The logic of designing residential buildings, cottages and baths largely depends on the functional purpose of the buildings. Recently, the method of frame house construction has become very popular: it is fast, relatively cheap and, at first glance, very simple from the point of view of thermal insulation. However, the fashion for using certain schemes does not help to find universal construction solutions, since they simply do not exist. What is good for the home may not be suitable for the spa area. Let's consider the insulation of the main surfaces of a frame bath and try to determine the feasibility of using various types of thermal insulation and other technological elements that form the necessary microclimate in the steam room.

Features of heat transfer of a frame bath

Frame buildings belong to inertia-free thermal systems, that is, to houses with low heat capacity. What is the meaning of this parameter? It reflects the ability of building components to accumulate thermal energy. Accumulated by the walls and foundation, heat is released into the room, ensuring, on the one hand, slow cooling of the space when the heating is turned off, and on the other hand, slow heating to the required temperature.

Frame sauna is economical and prefabricated

A house built on the principle of a frame filled with thermal insulation heats up quickly and cools down just as quickly. There are no strong (in the traditional sense) walls, and the insulation for a frame bathhouse does not transmit energy well, but it also accumulates it in itself poorly.

During operation of the heating system, the level of heat saving of such an object is very high and is usually close to the standard of a “passive house”. However, the need for constant heating brings serious inconvenience to permanent residence in buildings of this type. But no one lives in bathhouses! The heating rate of the steam room is much more important here. It is for such objects that low inertia is rather a positive factor than a negative one.

Estimated construction costs

The cost of 1 m2 of a turnkey frame bathhouse ranges from 10 to 15 thousand rubles. This price includes all materials and work on installing a shallow strip foundation, frame, roof, wall insulation (mineral wool 15 cm), installation of carpentry and plumbing. The specified price range includes electrical installation, installation of plumbing and a fireplace stove.

By taking on the construction of this object yourself, you will reduce its cost by almost a third. According to data provided by home craftsmen, the cost of a frame bath with an area of 20 m2 is less than 160 thousand rubles (7-8 thousand rubles per 1 m2).

Thermal insulation of walls

In accordance with the design of the wall sandwich in frame housing construction, the insulation of bathhouse walls is not external or external. It is internal because it is a filling of honeycombs created by vertical posts made of thick boards or timber.

Filling the voids

Of course, we are talking about the main insulating layer. Mineral (basalt) wool is most often used. But not because it is the “warmest material,” but for a number of other reasons:

- Fire safety. Wood frame is the most flammable wall structure. Therefore, filling with non-combustible stone wool greatly reduces the risk of fire.

- Vapor permeability. To reduce the level of moisture condensation from the air inside the wall sandwich, the principle of increasing the vapor permeability of layers is used: the value of the parameter should increase in the direction from the inner surface of the walls to the outer one. Rolls and mats made of mineral fibers have higher vapor permeability than internal wooden cladding. This increases the resource of the wooden frame by preventing rotting and the formation of fungal mold.

- Price issue. Firstly, cotton wool is cheaper than EPS boards and sprayed polyurethane foam (PPU). Secondly, when using cotton wool, you can avoid the expense of ventilating the wall sandwich. Thirdly, you can save on installers’ labor costs: insulating a frame bathhouse with your own hands using this scheme is a simple matter, since all the materials used are quite light.

Diagram of a frame bath

Since there is no windproof traditional wall material, the sandwich uses special windproof Isoplaat boards, made from fine softwood powder impregnated with moisture-proof compounds (resins and paraffins). These slabs also serve as structural rigidity for the walls. When using mineral wool, a sandwich for insulating bath walls looks like this (from the inside of the steam room to the outside):

- decorative finishing made of solid wood (lining, tongue and groove, or regular board cladding);

- vapor barrier membrane (for example, foil material);

- a layer of stone wool;

- waterproofing membrane;

- Isoplaat windproofing;

- decorative cladding with a high level of vapor permeability.

It should be noted that even without external cladding, high-quality wind protection retains its properties for 5 - 10 years. A special feature of insulating walls in frame baths using mineral wool is the installation of large thicknesses of insulation (up to 150 - 200 mm depending on the climate zone). A common technique is to combine rolled and slab materials, forming 2 layers of insulation.

Theoretically, EPS or PU foam can be used instead of cotton wool, but certain design tricks are required to protect these materials from exposure to temperatures above + 75 °C. Firstly, the stove is not located closer than 1.5 m to the wall. Secondly, it is mandatory to use foil reflective materials with their own insulating layer. Moreover, a ventilated gap of 1.5 - 3 cm must be maintained between the foil insulation and the insulation board.

Otherwise, the structure of the sandwich is the same as already described.

The greatest difficulty is the arrangement of powerful ventilation capable of drying the air inside the frame. This measure makes the insulation scheme using EPS and PPU significantly more expensive. Therefore, foamed polystyrenes and polyurethanes are practically not used in baths of this type.

External insulation with EPS boards is possible. In this case, instead of windproof materials such as Isoplaat, the frame is sheathed with OSB sheets, onto which a slab of foamed polystyrene foam is glued on top.

Foundation

The frame structure is not afraid of soil shrinkage, since it is built from wood - a fairly strong and elastic material.

Light weight is another plus in favor of frame technology. Thanks to this, you can choose the most inexpensive foundation for a bathhouse. Columnar or pile, slab or shallow strip - they are all well suited for such a structure.

The main thing is that the upper cut of the base, on which the support beam will rest, is smooth and well waterproofed (coated with mastic, laying roofing felt in 2 layers). It is better to choose the timber itself from hardwood (oak, hornbeam, larch) and also treat it with a high-quality antiseptic.

To connect the wooden belt to the foundation, you can use anchors made of reinforcing bars with a diameter of 14-16 mm with a hook at the end, buried 15-20 cm into the concrete. At the other end of the anchors, a metric thread is cut for a nut.

This is how the foundation looks schematically with a beam prepared for the installation of frame posts.

Insulation of ceilings and floors

There are practically no specific differences between the insulation of ceilings in frame baths and the work in buildings of other types. On flat ceilings, the main insulating layer is installed from the inside of the steam room, and in the case of hemmed ceilings - from above, from the side of the under-roof space.

On the inside, a reflective layer (foil material) and a thermal insulator located behind it (mineral wool or EPS boards) are used. Regardless of the type of insulation, there is an air gap between the infrared screen and the main layer. On the side of the under-roof space, the wool is protected by a waterproofing membrane.

When installing the bath floor, do not forget about the drain

False ceilings can be insulated with the same materials as floor ceilings, but bulk mixtures (most often eco-wool) are usually preferred for their installation.

Insulation of the floor in a budget frame bathhouse is carried out, as a rule, using cellular self-growing concrete. In more expensive buildings, options are possible for installing a heated floor on the ground, providing a concrete screed on top of an EPS layer. A finishing plank floor made from a jointed “magpie” is laid on the concrete, which is the subfloor.

How to build

Let us briefly describe the stages of building a simple bathhouse from boards.

- First, the foundation is laid - if it is columnar, then you need to dig holes in the deepening areas, make a proper cushion of sand and gravel at the bottom, compact it, spill it with water, and after that make columns.

- If they are made of asbestos-cement pipes, reinforcement is placed inside and the pipe is filled with concrete. If it is made of brick, the platform should be made of 4 bricks. Posts are made at corners and under wall joints, as well as intermediate ones.

- The foundation is waterproofed with mastic and roofing felt. A strapping beam is placed on top of the roofing felt.

- Both the racks and floor joists are attached to the strapping beam. You need to start with the lag. But before that, a trench for drainage and a sewer pipe are laid (it is possible without this, but we are now describing an option that is optimal for the task at hand - cheap and high-quality).

- It is up to you to decide whether the floor will be insulated. If the bathhouse is summer, there is no need for this, if it is all-season, then it is worth insulating. For insulation, a subfloor is made of unedged boards, a film, insulation, film (if mineral wool), or simply insulation (if it is polystyrene foam, penoizol or something like that) is placed on it.

- Then it is closed with a screed, a slope is made for drainage under the steam room and washing area, and it is closed on top with a pouring finishing floor. If dry is selected, then the device is different, see the link above.

- The racks can be erected at the same time that the logs are installed. It is better to collect them on the floor, then lift them and secure them with corners on the strapping beam. Immediately make at least temporary cuts.

- When the top trim beam is laid, the rafter system is attached to it and the roof can already be built.

- A ceiling is made under the finished roof, for example, a floor ceiling is the simplest. These are boards laid on a strapping beam. They can be insulated on top with something light - ecowool, for example. You can cover the bottom of the steam room with foil, make a lathing and cover everything with clapboard.

- The racks on the outside are covered with boards, with which you cover the bathhouse in the chosen way - overlapping or with a dowel, or you have a tongue-and-groove board. From the inside, everything is covered with a waterproofing film, which is attached to the racks. Insulation is placed inside, covered again with film, but now with a vapor barrier (not to be confused! Hydro allows steam to pass through, but steam does not!).

- A sheathing of slats is placed on top of the vapor barrier, and the lining is attached to it. In the steam room, you can use foil as a vapor barrier. The lathing is needed to create a ventilation gap (!more about ventilation in the bathhouse here) and drying the lining.

- All that remains is to install windows and doors. And then - run the chimney pipe through the ceiling and roof.

Application of DIY insulation

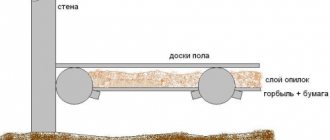

The second most commonly used insulation for frame-type baths are compositions based on sawdust and shavings. Processed in a certain way, the material is poured in portions and compacted. A sandwich wall using sawdust has the following structure (from the inside to the outside):

Insulating a bathhouse with sawdust

- plank cladding;

- kraft paper (no air gap);

- sawdust with a layer thickness of 10 cm;

- kraft paper;

- plank cladding.

The boards play the role of both a strength frame and decorative cladding. Reflective screens are usually not used, since the default option with sawdust should be the simplest structurally and inexpensively.

Pre-treatment of sawdust involves soaking it in a lime solution. Lime gives the material moisture resistance and is quite effective in fire protection.

If the work is carried out in the warm season, there is no need to dry the limestone chips before installation. Evaporation of excess moisture occurs quite quickly after backfilling.

In operation, processed sawdust has proven to be the same effective material as mineral wool, but lacking one of its main disadvantages - high hygroscopicity. To insulate floors, sawdust is used in the composition of cellular concrete. Treated sawdust is poured into natural coffered false ceilings in a layer of about 200 mm with moderate compaction. The top layer is covered with a waterproof membrane.

Protection of the chimney ceiling passage from heat

To pass through the ceiling of the bathhouse, the chimney section is made in the form of a sandwich: two metal pipes of different diameters nested inside one with a layer of non-combustible insulation between their walls. But even a sandwich pipe is prohibited from coming into contact with any wooden products. Therefore, it is carried out through the ceiling at the installation site of a special passage unit.

The assembly for the safe passage of the chimney consists of a metal sheet with a hole and a box surrounding it (made of metal). The passage unit is inserted and secured into a square hole in the ceiling, and the chimney is brought up through it. The top of the box is filled with expanded clay or stone wool.

Installation of a passage unit with a chimney section in the form of a sandwich pipe

A bathhouse with frame walls is cheaper than a log building and can be erected very quickly. Its main consumer advantages are high heating speed and slow cooling. To do this, it is important to take a responsible approach to the choice of wood and heat insulator material, as well as to form a layer-by-layer wall “pie” correctly and without errors.

Summary

By thermally insulating frame-type spa areas according to one of the described schemes, you can get a relatively inexpensive, but very effective version of a steam room with easy achievement of high temperatures and intense steam generation. The main attention requires careful consideration of the issues of vapor barrier and prevention of condensation of atmospheric moisture inside the sandwich walls. The inhibition of the development of undesirable microflora depends on this, ensuring the sterility of procedures and extending the service life of the wooden frame of the bathhouse.

More

Selecting a location

It is better to choose a flat area for construction so that you do not have to make a solid foundation. The place should not be too damp, otherwise the bottom of the building and the floor will begin to rot.

If there is a body of water nearby, it is better to build a bathhouse closer to it, in this case you can plunge into cool water after the steam room. The entrance to the dressing room is usually made from the south side so that snow does not accumulate in front of the door.