Practice shows that in ANY house or bathhouse there are places or structures for the manufacture of which it is desirable to use wood species that are particularly resistant to decay. Usually these are FLOORS in the house, floors of open vernades, terrace boards, boards on an open or closed veranda under a canopy or deck boards, solid wood floor boards used in wet places, near swimming pools, in baths, steam rooms, saunas, etc. To reduce the risk of damage to the floorboard and extend the time of effective operation of the floor from the moment it is laid to the renewal of the floor covering, it is possible and recommended to use larch boards and floors. Larch wood is particularly resistant to damage from moisture and does not rot for a long time. It is even used to make a lining beam, a lining board or the lower crowns of a wooden house, on which a frame made of pine, fir, aspen, etc. is laid. But having chosen larch as a building material or made floors from larch, we may be faced with the task of selecting a finishing protective impregnation for a given type of wood, that is, how to paint and treat the larch floor. The thing is that it is difficult to apply varnishes and paints to larch wood and lumber due to its specific properties - natural oiliness, which prevents the “sticking” of surface paints and varnishes and quite high friability, which affects the degree of change in the geometry of the board when humidity changes treated wooden surface. Ordinary varnishes and paints practically DO NOT last on larch floorboards, or the protective coating treated with varnish and paint for wood on larch turns out to be NOT durable at all. It is safer to treat larch floors with impregnation, which does not peel off, does not form a hard surface film, but protects the wood from moisture and allows the wood to “breathe”, i.e. OIL and WAX.

A few words about the material

It is known that a resinous and elastic board made of coniferous wood is second only to oak in terms of hardness.

Larch is one of the most practical and durable species of coniferous trees, which is used primarily for finishing “damp” rooms. A board made of this material has better technical parameters in comparison with other wooden coverings made from coniferous wood. A distinctive feature of this coating is low water absorption. Despite the excellent qualities of the tree, it costs little, due to its prevalence.

Why is larch most often used for flooring in bathhouses? The popularity of the material is associated with its excellent physical and mechanical characteristics. They almost 100% comply with the requirements for coatings used in bathhouses:

- high strength;

- resistance to temperature changes;

- resistance to rotting;

- increased moisture resistance.

It is known that a resinous and elastic board made of coniferous wood is second only to oak in terms of hardness and only by a couple of points. That is, the hardness of larch, according to the Brinell scale, is 3.2 units. In other words, the end hardness of wood ranges from 38 to 82 MPa. For comparison: spruce and pine have a hardness of up to 38 MPa.

It is also surprising that as the material dries, its density increases greatly, to the point that it is simply impossible to drive a nail into the plank. However, it was precisely this feature of the coating that determined its service life. Even in conditions of very high humidity, larch floors can last at least 30 years.

We save wooden floors in a bathhouse from rotting: the best impregnations and methods of their use

We treat the floors in the bathhouse “The weaker sex are rotten boards” (Faina Ranevskaya) Good day, reader!

So I thought about the meaning of the bathhouse in my life. And I couldn’t answer myself, what is this? hygiene or traditional long-term ritual. What do most men remember in damp, chilly weather? - about a steam room with a fragrant whisk.

I am wrong? The feeling of spiritual flight is given by a simple heated wooden room, which has retained its unchanged appearance over the centuries. Unfortunately, concerns about maintaining its proper appearance also remained unchanged. Wooden floors especially require them. So, today’s topic is how to treat the floor in a bathhouse from rotting.

A little about sad things. The floors in the bathhouse are rotting. Sooner or later you will have to re-cover it. Even if the boards look perfect and there are signs of rotting, no, this does not mean that everything is in order. Competent builders determine the presence of a process by knocking. Rotten wood will produce a dull sound.

Article on the topic: What to plant near a chain-link fence

To begin with, I’ll tell you why this happens in the bathhouse (although the reader can guess without me). There is only one reason - moisture. Moreover, in the most extreme manifestation - multiple cycles of getting wet and drying, plus sudden temperature changes. The main question is what needs to be done to slow down the process of inevitable wood rotting?

Material advantages

Wood has minimal thermal conductivity, due to which the bathhouse maintains a high temperature for a long period. The bathhouse has

a very specific microclimate, so repair work in such a room always involves the search for materials that could stoically withstand large temperature changes and humidity. One of these materials is larch. Its popularity is due to its unique physical and mechanical properties, which include:

- High strength. As already mentioned, coniferous wood is second only to oak in terms of strength, but costs significantly less;

- Resistance to pathogenic flora. The coating contains gum, which is essentially a natural antiseptic. That is why coniferous wood floorboards are not at all afraid of fungi and mold;

- Moisture resistance. Wood fibers are thoroughly impregnated with resinous substances that prevent the penetration of moisture. That is why the coating is not subject to warping and any types of deformation;

- Sound and heat insulation. Wood has minimal thermal conductivity, due to which the temperature in the bathhouse remains high for a long period. In turn, the high density of the material provides it with good soundproofing qualities;

- Effect on the body. The resinous substances found in the structure of larch floors include phytoncides. During the heating process of the coating, volatile “helpers” kill pathogenic microbes and viruses in the air;

- Decorative. The coating has a unique texture that is well set off by the honey color of the board. Such floors can decorate almost any interior;

- Price. The prevalence of larch ensured its low cost. For m2 of flooring you will have to pay only 10-15 USD.

What varnishes to use when treating the wooden floor of a bathhouse

If the question arises about how to coat a floor or other wooden product, we usually use varnish.

It can be used, however, not every paint and varnish composition meets the requirements for use in baths. It should not only protect the steam room floor from rotting, temperature influences, and mechanical damage (scratches, impacts). It must also be non-hazardous to people. Article on the topic: Do you need a wash station in a bathhouse with your own hands?

Before applying varnish, it is important to properly prepare the surface. It must be clean, dry, free of grease, and the wood must be freed from its former coating, which is sometimes not so easy. If there are defects or other irregularities on it, it will be better to get rid of them using a special putty. Wood that has been varnished many times must be sanded. Pay special attention to surfaces affected by mold, rot or fungi: you can get rid of them by first treating them with an antiseptic. Quality varnishes:

- "NEOMID Sauna" is used for decorative finishing of wood in rooms with extreme temperatures and humidity, which makes it useful for use in baths or saunas. The varnish has an acrylic base and can form a dirt-repellent, moisture-proof coating with high elasticity; protects the composition from biological threats, and therefore the floor of the steam room will not darken. A useful feature is quick drying, which takes 20-30 minutes. It is almost translucent, but has a beautiful matte shine; if desired, it can be tinted, and this provides a number of possibilities for decoration;

- "ATOM-COLOR" is optimally suited for baths; it can completely cover a steam room. This composition mixes well and is applied at temperatures of at least plus 10 degrees. To cover the floor surface, you need to take a simple repair brush. In the steam room, limit yourself to only 1 layer. Then you need to let the varnish dry, and then you need to heat and ventilate the room well. When everything is done, you can use your sauna.

What do consumers think?

Larch in the bathhouse has received a huge number of positive reviews.

Most consumer reviews of larch wood coverings are positive, which once again confirms the practicality of the material. The attitude of 90% of consumers towards wood flooring can be expressed in literally three reviews from individuals that were collected online:

- About a year ago I was renovating the bathhouse and decided to use larch as a covering. Before this, there were oak boards in the steam room, but literally three years later a fungus ate them. I’ve been using the sauna for a year now and the floor hasn’t even darkened yet;

- I never thought that inexpensive larch would surpass beech in its technical qualities, but this is a fact. In the bathhouse, I laid a tongue and groove board on the screed more than 5 years ago, I still haven’t replaced a single plank, everything is intact;

- Finishing floors with wood is always a risky undertaking, especially in a room where water literally flows onto the surface in a stream. But the larch exceeded my expectations; in the wash room I lined the floor with pine boards, but even under constant exposure to water it did not warp.

Of course, coniferous wood has many advantages compared to other types of materials. But in order for the coating to last a really long time, the laying of the boards must be carried out taking into account many nuances, which we will talk about a little later.

Larch floor boards - advantages and disadvantages

Original wood floor coverings

In Scandinavian countries, the ancient method of covering floorboards is still used. It involves frequently washing the floorboards with a strong solution of laundry soap in water until the wood is saturated with it.

This method of covering wooden floors is suitable for larch, since this species is not naturally afraid of moisture and even hardens from it: soap will form a layer that protects from dirt and dust, and water will react with the gum and make it durable. However, for other types of wood, especially soft pine and spruce, such design is very dangerous. Excessive waterlogging is likely to lead to warping, cracking, rotting and discoloration.

Wood grade

An example of the main types of wood used for flooring in a bathhouse.

Which type of wood is best to choose for flooring in a “damp” room? The grade of raw materials determines not only the aesthetic, but also many technical characteristics of the materials. The following types of wood are distinguished:

- “Extra” or “Elite” - the first grade board contains minimal color transitions. There is no sapwood or the slightest scratches on the surface;

- “Natur” is a medium selection coating that can have several pronounced color contrasts and a small number of knots with resin pockets;

- “Rustic” is a budget option for coating, which may contain traces of knots, visible scratches and color contrasts.

What coating will be optimal for the floor in a bathhouse? In many ways, this indicator depends on the functional purpose of the room. For example, the washing room is always quite humid and the water has direct contact with the base. To reduce the negative impact of moisture on wood, it is better to make the flooring from boards with a minimum number of flaws, i.e. "Extra" variety. For the dressing room and steam room, where the humidity is moderate, a board of the “Natur” variety is suitable.

Features of painting for different coatings

Finally, we’ll talk not about what you can use to paint the floors in a bathhouse, but about how to do it correctly, because different compositions require different brushes.

If you decide to use oil (not oil paint, but floor oil), then the brush you will use to apply it should be made of natural bristles . Due to its structure, such a brush will not leave streaks on the surface of the wood. By the way, you can only remove oil from it with a solvent.

Article on the topic: What kind of brick for heating a bathhouse

Wood glaze mixed bristles . Wash off with water.

Colored wax artificial fibers for application . It is liquid, so you can use a roller or a spray gun.

In general, there is such a division: water-based paints and varnishes are applied with artificial brushes, and other varnishes and oils are applied with natural bristles.

Types of larch boards by type of processing

Each type of board has its own advantages and areas of application.

There are several types of larch boards that are used in the construction of floors:

- Unedged - boards whose edges remain unprocessed. As a rule, they are used to create subfloors;

- Edged - smooth wooden slabs of regular geometric shape. Unplaned planks are used for finishing the rough base, planed ones are used for finishing the floor;

- Tongue-and-groove slabs with interlocking joints that form a monolithic coating of high strength.

Each of the above types of larch materials has its own characteristics. To evaluate the benefits of using each of them, let's consider all types in more detail.

Unedged boards

In rare cases, untreated wood is used as a finishing coating.

An uncut board is made by cutting logs without additional processing. It may have an irregular geometric shape and therefore is more often used as a rough covering, on which waterproofing is subsequently laid when installing wooden floors in a bathhouse. This type of material is inexpensive, which helps save a decent amount at the stage of preparing the base for laying the finishing coating.

In what areas of bathhouse construction are they used?

- installation of wooden sheathing;

- sheathing of frame structure;

- arrangement of the black base.

In rare cases, untreated wood is used as a finishing coating when installing poured floors. However, untreated boards are more hygroscopic, so after each water treatment they need to be thoroughly dried.

Edged boards

This coating can be used for installing both rough and finished floors.

This differs from the previous type of material in that it has a rectangular cross-section. In the process of cutting the larch trunk, the boards are given the correct geometric shape, which significantly expands the scope of their application. This coating can be used for installation of both rough and finished floors.

Floor boards made of pine, oak and larch: characteristics and prices

There are two types of trim strips:

- Unplaned. After sawing, they are not subjected to any type of processing, therefore they have a rough surface. Used as a rough material for assembling wooden frames, subfloors, etc.;

- Planed. They are subjected to mechanical cleaning, due to which the coating becomes smooth and, accordingly, less susceptible to moisture.

tongue and groove boards

Often, tongue-and-groove coatings are used to assemble a finished floor.

A tongue-and-groove board is a practical and wear-resistant material that is suitable for installing non-spillable floors in bathhouses. This type of coating is equipped with a locking system, in which one of the strips has a “ridge” and the other has a “groove”. This allows you to achieve high-quality connections between the planks.

Often, tongue and groove coatings are used to assemble a finished floor. In this case, installation can occur in two ways:

- In the form of a styling covering. Long planks are laid along the entire room, forming a monolithic wooden floor;

- In the form of a typesetting covering. Sufficiently short slabs are laid in a checkerboard pattern, so that the surface resembles a parquet board in appearance.

Bath flooring

What you shouldn't try to do is cover all the floors in a bathhouse with the same type of paint. Firstly, the savings that are usually claimed in this case turn out to be absolutely meager, and secondly, in different rooms there are completely different regimes, which means that the requirements for covering a wooden floor are also different.

How to cover the floor in a bathhouse vestibule

In this case, there are two options - use inexpensive alkyd enamels or try to protect the wooden floor with more durable polyurethane or acrylic paints. If there is a wood-burning stove in the dressing room, then it is better to use the second option. In addition, for rooms with stoves or fireplaces, the floor cannot be covered with polyvinyl chloride and rubber materials.

According to reviews, most owners prefer to use inexpensive water-dispersed and alkyd materials in their bathhouse. The calculation is very simple, it’s easier to cover a wooden floor with a fresh coat of paint once a year and have a great look than to spend money on very expensive but safe silicate coatings. It is clear that with this approach, the interior inside the bathhouse looks very attractive, but the floor and wooden floorboards practically rot under a thick layer of enamel, which does not protect at all from moist air.

Article on the topic: How to build a bathhouse from cinder blocks with your own hands

How to paint the floor in a bathhouse in a washroom

Two types of paints and varnishes are best suited in the washing department:

- You can paint it with quite expensive, but very beautiful and durable polyvinyl chloride paints. The protective layer can withstand any detergents, powders and soaps; the wooden floor under such paints and varnishes lasts in the bathhouse for quite a long time, since PVC is absolutely plastic and does not allow moisture to pass through, even when completely flooded with water for a long time;

- Butyl styrene paints protect any wooden surface well from moisture, provided that the protective coating is applied to the wood without old paints and varnishes.

Before covering the floor in the bathhouse with a protective layer, the surface must be cleaned and dried with a hair dryer with air at 70-100 o C.

Rubber paint is only suitable for concrete

If the washing room has a concrete floor, then acrylic-silicone or epoxy materials can be used.

How to cover the floor in a steam room

For a very difficult, humid and very hot steam room atmosphere, we can only recommend special paints based on alkyd-urethane compositions. They are not distinguished by high decorative qualities, but at high temperatures they ideally withstand wear and contact loads.

In addition, even over time, varnish and paint do not lose their plasticity, do not peel off or “glaze” to the state of tiles. At the same time, they remain safe and do not emit any harmful substances into the atmosphere in the bathhouse.

Installation nuances

Options for laying floor boards in a bathhouse

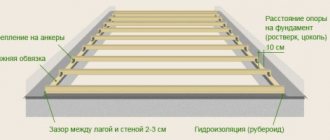

Finishing the rough base with larch boards has a number of technological nuances that are worth knowing about:

- Before installation, it is advisable to treat the planks with antiseptic compounds with water-repellent properties. Despite the fact that larch floors are not susceptible to rotting, in the process of washing out the resin, pathogenic flora can still develop on its surface;

- The planks are secured to wooden joists using self-tapping screws, since they are able to press them to the base with greater force;

- Since larch has a high density, so that it does not crack during the process of screwing in the screws, holes are first made in the designated places;

- If materials are laid using the adhesive method, for more reliable adhesion to the rough surface, it is advisable to use one- or two-component adhesive compositions.

Processing different parts of the bath

Conditions in different parts of the bathhouse are different, therefore the requirements for finishing materials are different. In rooms where temperature and humidity are maintained at high levels, it is recommended to choose more expensive durable impregnations.

Waiting room

Among the most popular ready-made products are Sauna (Belinka) and Supi Saunasuoja (Tikkurila). Of the domestic impregnations, the U-409 remedy has proven itself well. It can be equally effectively used for processing wooden structures in baths, saunas, bathrooms, showers and living spaces. All these impregnations are made using only natural ingredients. After their application, a thin film is formed on the sheathing (eurolining) and logs, which greatly simplifies the removal of contaminants. They contain fungicidal and insecticidal components that help prevent the appearance and proliferation of pathogenic microorganisms in baths and saunas, which is especially important for the dressing room.

Article on the topic: How to make a floor in a garage with a strip foundation

Another well-known antiseptic is Eurotex Sauna, which contains wax. A colorless wax antiseptic creates a protective film on the surface of a wooden structure. The product is excellent for treating benches and shelves. Impregnation volume of 2.5 liters is enough for 35 sq. m. After using this product, wood has a more attractive appearance, is easier to clean and retains its original color for a long time. The only drawback that can be noted is the presence of a clear specific smell inside the room, but after 3-5 visits it disappears.

Steam room

Considering that the air temperature and high humidity inside the steam room are very high, a special approach is needed here, in particular, you should know how best to treat the lining in the steam room. Natural oils and wax are suitable for these purposes. Some home craftsmen impregnate the boards with linseed oil with the addition of a natural aromatic composition. Often, from a variety of oils, hemp oil is chosen for impregnation. If you need a more economical option, you can use refined sunflower oil.

There is a fairly large selection of products for treating industrial shelves. These are impregnations from Russian and Eurotex Sauna, and Supi Laudesuoja oil from Tikkuril.

Note! It is not advisable to use ordinary paints and varnishes to protect benches, joists, shelves, walls and ceilings.

Wooden surfaces must breathe - first absorb moisture and then release it. If conventional compositions are used, then such surfaces lose this quality. In addition, in conditions of high humidity and high temperatures, the evaporation of harmful substances that pose a health hazard is added, and the bathhouse no longer becomes a cure for many diseases, as it has been for centuries. This can be compared to finishing a bathhouse or sauna with linoleum or siding, which is strictly contraindicated.

Article on the topic: How to build a fence from foam blocks

Recommendations from experts

To ensure that the flooring in the bathhouse lasts at least 10 years, experts recommend paying attention to the following subtleties:

- During the installation process, floor boards must be secured with self-tapping screws at the junction of adjacent elements. In this way, warping of the coating can be prevented;

- During use, wood will inevitably swell under the influence of water. To eliminate the possibility of severe deformations, during the installation of the floor, a technological gap of 3-4 cm is left between the wall and the mounted planks;

- When installing non-leaking floors, it is advisable to place plywood under the larch planks, which minimizes the contact of the wood with the screed.

Features of laying and caring for larch floors

Floorboards must be laid on a flat horizontal plane without distortions to prevent floor deformation and cracks. When constructing a floor structure, care must be taken to ensure a reliable and high-quality ventilation system for the underground space.

If a floor is installed on the ground floor, then to prevent sudden temperature changes it is necessary to ensure reliable thermal insulation.

Before installation, the material must undergo acclimatization in unpacked form, that is, spend about a week in the room where the floor will be installed.

If the boards have not undergone industrial treatment, they can be coated with protective agents: varnish, paint or wax. Periodically you will have to update the protective layer.

You can care for your finished floor using conventional products. Periodically wipe the floor with a damp cloth or use a vacuum cleaner. Do not walk on this floor wearing shoes with thin high heels. In areas of constant foot traffic, use carpeting to protect the floor from abrasion.

Larch boards will make your floor high-quality and safe. This flooring, proven over centuries, will decorate any room and make it warm and cozy.

See below for more details.

Causes of mold and mildew

Wood is an organic environment for the development of pathogenic microorganisms, the development of which requires moisture and heat. The bathhouse is a source for their development, since the surface is finished with wood, and inside there is enough moisture and heat for the spread of mold, rot or fungus.

If left untreated, the joists and the rest of the cladding wood will rot and become unusable over time. The main reasons why decay occurs:

Rotten damage to beams

Important! Some types of wood are resistant to the development of pathogenic microorganisms.

Thus, coniferous species contain resins, which contain phytoncides, which provide immunity to the appearance of mold or mildew. Therefore, to finish the floors in the bathhouse, it is recommended to use:

Features of larch. When wet, this rock becomes much stronger and harder, and it contains special resins that prevent the formation of mold, rot and mildew.

Species such as maple, alder, birch, aspen, linden and ash are most susceptible to these microorganisms.

But in order to preserve the floor for as long as possible, it is necessary to treat it with special substances.

Features of the main types of antiseptics

Acrylic- based antiseptic has the following features:

- The acrylic-based antiseptic composition prevents the development of all types of pathogenic bacteria. Before applying the composition to the joists, floors and walls, it is diluted with water. This tool has the following distinctive features:

- Resistance to temperature changes. This property allows you to use the product for treating the floor both in the relaxation room and in the steam room.

Drying oil for treating wooden floors

Drying oil is a plant-based substance with a film-forming composition. Drying oil is suitable for treating all rooms of the bathhouse.

- During the treatment of boards with drying oil, its polymerization occurs, forming a durable film that protects the surface from moisture. Drying oil can be used to prevent wood coatings and to prevent the appearance of splinters.

- There are two types of drying oil - natural and oil. For bath rooms, it is more advisable to use a natural type of composition, without the content of synthetic components.

Mixed impregnations

- Mixed compositions are designed to protect wooden surfaces and prevent their fire. Since the bathhouse has rooms with high humidity, the possibility of fire is minimal. This product is mainly used to treat dressing room boards.

- Mixed impregnations contain fire-retardant reagents that do not pose a threat to human health.

Wooden floor after applying impregnation

Mixed impregnations

Where is it better to use mixed impregnations? Mixed products are products that not only protect walls and floors from rotting, but also prevent fire. The washroom is a room with high humidity, so the likelihood of a fire in it is low. In the rest room, air humidity is approximately 60%, and in the dressing room - no more than 30%.

To provide high-quality protection not only from rotting, but also from fire, it is advisable to use mixed types of impregnations in the dressing room. As a rule, such products contain fire retardant reagents that do not pose a threat to health.

Is it possible to use a terrace board for a bathhouse and sauna?

Without special treatment, logs and floor boards begin to rot. In a bathhouse, as a rule, wood is used to finish floors, walls, ceilings, benches and shelves. That is why, without special treatment, logs and floor boards begin to rot. What are the main causes of rot in a room?

- poor waterproofing;

- lack of normal ventilation;

- high temperature and humidity;

- poor quality wood processing.

Some types of wood are more resistant to pathogens than others.

Traditional Russian ancient baths have always been associated with healing and relaxation, as they are the most effective, healing and comfortable. Such old baths were built only from wood and only with their own hands; this structure will have an original beautiful appearance and is distinguished by a luxurious aroma of wood.

Wood is distinguished by its content of unique essential oils, which are especially beneficial for health and will have an interesting smell. The beautiful and stylish appearance of the bathhouse is created precisely by wood, which also contains antiseptic substances to disinfect the material.

Foundations for a wooden bath:

- Tape

- Pile

- Columnar

- Special slab foundation

To build a high-quality, durable structure, it is necessary to take into account all technological construction stages. This structure can be separate or combined with a house; it can be built from rounded or chopped logs. Construction begins with pouring the foundation, followed by assembling the house itself, installing the roof and finishing the building.

It is necessary to take into account literally all technologies of wooden house construction, so that the house will last a long time and of high quality. Building a wooden bathhouse is a complex and labor-intensive task that requires a lot of knowledge and extensive experience in working with wood.

Baths and saunas made of Siberian larch have several features that are important to consider during construction. Due to the fact that the wood of the queen of the Siberian forests is very dense, it is necessary to take care of a solid foundation that can withstand the load. Most often, a strip foundation is laid with additional reinforcement of the platform for the heater.

The log house, the size of which is determined by the number of people who like to take a steam bath, can be made from solid logs or timber. Each of the materials has its own advantages, so future owners should be guided by their own taste and financial capabilities. If the owners do not have the opportunity to completely assemble a larch frame, experts recommend using it at least on the lower crowns: over time they will become stronger than stone.

The floor requires special attention: wood impregnated with resin practically does not absorb moisture, so the boards are not laid close to each other, but with a small gap. This allows water to flow down freely without forming puddles. The walls of saunas and baths are usually lined with clapboard. This beautiful and durable material does not require special treatment, since the resin contained inside prevents the formation of rot or fungus.

When purchasing dachas or country houses, owners often receive buildings that can easily be converted into a bathhouse or sauna. They can be made of various materials, but larch wood will quickly and easily turn the room into a hot steam room or a comfortable dressing room.

To decorate the interior of the sauna, various larch lumber is used: for walls and ceilings - lining or plank. The floor can be made from a floorboard, but you can also use a decking board - then it will be durable and non-slippery. Small shelves will allow you to place a set of aromatic oils, a ladle and other accessories near the heater.

Boards and timber with a beautiful texture can also be used to make doors, carved platbands and jambs, and ladders. Experts count twelve colors of larch wood: from light to reddish-brown. By skillfully combining tones, you can create a magnificent room, to which the play of warm shades will add special beauty.

Speaking about the use of larch in the construction and decoration of baths and saunas, it is necessary to mention its healing properties. The incomparable aroma of its wood not only relaxes, but also helps strengthen the immune system and helps cope with diseases of the lungs and upper respiratory tract.

Phytoncides, which are released during bath procedures, serve as a prevention of hypertension, migraines, and have a beneficial effect on the nervous system. Some experts believe that larch also has a rejuvenating effect because it contains a large amount of antioxidants. You can enhance the therapeutic effect with the help of infusions of pine needles and bark, however, even without additional measures, a weekly visit to a larch sauna will help you quickly restore strength after heavy physical exertion. The unique qualities of this coniferous beauty will ensure Siberian health and longevity for everyone who inhales its aroma at least occasionally.

A popular, relatively inexpensive and easy-to-install material for decorating both the external and internal surfaces of premises for various purposes - walls, ceilings, balconies and loggias, dressing rooms, concert halls... (Turnkey interior finishing of a bathhouse). The division of lining into standard and eurolining is determined requirements of the relevant standards for the production of cladding boards. The domestic production standard is GOST 8242-88, the European standard is DIN 68126.

In many cases, larch lining is purchased for a bathhouse, because in addition to aesthetic characteristics, it is characterized by high strength, as well as resistance to moisture (Finishing a steam room in a bathhouse). In the modern world there is an increase in production volumes of products from this type of wood. Professional designers from many countries widely use such lumber in their creations, thanks to which they can bring interesting ideas to life.

Nowadays, it is difficult to find another natural material for cladding any surfaces that meets all the basic requirements than hardwood lining. It is perfect for external and internal decoration of verandas, gazebos, country houses and other buildings. Experts in the construction field recommend using panels made from such wood for lining washing compartments, because this species is not afraid of moisture and water. The cost of such products can vary significantly depending on the variety.

Anticipating possible questions, we will answer right away: the lining requires mandatory treatment, otherwise the tree will quickly begin to deteriorate.

We propose to consider the two most well-proven processing compositions:

- “Eurotek-sauna” is an environmentally friendly acrylic mixture containing wax. The product does not contain solvents, is colorless, and retains the wood grain.

- Supi Sauna Soja (Tikkurila) and “U-409” have proven themselves to be excellent compositions that prevent the penetration of moisture and are colorless.

When choosing for lining, be sure to consult with a specialist and do not forget to compare the antiseptic with the selected wood.

It is unlikely that anyone will be surprised by the statement that the most reliable floor for a bathhouse is reinforced concrete, waterproofed. It’s not for nothing that government washrooms have cement floors.

The concrete floor in the bathhouse is cold and becomes slippery when wet.

Concrete is durable and non-flammable. The construction of a monolith, in comparison with the installation of other coatings, requires the least financial and labor costs. If desired, the concrete floor can be made to leak: water will rush along the inclined surface to the drain and then through the siphon into the sewer. This floor is easy to clean and does not need to be repaired: the screed lasts for decades. Sanitation is simple: once a year, the cement surface must be treated with a solution of copper sulfate.

But along with a hundred advantages, a concrete floor has only one, but still a drawback: it is uncomfortable. Concrete is thermally conductive, but if wet it becomes slippery. There are many traditional ways to eliminate inconvenience. The concrete is painted (low-cost method) and covered with linoleum (economical). The most popular method is tiling.

The peculiarity of the deck covering is that the floorboards are not adjusted to each other when laying, but are laid with a gap

Wooden floors in the bathhouse are the only option. Yes, wood needs to be looked after: scraped, washed, treated with antiseptics, mastics. The boards need regular repairs, sometimes they need to be completely re-laid. However, the advantages of wood are higher than all its disadvantages.

In addition, a method that allows you to combine the comfort and coziness of a wooden floor with the convenience and functionality of a concrete floor is already known. This is decking - a terrace board, a removable deck (from the English deck). The peculiarity of the deck covering is that the floorboards are not fitted to each other during installation, but are laid with a gap to ensure water drainage. The decking design has been tested by time, winds, arctic cold, tropical heat, salt water, and on gun decks, even gunpowder.

An example of a polymer plastic board for a bath

Modern decking boards are intended for year-round outdoor use. For this purpose, the material is subjected to intensive steam treatment, the surface is coated with esters and resins, which provide the finish with additional water-repellent properties.

Terrace boards are made mainly from wood that is not afraid of temperature and humidity influences. Companies promote larch most widely. Its natural qualities, complemented by technological methods, make this wood almost eternal. The service life of varietal larch exceeds half a century. Oak is also common. Its popularity is due to the same reasons. There are products made from beech, ash, and cedar on the market.

Which are the best for outside treatment?

Let's start with the outside. It can be made of wood in two cases: when the wall is made of wood - timber or round timber, and when it is lined with wood. In this case, either clapboard for external cladding or board can be used.

Bathhouse with a large relaxation room

As for impregnations, they are divided into two categories: for protection against biological damage (antiseptics) and/or fire retardants and for protecting wood from the effects of nature and weather (coatings).

The antiseptic agents that are used to impregnate the outside of the bath will not differ for boards and logs, because in our case they are all intended for manual application . This means that their depth of penetration into wood is limited to a maximum of 5 mm, but in reality it is even less.

Therefore, it is advisable to approach the impregnation of bathhouse timber more responsibly and use stronger antiseptics.

For log and timber

Ideally, for the outside of a log bathhouse, impregnation made in an industrial environment . But it covers the entire surface layer of the log, which is not good for a steam room if it is not insulated and lined with clapboard. If the walls are covered (only in the steam room), then impregnated wood should be considered the most protected from rot and mold.

You can read in detail about what it is and what compounds are used there.

Applying antiseptics manually, as already mentioned, is less effective, but fairly strong formulations can be used.

In general, it is recommended to pay attention to those compounds that are designed for outdoor use.

An example of a good option for impregnating the outside of a log bathhouse is the “Valtti” . They are sold with an antiseptic primer. Ideal compatibility option.

Let me explain. to peel off after three years in the harsh Russian winter Oil impregnations are better in this regard because they form a more elastic coating. The same applies to acrylate compounds.

Actually, here it is. We coated the wood with an antiseptic, after which the impregnated layer must be protected from washing out and destruction by ultraviolet radiation. Therefore, pay attention to the presence of UV filters in the product you will use to coat the antiseptic.

What is good about exterior impregnation of a log house with oil? Thanks to it, the logs will crack much less , because the oil makes the wood less fragile. In our opinion, this is the best impregnation for the outside of a bath. You can use both domestic and imported oils. The main thing is that they are intended for facades, contain UV filters and are resistant to temperature changes and precipitation.

What is rotting, what impregnations protect against it?

One of the reasons why we found it necessary to write this review was the widespread illiteracy of people writing about wood rot and means of protection against it. You read such rare nonsense that you become scared - what if in other areas where you don’t understand, they just as cheerfully tell you nonsense?

Composition for baths 2.7 l. Saunasuoya soup for protection against moisture and dirt. Banka Photos

Mold is harmful due to its toxins and spores. Toxins are harmful if eaten - as some do when they cut off the moldy side of an apple, considering the rest healthy, but not realizing that the visible mold is its fruiting body, and the hyphae penetrate the entire apple. But we don't eat the tree, so spores are the main type of damage caused by mold growing on the tree.

spores in the air, they cover objects, but are activated only in the presence of moisture. In normal concentrations, our body copes with spores that penetrate it. But when there is a colony of mold in residential or bathing areas, the concentration of spores grows so much that this becomes the cause of mycotoxicosis, allergies and many diseases that at first glance cannot be associated with mold at all - migraines and heart disease, otitis media, rhinitis, bronchitis , etc. .P.

IMPORTANT! You shouldn’t believe Wikipedia that mold destroys wood, but you should definitely be afraid of it and fight it. It is also necessary to distinguish between rot and mold, because the means of combating them are different.

The very mechanism of wood destruction by fungi boils down to the fact that their hyphae eat away cell walls with enzymes, leading to their corrosion or destruction (they differ in the scale of dissolution - in the first case, holes are formed in the cell walls, in the second the walls dissolve entirely). The contents of the cells become stained, which leads to the darkening of rotting wood.

There are quite a few types of fungi that cause rotting, and they belong to different classes. Therefore, substances that successfully cope with some types are useless against others.

ATTENTION! There is no universal fungicide. Only compositions are possible that complement each other, affecting species over which the other has no control. But we have not found a single ready-made product that would work in this way. Only fungicides with limited spectrums of action are commercially available.

But what’s even sadder is that many fungicides that are sold specifically for baths are effective only against molds and staining fungi! And they sell them as a remedy for rot, taking advantage of the general illiteracy of buyers.

Why is that? Yes, because remedies for mold and staining fungi are simple antiseptic impregnations based on boron or chlorine. But the real remedies against rot are high-tech chemicals , expensive and imported. We simply have no other explanation. And that is why you will almost never see the composition on the label. The most you can count on is a streamlined statement that the composition contains “highly active biocides” or that the product “does not contain heavy metal salts.”

ADVICE! If you want something effective, look for imported products with clearly stated ingredients on the label and expensive ones.

Important points

Some of the volatile components in the composition of impregnations can cause real harm to health, so they cannot be used in a steam room.

If necessary, you can carry out disinfection in a bathhouse with your own hands. However, many experts do not recommend using synthetic compounds for these purposes. Why? The temperature in the sink and steam room is often very high. It provokes the evaporation of antiseptic components from the surface of the floor or wall that has been treated with it. Some of the volatile components can cause real harm to health.

To prevent the negative effects of anti-putrefactive agents on the body, the choice of protective compounds must be approached with care:

Types of compositions for interior work

We have already said a lot above about various impregnations, but it’s time to clarify what exactly you may find on sale.

We will separately consider water-repellent and antiseptic impregnations.

Mixtures for wood: with wax and oil

Pure wax for impregnating wood is used in limited cases. This operation is called waxing, it is applicable to furniture, but our case is different.

The task of water-repellent impregnation is inherent in its name. In addition, it allows the wood not to absorb dirt, sweat and grease. Another couple of important advantages are a reduction in the swelling of wood (you don’t think that after impregnation it will completely stop absorbing moisture? In fact, its amount will become much less), as well as an increase in its elasticity, that is, it will not crack after drying.

Therefore, the basis of impregnation is oil. It comes in flax and paraffin.

Paraffin oil is made from petroleum. It is as safe as flaxseed. In particular, paraffin oil can be bought from Tikkurila, it is called “Supi Laudesuoya”.

Impregnation for shelves in the Tikkurila steam room - Supi Laudisuoja. Banka Photos

By the way, the same company has an impregnation for baths inside with wax, which is called “Supi Saunavaha”. Water-soluble, which means that there is not only wax, but also something that polymerizes when it dries. There are no ingredients on the label.

Flaxseed oil is more traditional, it can be found in many varieties, both domestic and imported. You can buy pure raw (or boiled) flaxseed oil at a pharmacy or in a regular supermarket. Even in this form it can be used as an impregnation, but it will take three days to dry one layer.

Usually the buyer is offered a composition that requires much less time to dry. Boiled butter requires less time to polymerize. Dryers also reduce time, but their use here is inappropriate.

The mixture of oil and wax is called oil wax. Such compositions can be of varying degrees of solid-liquid. Liquid formulations are more convenient to apply, but they have higher consumption.

There are a lot of impregnations. Almost every company that has something for a bath produces such impregnations. Therefore there is no need to list. Decide what is more important to you - price or the authority of a large company. And so, by and large, even what you can do with your own hands will be of very good quality. You use natural ingredients.

Antiseptics

You can also learn about what types of antiseptics can be found on the market from this article of ours. However, here we will briefly go through some of the major market players that everyone knows about.

"Senezh"

produces a whole range of antiseptics that can be used for both internal and external work, that is, you have the opportunity to buy everything you need to protect wood from this company.

Impregnation Senezh and brush

Structural parts such as joists and beams that will not be visible can be treated with a strong, non-washable antiseptic. For example, “Senezh Ultra”, “Senezh”, “Senezh Bio”.

Non-washable is not suitable for facades, because it gives a green color to copper salts. Therefore, weaker compounds are used, but they do not produce coloring (at least in unnatural colors). For example, "Senezh Aquadecor".

Inside, you should use even safer options, which are marked that they are suitable for interior work - “Senezh Ecobio” .

“Senezh Sauna” was developed . To stand out in the market, they added antimicrobial agents. But it is not recommended to use this antiseptic on shelves.

"Neomid"

The products of this company are widely advertised and are known to many. For baths, she has developed such impregnations as “Oil for baths and saunas” - already with an antiseptic, as well as the composition “Neomid 200” , which is suitable for antiseptic steam rooms.

Antiseptic for baths and saunas NEOMID 200, 0.5 l., concentrate. Photo by Maxidom

The rest of the impregnations from this manufacturer are universal for any interior and exterior work. In particular, to protect wood from biological damage, you can use Neomid 400 Neomid 440 outside

There are other options in the catalog on the company’s website that are suitable for building elements under heavy-duty conditions. As well as a series of comprehensive protection against fire and biological damage. Below is a video about using this manufacturer's anti-mold composition.

"Tikkurila"

Well, this name is definitely on everyone’s lips. We have already mentioned their impregnations for baths and saunas inside. Let us repeat - these are “Supi Laudesuoya” and “Supi Saunavaha”.

In addition, the company offers oil for shelves, as well as protective compounds for walls and ceilings, but they are no longer impregnations, but acrylic varnishes. Antiseptic additives are already included in these formulations - “Supi Arctic” and “Supi Saunasuoya”.

For the floor they have Supi Lattiaoljy .

Conclusion

Floor coverings made from Siberian larch, despite the relatively high price, are becoming increasingly popular. No wonder. This type of wood has many advantages that will help you create reliable, warm, moisture-resistant and beautiful floors.

In the video presented in this article you will find additional information on this topic.

- Make sure that there are expansion joints about one centimeter wide between the outer boards and the walls of the room. They can be covered with floor skirting boards.