3 cm, a window and an opening for inflow, then you can suffocate in such a steam room. This is an extremely bad option.

The third mistake made when installing a ventilation system is making only an exhaust hole under the ceiling. It will provide a greenhouse effect when air exchange does not occur. To breathe in a breath of fresh air, you have to open a window or door.

The exhaust and supply openings should be provided with a valve - it is convenient to use, and it can fit into any interior without violating the overall concept

Fourthly, the air mass inlet/outlet openings must not be left without a valve. Its presence will help to optimally regulate the indoor microclimate in any weather and outside temperature.

It is the valve that helps to clearly select a comfortable temperature and humidity by releasing excess hot air. With the valve closed, on the contrary, you can quickly heat up a well-ventilated room.

The presence of a protective grille at the inlet or outlet will protect against accidental entry of insects, birds and other living creatures into the steam room.

The fifth mistake is placing the inlet and outlet valves at the same level opposite each other. With this scheme, you can observe drafts walking along the legs and a complete lack of mixing of air masses. The air coming from the street will not have time to heat up and mix into the steam mixture under the ceiling of the room.

The sixth mistake is installing complex, expensive ventilation systems. Equipment cannot withstand sudden temperature changes for long and requires periodic repair and replacement of individual devices.

Complex systems are not a cheap pleasure, especially if the steam room is used occasionally - a couple of times a year

Therefore, when selecting the optimal ventilation scheme, you should take into account the characteristics of your room, its size, and ceiling height. It is important not to forget about this at the planning stage of construction work, so as not to overpay later.

Methods of natural ventilation

The peculiarity of bath air exchange is that the flow of fresh air does not displace heat, but directs the flow heated by the stove in the desired direction, creating a special microclimate in the room. To know how to make inflow and exhaust , let’s remember the principle of operation of the system, which is based on simple laws of physics:

- in any room with any type of heating, the air moves - dense and heavy cold air goes down, warm air rises up;

- Without an influx of oxygen, this movement is ineffective: oxygen is used up, it becomes less abundant, and at the same time the concentration of carbon dioxide increases.

Breathing air that moves without renewal is not only difficult, but also life-threatening. When the temperature outside is lower than in the room, air enters through the hole in the lower part of the wall, and through the upper part it is removed from the building under the influence of draft , performing natural ventilation. One of the methods of natural ventilation in a bathhouse is ventilation by opening windows or doors. Fresh air comes in, which is good, but condensation quickly settles on the walls of the premises, and stable microclimate parameters cannot be achieved. Therefore, opening ventilation can be done before bath procedures, but not during or after them. And for more efficient air circulation, you should use other methods for ventilation in a bathhouse .

Ventilation through the chimney

A steam room equipped with a stove with a chimney will always have a comfortable temperature for receiving procedures, because the stove has a vent. draft occurs during combustion . The fume extraction process occurs only when air from outside flows into the room. A few simple ways to ensure inflow:

- A hole is made in the wall opposite the stove at a height of 20-30 cm from the floor.

- Periodically the door is closed and opened briefly.

- A 1 cm gap is made at the bottom of the door, or an opening is left between the floor and the door.

- If the log house of the bathhouse is not sheathed, a gap is left between the first crowns below the floor level if the boards do not fit tightly.

Penetrating into the room, the cold flow moves towards the heat source, the heated air is forced upward. Circulating up and down, the warm flow gradually cools, descends and is drawn in by the ash. Together with combustion products, it goes outside through the chimney.

Note! Ventilation through the chimney duct occurs only when the stove . In the absence of fire, air exchange does not take place.

Ventilation through vents

In case the stove is not heated, but ventilation is needed, air flow is made through special holes. To do this, before constructing and installing the stove, you need to provide a diagram of how to properly make a hood in a bathhouse :

- The exhaust hole is planned where the heated air accumulates - under the ceiling of the bathhouse.

- The inflow is provided low above the floor on the wall opposite the hood, choosing the place closest to the stove. It is best if the inlet is located immediately behind the stove.

The vertical distance between the vents is 1.5 - 2 m. The exhaust hole is larger in cross-section than the exhaust hole.

Cold air entering the room immediately begins to heat up. It displaces warmer air upward, which rises upward towards the exhaust hood. In a steam room with this type of ventilation, there are no noticeable cold flows and levels with different temperatures.

Important! There must be a difference in height between levels. Being at the same level, the vents create a straight-line air flow, without circulation, which is known as a “draft”, which is dangerous to health, especially for a heated and wet body.

A few words about sauna ventilation

The ventilation options for an ordinary Russian bath are described above. In the sauna, everything works a little differently. Here only forced or combined ventilation is acceptable. In small saunas, the latter is more appropriate, namely a mechanical hood.

The main task when ventilating a sauna is to ensure that the flow of cold air quickly warms up and spreads smoothly throughout the room.

For proper ventilation of the sauna, it is necessary to carry out forced air exchange, for example, using an exhaust fan. Smooth mixing of air flows with different temperatures is important

Even a hint of a draft is categorically unacceptable, since the effect of soaring will lose all its charm. Therefore, the dimensions of the inlet opening are calculated according to the scheme outlined above, and the opening itself is located strictly behind the heater stove to ensure fast, almost instantaneous heating of the air flow.

The exhaust vent can still be located in the opposite corner of the room under the ceiling, however, if there is an exhaust fan, this requirement is not so strict. There are situations when the sauna room has only one outer wall, through which both fresh air is taken in and exhaust air masses are removed.

To maintain comfortable conditions during ventilation in the sauna, air flow is carried out near the heater, and a hood with a fan can be placed near the floor on the opposite wall

In this case, it is recommended to make the inlet hole at a level of approximately 20 cm from the floor, but it should be located strictly behind the heater. The hood is placed on the opposite edge of the wall, still under the ceiling. The flow of cold air will warm up and move in a circle along the walls of the room, gradually mixing with the rest of the air in the sauna.

This order will ensure the necessary air exchange and maintain the air temperature at an acceptable level. To achieve the fastest possible air exchange, the so-called high-speed scheme is used. The inlet hole is made as usual - 20 cm from the floor level. A mechanical hood is also placed at the same level from the floor, only it is mounted on the opposite wall.

Hot air rises to the ceiling of the sauna, where it cools down, falls down along the opposite wall and leaves through the exhaust hole. Ventilation is carried out quickly, and the change in air temperature is practically not felt.

The gentlest mixing of fresh air from the street and heated air masses indoors can be achieved if you install the supply opening at a level of about 50 cm, but still in close proximity to the heater. The hood is placed near the floor at a height of 20 cm. The ventilation speed in this option is slightly lower than when using other schemes.

Read about how to organize the ventilation of a sauna with an electric heater in this material.

Methods for installing forced ventilation

Modern baths can be located in a house, be attached and have common walls with the main structure. In such rooms it is difficult to ensure natural ventilation, especially if the bathhouse has many functional rooms.

Ventilation in the steam room of a Russian bath is forced; for this purpose, exhaust or supply type fans are used. The devices create artificial air currents and make them move quickly. Forced ventilation is:

- Supply and exhaust, when equipment of both exhaust and supply types is used.

- Exhaust: A fan pulls air outside, creating a rarefied effect in the room. The deficiency is compensated by the natural supply of air from the street, which occupies the freed-up volume.

- Supply air, when a fan blows air from the street, creating excess gases in the room. Under the created pressure, the exhaust air is pushed out.

When choosing what type of ventilation to install in a Russian steam room , the needs are taken into account. Supply and exhaust equipment creates intensive air exchange; this is not required in small baths. When using one supply ventilation, the air does not have time to warm up to the required temperature. Most often, baths and steam rooms are equipped with exhaust .

Forced ventilation schemes

In a steam room that has only one outer wall, it is possible to install vents only on it. In this case, as well as when you need to refresh several rooms at once, you will have to force air displacement. To prevent incoming fresh air from immediately escaping into the exhaust vent, one of the following schemes is used:

- The stove is placed opposite the “inlet”. The hood is mounted as high as possible from the floor, or in the ceiling. If the attic is residential, make an air vent and bring it to the roof. How it works: cold air entering the room immediately moves to the heating device. As it heats up, it rises, giving way to the next portion of cold mass from the street. Warm air rises to the top, is sucked in by a fan, and comes out.

- The second option is suitable for a steam room that has a common wall with a room without a firebox. The exhaust vent is not mounted under the ceiling, but below, on the opposite wall from the supply vent. The channel through which the hot air escapes is hidden in the wall; it simultaneously heats the adjacent room. This room is provided with its own individual, possibly natural, ventilation.

View this post on Instagram

Publication from Ideas for home and garden. Lifehacks (@asbocem)

Both methods of forced ventilation have a drawback - cold air, which rushes from the supply opening to the stove, crosses the room and cools the floor. Therefore, air exchange is carried out when there are no people in the steam room, and the rest of the time the hole is closed with a valve.

Fan selection

Equipment for premises with special conditions must meet safety requirements. Therefore, they choose devices that can withstand heat, high humidity, and temperature fluctuations. Where to begin:

- Select a fan from among the devices for baths and saunas. Made of glass-filled polyamide, the sauna can withstand temperatures up to 180°, while maintaining functionality. The motor has special moisture protection, as well as bearings that provide 30,000 hours of operation.

- You need to know the area of the room to calculate power . The area is calculated using the formula S = l * b * h (length*width*height). The resulting number is multiplied by 5 (air exchange coefficient recommended for baths). For example, the area of a room is 12 m2. 12*5=60 m3/h. Choosing a fan with excess power is wrong; it is dangerous in bathhouses. In addition, the fan must be used according to the instructions .

- A device with a timer will help make ventilation easier. The option periodically turns the fan and regulates power.

- Built-in humidity and temperature sensors in auto mode turn on the fan only when the settings reach certain values.

Depending on the system, the fan is installed directly into the hood opening or on the wall behind it.

The need for forced ventilation

Forced ventilation in the bathhouse is used extremely rarely. It is usually used in large complexes with a large steam room, swimming pool, etc. And in a standard-sized bathhouse, such methods are used in cases where, for some reason, natural ventilation does not work very well or does not work at all.

When choosing an exhaust fan for a bathhouse, it makes sense to choose a model that can withstand heat and work for a long time in conditions of high humidity.

To correct the situation and turn natural ventilation into forced ventilation, it is enough to install a supply fan in the appropriate opening or an exhaust fan in the hood. Both fans are usually not installed at the same time; complex supply and exhaust ventilation is used only in large facilities. And in a regular bathhouse, a mechanical hood is sufficient.

If air is forcibly removed from the room, fresh flows will take up the free space in accordance with the laws of physics. In large bath complexes everything is a little more complicated. At such facilities, the air exchange rate is first calculated, a ventilation system is designed and fans of suitable power are selected.

For a small steam room, an ordinary, not too powerful fan, which can be purchased in a store, is also suitable. Some craftsmen even make mechanical hoods using a cooler from an old system unit. Here is a simple example of calculating fan power for a regular bath.

Let's say there is a room with an area of 9 sq.m. with a ceiling height of 2 m. The volume of such a room is 18 cubic meters. m. The air exchange rate recommended for baths is five. Multiplying the volume of the room by the air exchange rate, we obtain the required performance of the exhaust fan - 90 cubic meters. m/h.

It is possible to use a fan of slightly higher power, but you should not be overzealous, otherwise the air exchange will become too intense. If you want to upgrade the forced ventilation in the bathhouse, you can set a timer so that the device automatically turns on at certain periods of time.

Using appropriate sensors, you can configure the ventilation to turn on when the specified air temperature or humidity is reached. But in an ordinary bathhouse such difficulties are usually unnecessary.

Ventilation of walls in a steam frame bath

The constant humidity that is present in the bathhouse leads to the risk of moisture accumulation. In order not to shorten the service life of the premises, they make the correct design for moisture and wind insulation of the panels, and also equip the building with sufficient ventilation. The “pie” is formed as follows: a wind-hydroprotective membrane is laid on the frame posts, a sheathing block is sewn onto it, on which decorative siding or other facing material is mounted. If a large amount of moisture potentially enters the plane of the wall from the inside, the membrane freely releases this moisture using a ventilation gap.

To better protect the insulation from the inside of the bath, it is covered with foil material, and all joints are sealed with an airtight film. Additionally, slats are mounted after the foil, creating an air space between them. Elements of interior decoration are screwed onto the slats.

The absence of an exhaust hood “kills” the building in 2-3 years. Walls and floors damaged by fungus cannot be repaired. Installing ventilation in a bathhouse does not require significant funds, and openings for natural air circulation are completely costless. You just need to know how to make ventilation in the steam room , where to place it, and what cannot be used specifically in this room.

General instructions with photos

Installing ventilation in a bathhouse with your own hands is not a difficult task. In the simplest version, you only need asbestos-cement pipes and gratings, which can be selected according to the diameter of the channel.

We offer you a master class on how to make ventilation in a bathhouse with your own hands using a supply valve (if the walls are made using frame technology):

Illustration of work being done

| Disassemble the valve into its component parts. | |

| Trace the circumference of the ventilation duct on the wall using a marker or pencil | |

| Use a drill to make several holes in the casing. They must be large in diameter so that a jigsaw blade can fit into the hole. | |

| Using a jigsaw, cut out a circle in the trim. | |

| Remove the wooden part. | |

| Remove the insulation and vapor barrier. | |

| Using a long drill, drill through the outer casing so as not to make a mistake with the location of the outer part of the valve. | |

| Make a hole from the outside, following the marks of the long drill bit. Preliminarily outline the circle with a marker. | |

| Saw off the valve tube to the required length (wall thickness). This can be done using a hacksaw. | |

| Install the air duct tube into the finished hole. | |

| Attach the inside of the valve to the wall using self-tapping screws | |

| Secure the outer part of the valve. |

Such valves can be installed in the washing room and dressing room.

How to make a hood in a bathhouse with your own hands

Equipped subject to the following conditions:

- direction of the supply air flow - from the residential building to the steam room (when the bathhouse building is adjacent to the residential building);

- the remote flow must be vented outside, the pipes are installed above the roof;

- It is not recommended to install exhaust openings immediately above the shelves to avoid drafts.

When thinking about whether a hood is needed in a bathhouse, you should remember that carbon monoxide can accumulate inside the steam room, which cannot be detected by a person in advance. To avoid an accident, it is imperative to install a ventilation system.

Let's briefly look at how exhaust and supply ventilation is installed in a bathhouse:

- It is best if you are wondering whether a hood is needed in a bathhouse, to begin installation while the building is being erected. Then you can correctly distribute ventilation openings and channels to ensure high-quality air exchange;

- the placement of a steam room, washing room, and dressing room is planned in advance;

- then the inlet and outlet openings for ventilation are determined;

- the cross-section of the ventilation holes is determined to be 10-20 cm;

- prepared openings, if necessary, are equipped with boxes made of wood, plastic, galvanized steel;

- if necessary, a fan is installed to remove air inside the steam room, washing room, or dressing room;

- openings are closed with grilles and plugs to regulate the volume of air flow and its speed;

- the exhaust pipe is mounted above the roof.

Useful video on the topic

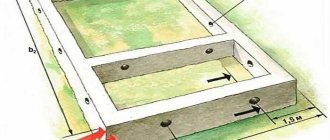

Ventilation of the bathhouse foundation

Actually, it all starts with it, because it is installed when laying the foundation. To do this, cut pieces of asbestos-cement pipes are taken, filled with sand and laid in this form among the reinforcement, fastened with knitting wire between the rods at a height of 5 to 12 cm above the ground level. After stripping, the sand is removed.

There can be two such holes in total, placed on opposite sides of the base. However, in reality, it is necessary to take into account a number of different factors, on which both the number of holes and their diameter ultimately depend. By the way, the usual diameter is 11 cm.

Before designing ventilation, the following are taken into account:

- distance of the bathhouse from the reservoir;

- location (high or low);

- surrounded by other buildings on all sides;

- wind rose of this area;

- bath area.

It is clear that if the bathhouse is in a low area or there are solid buildings around it, more holes must be made, even on all sides. You can also increase the diameter, but install a louvered grille or a damper.

CAREFULLY! Rodents can enter unprotected vents, so it is also recommended to tighten them with a metal mesh.

The plugged holes are usually left closed during procedures, but are opened for drying.

Ventilation calculation

We take into account that when using an electric heater, the ventilation holes are selected smaller, but for a sauna with wood or gas heating they should be selected 10–15% larger than calculated.

Based on the specified document on air exchange, we will calculate a conditional (!) bathhouse. With main supply and exhaust air ducts.

Table 1

| Name | Length Width Height | Volume, m3 | Air exchange, frequency | Air exchange, m3/hour | Note | ||

| Inflow | Hood | Inflow, Gr.3 x Gr.4 | Hood, gr.3 x gr.5 | ||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Waiting room | 2 x 3 x 2.4 | 14,4 | 3 | 0 | 43,2 | Add an inflow of 158 – 43 = 115 m3 | |

| Washing room, shower | 2 x 2.5 x 2.4 | 12,0 | Not less than 50 m3/hour | 50 | |||

| Bathroom | 2 x 1.2 x 2.4 | 5,8 | Not less than 50 m3/hour | 50 | |||

| Steam room | 2.3 x 2.3 x 2.2 | 11,6 | 0 | 5 | 58 | ||

| Total | 43,8 | Σп = 43 | Σв = 158 | ||||

A balance must be maintained between supply and exhaust. Therefore, the inflow volume should be 158 m3/hour.

Air flow speed is also normalized in the given recommendations. For natural ventilation of all rooms this is at least 1 m/s, steam room - 2 m/s. With mechanical (forced) – no more than 5 m/s.

In Table 2 we find the required diameter for a round air duct, in Table 3 - for a square or rectangular one. In the column with the required speed, we look for the closest value to the air exchange we received (158 m3/hour). For 5 m/s it is 125 mm. For a steam room (58 m3/hour) at a speed of 2m/s – 125 mm.

table 2

Table 3

Similarly, we find the required values for non-round air ducts.

In a bathhouse with the indicated premises, the inflow comes from the dressing room and exits in the bathroom. These rooms and the soap room are equipped with forced ventilation. Ventilation in the bathhouse in the steam room is provided by air supply from the dressing room or (if possible) from the street.

Bath hood: in which compartment?

If we leave aside the issues of ventilation of walls, foundations and roofs already discussed in other articles, there remain rooms - steam room, washing room, dressing room and rest room - where air circulation needs to be organized. At the same time, there are certain standards regarding ventilation in each of them and the specifics of the manufacture of the hood. But first things first.

Hood in the steam room

For steamers, an exhaust hood in a steam room is a guarantee that they will come out of there alive and healthy.

IMPORTANT! You should not leave the steam room without any ventilation holes at all; there is a high risk of burning or losing consciousness and suffocating on carbon dioxide. You can’t make only one hole - that’s how ventilation doesn’t work.

The method of ventilation of the steam room can be natural (due to the laws of physics) or forced (due to fans). The openings can lead to the street, into air ducts and into adjacent rooms. Ventilation openings are fitted with either blinds or dampers. The air flow can be organized through the bottom of the steam room door, spaced 3 cm from the floor, or from the blinds at the bottom of the door leaf.

You only have to make the box with your own hands. Everything else (corrugation, valves, valves, flaps) is on sale. Fans (if needed) vary in diameter and power. A relay can be used to automatically control forced ventilation. Holes in the wall were either left during construction or made in an already built bathhouse.

Useful video

Look how the craftsmen made a “bastu” type ventilation duct from boards:

In the washing room

According to the already mentioned standards, air circulation in a washing room per hour should be a multiple of 8 room volumes for supply ventilation and 9 for exhaust air. It means:

- that the dimensions of the exhaust opening will be larger than the supply opening;

- or there will be two exhaust for one supply;

- or a fan .

In any case, this is an intensive air exchange, which is intended primarily for quick drying of the washing area. It is not required during the washing process, so it is regulated by dampers.

By the way, supply openings can be made in the dressing room or rest room, and exhaust openings can be made in the washing room. This will allow you to ventilate two rooms at once. Similarly, the hood is done in the bathroom, and forced, to create low pressure. Then the air will be drawn from neighboring rooms and escape through forced exhaust. Thus, the rooms are connected by through openings, which will be supply on one side and exhaust on the other.

The components of the hood in the washing bath do not differ from those used in the steam room.

Ventilation in the washing room

A DIY sauna hood installed allows you to efficiently dry the washing area. Here is the largest amount of water allocated for the bathhouse building. The exhaust vent is closed during washing. After procedures, it is opened for ventilation.

It is important to maintain a comfortable temperature inside the washing room. It should be warm, but not hot. At the same time, the lower tier of air masses remains cool enough not to create discomfort.

Forced ventilation in the bathroom

Kinds

Today, there are three types of sauna ventilation. Let's look at each of them in more detail.

Natural

Occurs due to pressure differences indoors and outdoors. It is characterized by low installation costs and ease of operation. This is done in the following ways:

- Due to wind pressure, which seems possible only in buildings made of logs. Air pressure inside a room arises due to powerful gusts of wind, which create a significant vacuum of air on the leeward side. The movement of air in and out occurs through the gaps between the logs.

The disadvantage of this type of ventilation is that it is impossible to regulate it, which directly affects the temperature inside the bath.

As a result of strong winds, drafts are possible, which also causes no less inconvenience for vacationers.

- Thanks to aeration. Its meaning lies in the penetration of air masses directly from the street through the bottom of the room, in which there are special vents. Street air, entering the sauna, squeezes out a hot stream from above and directs it into the air duct. This sauna ventilation system is perfect for rooms with very hot air and a lot of steam. Oxygen circulation occurs very quickly here.

Mechanical

It is installed only in cases where it is impossible to provide fresh ventilation in the sauna. That is why it is also called forced. It consists of quite expensive elements: coolers, heaters, fans and air filters.

To achieve the exit of treated air from the room, during forced ventilation in the sauna, exhaust fans are used, on which filters must be installed.

This type of ventilation is used in very large rooms where there are swimming pools, showers and a huge number of visitors. It makes the air clean from steam, sweat and unpleasant odors in a short time.

Using mechanical ventilation, a forced flow of oxygen is used. This is achieved through a very complex system, which has the following components:

- Supply chamber.

- Mechanisms that reduce noise.

- Diffusers.

- Check valves.

- Distribution grids.

To ensure that the supply air is comfortable when entering the room, it is pre-cleaned and heated.

Combined

It is used in baths only if this is directly due to the peculiarities of their structure. Thus, a sauna located in a house and bordering three of its walls with common housing cannot have natural ventilation. In this case, it will not be possible to arrange the inlet and outlet holes according to all the rules. Therefore, in compliance with the standards, it is allowed to equip the supply opening at a height of at least 20 cm from the floor, and the exhaust opening is placed on the same wall at a similar distance from the ceiling.

The principle of operation of such air exchange is that cold air enters the room, passes it through the stove, heats it and circulates throughout the sauna.

Be sure to install valves on all openings to regulate the flow.

The disadvantage of such a system is the rather strong speed and amount of air masses.

In some cases, the supply channel is mounted not under the heater, but above it. The outlet is placed on the opposite side a few centimeters higher. This will reduce the air flow, but there is rice that does not have enough air flow. To avoid this, a fan is additionally installed in the outlet channel.

Ventilation of the waiting room

When considering whether a hood is needed in a bathhouse, you should remember that the dressing room also needs to be ventilated, especially if it is combined with a relaxation area. The temperature difference between the dressing room and the steam room can cause condensation to collect and fine moisture to settle in the form of a slight fog.

Here, the exhaust opening is installed at the top under the ceiling, opposite the door of the steam compartment, in order to promptly remove the hot air flow. Placed at a distance of 15-20 cm from the ceiling, but not inside it. A ventilation duct can also be used to remove air masses. This method is more effective.

If natural exhaust ventilation is not functioning sufficiently, it is possible to install a fan for artificial stimulation.

How to make cellar ventilation in a garage with your own hands >>>>

How do Finns do ventilation?

In the last few decades, the design of classic saunas has undergone significant changes. Regardless of the sauna design used, it must have an effective ventilation system. The problem is that taking bath procedures in a sauna implies a humidity level that tends to zero. Often, without high-quality ventilation in a room, it is difficult to ensure such zero humidity. As a result, the effectiveness of visiting the sauna is significantly reduced. If when organizing ventilation in a bathhouse it is enough to make a window in it, then in a sauna such a technique is not effective. The fact is that if there is a window, it can be difficult to keep the humidity and the required high temperature in the steam room at zero. At the same time, it should be borne in mind that visiting a sauna will be useful if it has a ventilation system that allows you to update six to eight volumes of air per hour.

The air must be taken fresh from the street. To achieve this, special sauna systems are used. It is necessary to organize the correct movement of steam in the sauna, effective inflow and outflow of air. Moreover, the volume of outflow and inflow must be equal. Otherwise, the ventilation system will not be able to function effectively. The optimal location for the supply vent is behind the stove. In high-quality ventilation systems, street air is supplied inside the steam room using a special box.

If you supply air to the sauna steam room from an adjacent room, then the room must be well ventilated, which will ensure fresh, clean air in the steam room. With natural ventilation, air will be sucked in from the adjacent room through the cracks under the door. Although this is acceptable, it is at the same time ineffective. In this case, there may be strong drafts across the floor.

In properly organized ventilation, the role of an effective heat pump is played by a heated stove. The stove actively sucks in cold air, and it passes through the hot walls of the stove, which allows it to heat up quickly. This heated air enters the steam room through the stove, thereby ensuring a comfortable bathing experience.

If there is no outflow in the sauna room, then when fresh air enters the steam room, excess pressure appears. As the pressure in the room increases, air movement slows down, and ventilation soon stops completely. The air outflow in the sauna is carried out using a small hole, which is located in the corner opposite from the stove near the ceiling. Please note that the holes must be equal. It is allowed to use a slightly larger inlet hole, which in diameter should not exceed the outflow hole by 10 - 15%.

There is an effective ventilation option in which the outflow hole is closed with a ventilation duct. This box goes down and ends approximately 30 centimeters from the floor. In fact, the exhaust air is taken in close to the floor, after which the air flows through the duct and exits through an opening near the ceiling. Such ventilation systems are highly efficient, but they require proper organization. Let's say that this ventilation option is not widely used today, since it is difficult to arrange.

The outflow hole must be covered with a grill. The cross-sectional area of the hole covered with such a wooden lattice must be adjusted. And remember that ventilation, regardless of the use of the room, must work constantly. The exchange rate of air during bath procedures can be adjusted by changing the diameter of the outflow hole. By correctly adjusting the diameter of the hole, you can achieve a constant temperature, and fresh air will actively flow into the room. No electronic fans are required and all ventilation is by gravity.

Ventilation in “drown-wash” baths

A modern dry-air steam room in a sauna differs from a traditional Russian bath in the presence of high temperature and minimal humidity. In this case, it is not possible to use a window for ventilation, since it is necessary to keep the temperature at about 100 - 120 degrees Celsius. To ensure such a high temperature, the steam room must be sealed as much as possible. Whereas the window will interfere with such high temperatures in the steam room. It is also not possible to use the sauna-style ventilation option here. Due to the temperature difference, a large amount of air will escape into the outflow hole, which in turn will lead to cooling of the steam room. In this case, it is recommended to use Basta-type ventilation. We will talk in more detail about this type of ventilation, which can also be successfully used in a Russian bath.