The key element of the heating gas unit is the burner nozzle. It creates a mixture of fuel and air that supports combustion. If you make a gas burner for a sauna stove with your own hands, then this fact gives confidence in the reliability of the design. And this, you see, is a fairly compelling argument in favor of making your own.

You can make a nozzle for a sauna stove from scrap materials. Empty gas cylinders, scraps of metal pipes, and parts from old equipment will be used. Before commissioning, the finished product is checked by Rostechnadzor specialists.

We'll tell you how to do everything correctly. We will tell you how to obtain a certificate of suitability for a homemade gas burner. It confirms the safety of the device and allows connection to the heating system of the bathhouse.

Advantages of using gas burners

Let us note the most important advantages of this heating equipment:

- You don't have to waste time and effort lighting the stove. Just open the valve and just light the burner. In just an hour and a half, the steam room will warm up to the desired temperature.

- You can save a lot of money. Gas heating is 20-30% cheaper than wood heating. And if you compare such stoves with electric ones, the benefit will be even more impressive - about 100-120%.

- You will ensure maximum fire safety for your bath. The gases generated during the combustion of this type of fuel do not heat up to the critical temperature that can cause a fire. Therefore, you do not have to additionally insulate the chimney at the points of contact with the roof.

Thus, a gas burner for a sauna stove will greatly facilitate the entire process of heating a steam room and save you from the need to prepare and store firewood.

We invite you to familiarize yourself with the types and features of such devices.

Operating principle and differences of gas equipment

You cannot objectively judge the quality of the purchased injector. Do not disassemble the finished product in search of possible defects. So there is a chance to damage rather than check an expensive device.

By assembling each element of the burner yourself, you will receive not only pleasant satisfaction from the work done, but also savings. At the same time, the operation and repair of gas bath equipment will become safe and conscious.

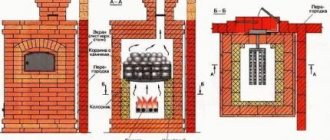

The heating gas unit is a sauna stove body with a gas supply device located in it. Here are the main elements of the control mechanism with which the fuel supply is regulated.

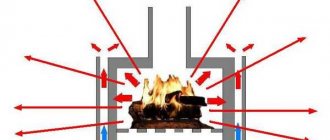

The burner heats the air in the firebox. The thermal energy of the nozzle is transferred through the body to the tray with stones

A heating stove with a gas nozzle requires special attention to the chimney, which must be cleaned periodically.

The advantages of heating water and sauna stones with a gas burner include:

- Simplicity of the workflow. To heat up, just turn the valve and ignite the gas in the burner. In an hour, the steam room of the bathhouse will be sufficiently heated.

- Environmental friendliness. During operation of a gas device, harmful emissions during gas combustion have the smallest volume compared to other types of fuel.

- Ease of maintenance of the burner and the stove itself. There is no need to deal with soot from walls and remove waste, as with coal or firewood.

You can equip the oven with special sensors that are triggered at a critically low exhaust speed. In this case, the gas supply is automatically turned off.

Inexpensive fuel from a gasified stove allows you to not limit the number of bath procedures. Even with daily heating of the bathhouse, maintaining cleanliness becomes very easy

Such a disadvantage of a homemade burner, such as additional registration of technical permits, pays off due to high productivity. Using a gas injector will save 30% costs compared to solid fuels. Heating a sauna with gas is two times cheaper than using an electric boiler.

Types of gas burners for sauna stoves

You can install two types of gas burners in the sauna: atmospheric and forced. Atmospheric ones are cheaper and work autonomously without electricity. They are one or more hollow tubes into which gas is supplied under pressure. The air necessary for productive combustion of gas is taken directly from the room in which the stove is installed. It is mixed with gas, then the gas-air mixture is ignited using electric or piezo lighters.

The structure of an atmospheric gas burner

It is in the mechanism of operation that the main drawback of atmospheric models lies - good traction is required, as well as an effective ventilation system that ensures air flow. The dependence of this type of equipment on the state of the atmosphere in the room from which the bathhouse is heated causes a lot of trouble. With each more or less active movement of air, the proportions of the gas-air mixture change, which leads to a change in the amount of heat that is released. In general, such burners do not burn gas completely, and a significant part of it flies into the chimney. A minimum of automation, of course, monitors the presence of air and flame, ensures minimal safety, but it is necessary to monitor the operation of the equipment.

What is also important is that an atmospheric burner cannot be simply placed in a wood-burning sauna stove if this was not provided for during the design. If this is done in stoves with an internal heater, the flame will rest against the stone container. And the gas must burn in the air, without contact with metal. If you put an atmospheric burner in a stove without a heater, the gas burns normally, but only the upper part of the fuel compartment heats up - the flame is directed upward and the lower part remains almost without heating, which reduces the heating rate of the steam room.

One of the gas stoves for a bath - Taimyr company Teplodar

One more point: experts advise installing only gas burners specially designed for them in sauna stoves. They are longer than usual, since they are designed for a remote firebox (when using gas, it is necessary to heat only from the room adjacent to the steam room). One problem: they are several times more expensive than conventional ones used for heating boilers. The price is almost the same as for forced-air burners, and the efficiency is almost two times lower. Therefore, more often they either install devices for heating stoves, or with forced air supply.

The second type of gas burners for sauna stoves is fan or forced-air, blown (these are all different names for the same design). In them, gas is mixed with air using a fan. Its rotation speed is adjusted during installation. Subsequently, the parameters of the atmosphere in the bathhouse have little effect on the intensity of gas combustion. Structurally, it looks like a block with attached sensors and a controller.

Scheme of operation of a burner with a fan

This type of equipment is on average two times more economical than atmospheric type installations. Their disadvantage is their volatility (they only work when there is a power supply) and their high price - 2-3 times higher than atmospheric ones. Nothing can be done about the price, but you can reduce the dependence on the availability of power if you create a backup source (battery or diesel generator).

The advantage of forced-air gas burners is that they can be installed in wood-burning stoves. You just need to select a model so that the flame does not rest against the back wall of the firebox (use short-flame models). Wood-burning sauna stoves are designed for the combustion temperature of wood - this is about 800°C. When gas burns, the temperature at the top of the flame can reach 1600°C. That is why it is so important not to allow the flame to touch parts of the furnace (in the case of an atmospheric installation the situation is the same). But even in this case, the metal will most likely burn out faster - the temperatures are higher.

The positive aspect of burners with fans is the ability to adjust to any power and switch to liquefied gas (and vice versa).

Pressurized gas burner from Termofor

How to determine the power of the furnace

Gas furnaces can produce different power during operation. Therefore, this factor must be taken into account when purchasing equipment. The power calculation is determined based on the area of the bathhouse. Accordingly, the larger the area it has, the greater the power parameters the oven should have.

| Characteristics of the gas heater Sibir 20 (Teplodar) | Index |

| Steam room volume | 10-20 cubic meters |

| Height | 778 mm |

| Width | 376 mm |

| Length | 552 mm |

| Chimney diameter | 115 mm |

| Furnace weight | 53 kg |

| Mass of stones | 55 kg |

| Recommended water tank capacity | 55-80 l |

In order to correctly calculate the required furnace power, it is important to take the most accurate measurements of the steam room area. The correct operation of the system as a whole will depend on this. Even small deviations in measurements and calculations will subsequently bring many problems with creating a comfortable temperature regime.

The operation of gas sauna stoves involves mixing gas with air. The intensity of combustion and heat supply can be easily adjusted by opening the door located at the bottom of the stove.

Preparing for the manufacturing process

Having understood the structure of the gas burner and decided on the model, you can move on to the next preparatory step. Make a list of the necessary materials and tools.

The following list can be taken as a basis:

- steel tube 100 mm long and with walls 2 mm thick;

- fuel control valve;

- steel cap, piezoelectric element, rubber for handle;

- welding machine, grinder.

Don't forget about little things like connecting elements. For example, for a valve type VK-74 you need to stock up on a cap with a conical thread.

Device

In the vast majority of cases, household gas burners for stoves are designed to be connected to an air heating main. Connection to water circuits is much less common. In some cases, a system is provided that removes heat to adjacent rooms.

Some models of burners for stove heating can also be designed to burn solid or diesel fuel. The standard temperature of the system itself is usually 130 degrees.

A burner device for home or bathhouse consists of:

- valve assembly that regulates the fuel supply;

- steel pipe (usually with a wall thickness of 0.2 cm and a length of up to 10 cm);

- fuel metering cap;

- control knob or button.

Automatic burners are widely used for heating systems in any room. They are much more convenient than designs that do not have automation equipment. Each model is equipped with a strictly defined type of automation. There is virtually no compatibility between these types. Installation of modern burner equipment is very simple and does not require contacting specialists, which is also due to the simplicity of the device.

DIY options

Often, a homemade gas heating unit is made from an old empty cylinder, which is first filled with water to remove any remaining fuel. To assemble a metal heat generator with your own hands, use ready-made drawings.

Materials and tools:

- empty gas cylinder. You can buy a new cylinder or find a used one at a scrap metal collection point,

- used wheels from trucks and cars, they are selected depending on the expected power of gas-fuel heating equipment,

- metal pipes. For gas and air supply, a model with a cross section of 2 cm is used; for the construction of a chimney, a pipe with a diameter of 4 cm is suitable,

- atmospheric burner,

- Bulgarian,

- drill with appropriate attachments,

- welding machine.

Sequence of work:

- Using a grinder, cut a hole in the upper part of the cylinder to fit the dimensions of the wheel rim.

- The disk is inserted into the hole and welded using a welding machine.

- The air supply structure is made from a pipe d2 cm by drilling 9-11 holes with a diameter of 5 mm on the surface.

- A hole d50 mm is drilled in the lower part of the cylinder, a pipe is inserted so that on one side it protrudes 15-20 cm. The seams are sealed by welding.

- The gas pipe is welded in a similar way, the free end is equipped with an adapter for connection.

- A chimney is installed in the upper part of the structure.

At the end, the firebox door is made from a steel plate, a hole is cut out from the side of the homemade structure for it and installed on the hinges.

Hand-drawn diagram of a homemade gas burner for a sauna stove

How to achieve safety

Here the matter is in the so-called. Reynolds number Re, showing the relationship between flow speed, density, viscosity of the flowing medium and the characteristic size of the region in which it moves, for example. cross-sectional diameter of the pipe. From Re one can judge the presence of turbulence in the flow and its nature. If, for example, the pipe is not round and both of its characteristic sizes are greater than a certain critical value, then vortices of the 2nd and higher orders will appear. There may not be physically distinguished “pipe” walls, for example, in sea currents, but many of their “tricks” are explained precisely by the transition of Re through critical values.

Not all homemade gas burners are accurately calculated according to the laws of gas dynamics. But, if you arbitrarily change the dimensions of the parts of a successful design, then the Re of fuel or sucked air may jump beyond the limits that it adhered to in the author’s product, and the burner will become, at best, smoky and voracious, and, quite possibly, dangerous.

Injector diameter

The determining parameter for the quality of a gas burner is the cross-sectional diameter of its fuel injector (gas nozzle, nozzle, nozzle - synonyms). For propane-butane burners at normal temperatures (1000-1300 degrees), it can be approximately taken as follows:

- For thermal power up to 100 W – 0.15-0.2 mm.

- For a power of 100-300 W - 0.25-0.35 mm.

- For a power of 300-500 W - 0.35-0.45 mm.

- For a power of 500-1000 W - 0.45-0.6 mm.

- For a power of 1-3 kW - 0.6-0.7 mm.

- For a power of 3-7 kW - 0.7-0.9 mm.

- For power 7-10 kW – 0.9-1.1 mm.

In high-temperature burners, the injectors are made narrower, 0.06-0.15 mm. An excellent material for the injector would be a piece of needle for a medical syringe or dropper; from them you can select a nozzle for any of the indicated diameters. Needles for inflating balls are worse; they are not heat resistant. They are used more like air ducts in supercharged microburners, see below. It is sealed into the injector cage (capsule) with hard solder or glued with heat-resistant glue (cold welding).

Power

Under no circumstances should you make a gas burner with a power exceeding 10 kW. Why? Let's say the burner efficiency is 95%; for an amateur design this is a very good indicator. If the burner power is 1 kW, then it will take 50 W to self-heat the burner. A 50 W soldering iron can get burned, but it does not threaten an accident. But if you make a 20 kW burner, then 1 kW will be superfluous; this is an iron or electric stove left unattended. The danger is aggravated by the fact that its manifestation, like Reynolds numbers, is threshold - either simply hot, or flares up, melts, explodes. Therefore, it is better not to look for drawings of a homemade burner for more than 7-8 kW.

Armature

The third factor that determines the safety of the burner is the composition of its fittings and the procedure for using it. In general the scheme is as follows:

- Under no circumstances should the burner be extinguished using the control valve; the fuel supply is stopped using the valve on the cylinder;

- For burners with a power of up to 500-700 W and high-temperature ones (with a narrow injector, excluding the transition of Re gas flow beyond the critical value), powered by propane or isobutane from a cylinder up to 5 liters at an external temperature of up to 30 degrees, it is permissible to combine control and shut-off valves in one - standard on the cylinder;

- In burners with a power of more than 3 kW (with a wide injector), or powered from a cylinder of more than 5 liters, the probability of “overshooting” Re beyond 2000 is very high. Therefore, in such burners, between the shut-off and control valves, a reducer is required to maintain the pressure in the supply gas pipeline within certain limits.

How to install it yourself?

It is extremely important: independent installation of gas systems, including installation of burners in a household or industrial oven, is prohibited for non-specialists. With such actions, people take full responsibility for the consequences. First you need to make sure that the installation itself is possible. Check that the length, geometry, and temperature of the flame correspond to the firebox material. The fire must be free in the combustion chamber, without contacting the walls.

Next they check to see if there are any cavities, cracks, or problematic seams. They can contribute to the contamination of room air with combustion products. The installation procedure itself is as follows:

- remove the combustion door;

- insert the burner;

- attach the shield to the door frame;

- connect the automation, which is then used for configuration.

The connection of automatic systems must be carried out in strict accordance with the original instructions. To complete the work, connect the burner device to the hose. At the opposite end, a gas pipeline or cylinder reducer should already be connected.

Important: even in the warm season of the year, immediately after installation you need to turn on the gas and light the burner. This will allow you to accurately determine whether everything was done correctly.

Gas service professionals evaluate the operation of nozzles, adjustment devices, and safety automatics. Additionally, sensor activity is configured and tested. When installing it yourself, this is no less important. When installing a gas burner in an industrial furnace, a remote control and a thermal cylinder are installed. Immediately after this, all joints and drafts in the chimney are inspected.

Trouble-shooting

Having a boiler at home brings many advantages, but it also has a number of disadvantages, and the user does not always know what to do correctly. Boiler faults are common to many types

It is important to promptly determine the cause of these faults before calling emergency services. List of the most common and most likely faults

First of all, if the boiler does not start, you need to check the circuit components:

- network voltage;

- faulty boiler fan switch or motor;

- damaged boiler cables;

- false triggering contacts of automation or commissioning equipment;

- availability of water, whether the gas boiler is powered to the minimum required level specified by the equipment manufacturer.

If the boiler failure is not caused by any of these problems, the following procedure:

Pay attention to the noises made by the boiler, because they are often the first witnesses of destruction. They can also be due to hot water trapped inside the firebox or due to the presence of air in the heating system due to clogged air ducts. Pipe rupture

It usually occurs due to problems with a jammed boiler feed valve, various scale-forming deposits in the boiler, or a malfunction of the condensate drainage systems. Failures due to exceeding the pressure and temperature readings, their corresponding sensors can trigger, for example, due to a broken thermometer or, conversely, which is especially dangerous as a result of real overheating of the boiler. The heating circuits are not working, possibly due to poor quality of feed water and scale formation in the boiler pipes. A problem occurs with the burner (flame breaks, gas accumulation causes detonation and explosion).

For some of these problems, mainly pressure or temperature, the boiler monitor displays an error message, then the system shuts down and automatically restarts. If the problem persists after restarting, it is best to call a professional to troubleshoot the problem. It should be noted, however, that most of these failures can be avoided.

The best prevention is to have your boiler inspected, maintained and cleaned annually, usually by a professional. This will prevent the pipes from clogging and bursting. Prevention is better than restoration, and a simple annual inspection will protect the equipment and the health of users from possible emergency situations.

Supplying gas to the bath

Sauna stoves with gas nozzles have become a technological breakthrough for people living far from forested areas. Considering the low cost of gas fuel compared to firewood, the cost of heating with a burner becomes completely negligible.

Steam room lovers do not have to limit themselves and use such a bathhouse every day. Only, of course, if health allows.

An uninterrupted supply of gas fuel to a sauna stove can be ensured from:

- A backbone network laid to a suburban area and connected to a bathhouse.

- Gas cylinders that require periodic refilling.

- A gas holder installed on the site either permanently or in a mobile version, suitable for periodic refueling.

The most time-consuming procedure will be the connection to the general gas system of a city or rural settlement. It requires the purchase, installation and registration of gas meters. You will also need to obtain permits, technical and payment documentation.

The gas pipeline in the area with the bathhouse facilitates the task of supplying fuel. Solving technical issues with connecting a reliable gas burner will not be difficult

Connecting a regular gas cylinder will also require inviting a representative of the gas service and preparing technical documentation. Tanks have special placement requirements.

For example, gas cylinders cannot be installed in a bathhouse. They should be located outside in an easily accessible, ventilated place. There must be fire-fighting protective equipment nearby - a fire extinguisher, sand.

Types of gas burners

There are only two main types:

- Atmospheric burners. Atmospheric GGs are distinguished by their affordable cost, ease of manufacture and operation. Such devices ensure mixing and combustion of gas in the firebox due to changes in atmospheric pressure. They operate without electricity, but are highly dependent on air movement in the room where the stove is located. With any noticeable movement of air, the volume of heat generated by the firebox changes in one direction or another.

When using an atmospheric burner, it is necessary to equip the room with an additional air source and constantly monitor the condition of the chimney. It should also be taken into account that the fuel in such a furnace will not be completely burned; some of the gas will inevitably go into the chimney.When installing an atmospheric burner, you will have to seriously improve both the fuel chamber and the burner itself. This is due to the fact that in a standard size chamber the flame will touch the bottom of the heater or the metal elements of the stove. To correct this state of affairs, it is necessary to place the fire source as low as possible and strictly in the center of the firebox.

- Pressurized burners.

Supercharged GGs are considered more practical and easy to use, since they provide forced air into the fuel chamber. Such devices are equipped with a special fan, the rotation speed of which determines the rate of fuel combustion in the chamber. A pressurized gas burner for a sauna stove runs on electricity - and this is perhaps its only significant drawback. If there is a power outage, it will not be able to start the steam room heating process, so for such situations it is good to have an alternative option. When choosing such devices, it is important to consider the depth of the fuel chamber so that the fire does not touch its rear wall.

Burner AGG-40P for the Sibir 30 LK, Sibirsky Utes 20 furnace with an external fuel channel.

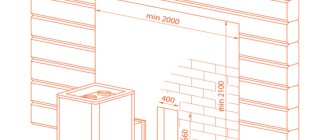

How to properly install a chimney with a gas generator

The easiest option is to install a sandwich pipe in the bathhouse. For a gas stove and boiler, a chimney is needed in the same way as for wood burning. Carbon monoxide will form in the stove and, in the absence of a chimney and good exhaust hood, will accumulate in the steam room. The main danger is that it has neither color nor smell and it is very easy to get poisoned by it.

Modern gas furnaces are equipped with special sensors that, if the exhaust is poor, are triggered and shut off the gas supply. But in order to save money, they buy the cheapest generators for their dacha or garden plot.

A properly organized chimney should have the following components:

- Passage hole in the ceiling.

An umbrella that prevents sparks from hitting the roof of the bathhouse.

For a brick oven, you can assemble a gas pipe. But it will be more difficult to care for it, and installation work will not be cheap. It is easier to install a sandwich pipe.

The structure is easy to install; even a beginner with no prior training can handle it. The joints will be located at the outlet of the furnace, at the joints between the ceiling and the roof.

The sandwich pipe design has a heat-insulating lining, but since the temperature in the bathhouse is always high, the roof and ceiling can still burn out. To avoid this, it is necessary to insulate the ceiling and roof from asbestos fiber or metal sheets.

An umbrella is mounted on top of the pipe. You can do it yourself from an old tin can: cut out the bottom and lid, cut the walls in one place to form a rectangle, and roll it into a cone. It will prevent precipitation from getting inside.

With proper installation of the chimney and equipment, gas in the bathhouse will become a convenient and safe fuel. You can make an iron stove with your own hands. But you need to understand that any little thing can lead to dire consequences. If you are not confident in your knowledge, then it is better to seek the help of specialists.

Heating a private building is one of the main tasks

, which arises in front of people who want to live in a warm and comfortable room.

The use of a stove is still considered a very popular method, the type of which depends on the size of the building, the preferences of the owners and other factors.

.

Advantages and disadvantages

Using burner equipment already has the advantage that you no longer have to spend a lot of time igniting the furnace itself. The combustion process will be initiated as quickly as possible and will not require any special effort. You just need to unscrew the valve and put the system into operation. But it is also worth noting that gas fuel is significantly cheaper than heating with wood, coal, electricity or diesel.

Even taking into account the gradual convergence of prices, the opportunity to save space on fuel storage is very attractive.

It is also worth noting that the devices are quite safe in terms of fire. The designers did not stand still, but continuously solved the problems of fire protection with the means available to them. In addition, natural gas burns at a lower temperature than coal or other fuels. Therefore, the chimney will become less hot. However, in just 60-90 minutes the room will be completely heated.

Primary requirements

We list the signs of a high-quality gas burner:

- The fuel burns completely: this requirement is very important, since incomplete combustion of gas not only reduces the efficiency of the heater, but also pollutes the atmosphere with nitrogen oxide and carbon monoxide.

- The device has a fairly long service life.

- The design is extremely simple, installation is not difficult.

- The noise emitted by the burner does not exceed the values permitted by sanitary standards.

If the burner is a combination burner, that is, it is capable of working with different types of fuel, then it should be quickly and easily switched to one or another type of fuel.

Required Permissions and Installation Requirements

To install a burner in a sauna stove, permission from the gas supply authorities is required. In the case of atmospheric devices, operating conditions must meet the following requirements:

- the presence of a high-quality room ventilation system,

- adjustable traction,

- the volume of the premises being used is at least 12 m³,

- ensuring fire safety measures: reliable insulation of the chimney when laying the chimney through the floor slabs and roofing system, equipping the top with a spark arrester.

When purchasing a device, a set of documents is included in the form of certificates of conformity and permission from Rostechnadzor. If the installation rules are followed and the above documentation is available, there is a chance to obtain permission for operation from the gas supply organization.

When installing supercharged models, it is sufficient to comply with fire safety rules and the availability of accompanying documentation, since due to the features of the functionality, there are no requirements for the place of operation.

It is worth considering that all this is valid when using main gas. In the case of autonomous gasification, for storing liquefied gas cylinders, according to the regulations, a separate metal cabinet is used or a gas tank is equipped. The underground tank provides for volumes of 3 m³ and a location at least 5 m from the building. A pipeline of steel pipes is laid from the storage facility to the heat generator, ensuring reliable tightness of the channel.

Connection to the gas pipeline

There are two subtleties in connecting to gas pipes: Firstly, a shut-off valve must be installed on the gas pipeline, which will allow you to turn off the gas supply to the burner when it needs to be removed or simply during a long-term heating shutdown (in summer). Secondly, during operation the burner vibrates quite strongly due to the operation of the turbine. Under no circumstances should this vibration be transmitted to the gas pipe, otherwise depressurization may occur. There are two options. You can use a special anti-vibration coupling, or you can connect the burner to the gas pipe using a bellows (corrugated metal) connection. The second option is much more convenient, since the flexible pipe, in addition to its anti-vibration function, will also provide a convenient connection method.

Which burner is better to choose?

When you think about converting your stove to use gas fuel, you will sooner or later be faced with the issue of selecting the most suitable burner for this purpose.

The following alternatives exist:

- Atmospheric or supercharged. Owners of large baths and saunas increasingly prefer more expensive but convenient forced-air burners. Their important advantage is that they require a minimum of attention and personal participation from the user, working regardless of external conditions and changes in air pressure. An inexpensive atmospheric burner is quite suitable for heating a small steam room.

- One- or two-stage. Devices of the first type automatically turn the fuel supply on and off, while the second have an economical heating mode. There are also models with floating adjustment, which allow you to change the power of the equipment as smoothly as possible. The choice of a gas burner for a sauna stove depends in this case on the mode in which you plan to heat your steam room.

- Exclusively gas or combined. Gas burners are characterized by a relatively simple design and affordable price. However, they justify themselves only if there is an uninterrupted supply of fuel. Combination type burners are designed to work with natural and liquefied gas, as well as diesel fuel. The latter option is especially good for large baths, as it provides quick heating of rooms of any size.

Conclusions and useful video on the topic

Installing an automatic gas burner in a furnace:

General information about the operation of gas burners:

When studying the variety of models and functions of gas burners for furnaces, you need to pay special attention to safety.

Any actions related to design and installation must be coordinated with the gas supply organization, and the installation must be entrusted to an experienced technician. Before purchasing a gas burner, it is also better to consult with gas specialists.

Please share your own experience in converting solid fuel units to gas consumption. It is possible that your recommendations will be very useful to site visitors. Please leave comments in the block form below, post photos related to the topic of the article, and ask questions.

Design features and types of burners

Important parameters of a homemade gas burner are safety, ease of manufacture, suitability for use in specific conditions, and efficiency. There are quite a lot of options for choosing modifications of the device supplying the gas mixture. They are used for heating a house, heating water boilers, even for hiking.

It is necessary to navigate this variety of types of devices in order to make a high-quality sauna burner with your own hands.

Based on the method of air entering the burner, they are conventionally divided into two types:

- Atmospheric, with natural air supply to the combustion zone.

- Fan-type, with forced air supply carried out by a built-in fan. They are blown and supercharged.

For DIY production, atmospheric burners are more popular among craftsmen. The simple nozzle design can be improved with additional options. For example, equip the burner with a thermostat, draft sensors, flame control, and gas shut-off valve.

The physical parameters of both the sauna stove and the selected nozzle model should be taken into account. Before you start making the burner, decide on the dimensions

All these functions will increase the reliability and safety of operation, but at the same time they will increase the cost of your product. You will decide for yourself how appropriate the additional equipment is, based on your financial capabilities and the frequency of operation of the burner.

Atmospheric devices

Such burners are one or more hollow metal tubes through which gas fuel is supplied under pressure. Ignition is carried out using a piezo lighter. Atmospheric nozzles are the cheapest and easiest to manufacture.

Usually they make atmospheric gas burners with their own hands. Their advantages are independence from electricity and pressure drop in the gas main

The main disadvantage of atmospheric gas burners is considered to be the need for a constant high-quality air flow. It will have to be equipped additionally in the bathhouse. Typically, an ash pan or an air duct connected to it is used for this purpose.

A ventilation pipe with air intake from an adjacent room is effective. At a low draft level, most of the poorly burned fuel goes into the chimney. This poses a risk of gas leakage if there are microcracks in the brick mass.

Therefore, a brick stove with such a burner requires constant inspection and monitoring of the condition of both the stove mass itself with smoke circulation and the chimney.

Complete set of blowing devices

Fan burners are a unit with a fan, sensors and controllers. Air intake and injection from the street is carried out automatically, the operation of the equipment is controlled automatically. The combustion power in the blowing device can be adjusted according to needs.

Forced uninterrupted supply of air allows you to increase the efficiency of the heating device due to high-quality gas combustion. Accordingly, fuel consumption for heating the sauna stove is reduced.

A fan burner is more difficult to install, but easier to operate. The intensity of the nozzle in such a scheme is easier to regulate using automation

The cost of the equipment is affected by connecting the burner to electricity. In case of possible power outages, it is necessary to have an alternative source, for example, a diesel generator or battery.

Both types of gas burners can be converted from liquefied gas to main gas and vice versa. To transfer, the nozzles are replaced, due to which the volume of the gas mixture pumped into the combustion chamber changes. Replacement nozzles are selected in accordance with the manufacturer’s recommendations, or more precisely with the dimensions indicated by him.

Criteria for choosing a design option

Each type of burner has its own power and gas consumption parameters. An energy-dependent inflatable burner with more expensive components is used for heating boilers in large-volume baths.

To heat small and rarely used rooms, it is recommended to install an atmospheric burner. For a modest-sized bathhouse, a model with a flow rate of 1.5-4.5 m3 per hour is sufficient.

To maintain a comfortable temperature in the bathhouse, you need a burner with an even flame distribution. This problem is solved by all kinds of distribution tubes or flame dividers. They are usually round holes. But sometimes the format is changed to narrow slots; such nozzles are called slot nozzles.

A slot gas burner demonstrates the difference in the physical parameters of the fire when the external shape of the holes changes. This small difference in burner design significantly affects the overall flame pattern.

For any selected type of burner, it is preferable to make a long, elongated outlet. This will speed up the heating of the firebox by increasing the flame area. After all, gas heating is allowed only from the room adjacent to the steam room.

Types of sauna boilers for heating water

A sauna boiler is often confused with a stove, especially when considering the simplest units, the energy source of which is special solid fuel, or, more often, firewood. In fact, the boiler has a more complex structure and is equipment that consists of a furnace, a tank for heating water, a heat exchanger, and a chimney.

The heat exchanger is a coil consisting of a two-in-one pipe design and a radiator grille. The main pipe contains coolant for heating. It also contains a second pipe for supplying hot water. For maximum heat transfer, water circulates in them in different directions.

Equipment for heating water can be built-in or remote. Often the tank is placed in a steam room, in a dressing room, or in a washing room. Cover it with stone or brick for better heat retention. First of all, the choice of unit depends on what energy carrier will be used: electricity, gas, firewood, or special solid fuel.

Electric boilers for baths

An electric boiler is used today in almost every apartment, since according to the principle of operation it is a regular boiler. If we consider such equipment as an option for heating the coolant for heating, an electric boiler is uneconomical.

At the same time, the equipment itself and its installation are inexpensive. Electric boilers for baths are practically not used because they have significant disadvantages:

- high energy consumption;

- the need for a three-phase network with high power.

But the use of electric boilers also has positive aspects: environmental friendliness, cleanliness of the room, compactness, and automatic operation. Therefore, in a small bathhouse they often install a boiler, or a small single-circuit boiler, to heat the water in the washing room.

An electric boiler is installed when the bathhouse is located in the basement or garage of a private house. If such equipment is installed, it should be taken into account that the stones used to create steam can also be heated by electricity.

Gas boilers for baths

The most profitable and efficient gas units to use: compact, simple and inexpensive to operate, multifunctional. There is no need to constantly purchase fuel. They are used for heating dressing rooms and washrooms, and heating hot water.

During the combustion process, gas heating equipment does not emit any burning or odor. Since gas devices are explosive, it is not recommended to make them yourself. There are specialized gas sauna boilers that are intended only for heating stones, a steam room, and a small dressing room.

For large bath complexes, or simultaneous heating of residential premises and extensions, gas boilers for the home are used:

- Single-circuit - for heating a small bathhouse, heating water in the washing room.

- Double-circuit - they heat the dressing room, heat the water. If the bathhouse is attached to the house, then the equipment can also be used for its individual heating.

- Three-circuit - for heating the floors of a room, and when a small pool is equipped with a bathhouse.

Gas pressure is an important criterion when choosing a boiler for a sauna

It should be taken into account that when supplying gas to the boiler from the central line, or even more so from a cylinder, it is necessary to monitor the pressure. When purchasing a boiler, the pressure in the network is one of the criteria for its selection, since manufacturers warn that a disruption in the energy supply is not safe for operating the device.

Solid fuel boilers for baths

Solid fuel units store heat for a long time and do not require additional connection to a power source. But their operation is expensive, so they are used only for heating water in the washing room, and, less often, for heating a small dressing room.

For this type of boiler, coal of a certain fraction and humidity is required, since too much firewood will be needed to heat the water. Because of coal, there will be specific dust in the room, which is difficult to get rid of. In addition, this equipment cannot operate in automatic mode. And the most unpleasant moment is that the boiler will need regular cleaning.

The operating principle of a solid fuel sauna stove with an external firebox is described in detail in our article.

Most often, for small baths, simple wood-burning boilers are used, which are also classified as solid fuel. Such equipment is usually installed together with the stove during the construction of a bathhouse. Unlike other types of energy carriers, you can make a wood-burning stove and a boiler for a bathhouse with your own hands, but this will require some experience in construction.

Description of work stages

Before you begin assembling the burner parts, it is better to have a drawn diagram on hand for convenience.

Self-production technology provides for the following sequence:

- the base of the device, the nozzle, is made using a grinder;

- the fuel dispenser is assembled from a valve and a steel cap screwed onto it;

- a cap is welded to the nozzle, then a piezoelectric element is installed.

When installing a burner assembled and tested by specialists, you must comply with the distance restrictions. It should be no more than 5 meters from the gas nozzle to the end of the chimney pipe.

Automatic protection system

Unburned fuel in a sauna stove sometimes causes an explosion of the gas-air mixture. Therefore, monitoring the flame of a working nozzle is necessary for your safety. This can be done visually or using automation with modern photocells sensitive to light.

The burner protection system automatically provides the following functions:

- power regulation;

- fuel and air supply;

- completeness of gas combustion.

It is necessary to take into account the increase in dimensions of the modernized design. Especially with small bathhouse sizes. If device size is an important criterion for you, then all automation can be placed outside for compactness.

You can add automatic schemes for working with simple elements. Compact placement will save usable space in a small bathhouse

To control the combustion process, you can use an automatic factory-made installation such as SABK-8-50S. It provides a high level of security thanks to four levels of protection. The operation of furnace gas equipment with such a device will automatically stop in the event of a dangerous emergency mode.

Assortment R-sauna.ru

We offer burners from famous domestic manufacturers:

- Teplodar. A company operating on the market for more than 20 years. The main advantage of products from the brand is high quality at an affordable price.

- Termofor. The brand occupies one of the leading positions in sales of heating equipment among domestic companies. It offers a wide selection of furnaces and components for their maintenance.

The thermal power of the gas burners for sauna stoves presented in the catalog varies from 13 to 40 kW.

Modernization of heating equipment

Any home craftsman can install a homemade atmospheric gas burner for a sauna stove. So, without any special costs, a solid fuel boiler can be converted into a gas one.

Equipping an existing solid fuel stove in a sauna with a factory-made gas burner unit will require some adjustment. You will be faced with the need to modify the dimensions of both the burner and the combustion chamber of the wood-burning stove.

Converting a solid fuel sauna stove into a combined gas and wood stove is within your power, but it will require precision and some effort. Do not allow the flame to come into contact with the walls of the firebox

To heat the combustion chamber evenly, the burner should be positioned closer to the bottom of the stove and strictly in the center. It is unacceptable to place the source high and offset in any direction. In this case, the camera will not warm up completely. And the flame from the burner can touch metal parts or the heater of the sauna stove.

DIY instructions

Next, we will talk about several options for homemade propane burners that you can make with your own hands. In order to build a simple burner, you won’t need a lot of effort and skill, but creating the other two options will require you to work harder.

Option 1 - the simplest burner made from a piece of pipe

Building such a burner will require very little time and effort. But the process of creating a homemade product must be approached with all responsibility, because you will have to work with an explosive substance and any error in the design of the device can lead to dire consequences.

Using such a device, you can heat metal blanks for forging or warm them up before welding, and you can also repair bitumen roofing. The owner of a private house will definitely not find such a homemade product superfluous.

A properly made propane burner will last a long time. With its help you can perform many household tasks without using a number of expensive tools.

To make a homemade gas burner you will need the following tools and materials:

- two pieces of pipe of different diameters;

- union;

- gas hose;

- gearbox;

- propane tank;

- welding machine;

- Bulgarian.

Having prepared all the tools and materials, you can begin assembling the propane burner. But before that, we recommend that you familiarize yourself with the rules for safe work with an angle grinder.

As you can see, there is nothing complicated about assembling a gas burner yourself. Having studied the instructions and having the necessary set of tools and materials at hand, assembling the device will take no more than an hour.

Option 2 - powerful gas burner

We also suggest trying to assemble a more structurally complex, but also more powerful burner.

To build this option, you will need a little more tools and materials, but the result will not disappoint you.

Such a propane burner can be used, for example, for melting metal in a forge, for burning weeds in your own area, as well as for other purposes

So, to build a propane burner you will need to prepare the following materials:

- connecting couplings – 1/2” and 1/4”;

- threaded barrel – 1/2” and 1/8”;

- plug with internal thread – 1/8”;

- foot – 1/4”*1/8”;

- nipple – 1/2”;

- quick connector for low pressure gas equipment;

- propane supply regulator – 0.068-0.34 atmospheres;

- thread sealant;

- a metal sheet;

- self-tapping screws;

- drills – 6.4 mm and 0.8 mm.

It is better to give preference to brass products. In addition, to construct a homemade product you will need the following set of tools: an adjustable wrench, a drill, a punch, solder and flux, a blowtorch.

Having prepared everything you need, you can begin assembling the device.

During work, do not forget that propane is an explosive gas, and any failure to comply with safety regulations can lead to irreversible consequences.

Therefore, before testing the device, it is necessary to check all connections for leaks. And only after making sure that there is no leak, you can start working with your homemade product.

Option 3 - miniature burner model

Let's look at another option for a gas burner that runs on propane. This miniature gas burner is often called a Bunsen burner.

The peculiarity of this device is that you can hold it freely in your hands without fear of getting burned. Let's try to assemble it with our own hands.

To work you will need:

- Old gas burner.

- Thin copper tube 10 meters.

- Copper wire.

- Needle from a medical syringe.

- Bolt No. 8.

Having prepared all the necessary materials, you can begin to create our homemade product.

To do this, we will use the following instructions:

Now you know how to build a gas burner with your own hands and what you will need for this. As you can see, there is nothing complicated about this; it is enough to follow the rules for the safe operation of equipment, which we will discuss a little below.

Atmospheric burners

These are the cheapest, easiest to manufacture and use burners, with which you can quickly and cost-effectively convert your wood-burning stove to gas (see photo below).

Atmospheric burners do not depend on the availability of electricity; their operation does not stop when the gas pressure in the main line changes. The mixing and combustion of the gas mixture in the firebox occurs due to the pressure difference, i.e. in a natural way, hence the main drawback - the bathhouse will need to be additionally equipped with a high-quality air flow, as well as monitor the condition of the chimney. Otherwise, gas will be consumed inefficiently, and there may also be problems with high-quality, uniform heating of the fuel chamber and, accordingly, the entire steam room.

Installing atmospheric burners in existing wood stoves usually requires additional modifications and improvements, both to the fuel chamber itself and to the dimensions of the burner. The fact is that the fireboxes of a conventional sauna stove have more or less standard sizes; By placing a burner there, we get a situation where the flame from it, when burning, touches the bottom of the heater, or the metal parts of the stove, i.e. the burner is too high. This is unacceptable, since for proper heating of the fuel chamber and the entire furnace, it is necessary that the flame heats the air, and the source must be as close as possible to the bottom and exactly in the center. According to reviews from people who have already converted their wood-burning sauna stoves to gas, this is quite possible, although it requires some effort.

With or without an injector: how does it work?

There are two types of gas burners. Let's look at each of them in detail.

Burners without injector

Design of injection and non-injector burners.

These gas burners operate at high pressure, have a relatively simple design and are extremely efficient to use.

Here is the algorithm in which they operate:

- The necessary oxygen is supplied from the air through special rubber slots and a valve, after which it enters the mixer.

- The function of the mixer is to divide the total flow into small jets that enter the nozzle. In the same way, the flow enters a special valve.

- Mixing of gas with oxygen occurs through circulation to ensure that the output is as homogeneous as possible.

- The mouthpiece at the tip is usually made of durable metal, such as copper. The mixture, heated to a very high temperature, comes out through it. The outlet temperature will be even higher than the melting point of metals.

The technical requirements for these devices are simple and specific: the gas flow must be uniform and have a specific speed that can be controlled and very accurately.

An additional requirement applies to the mixture: it must burn completely. The speed of the gas flow must be sufficient to prevent the flame from spreading to the top of the device, which is very, very dangerous due to the high risk of explosion.

On the other hand, the speed of the hot gas flow should not be too high due to the risk of the flame detaching from the mouthpiece with its subsequent attenuation.

How to calculate the optimal gas flow exit speed?

There are several factors to consider:

- composition of the combustible mixture;

- diameter of the inner wall of the nozzle;

- technical device of the mouthpiece.

The average speed is in the range of 70 – 150 m/sec.

Burners with injector

Methane, oxygen or acetylene are used as combustible gases, which are pumped into the mixer using an injector. This is the technological feature of the injection family of welding torches.

Here's how the injector design works:

- Combustible gas is pumped into the mixing chamber by an injector.

- Oxygen comes from the cylinder there too.

- After entering the mixer, the gas is mixed with oxygen in the air.

- The resulting mixture flows through the pipe into the mouthpiece.

- The gas pressure from the mouthpiece must be at least 3.5 atmospheres.

Injection models have a significant technological drawback that must be constantly remembered: the mixture of combustible gas and oxygen is not constant, it changes its composition all the time. As a result, the flame of such a gas burner, by definition, cannot be even and stable.

Such gas burners are used very widely, despite the low pressure and rather complex design. They have a built-in cooling system, since due to the low pressure the nozzle and mouthpiece become very hot. Therefore, the most important point is to control the overheating of the chamber so that it does not explode.

Pressurized burners

Pressurized or blown burners are a higher quality, fully automatic analogue of atmospheric burners, which are sold complete with a fan that forces air into the fuel chamber. When installing a forced-air burner in a wood-burning stove, it is not necessary to place it exactly in the center of the firebox - the fan creates forced circulation of hot air in it, which promotes uniform heating of the chamber.

Such burners, as a rule, have many settings - depending on the average gas pressure, the size of the steam room, the mode of use of the oven, etc. Multi-stage safety systems and high-quality automation make the use of stoves with forced-air burners quite convenient and comfortable, while they can be adjusted to almost any power in a wide range.

Perhaps the only drawback of such burners is their dependence on power supply, so in places where the power supply is unstable, it makes sense to provide alternative power sources. Also, when purchasing a forced-air burner, it is necessary to correlate its length with the depth of the fuel chamber - the flame should not touch its rear wall.

Classification of species

Manufacturers offer two types of gas burners for sauna stoves:

- atmospheric,

- supercharged.

Models vary in design characteristics and have different advantages and disadvantages.

Atmospheric burner for sauna stove

Atmospheric burners

Atmospheric devices are sold in an affordable segment, are non-volatile, and provide a minimum of automation. The design consists of one or more hollow tubular elements for supplying gas under pressure. To operate atmospheric burners for sauna stoves, good air circulation in the room is required.

Pros:

- autonomy,

- simplicity of design,

- compactness,

- quiet operation,

- availability.

Minuses:

- relatively low power,

- low level of efficiency.

The high traction requirements must also not be overlooked.

Pressurized gas burners for sauna stoves

Blowing devices structurally look like a block with sensors equipped with a controller. The package includes a fan for forced air supply to the firebox.

Pros:

- multi-stage security systems and high-quality automation are provided,

- 2 times more economical than the atmospheric model,

- the ability to adjust to any power in a wide range,

- possibility of conversion to liquefied gas and vice versa.

Minuses:

- energy dependence,

- high price.

To level out dependence on the electrical network, it is recommended to use a diesel generator or other alternative source.

Pressurized burner for sauna stove

Criterias of choice

When choosing a gas injector, take into account the following points:

- Model specifics - power, efficiency level, efficiency, economy, safety,

- Features of operation. When arranging a small bathhouse, preference is most often given to atmospheric models. Powerful automatic burners for blow-type sauna stoves are recommended for use in large rooms.

- Type of heating equipment.

- Features of fuel supply - from the main line, gas tank or cylinder.

- Purpose of the product.

Models of nozzles of certain categories provide for installation in certain types of heat generators. For example, some proposals from domestic manufacturers are designed for use exclusively in boilers with a long channel for the fuel mixture.