From time immemorial, the insulation of a wooden house has been done using caulk. This is hard and time-consuming work that requires accuracy and certain skills. Today, in the age of high technology, new methods of insulation have been invented, which are replacing the ancient craft. Disputes about the best way to close the gaps between beams or logs are ongoing. Many adherents of progress use foam instead of caulking to seal crown joints; conservatives prefer the traditional method of thermal insulation using caulking. Let's figure out what material is best to insulate a house and why.

What is better for insulating a wooden house: foam or caulk?

From time immemorial, the insulation of a wooden house has been done using caulk. This is hard and time-consuming work that requires accuracy and certain skills. Today, in the age of high technology, new methods of insulation have been invented, which are replacing the ancient craft. Disputes about the best way to close the gaps between beams or logs are ongoing. Many adherents of progress use foam instead of caulking to seal crown joints; conservatives prefer the traditional method of thermal insulation using caulking. Let's figure out what material is best to insulate a house and why.

Possible reasons for restricting access:

Access is limited by court decision or on other grounds established by the legislation of the Russian Federation.

A network address that allows you to identify a site on the Internet is included in the Unified Register of domain names, page indexes of Internet sites and network addresses that allow you to identify sites on the Internet containing information the distribution of which is prohibited in the Russian Federation.

A network address that allows you to identify a site on the Internet is included in the Register of domain names, indexes of pages of sites on the Internet and network addresses that allow you to identify sites on the Internet containing information distributed in violation of exclusive rights.

Material requirements

Before answering the question: which is better, it is necessary to provide a list of requirements for insulating material for a wooden house:

- Vapor permeability, i.e. the material must freely pass through itself water vapor that forms in a warm house. If the material does not have this property, moisture is retained in the insulation without coming out. As a result, the heat insulator gets wet, the wood becomes damp and begins to rot.

- Moisture resistance. This characteristic indicates that the insulation does not accumulate moisture.

- Resistance to microorganisms and fungi.

- Breathability. The material must allow air to pass through well.

Advantages and disadvantages of caulking

The log house is caulked only with natural materials: moss, jute, tow, flax.

- do not violate the environmental friendliness of a wooden house;

- do not interfere with the air exchange of wood;

- They retain heat well in the house because they have low thermal conductivity.

Article on the topic: How to properly make a canopy in a bathhouse

A log frame, caulked in the classical way, looks very expressive; the color of a traditional Russian hut is preserved in the house. Additionally, the crown seams are decorated with jute tape or cord, and a rope or decorative cord is laid between the logs. This not only improves the appearance of the house, but also improves its thermal insulation.

Despite many positive aspects, caulking also has some disadvantages:

Firstly, it is a long and tedious job that requires a lot of effort and patience. It is very important to have experience and work skills. Even a non-specialist can caulk logs. However, there are many nuances. If the seams and joints are caulked incorrectly, the house may become distorted, the insulation may be pulled apart by birds, or it will be knocked out during shrinkage. Every problem has its own solution, which only professionals know.

Secondly, caulking is done several times. This work cannot be done once and for all. The primary one is performed during the construction phase or immediately after its completion. The log house is caulked the second time after the main shrinkage has passed, the work is done both outside and inside. If the exterior finishing has not been done, then a third caulking is done 3-5 years after the construction of the house. In some cases it is necessary to perform intermediate caulking.

It should also be taken into account that only moss, and to a lesser extent tow, has good antibacterial properties. The remaining insulation materials must be treated with special compounds. On the other hand, tow tends to accumulate moisture, so it is advisable to use it to caulk areas that are least exposed to the influence of natural precipitation. Birds love to take away natural insulation materials, so you will also have to take care of protecting the material.

Positive characteristics of elastic polyurethane foam and its advantages

In the construction of wooden houses from timber, the construction of frame-panel buildings, filling voids in building materials with different expansion rates for installation and finishing work, thermal and noise insulation between structural elements, highly elastic foam PURAFOAM 5175 from modified polyurethane is widely used.

Due to its distinctive characteristics, it has a number of advantages:

- Ability to withstand large weight and deformation loads;

- The high adhesive ability and elasticity of the mass of the composition prevents the occurrence of edge breaks and the formation of cracks during operation, which improves the durability of the foam and maintains thermal insulation and noise insulation up to 60 dB for a long time;

- Perfectly grips elements of wooden structures, PVC, metals, polymers, concrete, brick;

- When the surface is wetted before applying elastic foam, its fine-cell structure, sealing properties are improved, and the structures fit more tightly to each other;

- Thanks to high elasticity, seams and joints are elastically strong and durable and can last for more than 30 years;

- Ability to use foam at sub-zero temperatures (down to -10°C);

- The moisture resistance and fine porosity of the foam give it electrical insulating properties;

- Due to their highly expansive properties, they completely fill voids and cracks, which ensures increased strength and reliability of the seams;

The product is certified by the world famous to meet the highest requirements of compliance with the declared qualities.

Pros and cons of polyurethane foam

Since the caulking process is very labor-intensive, many are trying to find other easier ways to seal the seams between the beams.

One option is to foam the joints with polyurethane foam. Let's figure out whether this can be done and how effective this method is. The material has excellent performance characteristics:

- high heat and sound insulating properties;

- moisture resistance;

- non-flammability;

- ability to densely fill voids and cracks.

In addition, the big advantage of polyurethane foam is its simple and quick installation and inexpensive price. For this work it is not necessary to hire installers; it can easily be done independently. It is these indicators that, first of all, those who have made their choice in favor of this insulation are guided by.

Article on the topic: How to build a house from aerated concrete

However, foam cannot provide a home with reliable and high-quality thermal insulation because:

- does not have sufficient elasticity, which leads to the formation of cracks and crevices when the timber moves during shrinkage;

- when heated strongly, it releases harmful toxins;

- cracks and collapses under the influence of UV rays;

- wood is a breathable material, foam does not allow air to pass through, it simply clogs the pores in the wood and deprives it of natural air exchange;

- Moisture can accumulate at the junction of the foam and the timber, which leads to rotting of the wood.

As you can see, the list of shortcomings is quite wide, which limits the scope of its application.

With great reservations, you can foam cracks and roof joints in wooden houses only if this option is considered as a temporary measure.

How to foam correctly, foam cracks, joints and seams, large and not only

One of the important advantages of polyurethane compounds is ease and ease of use . Regardless of the type of cracks being filled, the work is carried out according to a similar principle. It is first necessary to prepare the surface , clean it from dust and dirt, old sealant (! how to clean polyurethane foam from metal doors, plastic windows, clothes and hands). The surface must be degreased with acetone and moistened with water from a spray bottle.

Soudal super-elastic all-season pistol foam 750 ml. Low expansion is excellent for filling cracks and voids. Photo by Leroy Merlin

It is necessary to prepare a container of foam, bring it to room temperature, shake it to mix all the components of the composition. If professional foam is used, the gun must be installed before shaking. To do this, the lid is removed from the container and the container is connected to the gun. The performer will need goggles, a mask or respirator, gloves, and long sleeves.

The container nozzle is placed in the gap to be sealed and moves from bottom to top. The cylinder must be positioned bottom up. The composition hardens for 30 minutes, after which the excess may be cut off with a construction knife. Wide and deep cracks are foamed in several layers. Other recommendations for learning how to lather are presented here.

On the ceiling

Sealing ceiling cracks can be a particularly difficult process . But there is a way out. The length of the plastic adapter tube for household ones or the nozzle of the gun for professional compounds must be increased using a PVC tube , it is also called a dropper tube. It has sufficient strength and excellent elasticity, and has a suitable bore diameter. One end of the tube is connected to a gun or adapter, the other is directed into the gap required for sealing. By gradually pressing the material consumption is controlled and sealing is carried out.

If the foam continues to fall out, then there is another way. After carrying out the preparatory work, it is necessary to seal the seam with masking tape, in which holes are formed, through which the gap is filled with foam. After the composition has hardened, the tape is removed.

Reference. Do not forget about the preparatory work, since a lack of adhesion may occur due to dust or dirt present on the surface.

The best recommendation for sealing cracks in the ceiling would be to purchase compounds that can be worked in different positions, not just bottom up, for example, Tytan Lexy.

In the floor and under the baseboard

Problems with flooring cause a lot of trouble for owners of apartments, houses, bathhouses and other buildings. Gaps in plank floors and under baseboards present a whole range of problems : an untidy appearance, the appearance of dampness, the formation of mold and mildew, and possible insect infestations. Therefore, it is necessary to get rid of gaps as quickly as possible. In this case, it is necessary to ensure good heat and sound insulation, and to prevent increases in humidity.

The culprits for the formation of cracks may be incorrect technology for laying boards, poor-quality fasteners and violation of the location of the joists, low humidity in the room, which leads to a reduction in the size of the products, low quality lumber, poorly organized ventilation, rodents, and active use of the coating.

Polyurethane foam TYTAN LEXY 20 300 ml. Photo by Maxidom

There are a significant number of ways to eliminate cracks . Using foam is an easy repair method. The polyurethane composition allows you to get rid of the defect and provides floor insulation. When performing work, it is necessary to adhere to general recommendations and follow the standard principle of action.

Professional services

Experts do not recommend using foam to insulate a wooden house and bathhouse. Although caulking inter-crown joints is a more complex and time-consuming job, it guarantees good and reliable thermal insulation, provided that the work is carried out efficiently and professionally.

When performing work, we conclude a contract and agree on an estimate in writing. The stages and timing of the contract , guarantees and a list of materials used are also recorded in writing.

If you are attracted to new technologies and want your home to look modern and stylish, we suggest using the service of sealing log seams with sealant. This material is specially designed for insulating seams between logs and beams and provides a reliable and elastic connection.

The craftsmen of our company work carefully and accurately, strictly observing technology. Our specialists are highly qualified, have the necessary skills and extensive experience. You can entrust us with home insulation work of any complexity and volume.

To contact us, use the information posted on the “Contacts” page.

We also recommend you our partner: Help Consulting. These lawyers have long established themselves in the market of legal services in the field of construction. The company provides of legal services , a special place among which is occupied by: collection of penalties from the developer as well as debt collection in arbitration court .

Article on the topic: How to properly insulate a frame house with mineral wool

Calculate the cost of painting and insulating your home right now

The power of sealant in the rules of application and formation of the seam The rule of necessary sufficiency

To calculate the shape of filling inter-crown seams with acrylic sealant (forming seams), it is necessary to determine, first of all, what width will be sufficient to provide a protective coating for the seam between the logs. Naturally, the aesthetics of the seam is important; it should not be very wide and, on the contrary, too narrow. The proportion depends on the diameter of the log, the color of the sealant and the visual perception of the picture of the walls and the house as a whole. It is always better to make trial full-scale applications of different colors in advance for comparison, and, accordingly, select spatulas for the ultimately suitable seam size. Useful recommendations for installers - to form a beautiful warm seam, quickly work with sealant and achieve an ideal smoothing process without unevenness and sagging, use the smoothing agent Ramsauer® 506 GLÄTTMITTEL SPEZIAL .

Equally important for determining the optimal size of the seam is the sufficiency of the seam width to protect the space between the logs. To ensure excellent joint compensation under loads, a width to depth ratio of +/- 1:2 . At the same time, the depth of the seam on the sides can be slightly greater, so the adhesion to the tree is better and more reliable, and in the center it is less - this is where the loads are greatest. The tensile strength of PURAFILL® 7616 is more than 660%, which is more than necessary to ensure that the filling always remains permanently soft and does not collapse during the movements of the wooden house. From practice, it is not recommended to apply inter-crown sealant with a thickness of more than 12 mm.

The thickness (diameter) of the backing cord must correspond to the width of the seams between the logs or beams. A seam with a width of 10 mm or less is considered average. Backfilling narrow seams is cheaper due to the lower cost of cord with a smaller diameter. Another important aspect of the work on sealing inter-crown gaps or cracks in logs is the correct, uniform and sufficiently deep laying and reliable fastening of the cord between the logs and in the cracks. The cord must be laid carefully, in no way damaging or pinching it (with sharp objects), so experience and a patient approach are required here. Naturally, for a large number of strips, several coils of cord will be required.

Is it possible to caulk a log house with polyurethane foam? What does this mean?

Reading time: 2 minutes No time?

A wooden house has many advantages and one significant drawback: wood is a “living” material, and it breathes, changes its shape, gets sick, and eventually dies from age and various misfortunes. So you need to handle him carefully and competently, so as to prolong his health as long as possible. And if you are planning a house or a bathhouse made of logs, it is important to choose the right material to fill the cracks, otherwise it may just cause the log house to become sick. Or maybe you shouldn’t rack your brains and use regular polyurethane foam? Yes, our ancestors didn’t do that, but they didn’t have foam either.

Read in the article

Sealing seams between logs - traditional sealing options

Oddly enough, the time-tested methods of sealing joints in wooden houses remain optimal in our time. Our ancestors did not face the question of how to seal the cracks in a log house, because the correct answer grew in most forests and copses. This answer is called "natural moss". It perfectly protects joints and seams not only from wind penetration, but also from dampness. Another thing is that finding a sufficient amount of natural moss is not easy, and the sealing itself will be labor-intensive. When using natural materials to seal the gaps between timber and logs, a very high packing density is required.

It is checked with a sharp shoe awl - this tool should enter compressed moss or tow with almost the same force as into a massive log.

Tow for insulating joints in wood can be purchased at a hardware store. The purchase must be made in large quantities at once, because... even a narrow gap can “absorb” a large amount of tow. Natural moss does not need additional means of reinforcement - tow can be soaked in a liquid, flowing solution of cement or gypsum. Natural hemp provides high-quality protection for the joints between logs, and it looks attractive in appearance.

However, the cost of this material is quite high, especially considering the amount of work involved in the joint finishing of an entire wooden structure. Natural caulk for wood is optimal without additional impregnation. In this case, it can be supplemented with the following layers in a month or a year or two. Tow soaked in plaster or cement often crumbles and falls out of the cracks, and the work has to be redone. Tow, hemp and moss are hammered into the seams using a set of long chisels with varying blade widths and sharpnesses. The deeper the installation, the sharper and thinner the chisel blade used.

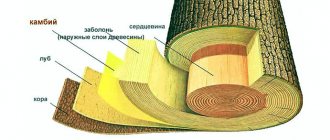

What materials should be used for caulking so that the log house does not “get sick”

To prevent the wood from starting to rot, an optimal microclimate must be maintained in the house - that is, there should be no condensation and no tin can effect. And this breathing is provided precisely by the materials that fill the space of the cracks. If the insulation does not allow moisture to pass through, but rather accumulates, it remains between the logs and becomes a breeding ground for rot.

How log houses are traditionally caulked

It is not for nothing that we are talking about the experience of our ancestors, because it has been tested for centuries. Traditionally, log houses are caulked with dry moss, jute and tow. All these materials are of natural origin. They, of course, breathe due to their fibrous structure, do not accumulate moisture, since it is thanks to their loose composition that they dry quickly.

And finally, natural caulk will have to be renewed from time to time.

Modern materials for caulking

It is the labor-intensive “fussing” with natural caulking that makes you think about replacing it with modern sealants. There are two available options: silicone or polyurethane foam.

It is better to sweep away silicone immediately. Filling the cracks with this composition will tightly seal the log house, and the log will begin to rot, since there will be nowhere for moisture to evaporate from it.

PHOTO: ximtex.ru Silicone has 100% tightness and an almost endless service life, but when used, the log house will most likely rot much earlier than its counterpart with natural caulk

Article on the topic: How to decorate a house from sip panels

What about foam? It’s very tempting to use it, because it perfectly fills everything, even very difficult crevices, and is so easy to apply?

Is polyurethane foam suitable as caulk?

What are the benefits of foam? It is resistant to moisture - this is good, which means this material will not accumulate water. The foam is non-flammable, has high penetrating ability and fills even the most inaccessible places due to its expansion.

PHOTO: samstroy.com This material is relatively inexpensive, you don’t need to bother with its preparation, and it is applied quickly and easily

All these factors make foam very attractive for caulking, but...

Once hardened, the foam is no longer elastic, and the wood continues to change with age and depending on the season. That is, it expands and dries out, but the foam does not. And as a result, new cracks form, and this negates all the work.

PHOTO: blog.leskos.ru In addition, foam does not allow air to pass through, that is, like silicone, it seals cracks with all the ensuing consequences of this fact, that is, rot and mold

Finally, this material is afraid of the sun; it makes it brittle. If foam is used somewhere, it must be followed by a finish that protects it from ultraviolet radiation.

So polyurethane foam is not a suitable material for caulking, although it’s a pity to admit it. Foam can only be used as a temporary measure and then with mandatory sun protection. But it’s better to caulk a log house with natural material. How to do it correctly - in this video:

Criterias of choice

Polyurethane foam is usually used to fill cracks with a width of no more than 100 and no less than 10 mm . It is recommended to use sealants to seal small gaps. Not every mounting foam is suitable for filling voids. Materials have different coefficients of primary and secondary expansion. Maximum expansion compounds are not suitable for filling small gaps. Since when the volume increases, the foam puts pressure on the structure and/or its individual elements, which can lead to deformation. Therefore, it is important to take these indicators into account.

Axton professional mounting foam, 750 ml. Photo by Leroy Merlin

Professional compounds are characterized by high primary and minimal secondary expansion , so they are the best option. In addition, the use of a gun allows you to regulate and dose the speed, quantity and consumption of the composition when performing work. However, household foams are produced in small-volume cylinders , sold at a more affordable price. One cylinder with a volume of 300 ml. enough to install one door block. Depending on the scale of future work, the optimal option in terms of price and properties is selected.

When performing work indoors, it is recommended to use all-season or summer compounds. The selection of products for outdoor work must be carried out in accordance with the ambient temperature. Summer foam is used at temperatures from +5 to +30-35 degrees Celsius. The special formula of winter products allows the mass to harden even at subzero temperatures. All-season suitable for use at temperatures from -10 to +30 degrees.

An important indicator when choosing is the foam yield : 30 liters will be enough to install one door, to foam two window frames you need 40-45 liters, 50-55 liters. enough for two door frames.

Household mounting foam Makroflex 500 ml. SHAKETEC is suitable for filling cracks. Photo by Maxidom

Thus, for sealing cracks, it is necessary to choose products with low secondary expansion and in small volume cylinders that meet the requirements of the work being performed. When carrying out the work yourself, it is possible to use both household and professional materials.

It is also possible to note other characteristics that must be taken into account when choosing foam, regardless of the type of work performed:

- manufacturer (trade mark) , the use of products from well-known companies contributes to obtaining a high-quality result: Soudal, Makroflex, Tytan, TECHNONICOL; the range of leading companies includes materials to solve any problem;

- purpose , there are products on sale for indoor work and universal compositions suitable for various conditions;

- flammability class , depending on fire safety requirements, compositions of type B1 (fire-resistant), B2 (self-extinguishing) and B3 (flammable) can be used;

- polymerization time , to complete chemical reactions, compositions of various types require an average of 24 hours, carrying out work in ideal environmental conditions in terms of temperature and humidity, complete polymerization occurs within 12 hours, the maximum is 30 hours.

Polyurethane foam instead of caulk: is it possible to foam a bathhouse with polyurethane foam?

From time immemorial, wooden buildings (between logs and beams) have been caulked with moss, tow, flax or jute. Caulked seams can be decorated with jute tape or cord.

These natural materials will retain heat well and will not interfere with air exchange. There are also disadvantages:

- Long work that takes a lot of time and effort,

- If you do everything wrong, the birds will pull out the insulation or it will become deformed when it shrinks.

- Caulking needs to be done several times. After the structure shrinks, it needs to be caulked again. After 3-5 years you need to do the work again.

Article on the topic: Which heated floor is better for a wooden house

There are more modern ways

: insulate using polyurethane, silicone sealant or polyurethane foam.

The option with silicone sealant is questionable. Wood absorbs moisture and evaporates it. The sealant will prevent evaporation. The tree will begin to rot.

Silicone sealant is 100% waterproof and has a service life of 10 years longer than its acrylic and silicone counterparts.

Execution of work

Each construction operation begins with the selection of materials and tools. In principle, any polyurethane foam can be used as insulation. “Any” means high-quality, professional. There is no point in fiddling with household spray cans on large areas of work.

But when choosing a material, it is important to take into account the characteristics of the building that is planned to be insulated. Eg. If you need to treat a wall, floor or ceiling at the exit of a chimney or chimney, then we buy heat-resistant polyurethane foam. This is a must.

Tools

Let us repeat once again: there is no point in insulating using cylinders. Nobody is doing this. Even spray foam guns will not work. You need a special device to spray the substance.

It's expensive. To insulate numerous houses, it is advisable for customers (for money) to purchase it. To perform one-time work, you can rent it.

A device for spraying polyurethane foam supplies the product to the sprayer under pressure. From there - to the surface. The flow rate is controlled by the user (the switch is located near the nozzle). Therefore, before use, it is recommended to test the machine and set a comfortable spray level.

Stages of work

It is recommended to insulate buildings with polyurethane foam while wearing protective suits, gloves and masks; in well-ventilated areas. The work area is still large. And the volatile substances released by foam are dangerous to the respiratory system.

1. Surface preparation.

We remove all dirt and dust. We moisten the clean surface. For good adhesion of polyurethane foam, high humidity is required. To moisturize, you can use a primer diluted with water in a 1:1 ratio.

It is also recommended to nail the slats to the surface with a certain pitch. This makes it easier to control the amount of foam applied. And the installation sealant itself will have a larger area for adhesion.

2. Applying foam.

Polyurethane foam is sprayed in portions, carefully filling all cavities and joints. The work is carried out in a bottom-up direction.

When the substance has completely hardened, the surface is considered insulated.

3. Finishing.

It is not recommended to leave hardened polyurethane foam open. It needs to be sewn up or puttied.

Polyurethane foam instead of tow

Another method of insulation is using polyurethane foam. Is foam suitable instead of caulk or not?

The cracks and gaps between logs or beams are foamed with polyurethane foam. This is very simple and easy to do. No need to use a chisel and hammer.

The foam is resistant to moisture and has high sound/heat insulating properties. It tightly fills all small cracks and voids. There is fire-resistant polyurethane foam that does not support combustion.

No need to hire specialists. You can do the work quickly yourself.

But foam also has disadvantages:

- Not elastic material. When moving and shrinking logs, small cracks and crevices may form.

- You cannot seal cracks inside the bathhouse. When heated, foam releases harmful substances (toxins).

- Foam does not allow air to pass through, but wood breathes. Therefore, moisture may accumulate and, as a result, the tree may begin to deteriorate and rot.

- The main disadvantage

: the foam is destroyed by exposure to sunlight.

But some believe that foam can only be used if it is covered with finishing material. Uncovered foam turns to stone and begins to crumble over time.

It is not recommended to cut off the foam. Because its properties change, and it becomes like a sponge. It is better to crush the excess polyurethane foam by hand after 20 minutes. after foaming.

RepairDom channel:

subscription .

Is it possible to foam the walls of a log house instead of caulk if you are going to insulate and sheathe it?

So I specifically went to him and looked at what happened to these boxes under the foam. NOTHING! Full order.

Thus, if your house rots in a hundred years, not a single expert will tell you why it happened. From foam, or from old age. Personally, I'm not going to give up foam. Maybe you just fed your Germans poorly, and they decided to take revenge on you?

I hope that among the readers of this site there will be foam experts who will express their strong opinions!

What and how to properly caulk a bathhouse - practical advice from an expert

Simply laying a frame when building a bathhouse is not enough - you will definitely need to caulk the bathhouse, that is, close the existing cracks and cracks formed after the wood has dried out. This article will discuss how to caulk a bathhouse.

The caulking of the bathhouse frame is needed so that it loses a minimum of heat. It is very important to use a well-prepared log house, lay it correctly and do not forget to install inter-crown insulation.

Article on the topic: What is a gazebo in VK

What to choose as insulation - moss, tow or jute - is up to the owner to decide, but it must be present.

The insulation is placed in two layers as follows:

- on the lower crown so that the edges of the insulation extend beyond the edges of the bowl by 30-50 mm, while the width of the insulation is determined by 50-100 mm more than the width of the bowl;

- the second layer of insulation is placed in the bowl of the upper crown, while its edges should also protrude by 30-50 mm.

It is worth keeping in mind that when laying moss or tow, tapping such material is not required. If you hit it with a hammer or an ax handle, the moss fibers are torn, and dents appear on the surface of the wood, which after some time can cause the appearance of rotting zones. It is recommended to compact the fibers only by pressing with the palm of your hand. Excess elements in the moss simply need to be removed.

If, when deciding on the best way to caulk the log house of a bathhouse, the choice fell on tape insulation, then you can fasten it with a construction stapler. In this case, it is important what to pierce the bathhouse with, since it can cause harm to the material.

Damage to the wood from the stapler will be minor, but this will allow the material to be firmly fixed. It is best to lay out insulated crowns together so that the log can be taken from both sides and slowly lowered without damaging the insulation.

Recommendations for foaming

- Foaming is carried out with smooth, uniform movements from bottom to top or from left to right.

- The gap is not filled completely, but by 30-50%.

- The foam is supplied in small strips, the length of which should not exceed 100 mm.

- The holes are foamed in several layers, each subsequent layer is applied after the previous one has hardened.

- The through holes on one side are covered with sheets of some material, cardboard is suitable, and after hardening they are removed.

- When carrying out work in the cold season, the foam container must be kept in warm water at a temperature of 30-40 degrees.

- The efficient pushing of material out of the container is facilitated by placing the container upside down.

- The optimal temperature for operation is +5…+25 degrees.

How can you caulk a log house?

There are natural materials for caulking and artificial ones. The first include tow, hemp, jute, moss, and so on. The latter include industrial sealants. Sealants are easier to work with and apply quickly. As a rule, in order to reduce their consumption, a cord is laid in the inter-crown gap, and the sealant, which is distributed with a special spatula before hardening, is applied on top of it.

However, sealants have a number of disadvantages:

- Some brands are afraid of exposure to ultraviolet rays - this leads to their destruction. This drawback can be eliminated by hiding the sealant seams under the strips.

- Some of them, after hardening, create a monolithic material that interferes with the process of expansion or contraction of wood, for example, due to weather, which can lead to the destruction of nearby fibers. To prevent this fact, it is better to purchase elastic sealants.

Article on the topic: How to properly insulate a frame house with ecowool

You can learn more about how to operate the sealant by watching the available video material. A simple tablespoon is perfect for distributing the sealing agent.

If, when determining how to caulk a bathhouse, you chose a sealant, then carefully study the instructions and make sure that it can be used with exactly the type of wood from which your log house is made, that it is suitable for your region, and also has all the necessary characteristics.

It is advisable to use a synthetic sealant for a log bathhouse if it is used to close caulked cracks. After double caulking the log house with tow, moss or jute, wait until the log house finally settles and reaches working dimensions. Next, a cord is inserted into the seams and covered with sealant.

Each of the natural materials for caulking has its own positive and negative qualities, and preparatory measures are required in any case.

Moss is considered the most common, time-tested material for caulking. It has been used for hundreds of years. Currently, there are many other materials, but they all have slightly worse characteristics. True, new materials are easier to operate, and they also have such positive qualities as antibacterial properties and special resistance to rotting.

Before caulking a log bathhouse with moss, it must be dried and soaked right before use. This action will give the moss fibers elasticity. The moss is laid out in a layer and leveled so that its ends hang down on both sides of the beam. After all the logs have been laid out, the excess moss fibers are shortened, and what remains is wrapped and tucked into the cracks. Thus, the first stage of caulking the log house is carried out. Further stages of caulking will be continued after a year and a half.

Recently, builders are increasingly asking the question of how to caulk a bathhouse with jute. Given that we mean rolled material. Jute fiber has excellent thermal insulation properties and contains natural binding resins. Jute is practically not afraid of moisture, and very rarely becomes unusable due to rotting. Even in conditions of high humidity it does not get wet.

Jute comes in several varieties:

- Jute tow . During the production of this material, the fibers are not torn, but combed, aligning them in the desired direction. This preparation of the material allows it not to lose all its properties. However, jute is not very convenient for caulking, because it is hard and has a low density; caulking has to be done several times due to the material drying out, the impossibility of obtaining a tight seam the first time, and birds pulling it apart for nests.

- Jute felt . This material is based on 90% torn jute fiber, and is supplemented with 10% long flax fibers. The result is a dense and flexible material that is much easier to work with. But if it has a short fiber length, it may get confused and fall out. When choosing jute, you should choose a material with a fiber length of at least 20 mm to obtain maximum elasticity. Short material will not have the necessary properties; it will either fall out or be blown away by the wind. Another disadvantage is the fact that moths can appear in it. In this regard, it is recommended to impregnate such material before installation with a composition against moths and against rotting.

- Flax-jute . It is a composite tape material, half of the volume of which is soft flax fibers, and the rest is hard jute fibers. This material is of interest to many builders, but it also has disadvantages, such as a tendency to rot and moth damage. That is, like the previous material, this one also needs to be treated with mixtures against rotting and pests.

Article on the topic: In which countries do public baths exist?

What is penoizol

Penoizol is a liquid foam plastic. Penoizol is a common name; this material is correctly called urea-formaldehyde foam. Liquid foam plastic is one of the universal insulation materials, which is used mainly in the construction industry.

It is used for insulating walls (including brick ones), when installing laminated panels, and for insulating multi-storey buildings (in this case it is “laid” between floors). The material is quite popular when insulating roofs and even when it is necessary to make decent sound insulation. This is not a complete list of works in which penoizol can be used. I have listed only the main ones.

What is good about foam insulation?

The difference from traditional insulation is that liquid foam does not take up much space. Stored in barrels. Prepared directly on the construction site.

Then it is pumped into the cavity between the walls. Penoizol insulation is good when the house has already been built.

In my opinion, this is the most budget-friendly way to insulate a house. After all, if you insulate a house with polystyrene foam or basalt insulation, you will have to make a facade. These are additional costs.

To compare thermal conductivity: one ten-centimeter layer of foam insulation can replace a three-meter concrete slab.

Of course, like any material there are advantages and disadvantages. So, about the advantages:

- The material is easy to apply. That is, the required layer of penoizol is simply sprayed where it is needed. The shelf life is equal to the average life of the house. As they say, insulate and forget.

- Nitrogen ensures the fire safety of the material. If a fire breaks out, the insulation will not become a catalyst for its spread, nor will it emit a toxic odor. And it is for this reason that penoizol is considered an environmentally friendly material.

- This is one of the universal insulation materials that can be pumped into hollow structures. It absorbs moisture and does not shrink if certain application rules are followed. There are no joints, penoizol is laid down in a continuous layer.

- If you are going to insulate the roof, then penoizol is well suited. They say that rodents and various insects do not eat it.

Disadvantages of foam insulation insulation

Despite the fact that the material is resistant to small amounts of moisture, it still suffers from constant exposure. Relatively speaking, if a water leak occurs, the insulation will stop working. Due to the fact that penoizol is able to absorb vapors from the air, it cannot be used to insulate the foundation or placed under a reinforced concrete screed.

Penoizol has shrinkage. But this can be avoided if you use micro- and macro-reinforcement technology, do not dry it on purpose, but let it harden naturally. This usually lasts up to four weeks.

There has been a lot of controversy over the release of formaldehyde and restrictions on its use have been introduced in a number of countries, however, if the technologies for preparing and pouring penoizol are followed, the risks of poisoning can be minimized.

Tow

This material is waste generated after the primary processing of natural fibers. The logs are caulked with jute, hemp and flax tow. The properties and quality of such material are determined by the raw materials, the length of the fibers and the level of their purification. During production, tow is pressed into blocks. To use it, you need to pull a strip of material from the block, twist it into a rope and place it in the seam. Although, it is easier to use tow sold in rolls.

In general, tow is not very convenient to work with, since it is very difficult to get an even seam. When caulking a log house, due to the high rigidity of the material, it is difficult to obtain a tight seam from the first approach. We have to resort to a repeat process. If you decide how to properly caulk a bathhouse by choosing between moss and jute tow, then you can confidently say that it is better to choose moss, since it does not harbor fungus and bacteria.

Using water at sub-zero temperatures

At low temperatures, it is not recommended to wet surfaces, as this may lead to icing. Conventional foams are not used in such conditions. In cold weather, it is recommended to use winter or all-season formulations.

If you avoid these mistakes, you can handle any seams yourself without the help of professional craftsmen.

vote

Article rating

At what stage can you start caulking a bathhouse?

If the frame was laid on moss or tow, pieces of material of various lengths protrude between the crowns. In this case, you can begin the initial caulking: trim off the excess fibers, and hide the rest in the seams. You should be careful and take your time, adhering to the rules of caulking. If the log house was laid on tape insulation, then further operations are not necessary.

The first caulking is carried out about 6 months after the construction of the log house walls. During this period, almost all the moisture will leave the logs, new mother-in-law will be visible, and most of the crowns and corners will shrink. After this, you can begin installing doors and windows.

Further caulking is carried out after 12 months. During this time, the log house will be completely stable, so that all found defects can be eliminated. Based on the selected material and the quality of the work performed, you may need a new caulk in about 5 years. Sometimes, due to negligent construction work or if insulation was not laid between the crowns, caulking has to be repeated several more times, every year.

Article on the topic: How to properly make a strip foundation for a bathhouse

How to calculate tow for a bathhouse

Before caulking a bathhouse with tow, you should decide on the required amount. Tow compresses quite well, so it is consumed quite heavily. Perhaps no one can say the exact figure. This is because there are a lot of nuances that influence this: the material of the log house, what grooves are cut into them.

If the grooves were made manually, then, often, the consumption of tow will be large. In addition, consumption increases if a sanded log was used rather than a rounded one. Less material will be used for the timber, although in this case its quantity will be determined by the parameters of the timber, the depth and number of cracks that appeared during the drying process.

Caulking technology

Before caulking the log house of a bathhouse, you need to study the basic rules of this process. In fact, caulking a log house is quite easy, but it takes a lot of time, and you also need to be patient. For a bathhouse with dimensions of 5x4 m, one person will need about 10 days, spending 7-8 hours daily.

At the same time, you should not overdo it when laying insulation, since this fact leads to the fact that the log house becomes 15 cm or more higher.

The basic rules for caulking include the following points:

- First of all, they start with the lower crown, moving along the entire perimeter. First, the outer part of the building is processed, after which they move on to the process of caulking from the inside. Only after this can you move on to the next crown.

- When caulking, special attention should be paid to the corners, because in such places, as a rule, the largest cracks are located.

- If this is the original caulking, then first of all the sagging material is picked up, folded and pushed into the gap. You can resort to any tool as needed. The process is carried out in stages - after the meter is processed, they move on to the next section.

- On the same area you can use a caulk, a hammer or a wooden mallet; the latter is much easier to work with. The caulk is beaten until it begins to spring back. After this they move on to a new area.

- Following the compaction process, cracks may appear into which fragments of insulation are inserted. If tow was used, a rope of a certain thickness is rolled up from it or a fragment of a specific length is disconnected from the tape, which is also driven in with caulk and a mallet until a springy effect is achieved. This operation is repeated until all the cracks are filled, after which you can move on to a new area.

Like any other part of construction work, caulking requires certain skills from the master. Based on the fact that there will be quite a lot of such procedures, after some time you will definitely develop them. Over time, as you gain experience, you will notice more and more new inaccuracies that were made in the initial stages of work.

You can eliminate them without much difficulty, bringing the work to almost perfection. Actually, those who do nothing make no mistakes, so caulking a log house with the proper quality is possible even without sufficient experience.

Cover or “panel”?

Often, when purchasing a plot with a log house, new owners rush to cover it with bricks. This strengthens the structure and makes it more solid. However, many people often make the same mistake. Without calculating that the weight from stone walls is not intended for the foundation of a wooden structure (which may not exist underneath them at all!), you risk experiencing significant shrinkage in the foreseeable future, the consequence of which may be cracks in the walls of the house. This also happens because a wooden house “breathes,” which means its walls can “walk” due to temperature changes in different seasons of the year. This is especially noticeable where the transition from season to season is very sharp. Subsequently, for the same reasons described above, it will be unsafe to try to build on a brick second floor.

In order to avoid such problems, consult with specialists and carry out all reconnaissance activities before restructuring. By the way, cosmetic cladding of a house can be done without resorting to brick, but using modern panel materials. Plastic exterior panels are much lighter than brick, look nice, and protect your home well from rain and snow. In addition, covering a house with panels is incomparably cheaper and faster than with bricks. The main thing is to lay an air cushion between the house and the sheets of panels: the panels are attached to the sheathing, which is made on the external wooden wall. By the way, in the case of a brick lining of a wooden house, an air gap is needed, which, meanwhile, is done differently.