A wooden house is valuable for its high vapor and air permeability. It is easy to breathe in, it is environmentally friendly and plastic. Easily repairable. However, situations arise when it is necessary to “make friends” between two incompatible materials: wood and concrete. Concrete floors are especially relevant when arranging washrooms in bathhouses, where it is planned to install a floor with a drain, or in utility rooms, on the first or basement floor, in which a large amount of pollutants gets onto the floor. Let's talk about how to install a concrete screed on a wooden floor.

Description of plank floors

A wooden floor, from the point of view of the theory of strength of materials, is an unreliable support for concrete. The fact is that plank floors tend to change their linear dimensions, depending on the temperature and humidity of the environment. The length of the boards varies in the cold and warm seasons, the wood swells when wet and contracts when dry. In addition to linear changes in size, boards tend to change their spatial structure - as they dry, they begin to curl. Such unfavorable changes are completely unsuitable for the construction of a concrete screed, which, after setting and gaining strength, becomes monolithic, practically not subject to linear expansion.

Another obstacle to installing a concrete screed is its heavy weight.

The usual base for installing a wooden floor is logs made of wood lying on the foundation or, in rare cases, beams made of reinforced concrete or metal profiles. They are not designed for significant loads and with additional pressure, the ties can become deformed and break.

The third nuance of floors is the small thickness of the base. A standard floorboard has a thickness from 2.54 to 50 mm. Inch boards are rarely used because they bend under the weight of a person of average build. Floor boards thicker than 40 mm are also rarely used in house designs, only in those rooms that experience strong static or dynamic loads. The most popular board is 36 mm - tactile (feels), does not bend when moving on the floor. But, if you make accurate measurements of the floor level, it becomes clear that when laying tiles it also “plays”, especially if the distance between the supporting joists exceeds 1000 mm and the floor boards are not reinforced. Such “floating floors” are installed in newly built houses in order to prevent the boards from deforming when the outer walls of the house shrink. It is impossible to install a screed on such an unsettled floor that is in the stage of natural deformation. Otherwise, there is a high risk of cracking of the screed, despite the reinforcement and installation of the sliding layer.

The fourth obstacle is the wood's susceptibility to rot. The concrete screed sharply limits the flow of air to the surface of the wood and creates favorable conditions for the growth of mold fungi that destroy the structure. In addition to fungi, insects like to make shelters in unventilated spaces, many of which feed on wood. Topographer beetles, sawflies, and in the southern regions – termites.

If the developer is not afraid of the obstacles that he will encounter when arranging the screed, he can proceed with step-by-step actions.

Technological principle of leveling with concrete

How to simultaneously create favorable conditions for moving wood and static concrete? This is possible if two conditions are met:

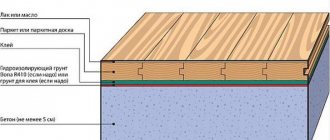

- It is necessary to carry out a sliding connection of materials. That is, the concrete should not stick to either the floor or the walls. To do this, polyethylene is placed between the concrete layer and the wood. It will perform several functions at once: waterproofing wood and concrete and sliding gasket. Lay a damping film made of foam material between the walls and concrete. This will allow the wood to expand freely under the heavy monolithic concrete slab.

- The weight of the concrete screed should be evenly distributed over the entire area of the wooden floor, that is, its surface should be flat. Then the concrete will not begin to collapse due to the movement of wood.

Design features of plank floors

The design features of plank floors include:

- Support material of the base (lags);

- Distance between joists,

- Board thickness;

- Connection type:

- regular board with straight ridge;

- tongue and groove;

- and a quarter.

Floors made of boards without connecting elements are not suitable for screeding, since each of the boards is subject to independent fluctuations in size under load or changes in humidity and temperature. This leads to rapid destruction of the screed. Boards held together provide a more reliable base for concrete. Although they are subject to linear changes in size, they behave more predictably.

An important factor when deciding whether to pour screed on a wooden floor is the material from which the boards are cut. The most popular and cheapest wood is coniferous wood: spruce and pine. It also has the lowest consumer and strength characteristics:

- High moisture capacity;

- Tendency to curl when dry;

- Susceptibility to damage by pests and microorganisms.

Larch floors are more suitable for screeding. This wood is practically not subject to rotting due to its high resin content. It has a low coefficient of linear expansion, is heavy and is not prone to deformation under load.

Hardwood is used less frequently for flooring, mainly in bathhouses or for decorative purposes.

What is board bonding?

When installing a wooden floor, it is necessary to press the boards as tightly as possible to each other. This is not so easy to do - they will not have ideal geometry. When drying, they bend in different directions. During installation, they must be attracted to each other without gaps, and then fixed. Manually, without devices - this is not possible, because special devices or improvised means are needed.

Screeding floor boards is the elimination of cracks and gaps by mechanically tightening the boards

This process (pressing the boards against one another) is called bonding or floor screeding.

Pouring technology

Pouring a concrete screed requires preparation of the base. If it is possible to avoid the “layer cake” effect, wood should be excluded. If a wooden floor is the only base, then the following measures should be taken:

- Remove the skirting boards around the perimeter of the room;

- Inspect the supports. To do this, remove about two boards along the entire length and find out on what basis the floor is constructed and the safety of the logs;

- The internal (lower) surface of the boards is subject to inspection. If there are traces of mold on it or pests are found, such boards are replaced;

- It is advisable to clean the surface of boards coated with oil paint/varnish using a plane or scraping machine;

- The outer and inner surfaces of the boards are treated with water-based antibacterial impregnation;

The boards are additionally strengthened in places of contact with the joists using screws/screws, but not nails or wooden pins, which become loose over time and allow the boards to move in the vertical direction. It is possible to firmly fix the boards to the joists only after 2-3 years have passed after the construction of the house or the laying of a wooden floor. This is exactly the period of natural drying of wood at room temperature. During this time, all internal stress in the boards is removed. Those defects that remain after the specified period are eliminated mechanically - by jointing or scraping.

On the feasibility of using polyethylene

Bearing in mind that wood is subject to linear changes in size more than concrete, measures are taken to isolate them from each other. The top layer of the floor - the screed - turns out to be floating. A thick (100-200 microns) film is used as a waterproofing agent and separator. The canvases will be laid on top of each other with an overlap of 200-300 mm, and in places of contact they will be glued together with bitumen mastic. The film is not attached to the boards in any way. In places of contact with the wall of the house, an overlap of 100-150 mm is made. The perimeter of the room is covered with damper tape over the plastic film, which will allow the concrete screed to move freely along the walls as they shrink or thermally expand.

Other types of waterproofing materials or insulation cannot be used as an intermediate layer. Roofing felt and other rolled materials impregnated with petroleum distillation products emit formaldehyde and creazote during operation, which will inevitably penetrate through the screed into the room. Under load, the rolled material is glued to the surface of the wood and tightly bonded to the concrete. Thus, materials with different expansion coefficients will be unable to move relative to each other. When there is a change in temperature or humidity, the screed will begin to crumble.

Condensation can form under polyethylene in damp rooms and on the first floors of buildings. Therefore, the surface of the wood must be treated with a hydrophobic antiseptic.

Insulation device for leveling with concrete

After the preparatory work, it is necessary to lay waterproofing coatings. This process can be divided into two stages:

- A foam tape is glued to the wall along the entire perimeter of the room; its width should be slightly larger than the thickness of the concrete screed. The presence of the tape will leave a gap between the screed and the wall, which will allow for a sliding connection. This tape also performs a soundproofing function.

- Polyethylene is laid over the entire area of the wooden floor. The main requirement is tightness. Therefore, if there are joints, they are glued together with tape or glue, and the installation is carried out with an overlap on the walls (200 mm).

If subsequent work results in a puncture in the waterproofing surface, it must be repaired. To do this, you can glue a plastic patch.

Calculations

The calculation of material requirements is made taking into account all necessary consumables with a reserve plus 10% for overexpenditure or unforeseen circumstances.

The calculation includes:

- Fastening hardware (screws, wood screws) for strengthening boards to joists;

- Hydrophobic impregnation in accordance with the manufacturer’s recommendations;

- Polyethylene film 200 microns with a margin plus 20% for overlap and lining under the damper tape;

- Damper tape - around the perimeter of the room;

- Reinforcing mesh - according to the area of the room;

- Dry concrete mixture for screed or cement and sand to prepare the solution yourself. For the screed, use the proportion of cement/sand/water/reinforcing filler:

- Cement grade M150 1:3:0.55:0.1

- Cement grade M200 1:2.8:0.45:0.1

Application area

Currently, the main area of application for wooden floors is the construction of small private houses. Especially often, floors on logs are installed in wooden houses and log houses, in which the floors between floors are made of beams.

Especially often, floors on logs are installed in wooden houses and log buildings, in which the floors between floors are made of beams

Much less often, wooden floors are laid in city apartments with reinforced concrete floors. However, the technology is still used, especially in cases where pouring a full leveling screed is impossible for some reason.

Wooden floor in the apartment

Sometimes plank flooring is a finishing coating and part of the designer’s idea when creating a renovation concept. In this case, beautiful wood species such as oak, larch or pine are chosen for the flooring. The boards are thoroughly polished, impregnated with an antiseptic and covered with varnish or wax. The result is a very beautiful and durable coating that pleases the eye with the natural texture of wood.

Natural wood floor

Wooden floors can be used even when arranging wet rooms, such as baths and bathrooms. However, this is done infrequently, as it requires careful selection of wood, reliable waterproofing and impregnation of the boards with very expensive solutions that prevent moisture absorption.

Wooden floor in the bathroom

Preparing the base

All protruding metal objects are removed from the boards: nails, staples, screws. Remove the top layer of oil paint. Seal holes and depressions from fallen knots, large chips and dents on the boards with oil putty mixed in a 1:1 ratio with sawdust. The surface is treated with a water-based antiseptic and allowed to dry for 2-3 days with active ventilation of the room. The drier the surface of the wood, the better.

Installation of dry screed on a wooden base

A dry screed consists of a layer of insulation and a rigid covering made of gypsum fiber board, gypsum plasterboard or special two-layer floor slabs of the Knauf system.

Expanded clay of different fractions, hard mineral slabs or Penoplex can be used as insulation.

Under the expanded clay we lay a layer of waterproofing made of dense polyethylene, 200 microns thick, so that it is not damaged when filling and compacting the expanded clay.

Important! We place polyethylene on the walls 10-15 centimeters above the screed mark and secure it with construction tape. We lay the polyethylene strips overlapping and glue them together with tape.

We mark the height of the expanded clay layer using a laser level. We transfer the marks to the walls around the perimeter of the premises.

We install beacons from a metal profile for drywall. We check lighthouses strictly according to building level marks.

Pour a layer of expanded clay, carefully compacting and leveling with a long lath. We fill and compact the junctions with the walls.

Figure 8. Installation of gypsum fiber board screed on expanded clay.

A day later, we lay plasterboard sheets or floor slabs of the KNAUF system over the compacted expanded clay layer.

If using sheets, lay out the first layer on the expanded clay surface, leaving deformation gaps between the sheets of 1 millimeter, with offsets at the seams.

We cover the first layer with glue and lay the second layer of sheets on it, also moving the seams by at least 30-40 centimeters. We fasten the layers together with self-tapping screws.

When using ready-made Knauf panels, we lay them on a compacted surface and fasten them together using special locking joints.

Seams, joints and recesses from self-tapping screws are sealed with putty, sanded and coated with two layers of primer.

Advantages of dry screed:

- perfectly level base;

- excellent sound and heat insulation due to expanded clay;

- low weight does not require reinforcement of structures;

- the surface is ready for finishing immediately after installation;

Figure 9. Diagram of the installation of a gypsum fiber board screed on a wooden base.

The only drawback of dry screed with insulation is its large thickness, which does not allow its use in rooms with low ceilings.

Marking

Marking is necessary if the area of the room exceeds 2 meters on one side. In this case, the room is divided into squares/rectangles no more than 2x2 meters. Otherwise, the screed will begin to crack spontaneously. To control the thickness of the screed layer, beacons are set - wooden choppers, the upper edge of which is leveled using a laser level or using a tensioned thread set to a level.

The use of wooden choppers is convenient because after the cement mortar has hardened, they can be cut off with a knife without damaging the integrity of the screed.

Why use plastic film

Polyethylene is a budget waterproofing material that has many disadvantages: wood rots and creates favorable conditions for the development of mold and fungi. Typically, film is not used in conjunction with wood. But in this case it is a necessity. It is due to the fact that concrete does not stick to its surface, which means it can slide when hardening.

Since the use of film is a prerequisite, it is necessary to take all measures to prevent the formation of mold and fungi. A wide selection of antiseptic agents with water-repellent properties will help with this.

Waterproofing

A layer of polyethylene film is laid on a floor that has been well dried after treatment with an antiseptic. Rolled materials are rolled out along the long side of the room, from the entrance to the window. Overlapping areas of 100-150 mm are glued with adhesive mastic. Places of contact with the walls of houses are applied with mastic or pressed with damper tape with a thickness of at least 5 mm.

Mixture for semi-dry screed

The mixture for semi-dry screed consists of:

- high-quality cement (grades 400-500) – 1 part;

- washed sifted sand – 3 parts;

- polypropylene fiber – up to 1 kg per 1 cubic meter of mixture;

- water, the amount of which is determined by the state of the final product (when the mixture is compressed, it should form a lump without releasing excess water).

To facilitate installation work, you can add a plasticizer for concrete.

Reinforcement

Reinforcement is a mandatory operation when pouring a concrete screed on a wooden base. The reinforcement will not be able to completely prevent vertical vibrations of the boards, but it will significantly prevent the screed from longitudinal cracking along the joints between the boards.

For reinforcement, it is advisable to use polymer mesh, used for fencing garden plots or ridges.

It is better not to use a metal mesh with a mesh size of 20-40 mm, since the metal ribs lying on the plastic film when the screed moves can eventually wipe the film and open access for moisture penetrating through the screed to the wood.

Method 1 - reinforcing mesh

If the choice is made on a mesh, then it is recommended to use a plastic mesh of the OSS brand, or a fiberglass mesh of the brand:

- SSP-95;

- SSDor-330 (road mesh) coated with impregnation;

- SSM-85;

- SSDor-300.

The advantages of polymer and fiberglass reinforcement are:

- Elastic;

- Chemical inertness in contact with moisture;

- No radio wave shielding effect;

- Ease of cutting and installation;

- Light weight;

- Cheapness.

Method 2 - fiber fiber

Fiber is an unconventional method of screed reinforcement, which consists of introducing short reinforcing fibers with a length of 20 to 50 mm into the solution at the mixing stage. The fiber can be metal - pieces of steel wire, or pieces of fiberglass (bundle) of the same size. Metal fiber cannot be used when pouring over polyethylene film. Sharp edges of pieces of steel wire protruding from the solution will tear the film and damage the waterproofing.

The fiber creates multidirectional reinforcement, practically preventing stretching and compression of the screed throughout its entire thickness. It is advisable to use fiber reinforcement on lightly loaded floors with low traffic.

Many standard formulations of leveling mixtures intended for pouring screeds include fibers of synthetic materials and special plasticizers that prevent cracking.

Using microfiber instead of reinforcement

Reinforcement is the process of strengthening a concrete layer with steel reinforcement. However, working with metal elements can damage polyethylene. Therefore, it is possible to replace steel rods with fiberglass. This is a special material that strengthens the concrete screed.

The use of microfiber greatly simplifies the installation process, because it just needs to be added to the concrete during mixing. The absence of a metal structure significantly reduces the weight of the monolithic slab.

Mixing the solution

The solution is prepared at home in containers with a volume of at least 50 liters. To do this, it is advisable to buy 2 containers to ensure continuity of filling. While 2 workers pour the solution from the container onto the floor and level it with needle rollers, the third one mixes the next portion of the solution for pouring.

First, a clearly measured amount of water is poured into the container, recommended by the manufacturer of the dry mixture for the screed or specified in the recipe for preparing the solution yourself. No DIY or cooking by eye!

The concrete pouring technology, proven over decades, is aimed at achieving the highest possible strength. An excess of any component leads to a weakening of the solution or its extreme brittleness.

First, fill the container with water. Then cement is added, or the prepared solution is gradually poured from the bag. Two people prepare the mixture. One controls the mixer mounted on an electric drill or a special electric drive, the second evenly and continuously pours the mixture. After thoroughly stirring the solution, there should be no lumps left in it. Fiber (basalt, polymer pressed) is introduced into the solution and the briquette is allowed to disperse in water for 10-15 minutes. After this, the solution is mixed again for 5-10 minutes to evenly distribute the fibers. Sand is added last, as it is heavy and quickly sinks to the bottom.

You can also use a concrete mixer.

Devices for screeding floor boards

Do not think that devices for screeding plank floors are an invention of recent years. Our grandfathers and great-grandfathers also wanted a flat floor. Old textbooks describe ways to eliminate cracks during installation. For this purpose, metal staples were used - ordinary or of a special design. Modern devices and techniques are just variations of old methods.

You can also tighten the boards using a regular metal bracket. It's the old way

Bowrench and Special Automation

We describe these two devices together, since the Belarusian Spetsavtomatika made some changes to the Bowrench design, which is produced by the Americans. But, in essence, it is also a device.

You can tighten the boards using Bowrench

So, there is a part with two protrusions that is fixed to the joist. A metal stop and a handle are movably connected to it. By pressing the handle, we ensure that the board fits tightly and install the fasteners. The disadvantage of this device is that it blocks access to the end of the board. When laying a tongue and groove board, you will have to move it several times if you need to fix it to each support.

Logs can be of different thicknesses. To be able to “rest” against them, there are replaceable nozzles. The stop can be easily removed: you need to remove the two studs that secure the mounting bolts. However, the set consists of three or four attachments, so there are not many options.

The Belarusians have made some changes to the design: one part of the joist grip is movable and adjustable

In the device produced by Spetsavtomatika, the log grip is adjustable. There is an adjusting bolt at the end that allows you to extend or retract one of the clamps. There are more adjustment options, but there is also a higher chance of damage. In operation, both are quite convenient, although the “American” is more refined. But the difference in price decides the matter - Bowrench costs 3.5-4 times more.

How to tighten floor boards using a clamp and wedges

You can tighten the floor boards using a clamp and two wooden wedges. The clamp is fixed on the joist at some distance from the board being installed. Two wedges are made from a piece of board 40-50 cm long by sawing the piece diagonally.

A device for tightening boards from a clamp attached to a joist and wedges that press the board

The clamp is installed on the joist, turning the arc towards the board. Wedges are installed between the arc of the clamp and the board. They hit the wide side of the wedges with a hammer or sledgehammer until the gap between the two boards disappears. Then you can fix the board. If you need to install fasteners in a tenon or groove, a “window” is made in one of the wedges, which is placed above the joist and through which a self-tapping screw is screwed.

Thrust board and wedges

The previous method is good for everyone, but the board is attracted only in one place. You can, of course, install several clamps, but this is time. And there are usually not many sufficiently powerful vices on the farm. The problem can be solved using boards and similar wedges.

A support board about a meter long is nailed at some distance from those being mounted. They are nailed to the joists above which it is located. It is not necessary to drive the nails all the way to the heads, but the support should hold well. The distance for installing the support is chosen so that three or four boards can be laid without moving it.

Backing board nailed to joists and wedges are another way to hold floor boards together.

A piece of “lining” with a window through which you can tighten the self-tapping screw is attached to the board being installed. In order to be able to tighten the floorboards, scraps are inserted between the support and the wedges. First you need long pieces, then smaller ones. The entire structure is assembled so that the wedges stand in such a way that by knocking them down, the boards can be held together.

Fill

Filling begins from the corner farthest from the entrance. The solution from the container is poured onto the base, continuously trying to distribute it evenly over the surface so that the beacons are completely immersed in it. If the room area is large, barriers made of 40x40 or 50x50 mm timber are installed to prevent the solution from spreading. Immediately after emptying the container, the solution is smoothed with needle-shaped rubber rollers to remove air bubbles. The curing time of different brands of industrial screed with plasticizers can vary from 25 minutes to 2-3 hours.

If you are using a fast-hardening screed, you must work quickly. The mass hardens quickly and sagging can form at the joints of two fills, which will be very difficult to remove.

video screed on wooden floor

Construction of alignment beacons

The lighthouse is a metal guide. It is used for convenient and effective leveling of the surface of a concrete screed after pouring.

The lighthouse can be purchased at the store, or you can make it yourself from any available material. The only requirement for a lighthouse is levelness.

The presence of polyethylene complicates the process of installing beacons, because the solution does not stick to its surface, and self-tapping screws cannot be used due to the tightness of the coating. But the solution is quite simple:

- Divide the entire area of the room into oblong zones, no more than 1200 mm wide. At the same time, leave a distance of 300 mm to the walls.

- Prepare concrete of the same grade that will be used for pouring the screed.

- Lay concrete in longitudinal lines according to the markings.

- Install beacons on top of the concrete, checking against a pre-made mark on the wall. For greater accuracy, you can use a bubble level.

Further care of the screed

In its pure form, a polymer screed with decorative elements - glass, stone, mosaic - can be used on a wooden floor. In other cases, the screed serves as the basis for laying another floor covering. If there is a need to install a concrete screed on wood, then this is usually a damp room. Then an artificial stone or a base under the tiles is laid on the screed.

The screed, prepared independently from cement and sand, is covered in the first days, until complete hardening, with a thin polymer film to avoid cracking. Subsequently, until the concrete gains full strength, which occurs after 25-30 days, the screed is periodically moistened with a spray bottle or with a broom dipped in water.

Which screed to choose

If you have a strong and rigid wooden base, it is better to choose a semi-dry floor screed.

It will not load the floor too much; water from the screed will not get onto the wooden structures, even if the integrity of the waterproofing is damaged. Will create a reliable basis for laying any finished floor covering.

When leveling floors in old and dilapidated wooden houses, preference should be given to a dry coating. Dry screed is suitable if you need to insulate the floor of the first floor or the ceiling above an unheated basement.

If you decide to make a screed on a wooden floor, contact specialists who will help you choose the best option for leveling your floor and will carry out the work efficiently, quickly and professionally.

Tiles as flooring

The physical characteristics of wood do not allow it to adequately retain the heat received from the heating system, so the best flooring option for horizontal water heating is tiles made of natural or artificial stone.

Tile screed

To obtain an independent screed for “warm floors” for laying tiles on wooden beams in a private house, the following work must be done:

- A “floating” screed is installed using the technology described earlier. The only exception is the thickness of the concrete solution. It should be 3-4 cm.

- After the screed has completely hardened, it is treated with a soil solution.

- Next, the floor covering is installed using tile adhesive.

Despite the possibility of installing tiled flooring on wooden logs, this technique has a significant disadvantage: the service life of wood is lower than that of porcelain stoneware and other tiled materials. To replace wooden blocks that have become unusable, you will have to carry out serious dismantling of the floor covering.

The advantages include:

- Significant cost savings due to lower wood costs.

- The total weight of the floor “pie” and the load on the supporting structure are reduced.

- The installation speed increases.

- The heating system is put into operation faster due to faster drying of the thin layer of concrete.

Despite some limitations, tiling a bathroom, swimming pool and other rooms with high humidity, together with a “warm floor” system, can significantly increase comfort and increase the durability of wooden structural elements.

“Warm floor” is maximum comfort in your home

Screed is an indispensable attribute of underfloor heating. It protects pipes from load and mechanical damage, allows you to obtain a perfectly flat surface of the floor covering, which has a beneficial effect on the comfort of residents. Its only drawback is that installing the screed “raises” the floor level, reducing the total volume of the room. If in rooms with high ceilings this will not have a significant effect, then in low ceilings it may interfere a little.

Specifics of the wooden base

The above materials behave completely differently. The situation when a wooden floor is installed on top of a concrete screed is quite practical. Concrete, after gaining maximum strength, becomes a static base, and wood is a living and breathing material throughout its entire period of operation.

Attention! Wooden flooring is especially active in the first 4 years. During this period, you should not even think about filling the boards with concrete.

Additional factors affecting wood are fluctuations in temperature and humidity indoors. Boards can shrink or increase in volume, fluctuate in height and even change linearity.

The topic of a separate article could be the case when wood is poured to create warm floors. In such a situation, the number of variables increases significantly. Based on the properties of wood, the first important conclusion can be drawn:

The screed, which is installed on a wooden base, must be autonomous. It is not recommended that the materials come into contact during operation, otherwise the properties of each layer may harm each other.

Preparation for pouring

The structure of a wooden floor can be different. If the boards are stuffed onto logs fixed to a concrete base, then don’t be lazy: remove the wood and fill it with a rough screed. And you will get a more durable floor, and there will be no problems in the future.

If you have boards as a base, then it is also better to exclude the logs and finishing layer from the floor pie structure - this will reduce the mobility of the base. Before preparation, baseboards and other decorative elements are removed.

For further work, the plank base should be prepared:

Concrete is characterized by increased weight, so you should gain sufficient load-bearing capacity of the joists, increasing their number, if necessary. Ideally, the step between the beams should be 35 cm + - 5 cm.

Repaired, replaced, secured, and the next stage will be processing. Choose primers with antibacterial and waterproofing properties, this way you will prevent the process of destruction of structural elements.

Waterproofing

It is this event that will allow us to isolate materials from each other. Therefore, durable polyethylene film of maximum width is selected. It is better to avoid gluing the seams on the poured surface.

Important! When laying the film, be careful: breaks and punctures are unacceptable.

The film is covered with an overlap on the wall, the entire perimeter is taped with damper tape. As a result, when pouring, you will get a floating concrete slab that does not come into contact with the material of the base and walls. In such a situation, the tree can continue to live actively, and the concrete will be at rest - which means it will not crack and will maintain its linearity.

Why film?

This question seems very important, because the tree under the film will begin to rot and rot. When working with such structures, other waterproofing materials are usually used, for example, glassine, roofing felt or something impregnated with bitumen.

The film is chosen not for wood, but for concrete. The solution does not adhere to polyethylene at all.

By laying polyethylene between wood and concrete, we get a triple floor pie in which each layer is absolutely autonomous:

Important! To minimize the damage caused by polyethylene to the boards, treat them with a waterproofing primer.