The modern construction market is replete with all sorts of new products, often universal materials with a wide range of applications. We will talk about one of these materials today. This miracle of engineering called “izolon” is widely used in construction as a heat and sound insulating material. Later we will describe all its capabilities in more detail. First, let’s concentrate on the main value – insulation of walls and floors. Attaching an isolon to a wall is a very simple process, but to the floor, in general, is as easy as shelling pears. The principle of fastening is similar to other soft-type insulation - they are attached to the wall using lathing, which also serves as a frame for future wall decoration, for example, plastic panels.

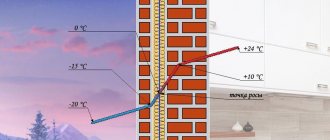

There are technologies for using isolon both indoors and outdoors. The second option is more practical (cold air is cut off, the walls do not freeze, and the heat from inside the house does not escape anywhere), but it is also more financially expensive, since the walls are insulated with insulation from the outside mainly under the siding. How to insulate - from the inside or outside - is up to you, but we will try to tell you in more detail about mzolon itself, the range of its applications, technical characteristics and other interesting facts.

How to attach isolon to the ceiling

how to glue isolon to concrete

During the construction of industrial facilities and residential buildings, modern building materials are used to meet the most important construction requirements for heat and sound insulation. Such material, for example, is isolon or polyethylene foam. The use of isolon allows you to reduce construction time and heating costs due to the excellent thermal insulation properties of this material.

Isolon has the following characteristics: 1. Low density (light weight) and at the same time good thermal insulation properties. A 10 mm layer of isolon can replace a 15 mm layer of mineral wool, 45 mm of wood or 150 mm of brickwork.

This reduces the weight of structures and helps save usable space; 2. Freons and other substances hazardous to humans are not used in the production of isolon. Izolon is non-toxic, does not affect the skin, and does not emit harmful substances when used. Has a hygiene certificate; 3.

Isolon is a chemically inert material and is not affected by organic solvents. It is possible to combine isolon with other building materials (concrete, gypsum, cement, lime, wood). It practically does not absorb water and steam, therefore it is resistant to rotting, mold and aging; 4.

Excellent shock-absorbing properties due to flexibility and uniform cellular structure. Isolon is used as a backing for carpet, laminate, linoleum or parquet. Izolon sheets are used to separate adjacent walls if adjacent walls are subject to movement or vibration; 5. The operating temperature range is from -60`С to +75`С, and if there are no mechanical loads, the operating temperature increases to +100`С. With the exception of special isolons with fire-extinguishing additives, isolon is a flammable material. But at temperatures less than +140`С no harmful substances are released from isolon; 6.

Izolon is produced in different thicknesses and densities (with different foaming coefficients) and is supplied in the form of rolls, sheets, tape or blocks. This significantly increases the possibilities of using isolon in construction. Depending on the production method, isolon is divided into cross-linked (when molecules are cross-linked, a network molecular model is formed) and non-cross-linked (there are no chemical bonds between the polymer molecules).

Cross-linked isolon has improved characteristics compared to non-cross-linked isolon: 1. Heat resistance increases (the operating temperature range increases by 20°C); 2. The service life of the material increases due to increased resistance to ultraviolet radiation and organic solvents: oil, gasoline, diesel fuel; Izolon can be used 1.

For sound, steam, heat, waterproofing of walls, foundations, floors and roofs for country houses, cottages, garages; 2. As a sealant under slate, ribbed metal roofs or tiles; 3. Isolon tapes with an adhesive layer seal the joints of windows and doors, connections between the frame and glass, protect against dust, moisture and noise; 4. Izolon strips can be used to insulate cold and hot heating pipes, as well as ventilation pipes; 5.

Selection of thermal insulation filler

Experts believe that insulating external walls is more effective. But in multi-storey residential buildings it will be almost impossible to carry out work independently. But the use of plasterboard as insulation allows you to significantly save on hired labor and achieve high thermal insulation properties. At this stage, the most important issue will be the choice of insulation. Currently used:

- Styrofoam;

- glass wool;

- isolon;

- basalt (stone) wool.

Foam plastic remains relevant in the insulation market. However, in residential premises it is better to avoid insulating walls with this material. Firstly, rodents love it, so over time the insulation layer will lose its properties, and warm air will begin to leave the room through the holes that appear. And to replace the foam, you will have to open the trim, i.e. go through the renovation again. Secondly, foam plastic has low sound insulation and does not “breathe”. A residential apartment will require additional ventilation. If you still choose it, then you will be pleased that it is a very simple and easy material to work with.

Glass wool also has low thermal conductivity, but this is a specific material that attracts only its low price. Its main disadvantage for internal wall insulation with plasterboard is the presence of glass fibers, which, if they come into contact with the skin, cause itching and burning. When working with glass wool, it is necessary to wear gloves, protective clothing and a respirator only. Such inconveniences, as a rule, repel buyers, so they are practically not used in residential premises.

Isolon is much more in demand. This material has a number of advantages. It not only retains heat, but also does not allow noise to pass through, which allows you to save on sound insulation. Do-it-yourself work on insulating walls from the inside takes up not only time, but also the usable area of the room. Izolon has a small thickness, which allows owners not to worry about meters “eaten” by the insulation.

Basalt wool is often used in the thermal insulation of walls. In terms of its properties, it is most similar to glass wool, but differs in composition. Rocks are used in its production, which makes it fire-resistant and hypoallergenic. But its disadvantage is the price; it is more expensive than glass wool and polystyrene foam.

Each apartment owner must answer the question of how to insulate walls with plasterboard. You need to build on your financial capabilities and your preferences. I would like to give only one piece of advice: if possible, purchase insulation in the form of slabs, not rolls. This will make the work easier and faster. The slab insulation has a standard width of 60 cm, which corresponds to the mounting step of the frame profile.

Technology for attaching isolon to the wall and material variations

Isolon with a metallized polymer film is used as a heat-reflecting screen to protect against heat loss through the areas behind the radiator walls. When using a combined material, a double effect is obtained.

Due to the metallized film, up to 90% of the heat emitted by radiators or other heating devices is reflected back into the room. The big advantage of isolon is its ease of use and installation. It is easy to cut and can be glued to the surface with adhesives (pre-glued surfaces should be cleaned of dust and degreased).

To attach to a smooth surface, use screws, slats, and furniture staplers. To connect the joints, use a hair dryer. Isolon is attached to curved surfaces with double-sided mounting tape.

Thus, when using this modern material, it is possible to significantly reduce construction time and heating costs.

Based on materials from the site: https://avtoladagood.ru

Foil insulation: advantages, disadvantages and installation features

To reduce heat losses in a private house, apartment, bathhouse or similar buildings, building insulation with foil (folgoizol) is often used. In addition to maintaining a comfortable temperature in the room, it protects the living space from external noise. The aluminum base is not subject to corrosion, which makes this material safe and durable in conditions of high humidity and temperature.

Foil insulation - purpose and properties

The main property of folgoizol is reflected in the name - heat preservation.

Unlike most analogues, insulation with aluminum foil consists of two components: in addition to the metal strip, it contains a mineral base. It is represented by three main types of polymers:

- Polyethylene foam is the cheapest option for foil insulation and the thinnest of its types. Its thickness is 2–10 mm. Most often, foiled polyethylene foam is used as a substrate for laminate flooring.

- Fiberglass is the most commonly used in construction. In addition to the ability of metal to reflect heat inside, this type of thermal insulation perfectly prevents the penetration of cold from the outside. This is achieved due to the low density of the fiberglass sheet, which has an air gap between the thin threads. This foil insulation is used to insulate floors, walls and ceilings of buildings.

- Stone wool is intended for use in extreme temperature conditions: thermal packaging of pipes, saunas, steam rooms in baths.

Foil insulation thickness: which one to choose

You can buy folgoizol in several types. Izolon is used as a waterproofing and thermal insulation material. When choosing a waterproofing material, you should pay attention to the fact that it has only one thickness option - 3 mm.

Folgoizol is a type of rolled material that consists of two layers: bitumen-polymer binder reinforced polyester and foil.

The roll has a length of 10 meters, a weight of 28 kg and a thickness of 3 mm. The roll is one meter wide. Folgoizol is absolutely waterproof. The material can be welded and self-adhesive.

What thickness to use:

- For insulation, you can use 3mm thick isolon.

- To insulate a wooden house, you can use 3 mm film.

- If the house is reinforced concrete or expanded clay concrete, then for its insulation you can use material 10 mm thick.

- For insulation of brick, shell tile, gas silicate, foam concrete, 5 mm thick isolon is used.

Advantages and disadvantages of foil insulation

The advantages and popularity of foil insulation are explained by its ability to reflect IR radiation back into the room, thereby significantly reducing heat loss and saving energy consumption, for example, wood for a fireplace or stove. Fiberglass products, due to the air content between the fibers, are similar in temperature regulation to animal fur. This also helps to reduce external noise levels and get rid of drafts.

The anti-corrosion properties of aluminum foil are useful in rooms with high humidity (baths, saunas) or when condensation occurs. Insulating the chimney, in particular with stone wool insulation, will help avoid unnecessary heat loss into the air.

Important positive qualities include low cost with a long service life - up to 50 years. The ability to install the insulator yourself without involving specialists is also appreciated.

The disadvantages of this material stem from its advantages: insulation with foil retains not only heat, but also moisture and odors. These side effects are most noticeable when you want to wrap the entire house in foil: floor, walls, ceiling. In this case, regular ventilation of the premises is recommended.

With maximum use of foil insulation, especially in rural areas, the cellular signal strength is likely to decrease, which can lead to frequent disconnections while talking or using the Internet. Placing the PC or the subscriber itself closer to the window will solve this problem.

Baths

Energofol insulation materials, which have a protective layer of aluminum foil, are placed under the internal lining of the room (with the foil inward). These materials are designed to resist heat without releasing any odors or harmful gases.

Energofol materials are also used for thermal and sound insulation of refrigerated containers and isothermal bodies, for air conditioning systems (as an insulator for air ducts) and pipeline systems. In residential premises they are laid between the wall and the heating radiator.

The materials are ideal for insulating roofs and attics. Mounting to the roof is identical to mounting to the walls. The material is attached to the rafters from below, with an aluminum layer inside the room. When using materials with double-sided coating, an ideal microclimate will be maintained in the house at any time of the year.

The use of Energofol coating in a “warm floor” heating system leads to:

- reducing energy costs;

- reducing floor heating time;

- reducing the heating of the ceiling of the apartment located on the floor below.

- Maskizol

- Overlap

- A heating element

- Cement-sand screed

- Ceramic tiles, linoleum, carpet

To increase the efficiency of the “warm floors” system, materials with a thickness of 3 mm, 5 mm, 10 mm are used. The material is placed under the heater with the reflective surface facing the room. The Energofol material reduces heat loss spent on heating the underground space and evens out the temperature field of the apartment.

When insulating the floor using electric heaters, you must carefully comply with electrical safety requirements, since aluminum foil is an excellent conductor of current.

In addition, Energofol is perfect for installing a “floating floor” (when the thickness does not exceed 3 mm), when installing heated floors located above a cold space, as well as when insulating the floor “along guide joists” (the material is laid between the joists).

| 1 | Energofol A2 | sq.m. | from RUR 21 | Thermal and sound insulation of walls and floors from -50 to +100 C |

| 2 | Energofol A3 | sq.m. | from 22 rub. | Thermal and sound insulation of walls and floors from -50 to +100 C |

| 3 | Energofol A4 | sq.m. | from 23 RUR | Thermal and sound insulation of walls and floors from -50 to +100 C |

| 4 | Energofol A5 | sq.m. | from 28 rub. | Thermal and sound insulation of walls and floors from -50 to +100 C |

| 5 | Energofol A8 | sq.m. | from 38 RUR | Thermal and sound insulation of walls and floors from -50 to +100 C |

| 6 | Energofol A10 | sq.m. | from 46 RUR | Thermal and sound insulation of walls and floors from -50 to +100 C |

How to properly install foil insulation - installation secrets, characteristics

The seams are connected and sealed with foil tape.

Conflicting reviews about the benefits of foil underlayment under laminate flooring are due to the lack of the recommended air layer between the metal and the bottom of the flooring. However, as experience shows, the thermal effect is also present in this case, especially on unheated floors or when assembling laminate flooring on a balcony. As a compromise, it is possible to lay a thin painting mesh on the foil.

It is worth choosing insulation with aluminum foil depending on the repair area.

Fiberglass foil insulation is used for walls and ceilings, but in rooms with high humidity and open fire it is safer to install stone wool insulation. Any type of insulator against cold, noise and moisture is easy to install yourself, but if you lack experience, it is better to turn to professionals.

Based on materials from the site: https://azbstroy.ru

Answers from experts

Anatoly Bondar:

.Moment. Apply in thin strips and glue

Vladimir Petrov:

Anyone who has everything at home will keep it, just not the clerical one. Liquid nails or wallpaper glue work well

BASIL:

double sided tape is good

Scarifier:

The most accessible and inexpensive BF-2, glues metal to organic matter.

Roman Shved:

Nothing but a stapler. It will fall off. Tested many times. And food won't work. Look for foil for baths and saunas, preferably on kraft paper, so you can glue it with glue. Do not stick clean foil.

Special opinion:

and why? If for thermal insulation - foam is better, for sound insulation it is better than mineral wool

User deleted:

not glue, but pin. With slats, you put the isolon on it, lay the slats evenly on it, drill holes, and fasten it. And so every 50 cm. Well, or vice versa - first the slats have a “lattice” of insulation on them. Is it really so difficult to figure it out? Why is it necessary to “glue”? It is pointless to glue anything other than stone or concrete to concrete. Otvalitsa. Or it condenses and leaves.

Special opinion, by the way, is right - a lattice made of slats with mineral wool and covered with plasterboard or plywood on top. Much better.

Emir of Bukhara:

There is also a self-adhesive one - prime the concrete with any interior primer, let it dry for 12-24 hours and stick it on - and if it is not foil-coated, then you need to buy a foil-coated one - if not, then glue for linoleum type 88 I don’t know what it’s called, but the effect is one thin layer on one and on the other surface and glue

Orest Postal:

You need to know the strength of the concrete slab. try turning to professionals who work with them slav-beton /index.php?id=2 I’m sure they will give you advice on how to do this, or they will do your work for you. Good luck to you

How to glue isolon to concrete

Not long ago a new product appeared on the building materials market - foil insulation. It is used for waterproofing, sound insulation and thermal insulation of facades, roofs, walls, floors, ceilings, saunas, baths, partitions, pipelines. What is foil insulation, and how to install it correctly?

Foil insulation is used for waterproofing, sound insulation and thermal insulation of facades, roofs, walls, floors, ceilings, saunas, baths, partitions, pipelines.

What is foil insulation?

Foil insulation is a combined material. On one side it is a polished foil, and on the other - pre-foamed polyethylene. Thanks to its “aluminum” component, it is capable of reflecting and retaining heat in the room. According to research, the reflection effect is 97%. It is distinguished by its thinness and excellent water-repellent qualities, so that the walls and floors do not become damp. In addition, this material perfectly protects the building from wind and frost. Due to the properties of foil, almost all the heat remains inside the room.

Among the advantages of such insulation, experts also highlight excellent soundproofing properties, ease of installation and high environmental friendliness. It does not emit hazardous and toxic substances, unlike conventional mineral wool and other modern analogues. Due to its elasticity, foil insulation is easily and safely mounted on the surface, and even a non-professional can install it correctly simply using the simplest instructions.

Return to contents

Types of foil insulation

Foil insulation does not emit hazardous and toxic substances, unlike conventional mineral wool.

There are four types of such insulation; they differ from each other both in appearance and in their area of application and functional features.

- Foamed polyethylene coated with aluminum is used to insulate building walls and ventilation systems. Usually sold in roll form.

- Foiled polystyrene foam is used for floor insulation. It is produced in the form of thick steel-colored sheets.

- Mineral wool with a layer of foil is used mainly for insulating roofs, chimneys and baths. Sold in rolls.

- Basalt foil-coated thermal insulation material is used in all areas of construction, including the construction of gas stations. It has increased resistance to aggressive environments. Withstands temperatures from -200°C to +700°C.

Installation: how to do it right?

Foil insulation is ideal for insulating floors, bathhouses and attics.

Required tools and materials:

- construction stapler;

- small nails;

- hammer;

- foil insulation;

- foil tape.

Many people, having bought foil insulation, wonder which side to lay it on correctly?

So, the first thing to consider is that the reflective surface of the insulation must be located indoors.

This is necessary to keep the heat in the room. In addition, it is important to leave a distance between the finish and the material of about 15-20 mm; this kind of air cushion will provide additional heat protection.

When laying on an insulated surface, the material must be in a wooden sheathing (2-3 cm thick) between the guides. Correctly attach it to the wall not overlapping, but end-to-end, using nails or a stapler. After all the sheets have been laid, the joints between them are taped with special foil tape. At this point the installation can be considered complete.

The cost of any insulation with aluminum foil is comparable to the cost of an alternative material with similar characteristics, but due to the fact that its installation is very simple, you can save a lot of time on installation and space (foil insulation is thinner than conventional ones). In addition, this material is environmentally friendly and fireproof. Before you choose and buy foil insulation, make sure that it is covered with aluminum foil and not aluminum coating. In the second case, the reflective properties of the material are unlikely to work correctly.

Areas of operation

The versatility of the characteristics determines the use of the material in many areas:

- underlay – after insulating the subfloor with Izolon, you can lay carpet or laminate in a wooden house;

- protection of communication systems - climate and refrigeration units, gas and water supply lines, as well as ventilation;

- thermal insulation of any surfaces - subfloor, walls, roof, ceilings or basement;

- insulation of outbuildings (bathhouse, sauna) and utility rooms.

The insulator is also used in commercial construction.

Features of loggia insulation

To insulate a balcony or loggia, you will need rolled Izolon, as well as a drill, a screwdriver, 2x4 cm and 5x4 cm bars, a stationery knife, and a furniture stapler. Using the material it is easy to create a kind of cocoon that retains heat:

- Attach the slats vertically to the walls in 90 cm increments.

- Form layer-by-layer thermal insulation - put foil Isolon 5 mm thick at the bottom, then foam plastic, then again foil Izolon 3 mm thick.

- Secure the insulation with a stapler. One edge is fixed with staples, the rest is stretched to the rail and nailed with staples.

- Seal the joints with metal tape or masking tape.

- Treat wide gaps with polyurethane foam to eliminate “cold bridges.”

The loggia is insulated with Izolon with a foil layer on the inside.

Creation of wall thermal insulation

Foil insulation is best suited for walls - the shiny surface of Isolon will direct thermal energy back into the room. When sticking to a polyethylene base, good sound, moisture and vapor insulation can be achieved. The work is performed as follows:

- Installation of wooden slats 2x4 cm with a gap of up to 1 m.

- Laying mineral wool into the frame by surprise.

- Attaching foil-isolon to the beams using a stapler - the shiny layer is directed into the room.

- Lay out the rolls so that all the joints match.

- Sealing the cracks with metal tape.

- Padding over the thermal insulation of the counter-lattice.

- Installation of decorative finishing.

The distance from the foil to the finishing material is from 15 mm.

Insulation Isolonon

Last time we talked about what liquid ceramic thermal insulation is, its characteristics and areas of application. Today we will talk about the already familiar material made of polyethylene foam. We will reveal effective and quick methods for insulating floors with Izolon, as well as walls and ceilings. Let’s say in advance that to obtain a high-quality thermal insulation layer, you need to use thick insulation, from 50 mm or more. Although the thermal conductivity of Izolon is quite low, with such a small thickness, frankly speaking, it is impossible to properly insulate. At the same time, the material has other useful qualities.

Types and characteristics of thermal insulation Izolon

Foamed polyethylene Izolon with and without foil.

Izolon is a brand that produces polymer materials for insulation, noise and sound insulation with a closed-cell structure. Product line:

- Isolon 100 – non-crosslinked polyethylene foam;

- Isolon 300 – chemically cross-linked polyethylene foam;

- Isolon 500 – physically cross-linked polyolefin foam;

- adhesive tapes;

- reflective insulation - foil foamed polyethylene or metallized lavsan film.

The scope of application of the material is very wide: from civil engineering to manufacturing. This is facilitated by high performance. Isolon insulation, characteristics:

- density from 25 to 100 kg/m. cube;

- thermal conductivity – 0.037 W/m*C;

- does not allow steam and water to pass through;

- foil materials absorb 97% of IR radiation.

Some items can withstand heating up to 100 degrees without changing their physical and chemical properties. The service life declared by the manufacturer is at least 30 years. All types of polyethylene foam absorb sound and vibration waves well.

The choice of insulation for a ventilation facade depends only on the material from which the walls are built. For wood, materials that allow steam to pass through are used; for concrete, anything is suitable.

You will find information about insulating hives with foam plastic here.

Insulation of ceiling and floor with Izolon

Metallized lavsan film Izolon.

The simplest option for insulating a floor with Izolon is to use it as a lining under a laminate, although it is also possible to lay linoleum on top of foamed polyethylene. In addition, this material can be used in structural elements of a building, for example, on the ceiling and wooden floor laid on joists. The installation technique in both cases is very similar, so we will consider them together.

Naturally, Izolon thermal insulation as an independent insulation gives insignificant results, since its thickness is too small. Therefore, in order to get a high-quality thermal insulation cake, you need to use more solid insulation materials, for example, mineral wool. In this case, in addition to auxiliary protection against heat loss, foamed polyethylene can act as a vapor barrier. Mineral wool, especially glass wool, is prone to absorbing moisture from the air, especially if it is laid on the ceiling. Therefore, insulating the ceiling with Izolon in some cases is not only desirable, but necessary.

Best answers

Grandfather Au:

ordinary food will not work - it is metal and if it can “reflect” some part of the radiation, then part of the convective flow will still heat it up, and since aluminum is an excellent conductor... Insulation is needed under the foil! The walls need to be insulated themselves, for example .termoplex /korund.php?table=korund

*:

Try to stick it with drool...

Marek Black:

You'd be better off insulating it with polystyrene foam from the outside. and the floor can be insulated. You talk to those who do this.

Evil Electrician:

I think you need to consult a construction store at the store or try installation

New:

First, prime it several times with bentonite, and then glue, but it’s better with a heat-insulating layer, even PVA, but there are some that are sold as self-adhesive on a heat-insulating backing.

Sergey Burmasov:

think about it, maybe galvanized iron, or better yet stainless steel, because foil is weak

Nina Ilyina:

oh, if the sticker is crooked, get a magnifying glass, with a focus like in ancient Greece they burned the fleet)

Albert Belkov:

I use Termoizol - foil on foam, it’s easy to work with: I insulate steel baths - they turn out no worse than cast iron ones, they are warm. And food grade can be glued onto cardboard with slots for hooks for easy insertion.

Yuri Martysyuk:

Buy penofol, they are sold in different thicknesses. It can be self-adhesive, but if not, try double-sided tape!

Chuck Kazemierczak:

If the foil is glued to the glass with egg yolk, then it will definitely stick to the concrete

Wall insulation with Izolon

It is important to lay the sheets end to end and seal the gaps.

As we have already found out, ordinary polyethylene foam does not provide the expected reduction in heat loss, so insulating walls with Izolon from the inside must be done with foil materials. The shiny surface will send heat rays back into the room. If the foil is glued to a polyethylene base, then the ability to absorb sounds and vibration, as well as retain water and steam, is added to the reflective properties. All this is necessary when you need to insulate a bathhouse, or rather a steam room.

Let's consider installation methods with additional insulation with mineral wool:

- We attach wooden blocks to the wall - in any order, the main thing is that later it will be convenient to stuff the counter-lattice;

- Mineral wool is placed randomly between the bars; you don’t even have to glue it to the wall;

- on top of the bars, Izolon insulation, foil-coated with the shiny side, is nailed into the middle of the room with a stapler;

- the rolls are spread end-to-end, and the cracks are sealed with aluminum-coated tape;

- the second tier of the lathing is nailed (counter-lattice);

- Any finish can be attached.

It is important to strictly follow the installation recommendations, especially with regard to the gap between the foil and the finish. It should be 15 mm or more.

This is necessary so that the material can realize its 100% potential. After all, the foil reflects IR rays, and they are transmitted only through the air; if there is no gap, then radiation is impossible in this case. Temperature will transfer from one material to another, and aluminum conducts heat very well. Therefore, instead of insulation, you can get the opposite result.

If we are talking about a sauna, then in addition to IR radiation, there is plenty of moisture there. It will condense on the foil insulation and, if there is no gap, it will certainly be absorbed into the finish. Dampness has never benefited any material; its service life in such conditions is catastrophically reduced.

Glue composition

To connect composite materials with a complex structure of chemical bonds, a substance with a large number of polyatomic elements will also be required. Adhesive for polyethylene and polypropylene is made on the basis of methyl methacrylate. This is an ester compound of methacrylic acid, which in its pure form cannot exist under normal conditions, since it has a negative melting point. To obtain an adhesive, xylene, complex organic and inorganic acids, chromic anhydride and other additives are added to the composition. If you need to combine it with polyethylene, the easiest way is to use heat treatment. This method is very reliable, as it allows you to create a continuous, unbreakable seam that can no longer be broken without rough intervention. But such processing will also lead to deformation of the edges of the processed products, which is not acceptable in every case. Therefore, special glue is in great demand in the modern market. Many different decorative elements are made from composite materials, which must be fixed without compromising their integrity. The mixture for combining polymers is sold on the market in the form of a rather thick paste. The kit also includes a special substance, the so-called activator. When it is added to the composition, the glue very quickly acquires the desired consistency and becomes ready for use. After diluting the mixture, there is no need to waste time, since the viability period is very short. On the one hand, this allows the products to quickly stick together, but on the other hand, it requires maximum efficiency and coordination from the worker.