Many developers have a feeling of uncertainty when choosing insulation; in the absence of practical experience, it is quite difficult to decide which material is best suited for thermal insulation. At the top of the list of the best offers is always penoplex or mineral wool. Having approximately equal thermal conductivity coefficients, these two materials compete mercilessly with each other, so for each specific case you have to understand thermal insulation and make a decision - it is better to insulate with mineral wool or penoplex. The answer, as always, lies in the details.

Mineral wool ideally insulates walls with good vapor permeability

Comparing two materials

Penoplex and mineral wool differ in structure, appearance and parameters, since they contain different components.

Penoplex and mineral wool differ in structure, appearance and parameters, since they contain different components. In addition, both materials are produced using different technologies. Before determining whether it is penoplex or mineral wool, it is worth studying the situation in detail, the properties of insulation and choosing the one suitable for thermal insulation in terms of effect and cost.

Description of materials and appearance

Penoplex is an advanced polystyrene foam that has been processed under the influence of temperature and pressure. This technology made it possible to create a dense, durable material with low weight and high thermal insulation qualities. In appearance, it resembles frozen polyurethane foam.

Mineral wool has a fibrous structure, which is due to the use of silicate rock solution as the main raw material.

The raw materials are fused, which gives the material the qualities necessary for insulation.

Types of materials

Mineral wool is presented on the market in several types: glass wool, slag wool and stone wool. Insulation is carried out with the latter type, since it surpasses the previous ones in technical characteristics. Penoplex is produced in different types, suitable for thermal insulation of roofs, foundations, walls and more. The parameters of extruded polystyrene foam or mineral wool depend on the type chosen.

Pricing policy, weight, packaging

The cost of high-quality basalt insulation is comparable to penoplex. Therefore, insulation with both materials will cost almost the same. The cost of insulation from different manufacturers varies. Basalt wool weighs more than extruded polystyrene foam, which makes its installation a little more complicated. Stone and polystyrene insulation is packaged in shrink film, which provides reliable protection during transportation and storage.

Thermal insulation properties

Insulation is best done with materials with low thermal conductivity. In this aspect, penoplex wins. But the difference is insignificant, since it will be possible to replace 50 mm extruded polystyrene foam with 60 mm thick mineral wool. In this case, the thermal conductivity indicator may deteriorate if there is inadequate protection or violation of installation rules. What is warmer depends on the specific situation, so other properties should be taken into account.

Vapor permeability of materials

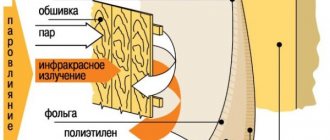

The vapor permeability indicator is an ambiguous criterion. Warmer penoplex has a vapor permeability coefficient almost equal to zero, which makes it airtight. Mineral wool is breathable, which is important to prevent condensation. It allows air to pass through, unlike penoplex. At the same time, the installation of mineral wool requires the installation of waterproofing, which reduces the coefficient of vapor permeability.

Flammability and fire resistance

Mineral wool has the best fire resistance characteristics: it does not ignite, since the mass fraction of the adhesive mass capable of burning in the composition is small, and for melting it will be necessary to reach more than 1000 ° C. Extruded polystyrene foam belongs to highly and moderately flammable materials (class G3-G4). In certain lines of penoplex, the manufacturer managed to reduce flammability by introducing additives into the composition.

We are trying to answer the pressing question - which is better: penoplex or mineral wool?

“The wise power of a builder is hidden in every person, and one must give free rein to its development.” (Maksim Gorky).

A huge hello to all blog readers! I hope you have already “come to your senses” from the holidays and are ready for the next portion of construction information. If yes, then read on, if your health still leaves much to be desired, close the site, turn off the computer and go to visit friends for “treatment.” Well, we will continue.

Today I decided to choose the topic of choosing two main “ideological competitors”, well, like a car with front or rear wheel drive. Or something similar, which has approximately an equal percentage of supporters on both sides. I’ll try to make a neutral comparison, and the choice is clearly yours. So, penoplex or mineral wool, which is better?

The right question is - what are we going to insulate? Well, let's take a little look at the main structures: walls, foundation, floor.

Subtle point. If penoplex* is, in fact, the name of the final product, then mineral wool is a broad concept, including glass wool, slag and stone wool. Therefore, as the Germans say, “apples must be compared with apples,” which means we’ll focus on one thing. I choose stone mineral wool, which is more often called basalt. It has better thermal insulation properties in comparison with its “slightly backward brothers”.

*There is another subtype of penoplex - technoplex. This is a bird of a feather. True, there is not a big difference in the name and minor parameters, but we will not go into these details. That's it, let's begin. In the red corner of the ring there is penoplex, in the blue corner there is mineral wool. Gong!

From this article you will learn:

Application

In various situations, penoplex or mineral wool is used for thermal insulation.

What is better is determined taking into account the nuances of each specific case, climatic conditions, the material from which the structure is constructed, and financial capabilities.

What material to insulate what with?

The best way to carry out thermal insulation is determined by each owner himself, but there are a number of recommendations from professionals that will help make the right choice:

- You can insulate walls from the inside with both materials. But it is better to insulate wooden buildings with mineral wool. Because it has higher vapor permeability.

- It is better to insulate the foundation of a house, blind area, basement, and basement with penoplex foam, since it has higher strength and can withstand significant loads.

- The roof is insulated with both mineral wool and extruded polystyrene foam. Here the choice should be given, taking into account the material of construction. Most often, house floors, attics and attics are insulated with stone wool.

- For rooms with high humidity: car washes, baths, saunas, the use of polystyrene foam insulation is strictly not recommended.

It is impossible to say unequivocally which insulation is better. There are many factors to consider to make the right choice.

Looking for energy efficient solutions?

Pay attention to FORUMHOUSE geothermal heat pumps

Ground source heat pump EU (start/stop)

Geothermal heat pump IQ (pseudo-inverter)

IQ ground source heat pump (inverter)

The article was NOT commissioned by either polystyrene foam or stone wool manufacturers.

Builders of frame houses often argue: “Which is better - polystyrene foam or mineral wool insulation?” How many people, so many opinions. As a result, novice developers find themselves faced with a difficult choice and do not know what is more profitable to insulate a home. We have simplified the task and collected answers from a thread where the pros and cons of these materials are discussed in detail. So, choose your insulation!

Ease of installation

Thermal insulation with both insulation materials has nuances. For installation to be effective and safe, you should strictly adhere to the technology:

- Penoplex weighs little, which makes installation simple. But when insulating with extruded polystyrene foam, reliable adhesion must be ensured. For this purpose, some manufacturers produce slabs with a special tongue-and-groove fastening. If it is absent, then it is rational to carry out insulation in two layers with overlapping seams. These are additional costs. At the same time, working with penoplex is comfortable, since it is easily cut and eliminates the formation of cold bridges.

- Mineral wool is heavier, but it is also convenient to work with, since it perfectly covers any unevenness. But thermal insulation should be carried out using personal protective equipment.

Penoplex and mineral wool effectively retain heat and are easy to install. Even an inexperienced person can carry out insulation with these materials.

Methods for laying thermal insulation before facing with siding

There are several options for how to insulate a facade under siding. The result of choosing a method for laying insulation is influenced by the following criteria:

After assessing these factors, you can determine the required thickness of the insulation, what method and in how many layers it should be laid.

Option #1. Use of roll insulation with a thickness of 5 to 20 mm. The material is glued to the walls, and a wooden sheathing is installed on top of it for mounting the siding panels. This provides acceptable wind protection, but does not prevent heat loss sufficiently. This method is suitable for country houses where the owners do not live permanently.

Option #2. Installation of insulation boards in the spaces between the vertical wooden sheathing elements under the siding. In this case, you need to take into account the thickness of the frame beams, which should exceed the thickness of the heat-insulating material by 2-5 centimeters. The difference between these values allows the formation of a good air gap (ventilation duct). The insulation boards are glued to the wall and secured with dowels with large heads. The disadvantage of this method is the appearance of cracks (unprotected joints between slabs, insulation joints and wooden sheathing bars), which become cold bridges.

Option #3. Cross frame and two-layer insulation help to avoid a decrease in the thermal insulation properties of the siding structure. First, the sheathing bars are attached to the wall in a horizontal position at a distance from each other equal to the width of the insulation boards, which are also laid horizontally in the gaps formed between the bars. In the first layer, the bars should be 5-8 millimeters thinner than the slabs. The second layer of the frame is placed vertically on top of the horizontal layer of sheathing with installed insulation. Thermal insulation slabs are laid vertically between the vertical bars, and the siding is attached to the sheathing elements. The disadvantage of this method is the high material and labor costs; the reliability of thermal insulation in the long term pays for all costs.

Option number 4. To save lumber, the sheathing for the siding is carried away from the wall on wooden posts at a distance equal to twice the thickness of the insulation plus a ventilation gap. Then two layers of thermal insulation are attached to the wall perpendicular to each other. Only after this are vertical siding guides mounted on the racks.

Option #5. To familiarize yourself, you should consider the most modern method of applying an insulating layer under siding. It is completely unsuitable for building a house with your own hands, because it involves injecting polyurethane foam into the gaps of the wall under high pressure. Foam applied to the right place quickly expands and fills all voids, hardens, forming a reliable insulating layer. Such insulation does not require wind protection. But as already mentioned, it is impossible to carry out such technically complex insulation on your own, since this requires special consumables and equipment.

Pros and cons of insulation

The main advantage of extruded polystyrene foam is its thermal conductivity and strength. The insulation is not attractive to rodents; it will retain its integrity and performance characteristics longer. Among the disadvantages, users highlight a high degree of flammability, as well as low vapor permeability, which leads to the appearance of condensation.

Mineral wool also has excellent thermal insulation properties. The main feature is the ability to combine with all types of bases, including breathable ones. Disadvantages include a high degree of moisture absorption and low strength, which can lead to deterioration in thermal insulation qualities and deformation of the insulation. Rodents can also spoil mineral wool. If the material accumulates moisture, mold appears.

What is better to insulate with stone wool?

Mineral wool is well suited for buildings that are built from breathable materials, for example, wood or brick. In general, it combines well with all coatings, and has no exceptions.

According to some indicators, materials differ specifically, and their choice should be made based on the conditions in which they will be located. It is almost impossible to say which of them is better, because each of them is good in its own way.

Service life

Manufacturers of expanded polystyrene and mineral wool indicate a service life of at least 50 years. To achieve this and extend the period of use, the insulation should be reliably protected from the influence of external factors:

- Penoplex - from ultraviolet radiation, which impairs performance characteristics.

- Mineral wool - from mechanical stress and moisture. Which can lead to deformation and shrinkage.

Users note the average service life of mineral wool is 25-35 years.

As for penoplex, there is no specific data, since insulation has appeared recently.

conclusions

When choosing durable and reliable insulation, many developers pay attention to mineral wool and polystyrene foam. Many inexperienced owners prefer mineral wool to polystyrene foam because it is environmentally friendly and has high vapor permeability.

However, this solution is not always optimal. This insulation is capable of allowing air and water to pass through. Moisture can settle on the inner surface of the facade. This can lead to freezing and destruction of the facade. The decorative layer deforms over time, and the insulation becomes like a sponge that has absorbed moisture.

Foam boards are capable of allowing air to pass through, but not too much. Since the material has no pores, and it itself is quite dense, moisture cannot pass through it. Due to the fact that air passes through the joints, a certain ventilation is created.

comparison table

The characteristics of penoplex and mineral wool are described in detail in the table.

| Properties | Mineral wool | Penoplex |

| Density (kg/m³) | 115 | 25-47 |

| Compressive Strength(MPa) | 0,1 | 0,2 |

| Flexural strength (MPa) | 0,5 | 0,5 |

| Water absorption (%) | 1 | 0,5 |

| Thermal conductivity (W/m•°C) | 0,043 | 0,03 |

| Fire resistance | NG | G1-G4 |

The indicators are averaged, since the indicators differ from one manufacturer to another.

Mineral wool and extruded polystyrene foam provide reliable insulation, subject to the purchase of high-quality material and compliance with operating conditions. Which insulation is better is a user decision, since it depends on the specifics of the situation.

Comparison by main parameters

Penoplex - produced on the basis of polystyrene, with the addition of special chemicals. They turn into a kind of foam under the influence of high temperature. Ready-made porous insulation is entering the market.

Penoplex

Often it contains substances that prevent thermal oxidation and flame retardants that resist combustion. The main characteristics of penoplex almost do not change under the influence of moisture. Therefore, it is permissible to use it to protect a building from cold outside and inside. There is no need to protect it from moisture.

A room insulated with penoplex

It is necessary to prevent the possibility of contact with ethers, tar, oil paints, fuels, lubricants and formaldehyde. These substances will lead to the decomposition of penoplex.

Mineral wool is produced by melting rocks, and after heating, thin fibers are formed.

Important! A huge advantage of mineral wool is that it contains exclusively natural substances that can withstand open fire and reliably protect against street noise.

Mineral wool is sold in the form of rolls or slabs, allowing you to protect surfaces of any configuration from the cold. It is not able to withstand moisture; even dampness significantly impairs the thermal insulation qualities.

There are several varieties of mineral wool, differing in characteristics:

- Glass wool. They are used for thermal insulation of non-residential premises, the reason is that it contains formaldehyde, but its cost is the lowest;

- Slag-like. Well suited for protecting heating pipes and external surfaces of buildings;

- Stone wool. The material is very durable. But it absorbs a lot of moisture;

- Basalt wool. It does not burn at all, successfully protects against street noise, but absorbs a lot of moisture.

Laying mineral wool

It is difficult to say which is better for protection from the cold than penoplex or mineral wool; the choice mainly depends on the surfaces that need protection. Penoplex is a little lighter and is convenient to use for flat surfaces. When using mineral wool, remember to wear protective clothing.

You can insulate rooms inside the house with any material. Penoplex is convenient to use on flat surfaces. It sticks securely and is easy to cut and sand. But in areas of the building where many turns and curves can be found on the surface, it is advisable to fix mineral wool; it easily fits on surfaces of any curvature.

How to cut mineral wool?

How to cut mineral wool is a very important question, because the fibrous structure of the material that is used to maintain thermal insulation properties must maintain an integral structure, i.e. using simple scissors is not acceptable. To install and repair soft roofs, it is necessary to use a special machine to cut the mineral wool.

If using a machine is not possible due to its high cost, then you can use more affordable tools: a hacksaw for metal or wood. You can use a mounting knife, but it is not very large, so if the canvas is thick, cutting it with this knife will be inconvenient.

What other tools can be used to cut mineral wool? The knife blade is better if it is made of stainless steel. It is very important that the materials used have a sharp blade, otherwise it will not cut, but tear the cotton fibers.

When working with mineral wool, you must follow safety rules, because... Mineral wool dust is harmful to human health; when working with it, it is necessary to close the respiratory tract and mucous membranes of the nose and eyes. It is better to cut the material in a roll so that there is less dust in the air, but still the room in which work with mineral wool is carried out should be well ventilated.

Video description

How to properly insulate the external walls of a house with penoplex, watch the video:

Therefore, to insulate the walls of a house from the outside, the best choice would be to use pegopolystyrene. Due to the lack of ability to absorb moisture, this material will last a long time without the use of additional construction membranes.

Therefore, when choosing the best way to insulate the walls of a house from the outside, penoplex or mineral wool, the best choice for insulating facades will be the use of PPS. Due to the lack of ability to absorb moisture, this material will last a long time without the use of additional construction membranes.

Mineral wool is used to insulate the facade of a private house or outbuilding in cases where it is possible to install a special sheathing. Often, insulation of this kind is combined with the installation of siding, since sheathing is also needed to prepare the walls. Therefore, when choosing stone wool or polystyrene foam, which is better for insulating the facade, what the exterior decoration will also matter

Chimney insulation with mineral wool or basalt

You can read about the comparative characteristics of chimney insulation with mineral wool or basalt wool in the article, which is entirely devoted to the options for using basalt wool in the household.

However, here we can say that the furnace gases heat the chimney to temperatures that exceed the melting point of both glass wool and slag wool. Therefore, their use for thermal insulation of chimneys is categorically unacceptable .

As for the basalt wool on the chimney... Well, over time the binder in it burns out. This can be seen by the way it brightens. Without a binder, the fibers fall apart. Oh, and condensation, of course - it reduces the thermal insulation properties of cotton wool.

In this situation, we recommend ceramic fiber - this is a new material, it is more expensive, but you don’t need much of it to insulate a chimney! Its characteristics are an order of magnitude better than those of old insulation materials.