Several years ago I expanded my product line. Such brands of insulation as Osnova, Facade, Pitched Roof, GEO, Foundation appeared on the market. What is the difference between Penoplex Base and Foundation, and what differences do other types have?

The characteristic features of each type are their size, level of thermal conductivity, water absorption and vapor permeability. According to these indicators, the Base and Comfort are similar, the only difference being the compressive strength.

The insulation materials Foundation and GEO are similar in their parameters. These types are intended for use under high loads, and therefore have increased compressive strength.

For what purposes is it better to buy thin Penoplex

The manufacturer produces extruded polystyrene Penoplex in two sizes: 1185 x 585 x 20 and 1200 x 600 x 20 cm. It is most advisable to use the slabs for:

- implementation of atypical projects that require laying insulation of non-standard thickness: 70, 120 or 170 mm. Simply put, you can buy Penoplex 20 as an additional thermal insulation layer in a roofing pie, facade system, for installing heated floors, where you want to “increase” the standard extrusion thickness.

- insulation of window slopes where the existing opening needs to be reduced. Thanks to the use of a thin layer of polystyrene, you will not only save on finishing materials, but also speed up the finishing process, reduce heat loss through windows, prevent condensation, and therefore protect your house from fungus and mold.

The difference between Penoplex Base and Penoplex Comfort

In 2015, which has been producing PENOPLEX thermal insulation boards from extruded polystyrene foam for more than 18 years, began production of new brands of Penoplex such as Osnova, Facade and others.

What is the difference between the Basic and Comfort modifications?

The main technical characteristics, such as thermal conductivity, vapor permeability and water absorption, are the same for Penoplex Comfort and Basics.

Only the compressive strength indicator has different values. For penoplex Comfort, this figure is 0.18 MPa, and for Basics - 0.20 MPa. This means that the penoplex Base is able to withstand more load, and accordingly is more rigid.

This is due to the fact that the Comfort penoplex was initially intended only for retail sales, and the Osnova modification is intended for professional construction.

In conclusion, we can say that Penoplex Base is a unique and effective insulation material suitable for most surfaces. It gained its popularity due to its high quality and excellent thermal insulation properties.

Material Sheet Size Options

Expanded polystyrene "Comfort" is produced in the form of sheets of standard size, 120 cm long and 60 cm wide. Extruded polystyrene foam, the sheet dimensions of which are 240 cm long, is considered non-standard.

The amount of material in the package depends on its thickness

The thickness of the heat-insulating material can range from 20 mm to 15 cm. The dimensions of the material packaging are 1.2 x 0.6 m, respectively, and the height is 30-42 cm. Thus, one package can contain from 1.44 m2 to 14.4 m2, depending on sheet thickness. When purchasing insulation, it is recommended to provide a reserve of about 10%, since small scraps of material are inconvenient to use.

Thermal insulation for buried structures: foundations, paths, septic tanks

For use in loaded structures!

Select sheet thickness:

—>

| 50 mm | 100 mm |

Description

PENOPLEX FOUNDATION® is a highly efficient thermal insulation material of the latest generation, manufactured by extrusion from general purpose polystyrene. Zero water absorption, high strength, low thermal conductivity and environmental friendliness are the main advantages of PENOPLEX insulation compared to other materials.

Application of PENOPLEX FOUNDATION®

A brand of slabs intended for use in private housing construction in loaded structures (for example, foundations, floors, plinths, garden paths). Plates of this type are characterized by increased strength and are able to withstand significant loads throughout their entire service life (more than 50 years).

Characteristics of PENOPLEX FOUNDATION®

- consistently low thermal conductivity;

- zero water absorption (homogeneous structure of sealed cells);

- high compressive and bending strength;

- absolute biostability;

- durability;

- environmental friendliness.

Norms/standards

- TU 5767-006-54349294-2014

- Production control and assessment is carried out by accredited laboratories

Appearance/Color

Surface: smooth Color: orange

Let's consider the pros and cons

Are you considering using eco-friendly insulation when building or renovating a private home? If yes, that's great! There are several types of insulation. Extruded polystyrene , or penoplex, is one of the most popular.

Advantages

advantages

- Extremely low thermal conductivity coefficient . Only 0.032 W/(m×°K) - 22 times less than that of sand-lime brick.

- Moisture resistance . The granules of Osnova products do not absorb water, so the performance characteristics remain normal.

- Decent durability . The material holds its shape well and is difficult to damage or tear, which cannot be said about foam plastic.

- High sound insulation . A nice bonus when there is a noisy highway outside the window, or the house is located in a densely populated area.

- Ease of installation . tongue-and-groove locks on the edges of the sheets , so during installation you can do without adhesives.

- Biostability . It is not destroyed by putrefactive bacteria and mold fungi.

- Environmental friendliness . The thermal insulation contains no harmful substances. After installing it indoors, you won’t have to keep the windows wide open for a month.

- Long life span . The manufacturer assures customers that the product will serve faithfully for at least 50 years.

Flaws

Penoplex Osnova thermal insulation also has disadvantages :

- High flammability . The insulation belongs to class G4 , which means that its flue gases heat up to temperatures above 450 °C. Even if the polymer just starts to smolder, you will have to stay away from it.

- Low vapor permeability . The walls will hardly “breathe”, and the windows will fog up, so you need to equip the room with a high-quality ventilation system.

- Susceptibility to UV rays . The insulator is “afraid” of ultraviolet radiation. Under the influence of the sun, the structure of the granules quickly collapses . The solution is to coat the polystyrene with a finish.

The material is lightweight, making it easier to work with. You can cut the sheets using a regular painting knife .

Type 31/31С

This type of Penoplex insulation is more reliable due to its resistance to deformation. It was used in the insulation of facade systems and internal partitions in private houses, balconies and loggias in high-rise construction. The excellent insulating characteristics of this type of extruded polystyrene foam insulation have made it also in demand for insulating sewer lines laid in the upper frozen layer of soil.

In road construction, Penoplex 31, due to its high degree of resistance to deformation and weight loads, is also used to minimize the risk of the formation of so-called “ice lenses” due to freezing of the soil directly under a highway or railway.

Penoplex 31C (Standard) is the most suitable material for insulating static, non-load-bearing structures. It was preferred in the process of insulating internal wall partitions in private civil construction, as well as when laying utilities as part of water and heat supply systems. In engineering construction, Type 31C was also used to protect sewer lines from freezing, during the construction of wells, water storage tanks, swimming pool bowls, and when laying underground networks.

The main advantages of the material include low level of water absorption, low thermal conductivity, durability, strength, resistance to biological damage and ease of installation. Disadvantage: instability to deformation.

| Parameter | Type 31 * | Comfort | The basis | Foundation | Geo |

| Slab density, kg/m³ | 28,0-35,0 | 25,0-30,0 | 25,0-32,0 | 29,0-33,0 | 29,0-33,0 |

| Compressive strength (at linear deformation 10%), MPa, not less | 0,20 | 0,18 | 0,20 | 0,27 | 0,30 |

| Tensile strength (for static bending), MPa, less | 0,25 | 0,4 | 0,25 | 0,4 | 0,4 |

| Water absorption over 24 hours/28 days, % by volume, no more | 0,4 | 0,4/0,5 | 0,4 | 0,4/0,5 | 0,4/0,5 |

| Fire resistance category | G1 | G4 | G4 | G4 | G4 |

| Thermal conductivity at 25±5°С W/(m×°K) | 0,31 | 0,31 | 0,03 | 0,03 | 0,03 |

| Calculated thermal conductivity coefficients (operating conditions A/B), 25±5) W/(m×°K) | 0,032 | 0,032 | 0,031/0,032 | 0,031/0,032 | 0,031/0,032 |

| Sound insulation, Rw | 41 | 41 | 41 | 41 | 41 |

| Improvement index for structural noise insulation in floor construction, dB | 23 | 23 | 23 | 23 | 23 |

| Operating temperature range, °C | -50 to +75 | -100 to +75 | -100 to +75 | -50 to +75 | -100 to +75 |

* The product has been discontinued.

Technical characteristics of insulation

When choosing thermal insulation, you need to pay attention to 2 main technical characteristics:

- Coefficient of thermal conductivity . The lower it is, the better, because the material is needed to retain heat inside the room, and not to “heat the street.”

- Moisture absorption level . A low score is good. This means that the polymer does not absorb water and, as a result, lasts longer.

“ Penoplex Osnova ” differs from other types of insulation in its decent strength, long service life and structural stability. According to research results, insulation is 1.5 - 2 times higher than the energy efficiency of polystyrene foam and mineral wool.

Details about the characteristics

Extruded polystyrene foam has gained popularity due to its excellent performance and quality characteristics.

Extruded polystyrene foam has gained popularity due to its excellent performance and quality characteristics. In many respects, the insulation is superior to all known thermal insulation materials.

PENOPLEX COMFORT® and PENOPLEX®WALL - what's the difference?

Each brand of PENOPLEX® thermal insulation has its own characteristics and its own area of application. Let's analyze the similarities and differences between PENOPLEX COMFORT® and PENOPLEX®WALL boards, and note their advantages over insulation from other brands.

PENOPLEX COMFORT® and PENOPLEX®WALL are made of extruded polystyrene foam, which is characterized by high heat-shielding properties (thermal conductivity coefficient not higher than 0.034 W/m∙K), zero water absorption, biostability, and durability of at least 50 years. The material has a wide temperature range of application and is resistant to temperature changes, including alternating ones.

PENOPLEX® does not contain chemically hazardous components. In the production of boards, the same grades of polystyrene are used as for the manufacture of children's toys, food packaging and medical products, and the most stringent sanitary standards are applied to materials for the food and medical industries. We also note that plastic processing waste is not used in its production; only virgin polystyrene is used.

PENOPLEX® is certified with a high degree of environmental safety. The slabs are painted orange, which symbolizes warmth and environmental friendliness.

These are the common features of the two insulation materials. PENOPLEX COMFORT® and PENOPLEX®WALL have the same technical characteristics, except for durability. PENOPLEX®WALL has slightly lower compressive strength, since this parameter is not important for products that are attached to the facade and will not experience compressive loads. The most important difference: in the texture of one flat surface. The PENOPLEX COMFORT® board has both smooth surfaces, while the PENOPLEX®WALL has one of the two surfaces rough.

Application of PENOPLEX®WALL boards

For structural reliability, double fastening of PENOPLEX® slabs to the insulated surface is usually practiced: with an adhesive composition and mechanically using a dowel system with self-tapping screws. Mechanical fastening can also be used on the other hand: for finishing materials, for example, siding. But there are types of finishes that cannot be secured with nails or screws. We are talking about plaster and tiles.

The process of constructing a wall with plaster finish is as follows. A layer of base plaster-adhesive composition is applied to the thermal insulation layer of PENOPLEX® slabs with a rough surface, reinforcing mesh is embedded into it, then, after drying, a façade primer is applied, and, finally, a finishing layer of decorative protective plaster. Therefore, for the reliability of such a plaster system, high adhesion (adhesion strength) of the insulation surface with the basic plaster and adhesive compositions is required. On the rough side of the PENOPLEX®WALL slab, this figure is, of course, significantly higher than on the smooth surface of PENOPLEX® slabs and the surfaces of other heat-insulating materials. In particular, it exceeds the adhesion of polystyrene foam by more than 1.5 times, and that of mineral wool by more than 2.5 times. It is important to note that the adhesive strength of the rough surface of PENOPLEX®WALL is 3 times higher than the standard value specified in the technical specifications for the use of adhesive compositions.

Thus, PENOPLEX®WALL slabs are intended for wall insulation followed by finishing with various types of plaster: cement, lime, lime-gypsum, cement-lime, polymer-cement, acrylic, etc. At the same time, PENOPLEX®WALL can be used both for external insulation with plastered wall, and internal with wall decoration with interior decorative plaster.

An example of a wall design with thermal insulation PENOPLEX®WALL and external finishing with plaster on a polymer mesh

From the smooth surface of PENOPLEX COMFORT® insulation, a layer of the base plaster-adhesive composition, polymer mesh, facade primer and decorative protective plaster may fall off over time due to insufficient adhesion.

Application of PENOPLEX COMFORT® boards

PENOPLEX COMFORT® is used where there is no need for a rough surface: for thermal insulation of balconies/loggias; heated floors (warm floor system) or pitched roofs. However, under certain conditions, PENOPLEX COMFORT® slabs can replace PENOPLEX®WALL slabs. The latter go on sale with a factory-quality rough surface. However, you can prepare the material for applying the plaster composition with your own hands. To do this, immediately before installation, notches are applied to PENOPLEX COMFORT® boards to improve adhesion. But it is better to buy a specialized plate that is prepared for plastering work in a factory.

Other brands of extruded polystyrene foam

These brands are available to order. The price and other terms of delivery are agreed with the client.

All data on the sale of polystyrene foam presented on the website is for informational purposes only and does not constitute a public offer.

ABOUT WHAT

Penoplex - thermal insulation made of extruded polystyrene foam. Let's look at the difference between a professional line and a line for individual construction.

Penoplex: The difference between professional thermal insulation and thermal insulation for individual construction

One of the leaders in the thermal insulation market is Russian, producing various types of insulation for use by professionals and private builders.

Types of Penoplex

- For professional construction. The products are used for insulation of buildings for various purposes, for the construction of roads, railway tracks, and for laying pipelines;

- For insulation of residential buildings.

Each type of thermal insulation has its own advantages, but the main advantages of the material are:

- low level of thermal conductivity; complete absence of water absorption; high flexural and compressive strength; environmental friendliness; resistance to all types of biological influences (fungi, mold); durability.

Thermal insulation for professionals

Thermal insulation for professionals is used for insulation of production, industrial and transport facilities, warehouse complexes, etc. Product types:

- "Penoplex Geo". Used to reduce heat loss in buried structures. Penoplex Geo should be purchased to protect structures from freezing when installing a wall-mounted garage. The material also helps reduce groundwater pressure on the foundation;

“Penoplex Osnova” is a universal material; it is used to insulate all elements of building structures. With its help, you can efficiently insulate the floor. If you do not have high load requirements, then it makes sense to buy Penoplex Basis. The price for Penoplex Basis is low.

"Penoplex Roofing" is intended for roofing work, thermal insulation of stylobates and parking lots. The advantages of the material, in connection with which it is worth choosing and buying Penoplex Roofing, are high flammability and compressive strength. It can be replaced with expanded polystyrene GEO or OSNOVA;

"Penoplex Slope" is used in cases where it is necessary to insulate inclined structures: insulate stringers, flights of stairs, etc. You can create a system for directing rainwater to water intakes using Penoplex Slope. The material will help reduce pressure on the structure;

"Penoplex Facade" is a material for thermal insulation of external walls of buildings. You should buy Penoplex Facade if you need to protect walls and basements from mechanical damage, moisture and temperature changes. Penoplex Facade also protects walls from deformation.

The Penoplex Roofing Slope system is needed in cases where it is necessary to create a slope for a flat roof. If you are installing a flat roof on a reinforced concrete base, you should purchase this particular material. It is also effectively used in reconstruction and repair. The use of professional-grade thermal insulation allows you to reduce the cost of heating objects, their maintenance and repair, and prevent the destruction of structural elements due to external influences.

Features: advantages and disadvantages

Previously, such insulation was called “Penoplex 31 C”. The high technical characteristics of this material are largely determined by its cellular structure. Cells ranging in size from 0.1 to 0.2 mm are evenly distributed throughout the entire volume of the product. This distribution gives strength and a high level of thermal insulation. The material practically does not absorb moisture, and its vapor permeability is 0.013 Mg/ (m*h*Pa).

The insulation manufacturing technology is based on the fact that polystyrene foams, enriched with inert gas. After this, the building material is passed under pressure through specialized press nozzles. The slabs are manufactured with clear geometry parameters. For comfortable joining, the edge of the slab is made in the shape of the letter G. The insulation does not contain harmful substances, so the material can be installed without using protective equipment.

Specifications:

- thermal conductivity index – 0.03 W/ (m*K);

- density – 25.0-35.0 kg/m3;

- long service life - more than 50 years;

- operating temperature range – from -50 to +75 degrees;

- fire resistance of the product;

- high compression rate;

- standard dimensions: 1200 (1185) x 600 (585) x 20,30,40,50,60,80,100 mm (for internal thermal insulation of a room, slabs with thickness parameters from 2 to 10 cm are used, for external finishing - 8-12 cm, for roofing – 4-6 cm);

- sound absorption – 41 dB.

Type 35

The most versatile type of insulation produced by this brand, due to its excellent performance characteristics and resistance to many external factors, including fire, is type 35. Fire resistance parameters are determined by the presence and concentration of special substances - fire retardants, which also affect the areas of application of various modifications of the material:

- Penopolex 35 with fire retardants is used for thermal insulation and roof insulation;

- Type 35 insulation without fire retardants is intended for insulation of foundations and floors.

The high mechanical strength of this material allows it to be used also for insulating utility lines, in the construction of pedestrian paths, and in the construction of cold bridges.

| Parameter | Type 35 * | Comfort | The basis | Foundation | Geo | Pitched roof |

| Slab density, kg/m³ | 28,0-37,0 | 25,0-30,0 | 25,0-32,0 | 29,0-33,0 | 29,0-33,0 | 28,0-33,0 |

| Compressive strength (at linear deformation 10%), MPa, not less | 0,25 | 0,18 | 0,20 | 0,27 | 0,30 | 0,25 |

| Tensile strength (for static bending), MPa, less | 0,4 | 0,4 | 0,25 | 0,4 | 0,4 | 0,4 |

| Water absorption over 24 hours/28 days, % by volume, no more | 0,4 | 0,4/0,5 | 0,4 | 0,4/0,5 | 0,4/0,5 | 0,4/0,5 |

| Fire resistance category | G1 | G4 | G4 | G4 | G4 | G3 |

| Thermal conductivity at 25±5°С W/(m×°K) | 0,31 | 0,31 | 0,03 | 0,03 | 0,03 | 0,03 |

| Calculated thermal conductivity coefficients (operating conditions A/B), 25±5) W/(m×°K) | 0,031 | 0,032 | 0,031/0,032 | 0,031/0,032 | 0,031/0,032 | 0,030 |

| Sound insulation, Rw | 41 | 41 | 41 | 41 | 41 | 41 |

| Improvement index for structural noise insulation in floor construction, dB | 23 | 23 | 23 | 23 | 23 | 23 |

| Operating temperature range, °C | -50 to +75 | -100 to +75 | -100 to +75 | -50 to +75 | -100 to +75 | -50 to +75 |

* The product has been discontinued.

Where is it used?

The performance qualities of Comfort penoplex allow it to be used not only in a city apartment, but also in a private house. If you compare insulation with other building materials, you can notice significant differences. Similar insulating products have a narrower specialization of application: thermal insulation of walls or roofs.

Penoplex "Comfort" is a universal insulation material that is used for thermal insulation of balconies, foundations, roofs, ceiling structures, walls and floors. The insulation is also perfect for thermal insulation of baths, swimming pools, and saunas. Penoplex Comfort insulation is used for both internal and external construction work.

Almost any surface can be finished with Comfort insulating material: wood, concrete, brick, foam block, soil.

Installation Tips

Insulation of external walls

- Preparatory work. It is necessary to prepare the walls, clean them of various contaminants (dust, dirt, old coating). Experts recommend leveling the walls with plaster and treating them with an antifungal agent.

- The insulation board is glued using an adhesive solution onto a dry wall surface. The adhesive solution is applied to the surface of the slab.

- Mechanical fastening of the slabs is carried out using dowels (4 pieces per 1 m2). In those places where windows, doorways and corners are located, the number of dowels increases (6-8 pieces per 1 m2).

- A plaster mixture is applied on top of the insulating board. For better adhesion of the plaster mixture and insulating material, it is necessary to make the surface slightly rough and corrugated.

- Plaster can be replaced by finishing with siding or wood.

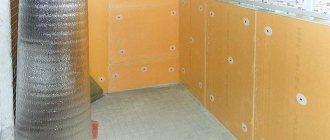

If it is impossible to provide thermal insulation from the outside, then the insulation is installed indoors. Installation is carried out in a similar way, but a vapor barrier is placed on top of the insulating material. Foil-coated polyethylene film is suitable for this purpose. Next, they install the gypsum boards, onto which wallpaper can be glued in the future.

In the same way, work on insulating balconies and loggias is carried out. The joints of the plates are glued with special tape. After installing the vapor barrier layer, the joints are also taped, creating a kind of thermos.

Insulation of floors with Comfort penoplex under screed may vary in different rooms. The rooms located above the basements have a colder floor, so thermal insulation will require a larger number of insulating layers.

- Preparatory work. The floor surface is cleaned of various contaminants. If there are cracks, they are sealed. The surface should be perfectly flat.

- The prepared floors are treated with a primer mixture.

- For those rooms that are located above the basement, it is necessary to perform waterproofing. A mounting tape is glued along the perimeter of the room at the bottom of the walls, which compensates for the thermal expansion of the floor screed.

- If there are pipes or cables on the floor, a layer of insulation is first laid. After that, a groove is made in the slab, in which communication elements will be located in the future.

- When the insulation boards are laid, it is necessary to install reinforced polyethylene film on top of the layer. This is necessary to protect the insulating material from moisture.

- A reinforcing mesh is laid on top of the waterproofing layer.

Insulation technology

Penoplex Base is excellent for insulating both floors and walls.

Insulation of a wooden floor with joists

Firstly, all damaged areas on the boards and joists are replaced.

Next, all wooden surfaces are impregnated with antiseptic agents to prevent rotting. Recesses and cracks found on the boards must be filled with special wood putty. Next, all wood surfaces are primed. After the primer has dried, the installation of insulation sheets begins. They are cut according to the distance between the joists and the length of the room and placed on boards.

The joints between the foam boards should remain as tight as possible; they are additionally secured with construction tape. Next, sheets of vapor barrier material are laid overlapping on the foam boards. Boards, plywood or chipboard are attached to the vapor barrier layer. The final stage is the installation of flooring (linoleum, laminate, parquet).

Floor insulation when laid on the ground

When insulating floors in a house with a pile or strip foundation, the method of laying insulating material on the ground is used. First, you need to level the layer of earth and then compact it.

Next, crushed stone and gravel are poured onto the ground. Sand is then poured in and compacted. Penoplex sheets are laid on the sand “pillow”, starting from the corner, pressing tightly.

To protect against moisture penetration, a waterproofing membrane is laid on the foam sheets so that its edges extend 10-15 cm up the wall.

To strengthen the structure, the screed is reinforced with metal mesh. Next, a cement-sand mixture is used for the screed, which is poured over the mesh. Finally, after the cement layer has completely dried, linoleum is laid on it or laminate or parquet is laid.

Insulating the floor under the screed

When using this method of insulation, it is recommended to choose the Foundation modification of penoplex.

Insulation of walls from the inside

Penoplex Base is often used when insulating the internal walls of a house. Firstly, the walls are cleaned of the old coating and a layer of primer is applied. Next, they begin to attach the foam sheets to the walls.

First, the underside of the base foam sheet is passed with a needle roller to ensure better adhesion. Next, an adhesive layer is applied to the sheet, the sheet is applied to the wall surface and held for half a minute.

Gluing begins from the bottom corner, then moving up and to the side. The glued foam sheets are additionally fixed with plastic dowels with an umbrella cap. After the glue has dried, use foam to fill the gaps between the sheets.

Important: recesses more than a centimeter wide must be filled with scraps of foam sheets.

At the next stage, the fiberglass plaster mesh is attached with glue or using dowels. Next, a leveling layer of plaster is applied, and then a finishing layer of putty. Finally, the surface is painted or wallpaper is glued to it.

Insulation of external walls

When insulating the walls of buildings and structures from the outside, it is recommended to use Penoplex Facade, which contains special flame retardant substances to reduce the risk of fire.

The main criterion for choosing insulation

Insulation is selected according to its heat-protective ability. This property is quantitatively expressed in thermal conductivity, which shows how much thermal energy per second will be released from the room by one meter thick insulation when the temperature difference between inside and outside is one degree. Extruded polystyrene foam, from which PENOPLEX ® slabs of all brands are made, has low thermal conductivity: from 0.029 to 0.034 W/m•K. In this, the material is superior to other widely used thermal insulators - mineral wool and polystyrene foam, whose thermal conductivity, respectively, fluctuates in the ranges of 0.037–0.055 and 0.041–0.059 W/m•K. Thus, to create the same temperature conditions in a room, a layer of thermal insulation made of mineral wool or polystyrene foam will need to be 30–70% thicker than PENOPLEX ® slabs. Useful space is saved.

Calculation of insulation thickness

To create comfortable conditions in the house, it is necessary to select the material for insulation as carefully as possible. One of the most important characteristics is the thickness of the sheets of material. The choice of a certain thickness depends on the thermal conductivity of the materials from which the house is made, as well as on the average air temperature in winter. If a building located in the southern region is being insulated, sheets 30 mm thick are often purchased. In regions with a temperate continental climate, penoplex with a thickness of 50 mm is usually chosen. If the house is being built in a region with a sharply continental climate, it is worth purchasing sheets whose thickness is 100 mm.

Knowing parameters such as the thermal conductivity of walls and air temperature, you can easily select insulation. When choosing, it is important to find out about the manufacturer's recommendations. In addition, when purchasing, it is important to pay attention to the presence of a certificate of product compliance with the requirements. Its absence may indicate that the material is a fake.

Stability is a sign of class

PENOPLEX ® boards of all brands are durable. The service life of extruded polystyrene foam, according to test results at the Research Institute of Construction Physics, is at least 50 years. During all this time, the material stably retains its heat-protective properties due to zero water absorption. Water has a higher thermal conductivity than insulation and impairs the thermal insulation properties of non-moisture resistant materials, including fibrous mineral wool and granular foam.

Zero water absorption of PENOPLEX ® also deprives the source of life for bacteria, fungus, mold and other harmful microorganisms, for which this material, moreover, is of no interest as a food product. Thus, PENOPLEX ® is characterized by absolute biostability, which is confirmed by tests in mycological centers.